Elotech R 1140 User manual

Manual R1140-PB-E Release: 2.03 © Elotech GmbH Page 1/16

Manual:

Data Transfer

Profibus DP,

EN 50170

Temperature Controller

Type: R1140

Content:

1.

Disclaimer of liability...........................................................................................................................2

2.

Interface, general................................................................................................................................2

2.1

Line routing, screening and measures to combat interference voltage ..........................................3

2.2

Shielding of lines.............................................................................................................................4

2.3

Connection guide ............................................................................................................................5

3.

Data transfer, general.........................................................................................................................6

3.1

Process reflection............................................................................................................................6

3.1.1

From master to slave:..............................................................................................................6

3.1.2

From slave to master:..............................................................................................................7

3.1.3

Transmission example.............................................................................................................8

3.2

Configuration channel .....................................................................................................................9

3.2.1

Data transmission, general......................................................................................................9

3.2.2

Terms.......................................................................................................................................9

3.2.3

Parameter values.....................................................................................................................9

3.2.4

Configurating of the parameters via the configuration channel. ..............................................9

3.2.5

Parameter list.........................................................................................................................11

3.2.6

Transmission examples.........................................................................................................13

3.3

Process reflection and Configuration channel.............................................................................16

ELOTECH Industrieelektronik GmbH

Verbindungsstrasse 27

D – 40723 HILDEN

FON +49 2103 / 255 97 0 FAX +49 2103 / 255 97 29

Manual R1140-PB-E Release: 2.03 © Elotech GmbH Page 2/16

1. Disclaimer of liability

We have checked the contents of the document for conformity with the hardware and software

described. Nevertheless, we are unable to preclude the possibility of deviations so that we are

unable to assume warranty for full compliance. The information given in the publication is,

however, reviewed regularly. Necessary amendments are incorporated in the following editions.

We would be pleased to receive any improvement proposals which you may have.

This document may not be passed on nor duplicated, nor may its contents be used or disclosed

unless expressly permitted.

Note: Only in PROFIBUS-technologie trained personnel following the safety regulations

may do the PROFIBUS - connections.

It is essential, that one has well experience in installing a profibus device.

2. Interface, general

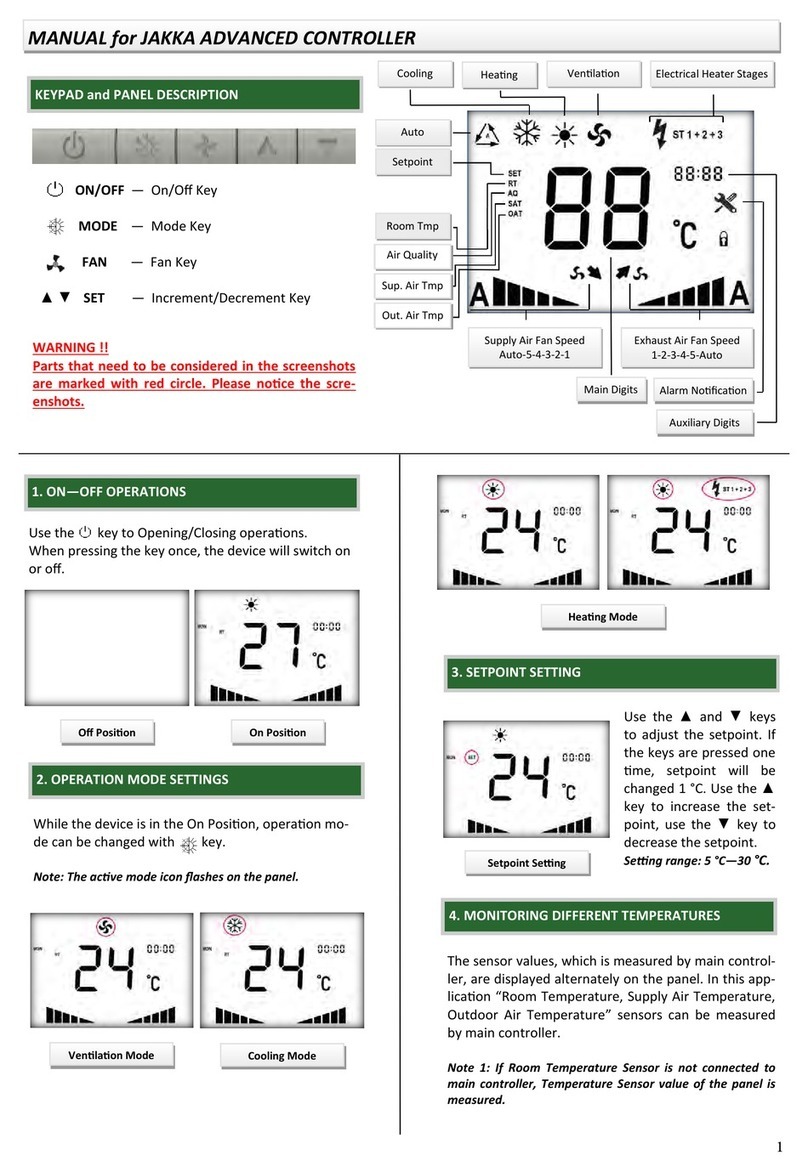

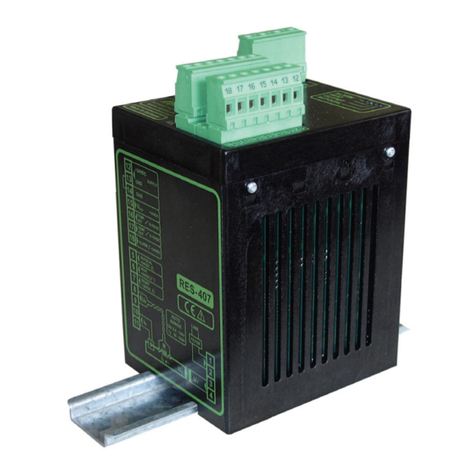

The ELOTECH – temperature controller is equipped with a PROFIBUS DP interface.

The temperature controller actuates as a slave.

MASTER Profibus - DP Temperature

Controller

The PROFIBUS -interface allows the slave to be monitored and controlled by a PROFIBUS master.

The data transfer between the slave and master takes place with the aid of the PROFIBUS-DP-protocol

acc. to EN 50170.

The communication is always controlled by the PROFIBUS-DP master.

The adress of the slave has to be programmed in the configuration level of the slave.

If there are transmission or other errors detected by the slave, it doesn`t accept this datas.

The old parameter values are still valid.

Slave adjustments:

Unit adress ( Adr ): The adress of the slave 1...255 has to be adjusted into the

configuration level. See parameter „Adr“.

Baudrate bAUd ): 9,6 kBaud ... 12 MBaud (with automatically detected)

Please take attention to the manual of the specific temperature controller.

See: FAQ`s

GDS - data file:

Will be delivered with each slave on disk.

Manual R1140-PB-E Release: 2.03 © Elotech GmbH Page 3/16

2.1 Line routing, screening and measures to combat interference voltage

This chapter deals with line routing in the case of bus, signal and power supply lines, with the

aim of ensuring an EMC-compliant design of your system.

General information on line routing

- Inside and outside of cabinets

In order to achieve EMC-compliant routing of the lines, it is advisable to split the lines into the

following line groups and to lay these groups separately.

Group A: •shielded bus and data lines (e.g. for PROFIBUS-DP, RS232C and printers etc.)

•shielded analogue lines

•unshielded lines for DC voltages ≥ 60 V

•unshielded lines for AC voltage ≥ 25 V

•coaxial lines for monitors

Group B: •unshielded lines for DC voltages ≥ 60 V and ≥ 400 V

•unshielded lines for AC voltage ≥ 24 V and ≥ 400 V

Group C: •unshielded lines for DC voltages > 400 V

The table below allows you to read off the conditions for laying the line groups on the basis of the

combination of the individual groups.

Line laying instructions as a function of the combination of line groups:

Group A Group B Group C

Group A 1 2 3

Group B 2 1 3

Group C 3 3 1

1) Lines may be laid in common bunches or cable ducts.

2) Lines must be laid in separate bunches or cable ducts (without minimum clearance).

3) Lines must be laid in separate bunches or cable ducts inside cabinets but on separate cable

racks with at least 10 cm clearance outside of cabinets but inside buildings .

Manual R1140-PB-E Release: 2.03 © Elotech GmbH Page 4/16

2.2 Shielding of lines

Shielding is intended to weaken (attenuate) magnetic, electrical or electromagnetic interference

fields.

Interference currents on cable shields are discharged to earth via the shielding bus which is con-nected

conductively to the chassis or housing. A low-impedance connection to the PE wire is

particularly important in order to prevent these interference currents themselves becoming an

interference source.

Wherever possible, use only lines with braided shield. The coverage density of the shield should

exceed 80 %. Avoid lines with foil shield since the foil can be damaged very easily as the result

of tensile and compressive stress on attachment. The consequence is a reduction in the shiel-ding

effect.

In general, you should always connect the shields of cables at both ends. The only way of achie-ving

good interference suppression in the higher frequency band is by connecting the shields at

both ends.

The shield may also be connected at one end only in exceptional cases. However, this then

achieves only an attenuation of the lower frequencies. Connecting the shield at one end may be

more favourable if

• it is not possible to lay an equipotential bonding line

• analogue signals (a few mV resp. mA) are to be transmitted

• foil shields (static shields) are used.

In the case of data lines for serial couplings, always use metallic or metallised plugs and connectors.

Attach the shield of the data line to the plug or connector housing. Do not connect the shield

on the connector of the slave (controller).

If there are potential differences between the earthing points, a compensating current may flow

via the shield connected at both ends. In this case, you should lay an additional equipotential

bonding line.

Please note the following points when shielding:

• Use metal cable clips to secure the shield braiding. The clips must surround the shield over a

large area and must have good contact.

• Downstream of the entry point of the line into the cabinet, connect the shield to a shielding bus.

Continue the shield as far as the module, but do not connect it again at this point!

Manual R1140-PB-E Release: 2.03 © Elotech GmbH Page 5/16

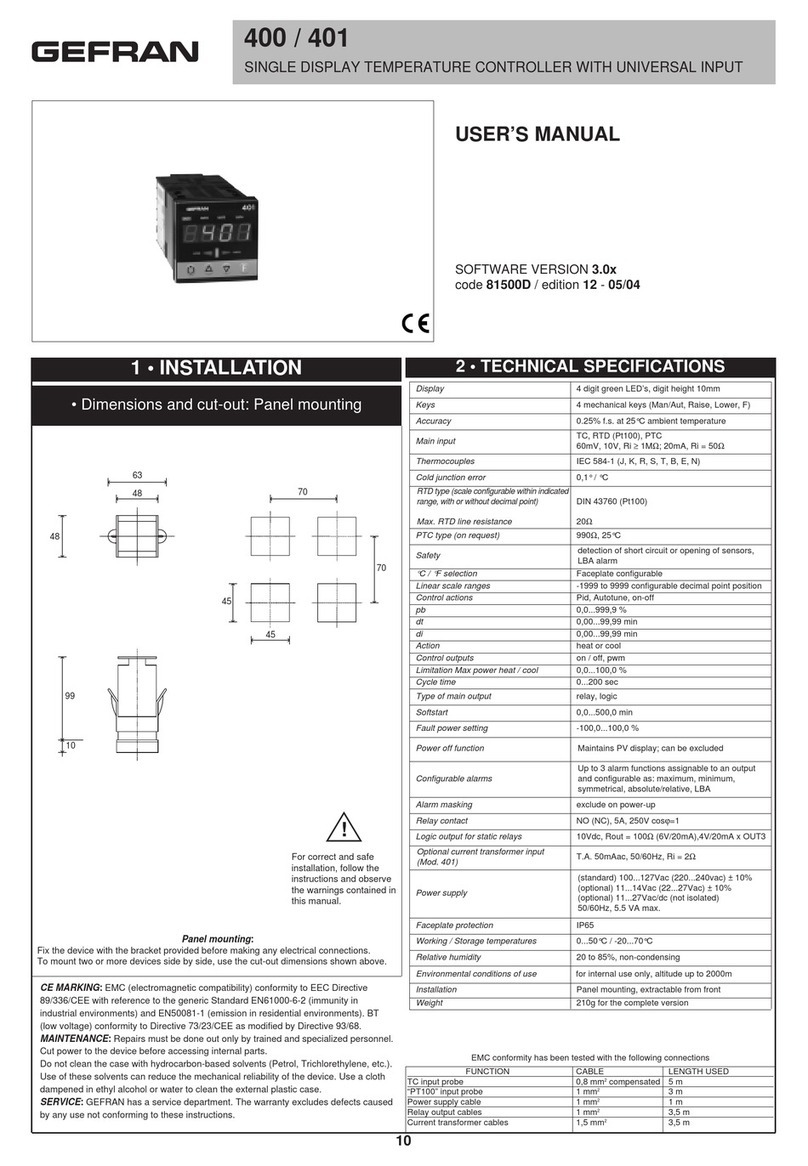

2.3 Connection guide

Note: Only in PROFIBUS-technologie trained personnel following the safety regulations

may do the PROFIBUS - connections.

It is essential, that one has well experience in installing a profibus device.

You will require the following components to connect the slave:

• Connector for Profibus connection to the slave

• PROFIBUS cable (this cable is generally already installed on site!)

• Diskette with type resp. GSD file

• Project planning tool for the PROFIBUS-Master

It is essential, that you perform the following during connecting in order to ensure that

the slave operates correctly:

PROFIBUS-Connections:

Connect the slave with the PROFIBUS. Take care to the terminals.

See: connection diagram of the specific controller type.

The terminals VP and GND have to be used to connect the terminating-resistors.

There is no further load allowed.

The terminating resistors have to be connected on the first and the last device of the Profibus-

bus.

Terminating-Resistors (Tol. +/-2%): VP +5V

390 R

RxTxP

220 R

RxTxN

390 R

GND

CNT

PROFIBUS – Adjustments:

Adjust the following parameters (slave):

Series R1140:

Parameter „Adress“: Adr: Adjustment of the Profibus-Adress

Parameter „Baudrate“: baud No adjustment possible.

The baudrate will detected and monitored automatically.

Display: „ndEt“ = no baudrate detected.

PROFIBUS - Diagnostic displays:

The diagnostic display works with the help of the decimal-point within parameter „Adr – Adress“.

The slaves of the series R11400 have to be set to „remote operation“ with the parameter „rEno“.

This makes sure, that the parameter values can be written via the profibus.

Dec.point, permanent on: The slave is in the data-exchange-modus.

The communication is ok.

The data-exchange with the master takes place.

Dec.point, flashing: The bus is detected. The slave is waiting until the master has

programmed the slave. This happens automatically.

Dec.point off: The slave is not correct connected to the bus.

E.g.:- Maybe there is a wiring error. - The master is not active.

Manual R1140-PB-E Release: 2.03 © Elotech GmbH Page 6/16

3. Data transfer, general

The Communication:

The master sends it´s data to the slave.

After this the slave sends an answer to the PROFIBUS DP - master.

This takes place cyclic and will be controlled by the master.

The configuration of the slave takes place with the help of the GSD-file.

The following moduls are available for the slave:

1. Process reflection: Module: „1 – channel process data“

2. Configuration channel: Module: „parameter channel“

3. Process reflection and Configuration channel:Module: „1 – channel process + parameter“

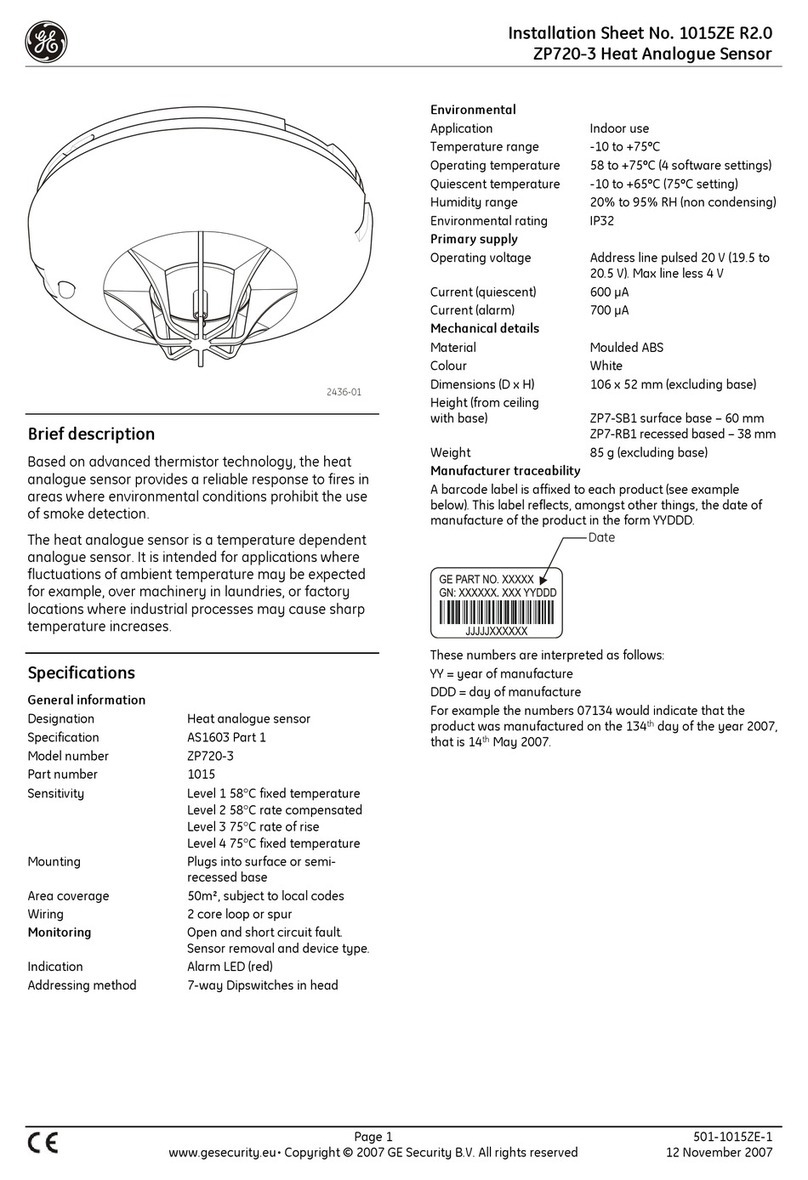

3.1 Process reflection

Parameter transfer according to the process reflection modul:

3.1.1 From master to slave:

Transfer of Setpoint 1 and Status word 1

Byte 1 Byte 2 Byte 3

Setpoint 1

High Byte

Setpoint 1

Low Byte

Control byte

WARNING: Every change of the setpoint is stored in the internal

nonvolatile memory. It permits max. 1.000.000 write

cycles!

Setpoint / process value: The parameter value consists out of 2 data bytes within the process

reflection.

Setpoint and actual process values will be transmitted always with a

decimal digit, although the measuring range has no decimal digit.

Example: °C Dec. Hex. High-Byte Low-Byte

Measuring range with dec. point: act. value 23,0 230 00E6 00 E6

Measuring range with dec. point: setpoint 170,0 1700 06A4 06 A4

Measuring range without dec. point: act. value 23 230 00E6 00 E6

Measuring range without dec. point: setpoint 170 1700 06A4 06 A4

Control byte: The parameter consist out of one data byte:

Bit 0: controller / slave 0 = on, 1 = off

Bit 1: self tuning 0 = off, 1 = on

Changing this bit from „0“ to „1“ will force the controller to do one selftuning action.

Set this bit to „0“, before starting a new selftuning action.

Bit 2: 0

Bit 3: actual setpoint 0 = setpoint SP1, 1 = setpoint SP2

Bit 4: 1 = delete warning „selftuning error“ into the status byte

Bit 5: 0

Bit 6: 0

Bit 7: 1 = delete warning „system error“ into the status byte

Manual R1140-PB-E Release: 2.03 © Elotech GmbH Page 7/16

3.1.2 From slave to master:

Transfer of the process data

Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6

Status

Setpoint

High Byte

Status

Setpoint

Low Byte

Actual

Process

temperature

High Byte

Actual

Process

temperature

Low Byte

Status byte

Alarm status

Status setpoint: Indicates, if a range error has been detected, when writing the setpoint:

Bit 0: 0 = setpoint value ok.

1 = setpoint value not ok. (out of range ?)

Bit 1–15: no function

Status byte: The parameter consist out of one data byte:

Bit 0: controller / slave 0 = on, 1 = off

Bit 1: self tuning 0 = off, 1 = on

Bit 2: remote action 0 = on, 1 = off, operation via keyboard

Bit 3: actual setpoint 0 = setpoint SP1, 1 = setpoint SP2

Bit 4: 1 = selftuning error

Bit 5: 1 = setpoint ramp function active

Bit 6: 1 = sensor error

Bit 7: 1 = system error

Alarm status: Bit 0 1 = alarm 1 active

Bit 1 1 = alarm 2 active

Bit 2–7:no function

Manual R1140-PB-E Release: 2.03 © Elotech GmbH Page 8/16

3.1.3 Transmission example

From master to slave: transfer of setpoint 1 and control byte

Byte 1 + 2: The setpoint 50,0°C should be send to the slave.

Setpoint: 500 decimal = 0x01F4 hexadecimal as a 16 bit integer-value

Byte 3: The slave should be switched „on“ (Bit 0 = 0).

Byte 1 Byte 2 Byte 3

Setpoint

High Byte

0x01

Setpoint

Low Byte

0xF4

Control byte

0x00

Answer from slave to master:

Transmission of the process reflection

The slave sends the following parameter-values:

Byte 1 + 2: status instruction setpoint transmission: the last instruction was ok.

Byte 3 + 4: act.process temp. value: 55,0°C 550dec. = 0x226hex. as a 16 bit integer-value

Byte 5: Controller status: controller = on

Byte 6: Alarm status: alarm = no alarm

Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6

Status

Setpoint

High Byte

0x00

Status

Setpoint

Low Byte

0x00

Actual

Process

temperature

High Byte

0x02

Actual

Process

temperature

Low Byte

0x26

Status byte

0x00

Alarm status

0x00

Manual R1140-PB-E Release: 2.03 © Elotech GmbH Page 9/16

3.2 Configuration channel

With the help of the configuration channel each parameter can be adressed individually.

The sequence of the desciped bytes is valid for „question“ and „answer“.

3.2.1 Data transmission, general

The PROFIBUS – master is allowed to monitore and controll all parameters of the slave.

The transfer of instructions and parameter values takes place with the aid defined data blocks.

3.2.2 Terms

Instruction-code [BC]: "tells" the device/slave, what to do (1 Byte)

Parameter-code [PC]: designates each individual parameter of the device (1 Byte)

Parameter-value [PW]: shows the value of a parameter (3 Byte)

3.2.3 Parameter values

Instruction-code [BC]: 0x10, 0x20, 0x21

Parameter-code [PC]: 0x00...0xFF

Parameter-value [PW]: 16 bit integer, mantissa PWH and PWL and exponent PWE base 10

Parameter-value High-Byte [PWH]

Parameter-value Low- Byte [PWL]

Parameter-exponent [PWE]

3.2.4 Configurating of the parameters via the configuration channel.

Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7 Byte 8

Current

number

0x00 ... 0xFF

Always:

0x01

Instruction

code

BC

0x10, 0x20 od.

0x21

Always:

0x00

Parameter-

code

PC

0x00 ... 0xFF

Parameter-

value

PWH

High-Byte

Parameter-

value

PWL

Low-Byte

Exponent

PWE

0x00 ... 0xFF

Byte 1

Current Number: For every new task the master should preset a current number.

This number will be repeated from the slave with every answer.

So it is possible to find out which instruction and which answer belong together.

Manual R1140-PB-E Release: 2.03 © Elotech GmbH Page 10/16

Byte 2: always 0x01

Byte 3

Instruction code, BC: 0x10 : Read parameter

0x20 : Write parameter

0x21 : Write parameter and store with powerfail protection

Take care: The EAROM or EEPROM of the slave

permits max. 1.000.000 write cycles.

Byte 4: always 0x00

Byte 5

Parameter code, PC: Enquiry:

Adresses the parameter which should be configured.

Answer:

If the read-proceeding to the slave was ok., than, in the answer of the slave,

byte 5 shows the parameter-code PC.

If the write-proceeding to the slave was ok., than, in the answer of the slave,

byte 5 shows the value 00H (acknowledge).

If the communication was not ok., the following error-warnings are shown in

byte 5:

03 H - Procedure error (instruction code not valid)

04 H - Non-compliance with specified range (value to low orto high)

05 H - Byte 2 ≠0

06 H - The adressed parameter is a read-only parameter

07 H - Writing of datas not possible. Slave status is not „remote“.

08 H - Parameter-code not valid

09 H - It is not possible, to execute the instruction

(e.g., the autotuning can´t be started)

FEH - Error during writing into the powerfail storage

FFH - General error

Byte 6, 7 und 8

Parameter value: The parameter value comprises three data bytes:

2 data byte (mantissa), 1 data byte (exponent).

Byte 6: Parameter value PWH

Byte 7: Parameter value PWL

Byte 8: Parameter value PWE

Examples: Dec. Hex. Mantissa Dec. point

Process value (°C): 215 00D7 00D7 00

Setpoint (°C): 230 00E6 00E6 00

Output ratio, cooling (%) -16 FFF0 FFF0 00

Setpoint ramp (°C/min): 2,2 0016 0016 01

The parameter value is calculated as follows: Dec.: 2,2 = 22 + 1 dec.point

Hex.: = 0016 (mantissa)

= 01 (1 dec. point)

Negative mantissa / negative Exponent: Built binary two´s complement.

Manual R1140-PB-E Release: 2.03 © Elotech GmbH Page 11/16

3.2.5 Parameter list

Parameter Mnemonics

Parameter-

Code R1140

Actual process values:

Act. temperature value 0x10 RO

Temperature offset value OFSt 0x18 RW

Sensor configuration SEn 0x1a RW

Linear input; decimal points r. dP 0x1d RW

Linear input; bottom end value r. Lo 0x1e RW

Linear input; top end value r. Hi 0x1f RW

Setpoints:

Act. setpoint SP, act. 0x20 RO

Setpoint 1 SP1 0x21 RW

Setpoint 2 SP2 0x22 RW

Setpoint limitation, low range SP.Lo 0x2b RW

Setpoint limitation, high range SP.Hi 0x2c RW

Setpoint ramp, rising SP ↑0x2f RW

Setpoint range, falling SP ↓0x2d RW

Alarms:

Alarm 3, Configuration Co.A3 0x34 RW

Alarm 2, Configuration Co.A2 0x35 RW

Alarm value 3 AL3 0x38 RW

Alarm value 2 AL2 0x39 RW

Switching behaviour A3 rE.A3 0x3c RW

Switching behaviour A2 rE.A2 0x3d RW

PID parameters „heating“:

Proportional range (P) 1 P 0x40 RW

Rate time (D) 1 d 0x41 RW

Reset time (I) 1 I 0x42 RW

Cycle time 1 CY 0x43 RW

Control sensitivity 1 Sd 0x47 RW

Dead band /

switch-point difference

(only for 3-point-contr.)

Sh 0x46 RW

PID parameters „cooling“:

Proportional range (P) 2 P 0x50 RW

Rate time (D) 2 d 0x51 RW

Reset time (I) 2 I 0x52 RW

Cycle time 2 CY 0x53 RW

Control sensitivity 2 Sd 0x57 RW

Manual R1140-PB-E Release: 2.03 © Elotech GmbH Page 12/16

Parameter

Mnemonics Parameter-

Code R1140

Parameters,

3-point-stepping controller:

Proportional range (P) P 0x40 RW

Motor actuating time tS 0x41 RW

Reset time (I) tn 0x42 RW

Dead band /

switch-point difference Sh 0x46 RW

Control sensitivity Sd 0x47 RW

Output ratio:

Actual output ratio Y 0x60 RO

Manual output ratio HAnd 0x62 RW

Output ratio limit (heating) 1LY 0x64 RW

Output ratio limit (cooling) 2LY 0x69 RW

Softstart output ratio So. Y 0x6a RW

Softstart setpoint So.Sp 0x6b RW

Softstart duration time So.ti 0x6c RW

Softstart function on/off So.St 0x6d RW

Status words:

Controller status / status byte 0x78 RW

Controller configuration:

Control action ConF 0x80 RW

Out1 or Out2 – configuration:

bist. voltage output Out4 0x83 RW

Adjustment lock LOC 0x85 RW

Self tuning OPt 0x88 RW

Manual output configuration

(PID) Hand 0x8b RW

Controller off/on Cont 0x8f RW

Manual R1140-PB-E Release: 2.03 © Elotech GmbH Page 13/16

3.2.6 Transmission examples

3.2.6.1 Configuration channel, Instruction code: 10 H

The slave is asked, to send the parameter „Process value, 10 H“ to the master.

The process value is 225 °C. 225 (Decimal) = 0xE1 (Hex)

Master to slave: Dec. Hex

Current number: 1 0x01

Always: 1 0x01

Send parameter: 16 0x10

Always: 0 0x00

Parameter code (process value): 16 0x10

Parameter value (High-Byte): 0 0x00

Parameter value (Low -Byte): 0 0x00

Exponent: 0 0x00

Transmission to slave: 0x01, 0x01 0x10, 0x00, 0x10, 0x00, 0x00, 0x00

Slave to master: Dec. Hex

Current number of instruction: 1 0x01

Always: 1 0x01

Send parameter: 16 0x10

Always: 0 0x00

Parameter code (process value): 16 *) 0x10

Parameter value (High-Byte): 0 0x00

Parameter value (Low -Byte): 225 0xE1

Exponent: 10° 0 0x00

Transmission to master: 0x01, 0x01 0x10, 0x00, 0x10, 0x00, 0xE1, 0x00

*) Repetition of the parameter code (PC = 16), because the read-process was ok.

Manual R1140-PB-E Release: 2.03 © Elotech GmbH Page 14/16

3.2.6.2 Configuration channel, Instruction code: 20 H

The slave gets the instruction:

"Overtake parameter „prop.-band heating“ (parameter code: 40H, parameter value: 5,0 %)

and store into the RAM".

Master to slave: Dec. Hex

Current number: 2 0x02

Always: 1 0x01

Instruction code: 32 0x20

Always: 0 0x00

Parameter code: 64 0x40

Parameter value (High-Byte): 0 0x00

Parameter value (Low -Byte): 50 0x32

Dec.-point 1 0x01

Transmission to slave: 0x02, 0x01, 0x20, 0x00, 0x40, 0x00, 0x32, 0x01

Slave to master: Dec. Hex

Current number of instruction: 2 0x02

Always: 1 0x01

Instruction code: 32 0x20

Always: 0 0x00

Parameter code (Prop-band, heating): 0 *) 0x00

Parameter value (High-Byte): 0 0x00

Parameter valuewert (Low -Byte): 0 0x00

Dec.-point 0 0x00

Transmission to master: 0x02, 0x01, 0x20, 0x00, 0x00, 0x00, 0x00, 0x00

*) If the slave has understood the instruction of the master, it answers always with the

parameter code (PC) = 00, because the writing-process was ok..

If there are transmission or other errors the slave answers with the corresponding error code.

Manual R1140-PB-E Release: 2.03 © Elotech GmbH Page 15/16

3.2.6.3 Configuration channel, Instruction code: 21 H

The slave gets the instruction:

"Overtake parameter setpoint 1 / SP1 = 200°C (param eter code: 21H) and store powerfailsafe into the

EEPROM“.

Master to slave: Dec. Hex

Current number: 3 0x03

Always: 1 0x01

Instruction code: 33 0x21

Always: 0 0x00

Parameter code (SP1): 33 0x21

Parameter value (High-Byte): 0 0x00

Parameter value (Low -Byte): 200 0xC8

Exponent: 10

0

0 0x00

Transmission to slave: 0x03, 0x01, 0x21, 0x00, 0x21, 0x00, 0xC8, 0x00

Slave to master: Dec. Hex

Current number of instruction: 3 0x03

Always: 1 0x01

Instruction code: 33 0x21

Always: 0 0x00

Parameter code: 0 *) 0x00

Parameter value (High-Byte): 0 0x00

Parameter value (Low -Byte): 0 0x00

Exponent: 10

0

0 0x00

Transmission to master: 0x03, 0x01, 0x21, 0x00, 0x00, 0x00, 0x00, 0x00

*) If the slave has understood the instruction of the master, it answers always with the

parameter code (PC) = 00, because the writing-process was ok..

If there are transmission or other errors the slave answers with the corresponding error code.

Manual R1140-PB-E Release: 2.03 © Elotech GmbH Page 16/16

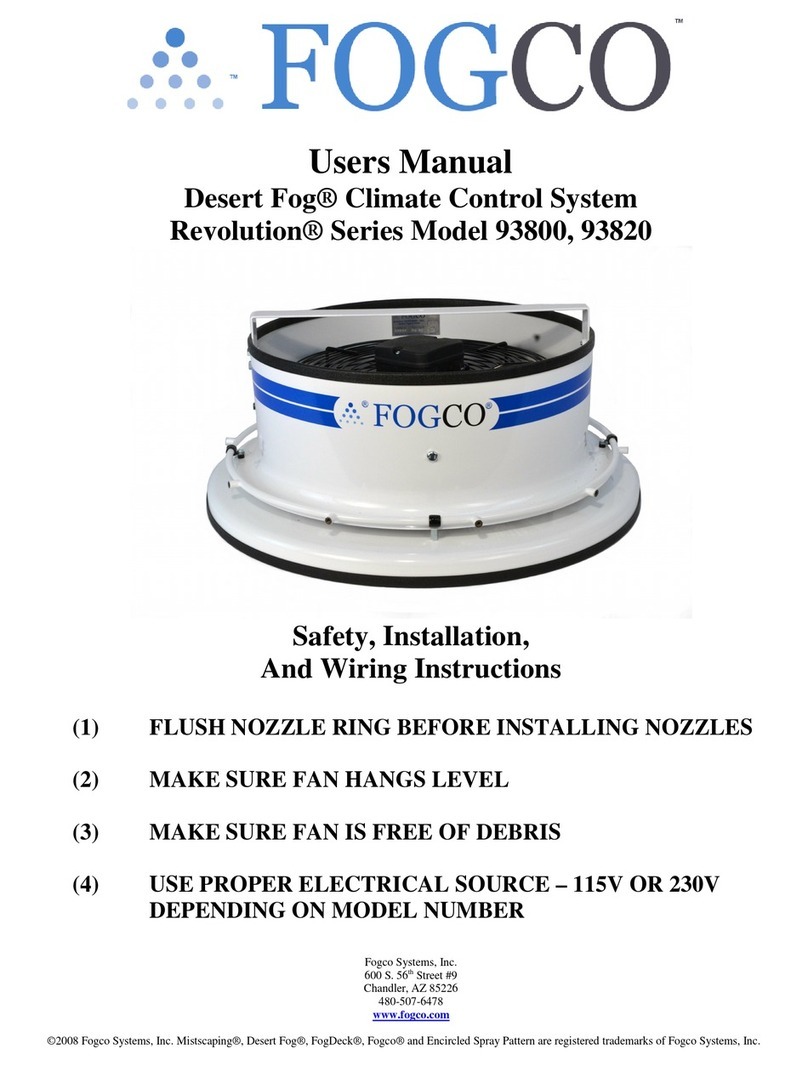

3.3 Process reflection and Configuration channel

It is possible, to transmit process reflection and configuration channel simultaneously

In this case the bytes of the configuration channel have to be fit together with the process reflection.

Master to slave:

Byte 1 Byte 2 Byte 3

Setpoint

High Byte

Setpoint

Low Byte

Control byte

Byte 4 Byte 5 Byte 6 Byte 7 Byte 8 Byte 9 Byte 10 Byte 11

Current

number

always:

0x01

Instruction

code

BC

always:

0x00

Parameter-

code

PC

Parameter-

value

PWH

High Byte

Parameter-

value

PWL

Low Byte

Dec.-point

PWK

Slave to master:

Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6

Status

Setpoint

High Byte

Status

Setpoint

Low Byte

Actual

Process

temperature

High Byte

Actual

Process

temperature

Low Byte

Status byte

Alarm status

Byte 7 Byte 8 Byte 9 Byte 10 Byte 11 Byte 12 Byte 13 Byte 14

Current

number

always:

0x01

Instruction

code

BC

always:

0x00

Parameter-

code

PC

Parameter-

value

PWH

High Byte

Parameter-

value

PWL

Low Byte

Dec.-point

PWK

FAQ: www.elotech.de / Products / Technical Data

Other manuals for R 1140

3

Table of contents

Other Elotech Temperature Controllers manuals

Popular Temperature Controllers manuals by other brands

dixell

dixell XR10CX Installing and operating instructions

DIEL

DIEL MT200 LITE Installation and instruction manual

Future Design

Future Design FDC-2220 user manual

S+S Regeltechnik

S+S Regeltechnik AERASGARD RFTM-PS Series Operating Instructions, Mounting & Installation

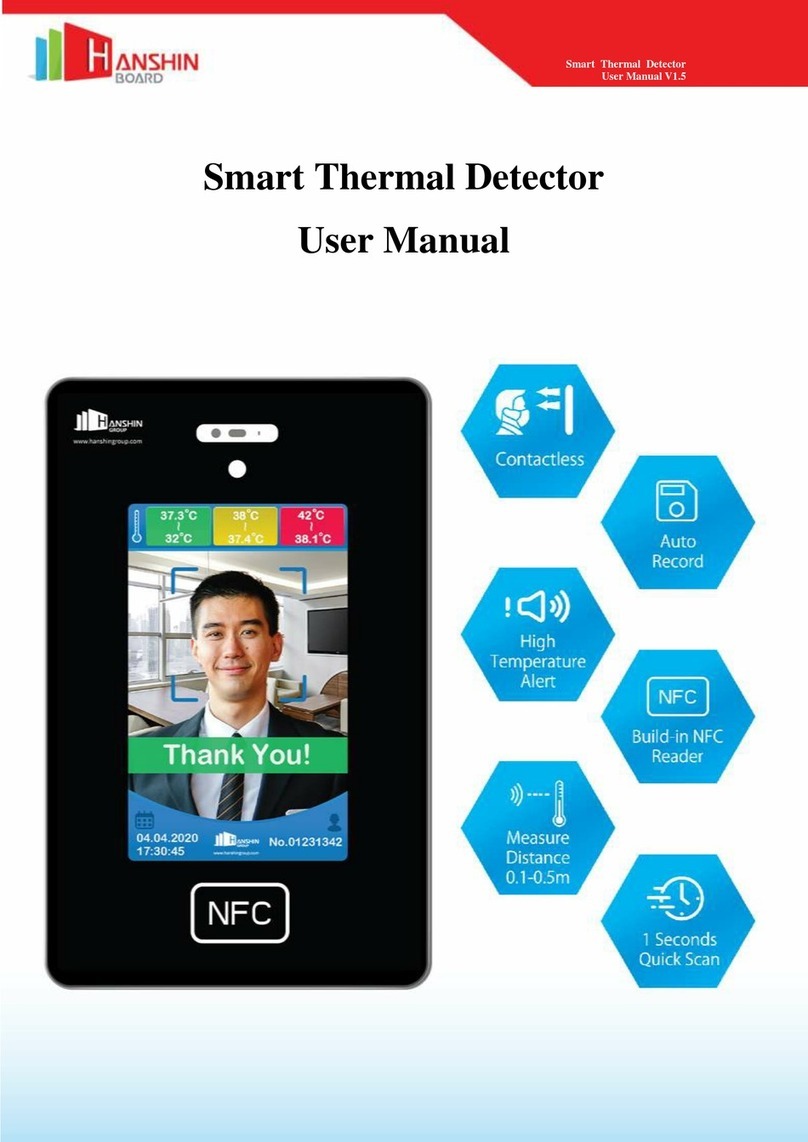

Hanshin

Hanshin Smart Thermal Detector user manual

BriskHeat

BriskHeat TTD instruction manual