EVCO S.p.A. • Code 1043B94E104 • page 2/4

Once the time you have set with parameter C13 has elapsed since the

input has been deactivated, the comp. could be switched on again.

Function antilegionella has the priority on function “green”.

3.8 Cold evaporator control

Once the time you have set with parameter C12 has elapsed, if the

evaporator temperature is below that you have set with parameter

SP9, the compressor will not be switched on and the water will be

heated thanks to the contribution of the heater; the control will be

done periodically (parameter C11).

3.9 Evaporator damaged control

Once the time you have set with parameter C14 has elapsed, if the

evaporator temperature is below that you have set with parameter

S10, the compressor and the evaporator fan will be switched off and

the water will be heated thanks to the contribution of the heater.

4 SETTINGS

4.1 Setting the work set point during “economy” opera-

tion

• Make sure that the keyboard is not locked and that no other proce-

dure is in progress

• press the display will show “SP1”

• press the LED will flash

• press or within 15 sec; see also parameters r1, r2

and r3

• press or do not operate for 15 s. the LED will switch off.

• press and release the key.

To exit the procedure before the operation is complete:

• do not operate for 15 sec (any changes will be saved).

It is also possible to set the work during “economy” operation using

the parameter SP1.

4.2 Setting the work set point during “comfort” operation

• Make sure that the keyboard is not locked and that no other proce-

dure is in progress

• press the display will show “SP1”

• press or to select “SP2”

• press the LED will flash

• press or within 15 sec; see also parameters r1, r2

and r3

• press or do not operate for 15 s. the LED will switch off.

• press and release the key.

To exit the procedure before the operation is complete:

• do not operate for 15 sec (any changes will be saved).

It is also possible to set the work set point during “comfort” operation

using the parameter SP2.

4.3 Setting the temperature below which it is possible to

start the “overboost” function

• Make sure that the keyboard is not locked and that no other proce-

dure is in progress

• press the display will show “SP1”

• press or to select “SP3”

• press the LED will flash

• press or within 15 sec; see also parameters r1, r2

and r3

• press or do not operate for 15 s. the LED will switch off.

• press and release the key.

To exit the procedure before the operation is complete:

• do not operate for 15 sec (any changes will be saved).

It is also possible to set the temperature below which it is possible to

start the “overboost” function using parameter SP3.

4.2 Setting the configuration parameters

To access the procedure:

1. Make sure no procedure is in progress.

2. Touch the ey for 4 s: the display will show “PA”.

3. Touch the key.

4. Touch the or key within 15 s to set the value

determined with the “PAS” parameter (the parameter is set at “-

19” by default).

5. Touch the or do not operate for 15 s: the display will

show “SP”.

To select a parameter:

6. Touch the or key.

To set a parameter:

7. Touch the key.

8. Touch the or key within 15 s.

9. Touch the key or do not operate for 15 s.

To exit the procedure:

10. Touch the key for 4 s or do not operate for 60 s (any

changes will be saved).

After setting the parameters, suspend power supply flow to the device.

4.3 Manufacturer’s settings

To access the procedure:

1. Make sure no procedure is in progress.

2. Touch the key for 4 s: the display will show “PA”.

3. Touch the key.

To restore the manufacturer’s settings:

4. Touch the or key within 15 s to set “149”.

5. Touch the key or do not operate for 15 s: the display

will show “dEF”.

6. Touch the key.

7. Touch the or key within 15 s to set “4”.

8. Touch the key or do not operate for 15 s: the display

will show a flashing “- - -” for 4 s, after which the device will exit

the procedure.

9. Cut the device power supply off.

Make sure that the manufacturer’s settings are appropriate; see ch. 9.

To store customized settings as manufacturer’s:

10. Set the configuration parameters (with the procedure described

in paragraph 4.2).

11. From step 4. touch the or ekey within 15 s to

set “161”.

12. Touch the key or do not operate for 15 s: the display

will show “MAP”.

13. Repeat steps 6. 7. 8. and 9.

To exit the procedure in advance:

14. Touch the key for 4 s during the procedure (i.e. before

setting “4”: Restore will not be performed).

5 COMPRESSOR OPERATING HOURS COUNT

5.1 Preliminary notes

The instrument is able to store up to 9,999 hours of compressor op-

eration, after which the number “9999” starts flashing.

5.2 Display of Compressor Operation Hours

• Make sure that the keyboard is not locked and that no other proce-

dure is in progress

• hold the key down for 1 s: the display will show the first

label available

• press and release the key or the key to select “CH”.

• press and release the key.

To exit the procedure:

• press and release the key or do not operate for 60 sec

• press and release the or key until the display

shows the temperature established with parameter P5 or do not

operate for 60 sec.

Alternatively:

• press and release the key.

5.3 Cancelling Compressor Operation Hours

• Make sure that the keyboard is not locked and that no other proce-

dure is in progress

• hold the key down for 1 s: the display will show the first

label available

• press and rel. the key or the key to select “rCH”.

• press and release the key

• press and release the key or the key within15 sec

to set “149”.

• press and release the key or do not operate for 15 sec the

display will show a flashing “- - - -” for 4 sec then the instrument will

exit the procedure.

6 SIGNALS

6.1 Signals

LED MEANING

compressor LED light

if the LED is on, then the compressor is on

if the LED is flashing:

• the working set point is in the process of being changed

(via the procedure described in par. 4.2, 4.3 and 4.4)

• compressor protection operation in progress:

- parameters C0, C1, C2

- parameters i2 and i7

Defrost LED

If it is on:

• defrosting is in progress

AUX Heating elements LED

if on, the heating elements will be on

Fan LED

if the LED is on, then the fan is on

maintenance LED

if on, compressor maintenance is required:

- parameter C10

HACCP Alarms LED

if it is on, an alarm or error is in progress

°CCelsius grade LED

if it is on, the unit of measurement of the temperature will

be the degree Celsius:

- parameter P2

°FFahrenheit grade LED

if it is on, the unit of measurement of the temperature will

be the degree Fahrenheit:

- parameter P2

on/stand-by LED

if it is on, the device will be in the stand-by status

CODE MEANING

Loc the keyboard is blocked; see paragraph 2.6

ObS the “overboost” function is in progress

7 ALARMS

7.1 Alarms

CODE MEANING

AL Minimum alarm temperatures

Solutions:

• check the temperature associated to the alarm

• see parameters A0, A1, A2 and A11

Main consequences:

• the instrument will continue to function normally

AH Maximum temperature alarm

Solutions:

• check the temperature associated to the alarm

• see parameters A3, A4, A5 and A11

Main consequences:

• the instrument will continue to function normally

id Multipurpose input alarm

Solutions:

• check the causes of input activation

• see parameters i0 and i2

Main consequences:

• the compressor will be switched off

iSd Blocked instrument alarm

Solutions:

• check the causes of multipurpose input activation

• switch off and re-start the instrument or suspend the

power supply

• see parameters i0, i2, i8 and i9

Main consequences:

• the compressor will be switched off

• the heating elements will operate like the compressor

during economy operation (see paragraph 5.1)

FiL Maintenance alarm

Solutions:

• see parameter C10

• press and release a key to silence the buzzer; silencing the

buzzer also causes the deletion of the compressor oper-

ating hours

Main consequences:

• the instrument will continue to function normally

UtL Evaporator probably dirty alarm

Solutions:

• see parameters S10 and C14

• check the evaporator

Main consequences:

• the compressor and the fan will be switched off; the water

heating goes on because of the heater

When the problem that caused the alarm disappears, the instrument

returns to normal operation, except during blocked instrument alarm

(code “iSd”) and the evaporator probably dirty alarm (code “UtL”)

which require that the instrument is switched off or the power supply

cut off.

8 INTERNAL DIAGNOSTICS

8.1 Internal diagnostics

CODE MEANING

Pr1 DHW tank upper part probe error

Solutions:

• see parameter P01

• check the integrity of the probe

• check the device-probe connection

• check the temperature of the upper part of the DHW tank

Main consequences:

• the regulators will switch off

Pr2 DHW tank lower part probe error

Solutions:

• the same as the previous case but relative to the DHE tank

lower part probe

Main consequences:

• the regulators will switch off

Pr3 Evaporator probe error.

Solutions:

• the same as the preceding case but with respect to the

evaporator probe

Main consequences:

• the instrument will continue to function normally

When the problem that caused the alarm disappears, the instrument

returns to normal operation.

9 TECHNICAL DATA

9.1 Technical data

Purpose of the command device: operating command device.

Construction of the command device: built-in electronic de-

vice.

Container: grey self-extinguishing.

Heat and fire protection class: D.

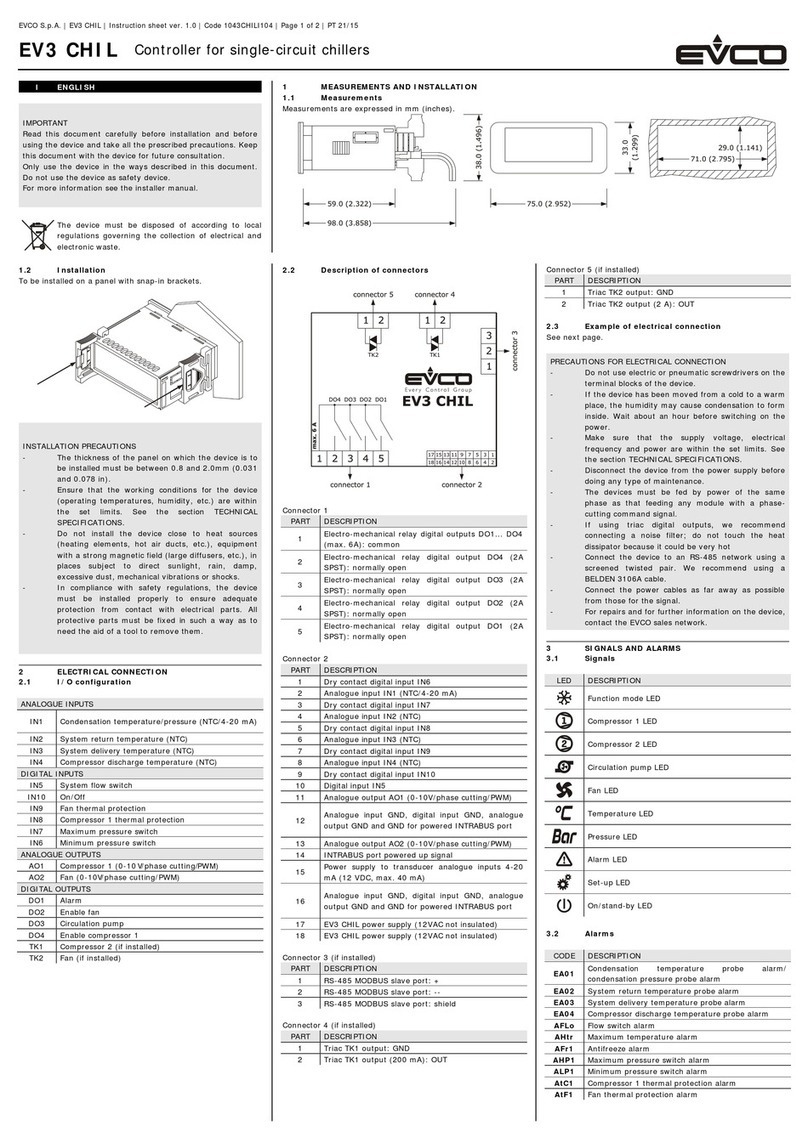

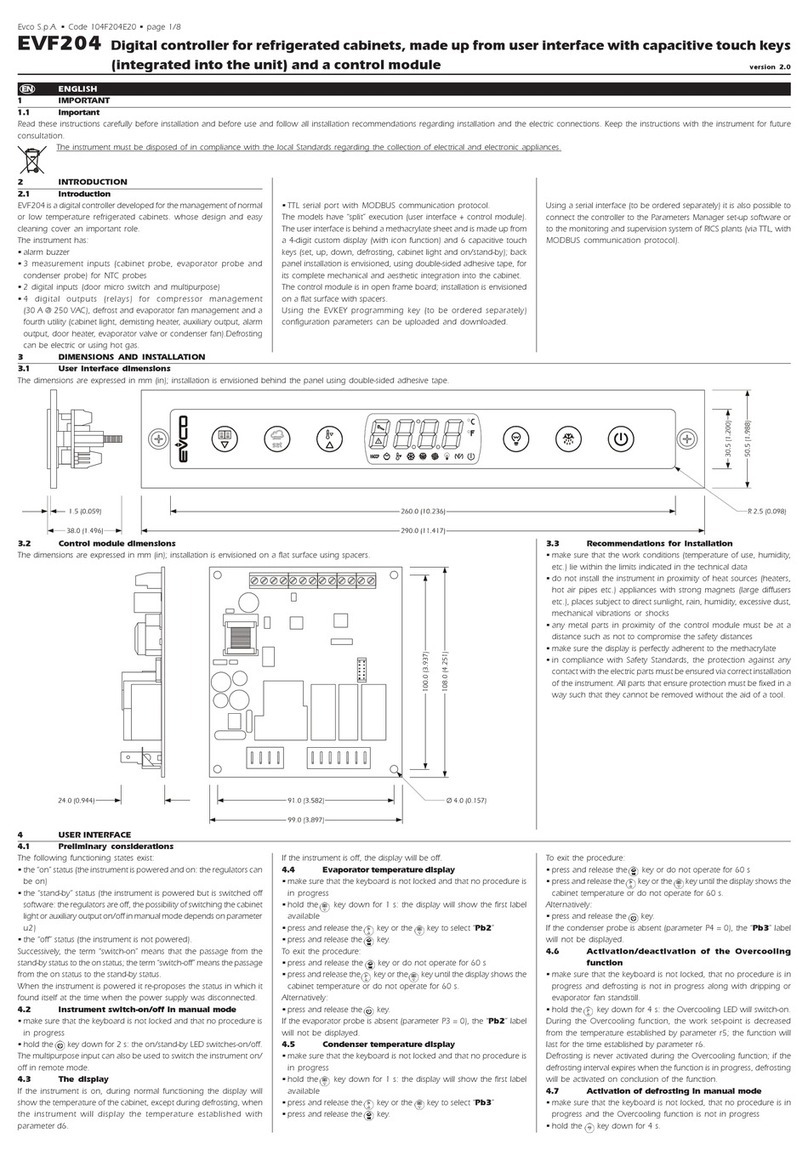

Dimensions: according to model:

- 75,0 x 33,0 x 59,0 mm (2,952 x 1,299 x 2,322 in;

L x H x P) with fixed screw connection terminal blocks

- 75,0 x 33,0 x 81,5 mm (2,952 x 1,299 x 3,208 in;

L x H x P) with removable screw connection terminal blocks.

Method of mounting the command device: on panel, with

snap-in brackets.

Shell protection rating: IP65 (the front one).

Connection method: according to model:

- fixed screw connection terminal blocks for wires up to 2.5 mm²

(0.0038 in²): power supply, analog inputs, digital inputs and

digital outputs

- removable screw connection terminal blocks for wires up to 2.5

mm² (0.0038 in²): power supply, analog inputs, digital inputs

and digital outputs.

The maximum lengths of the connection cables are:

- power supply: 10 m (32.8 ft)

- analog inputs: 10 m (32.8 ft)

- digital inputs: 10 m (32.8 ft)

- digital outputs: 10 m (32.8 ft).

Operating temperature: from 0 to 55 °C (from 32 to 131 °F).

Storage temperature: from -25 to 70 °C (from -13 to 158 °F).

Humidity for use: from 10 to 90 % relative humidity without con-

densate.