Elotech R4000 Manual

Manual: R4000-XX-X-000-X-X_EN Release: 1.08 ©Elotech GmbH Seite 1 36

R4000

Temperature Controller with 4 or 8 zones Heating/Cooling

Depth: 122mm

Format: 96mm x 96mm

DESCRIPTIO A D OPERATI G MA UAL

ELOTECH Industrieelektronik GmbH

Verbindungsstraße 27

D - 40723 HILDEN

FON +49 2103 255 97 0 FAX +49 2103 255 97 29

www.elotech.de Email: [email protected]

Manual: R4000-XX-X-000-X-X_EN Release: 1.08 ©Elotech GmbH Seite 2 36

Contents

Contents ....................................................................................................................................... 2

1 General Information ................................................................................................................ 3

2 Installation Instructions ........................................................................................................... 3

3 Type Code .............................................................................................................................. 4

4 Connection Diagram ............................................................................................................... 5

4.1 Connection Diagram: Power supply, Logic Inputs and Heater Current ................................ 5

4.2 Connection Diagram: Monitoring Relay ............................................................................. 6

4.3 Connection Diagram: Sensor Inputs ................................................................................. 6

4.4 Connection Diagram: Logic Outputs ................................................................................. 6

4.5 Connection Diagram: Relay Outputs ................................................................................. 7

4.6 Connection Diagram: Fieldbus Interfaces ......................................................................... 7

4.7 Connection Diagram: LAN and USB .................................................................................. 7

5 Display and Keyboard ............................................................................................................. 8

5.1 Window-Overview ........................................................................................................... 8

5.2 Display screens (Windows) .............................................................................................. 9

5.2.1 Window: Actual Process Values ................................................................................ 9

5.2.2 Window: Main ........................................................................................................10

5.2.3 Window: Zone synopsis ..........................................................................................11

5.2.4 Window: Monitoring display ....................................................................................12

5.3 Adjusting windows .........................................................................................................13

5.3.1 Window: Entering number value .............................................................................13

5.3.2 Window: Selection with tiles ....................................................................................14

5.3.3 Window: Selection List view ....................................................................................14

5.3.4 Window: Saving to multiple zones ...........................................................................15

5.3.5 Window: Setting text ..............................................................................................15

5.4 More display screens (more Windows) ............................................................................16

5.4.1 Window: Process ....................................................................................................16

5.4.2 Window: Graph ......................................................................................................16

5.4.3 Window: Log (Logbook) ..........................................................................................17

5.4.4 Window: Program (Program controller graph) ..........................................................17

5.4.5 Window: Program controller Selection Setting ..........................................................18

Course of program control: .................................................................................18

5.4.6 Window: Parameter ................................................................................................19

5.4.7 Zone – Parameter list .............................................................................................19

Menu: Heating Control Parameter ........................................................................21

Menu: Cooling Control Parameter ........................................................................22

Ramps: Ramp rising Ramp falling ......................................................................23

Menu: Softstart ..................................................................................................23

Menu: Alarm values ............................................................................................24

Menu: Sensor settings .........................................................................................25

5.4.8 Window: Tools .......................................................................................................25

Configuration Monitoring 1+2 ..............................................................................26

Configuration -Alarm 1+2 ................................................................................27

Configuration Current alarm (option) ...................................................................28

5.4.9 Wizard ...................................................................................................................29

5.4.10 Window: System ....................................................................................................29

Settings .............................................................................................................30

Field bus USB LAN ..........................................................................................31

About Firmware update ................................................................................33

Sensor ...............................................................................................................33

Configuration Output relay ..................................................................................34

Configuration Output digital ................................................................................34

6 Error Messages ......................................................................................................................34

7 Technical Data .......................................................................................................................35

Manual: R4000-XX-X-000-X-X_EN Release: 1.08 ©Elotech GmbH Seite 3 36

1General Information

Symbols used:

www.elotech.de

Messages shown by the

controller are written in this font.

MRS / MRE

M

easuring

R

ange

S

tart

M

easuring

R

ange

E

nd

<§>

Symbolizes the value of the factory adjustment of the respective pa-

rameters.

2Installation Instructions

Make sure the device is used for the intended purpose only.

R4000 controllers are designed for installation in control panels.

Protect the device against impermissible humidity and contamination.

The permitted ambient temperature range may not be exceeded.

Electrical connections must be made according to valid regulations and by properly qualified

personnel.

If using thermocouple sensors, compensation lines have to be connected directly to the con-

troller terminals. Sensors may be connected only in compliance with the programmed range.

Sensor cables and signal lines (e.g. logic or linear voltage outputs) must be laid separately

from control lines and mains voltage supply cables (power cables).

In order to maintain CE-Compliance screened detectors - and signal lines have to be used.

It is not permitted to connect the grounds of the sensor-inputs and logic-outputs with each

other.

Separate installation of controller and inductive loads is recommended.

Interference from contactor coils must be suppressed by connecting adapted RC-combina-

tions parallel to the coils.

Control circuits (e.g. for contactors) should not be connected to the mains power supply ter-

minals of the controller.

The configuration parameters (Window: System) are generally to be selected first.

Disclaimer of Liability

The contents of this document is checked for the conformity with the hardware and software

described. Nevertheless, we are unable to preclude the possibility of deviations so that we

are unable to assume warranty for full compliance. However, the information given in the

publication is reviewed regularly. Necessary amendments are incorporated in the following

editions.

We would be pleased to receive any improvement proposals which you may have.

The information contained herein is subject to change without notice.

Electronic scrap and components are subject to special treatment and must be disposed of

by authorised companies.

Manual: R4000-XX-X-000-X-X_EN Release: 1.08 ©Elotech GmbH Seite 4 36

3 Type Code

R4000 - y - 000aa- dd- - 5

24 VDC5

No00 RS 232-C +

RS 485 +

0/20mA TTY

03

CAN07 Profibus-DP09

No0

Power Supply:

Fieldbus Interface:

Heater Current Monitoring:

Yes

(Logic outputs only)

5

4-zones04 Zones:

8-zones08

Manual: R4000-XX-X-000-X-X_EN Release: 1.08 ©Elotech GmbH Seite 5 36

4 Connection Diagram

Ground connection

Ground connection (flat plug 6,3mm) must be connected to an earth rail via a thick cable

(>=4qmm) in the shortest possible way (<20cm)!

4.1 Connection Diagram:

Power supply, Logic Inputs and Heater Current

Function of the logic inputs:

In_1: 0 = Setpoint 1 active for all

zones.

1 = Setpoint2 active for all

zones.

In_2: 0 = Parameter “Authorisation”

is adjustable.

1 = Parameter “Authorisation”

is not adjustable.

In_3: no function

In_4: no function

Manual: R4000-XX-X-000-X-X_EN Release: 1.08 ©Elotech GmbH Seite 6 36

4.2 Connection Diagram: Monitoring Relay

4.3 Connection Diagram: Sensor Inputs

It is not permitted to connect the grounds of the sensor-inputs and logic-outputs with each

other!

RTD: The parameter “Sensor Settings Sensor” has to be set accordingly to the connection

diagram (2-wire 3-wire)

4.4 Connection Diagram: Logic Outputs

The power supply for the logic outputs has to be wired ex-

ternally:

+24V have to be applied to the terminals B3 and G3.

B3 is connected internally to E3 and G3 is connected to K3.

So the terminals E3 and K3 can be used to loop the +24V.

Manual: R4000-XX-X-000-X-X_EN Release: 1.08 ©Elotech GmbH Seite 7 36

4.5 Connection Diagram: Relay Outputs

4.6 Connection Diagram: Fieldbus Interfaces

Type 03 / 07 : Serial Interface / CA

The serial fieldbus module (Type: 03) contains the three interfaces RS232, RS485 und TTY.

By choosing the connection and setting the parameter ”HW-config“ the desired bus is

selected.

Typ 09: Profibus

The 5V-Supply is designed for the

supply of the termination resistors.

Further loads are not allowed.

4.7 Connection Diagram: LA and USB

USB: Save process data, configuration data and alarm data on an USB-Stick.

Write back configuration data from USB-Stick to the controller.

Make a Firmwareupdate. (Please use FAT formatted USB flash drives.)

LAN: Connection to configuration tool Elovision 3.

Read and write parameters by MODBUS-TCP protocol.

Bus Type Remark

A B RS485 03 Parameter HW-config = RS232 RS485

RxD TxD GND RS232 03 Parameter HW-config = RS232 RS485

- + TTY 03 Parameter HW-config = TTY (current loop)

H L CAN 07 Not available at the moment

Pin 3 Data RxD TxD - P

Pin 5 GND

Pin 6 +5V

Pin 8 Data RxD TxD - N

Manual: R4000-XX-X-000-X-X_EN Release: 1.08 ©Elotech GmbH Seite 8 36

5Display and Keyboard

The device is equipped with a backlight color LC-display.

After switching on the controller and completion of the initialization, the actual process val-

ues and setpoints of all connected zones are displayed.

The device is operated by menus. The different parameters are displayed mainly in plain text

and can be displayed in various languages.

There are several windows for different functions and settings.

5.1 Window-Overview

Home

Process

Log

Zone synopsis

Graph

Program controller

Main

Parameter

Tools

System

= Hold down the key (> 2 s)

Manual: R4000-XX-X-000-X-X_EN Release: 1.08 ©Elotech GmbH Seite 9 36

5.2 Display screens (Windows)

5.2.1 Window: Actual Process Values

Display of setpoints and actual process values of all connected zones.

The header displays

on the

left

the current unit,

here °C.

The top right shows the time.

The hexagon displays the zone number.

If the zone is turned off, the actual process value

displays “OFF“, here seen in zone 5, and the hex-

agon showing the number of the zone is grey.

8-zone-controller:

For every zone the actual process value is written

in large and the setpoint in small numbers.

4-zone-controller:

For every zone the actual process value (in the

right column) and the setpoint (in the left col-

umn) is displayed.

Monitoring

1 of zone 4 is active.

Monitoring

2 of zone 8 is active.

At this point the signal has an enable function. Therefore the

colour green was chosen.

Ramp

s

of zone 3 and 6 are

active.

Soft start

function

of zone 7 is

active.

Auto tune

of zone 2 is active.

Contact of

Monitoring

relay 1 is closed.

Contact of Monitoring relay 2 is open.

T

apping the area of the zone, here zone 2,

leads to

the next

menu. A grey frame and blue zone symbols show up while

pressing the key. Briefly pressing the key leads to the zone

overview. Holding down the key (>2s) leads to the main.

Manual: R4000-XX-X-000-X-X_EN Release: 1.08 ©Elotech GmbH Seite 10 36

5.2.2 Window: Main

This window contains a summary of the other function windows.

One gets to this window by pressing the area of a

selected zone in the window ”Actual Process Value”

for more than 2 seconds.

Likewise, you come into this window by pressing the

following icon. In different windows this symbol ap-

pears in the lower left corner.

Jump

to window “

Actual Process Value“

Display for all zones: Actual process value, setpoint, output ratio, alarms,

ramp, autotune, softstart

Jump

to wi

ndow “

Zone synopsis

“

Display and entry for selected zone: Actual process value, setpoint, output

ratio, current, monitoring state, ramp, autotune, softstart

Jump

to window “

Process“

(List view)

Display for all zones: Actual process value, setpoint, output ratio, current,

monitoring state

Jump

to window “

Graph“

Display for selected zone: Graphical display of the actual value process-

temperature over time

Jump

to window “

Log“

Display for all zones: Alarm- und status messages

Jump

to window “

Parameter“

Display and entry for all zones: All zone-parameter

Jump

to window “

Tools“

Configuration of the monitoring, the alarms and power-on mode.

Calling of the Wizard (set-up assistance)

Jump

to window “

System“

Configuration inputs, outputs and interfaces

Hold down

< 2 sec

. =

R

eturn to previous window

Hold down > 2 sec. = Jump to window “Actual Process Value“

Manual: R4000-XX-X-000-X-X_EN Release: 1.08 ©Elotech GmbH Seite 11 36

5.2.3 Window: Zone synopsis

This window contains the most important information of the selected zone.

The window appears after the area of the zone in the window “Actual Process Value” has

been briefly pressed.

In the header the currently

selected

zone is

shown.

Underneath from left to right the following is dis-

played:

Actual process value, output ratio and heater cur-

rent.

Negative output ratio implies cooling mode.

Shown is the current setpoint.

When editing the setpoint the blue area has to be pressed.

Setpoint 2 is active.

It is not allowed to edit setpoint 2 in this window.

Display of

m

onitoring

1.

Grey = signal not active. Colored = signal active

Pressing the area leads to the window “Monitoring display”.

The same applies to monitoring 2.

Output ratio

shown as bar.

White bar: positive output ratio (heating).

Blue bar: negative output ratio (cooling).

Autotune

:

grey = not active, yellow = active

Pressing the area leads to the window “Autotune”

Ramp: grey

=

not

active

,

yellow = ac

tiv

e

Pressing the area leads to the window “Ramp rising falling”

Softstart

: grey = not active, yellow = active

Pressing the area leads to the window “Softstart”

Heating: grey = Heater switched off, yellow = Heater switched on

.

Cooling: grey

=

Cooler switched off

,

blue

=

Cooler switched on

”+“ switchover to the next zone.

Display of the current zone number

” - “ switchover to the previous zone.

J

ump

to window

“

Main

“

Jump

to window

“

Parameter“

Jump

to window

“

Graph“

Manual: R4000-XX-X-000-X-X_EN Release: 1.08 ©Elotech GmbH Seite 12 36

5.2.4 Window: Monitoring display

In the header the currently selected zone is

shown.

The key “configuration Moni x Alarm“ leads to

the configuration of monitoring and alarms. See

chapter 5.4.8.1

The key “Log“ leads to the alarm logbook for fur-

ther information regarding the occurred alarms

The light blue background and the colored frame shows that the

event ”-Alarm 1“ has triggered the monitoring. In case the event

needs an acknowledgement it must be done by pressing the button.

The dark blue background shows that the event “Sensor error” is

programmed for triggering the monitoring. The event is not active.

The dark

grey background shows that the event “System error” is not

programmed for triggering the monitoring.

In case of a system error the monitoring will not be active.

”+“ switchover to the next zone.

Display of the current zone number

” - “ switchover to the previous zone.

Jump

to window “

Main“

Return to previous window

Manual: R4000-XX-X-000-X-X_EN Release: 1.08 ©Elotech GmbH Seite 13 36

5.3 Adjusting windows

5.3.1 Window: Entering number value

This window helps entering number values, here for the setpoint 1.

The header displays th

e current zone

and the

name of the Parameter, here “Setpoint 1 “.

By pressing the number keys the value of the pa-

rameters can be entered. In order to take over

the parameter value, it must be saved by pressing

the “SAVE”– key.

The value

,

entered by pressing the number keys, is now displayed

within the blue frame.

Underneath, on the left the unit is shown and the previous value is

displayed on the right (250).

The allowed range is displayed at the bottom (0...800).

If this Button

is visible, two adjustable parameters are available.

Such as: Setpoint: 1 2 or Ramp: rising falling

Switch over by pressing this button. The name of the actual parame-

ter is displayed in the header. After adjusting one parameter the win-

dow will not be closed and the second parameter can be adjusted.

This key is visible when the parameter has a valid value “OFF”.

“OFF” can be selected like a number key.

Number key

Key to enter “M

inus”

or

“

C

omma

”

.

The minus sign can be pressed before entering a number. After the

first number was entered the key automatically changes to comma.

Delete last character

Return to previous window

Saving of what has been entered and return to previous window

.

By pressing “SAVE” for > 2s., a selection window appears, in which

parameter values can be saved for other zones simultaneously.

See 5.3.4 Window: Saving to multiple zones.

Manual: R4000-XX-X-000-X-X_EN Release: 1.08 ©Elotech GmbH Seite 14 36

5.3.2 Window: Selection with tiles

The header displays the

zone numb

er and the

parameter name on the left, here “Zone On Off“.

By pressing the tile key, the element can be se-

lected.

Black text on a white background is used to dis-

play the selected element.

In order to save the parameter value, the “SAVE”-

key needs to be pressed.

Selected element.

Not

selected element.

“

+

”

switchover to the next zone.

Display of the current zone number

“–” switchover to the previous zone.

Saving of selection and return to previous window

.

When pressing

“SAVE” for >2s a selection window opens up, in which the parameter

value can be saved onto other zones simultaneously.

See 5.3.4 Window: Saving to multiple zones

Return to previous window

5.3.3 Window: Selection List view

The header displays the

zone and the

parameter

name, here “Zone On Off“.

The actual value is displayed in the middle with

light blue background.

By pressing the + - Buttons on the right (or

pressing the upper or lower areas of the list) the

list can slide up or down.

In order to save the parameter value, the

“SAVE”-key needs to be pressed.

“

+

”

switchover to the next zone.

Display of the current zone number

“ – ” switchover to the previous zone.

Saving of selection and return to previous window

When pressing “SAVE” for >

2s a selection window opens up, in which

the parameter value can be saved onto other zones simultaneously.

See 5.3.4 Window: Saving to multiple zones

Return to previous window

Manual: R4000-XX-X-000-X-X_EN Release: 1.08 ©Elotech GmbH Seite 15 36

5.3.4 Window: Saving to multiple zones

The

zone

(here 1)

that

now

has to be saved is se-

lected and cannot be deactivated.

By tapping the relevant zone field another zone

can be added or deleted.

Black number on white symbol means “Zone

chosen to be saved“

The lowest key “1…8” selects all zones at the

same time.

“ESC” closes the window without saving.

“SAVE”, saves the adjusted parameter value for

all zones selected and closes the window.

5.3.5 Window: Setting text

This window is used to enter text for description of program names.

The header

displays the actual program number

and the actual program name.

By pressing the number keys „0 ... 9” the new

text can be entered. To set the following letters

“ABC1” you have to press the key more times.

After one second the character is taken over and

the next character can be entered.

In order to take over the new text, it must be

saved by pressing the ”SAVE“– key.

The new text is displayed in the blue

white

frame.

Delete last character

.

Delete all characters

.

Key for setting the text.

Repeated pressing changes to the next char-

acter. Here "A B C 2 Ä"

Switching case sensitive.

C

apital and small letters.

Return to previous window

Saving of the new text and return to previous window.

Manual: R4000-XX-X-000-X-X_EN Release: 1.08 ©Elotech GmbH Seite 16 36

5.4 More display screens (more Windows)

5.4.1 Window: Process

This window displays an overview of all zones.

Six columns display

the following

for all zones:

1. Zone number

2. Actual Process Value (Proc[°C])

3. Actual Setpoint (Set[°C])

4. Output ratio (Y[%])

5. Heater current (I[A])

6. Monitoring 1+2 (bell symbols)

Display of Monitoring 1 (2).

Grey = signal not active. Coloured = signal active

Hold down

< 2 sec

. =

Return to previous

window

Hold down > 2 sec. = Jump to window “Actual Process Value“

Jump

to window “

Main

”

5.4.2 Window: Graph

This window shows the temperature progression for one selected zone.

In the case of a technical incident the actual process value can still be examined afterwards.

On

the right the actual p

rocess

v

alue is shown,

here 250°C.

By pressing the loupe keys “+” and “ – ” the reso-

lution of the temperature axis can be altered.

The time axis can be determined by the parame-

ter “Graph sampling time” in the window “Sys-

tem Settings“.

Turning off the device causes deletion of the val-

ues.

”+

”

switchover to the

next zone.

Display of the current zone number

“ - ” switchover to the previous zone.

Hold down

< 2 se

c

. =

Return to previous window

Hold down > 2 sec. = Jump to window “Actual Process Value“

Jump

to window “

Main

“

Manual: R4000-XX-X-000-X-X_EN Release: 1.08 ©Elotech GmbH Seite 17 36

5.4.3 Window: Log (Logbook)

This window displays alarm- and status messages for all zones.

The header displays

the

current date and time,

the window number and page.

Pressing the log-texts displays the full text if it is

are abbreviated in the normal display.

The logbook can take up to 40 entries.

The latest entry can be found on page 1 5.

If 40 entries exist already, the oldest entry will be

deleted.

The logbook is stored in a power failure safe man-

ner.

Switching between the logbook

-

pages

”+“ previous page; ” - “ next page

Alternatively press the upper or lower areas of the list for switching.

Hold down < 2 sec. = Return to previous window

Hold down > 2 sec. = Jump to window “Actual Process Value“

Deletion

of the logbook

-

entries

5.4.4 Window: Program (Program controller graph)

This image shows the graphical representation of the selected control program.

The header display

s

the current program, the cur-

rent step and the status.

Right above the graph is the indication of the cur-

rent program setpoint.

On the right side, the zones are displayed, whose

setpoints are specified by the program.

At the bottom (x-axis) the time is shown in hours.

The elapsed time is displayed as a blue ribbon.

Here on the left below the 105. The current time

is indicated by the thin blue line at the right end

of the tape.

These keys are used to control the program.

Stop Pause and Start.

If the program is stopped you will get to the menu for the program

controller via the Edit button.

If the total time of the program has expired (Stop displayed), the set-

point of the last program step is retained.

Hold down < 2 sec. = Return to previous window

Hold down > 2 sec. = Jump to window “Actual Process Value“

Manual: R4000-XX-X-000-X-X_EN Release: 1.08 ©Elotech GmbH Seite 18 36

5.4.5 Window: Program controller Selection/Setting

This window gives an overview of the 8 control programs. One arrives on the Edit button in

the "Program controller graph" into this menu.

Select the program

The green frame shows the selected program.

Select a other program by pressing + and – keys.

Press the respective program button branches to

the setup menu of the program.

Adjust the program steps

From this window, the individual steps can be set.

The name key is used to set the program name.

With the key "For Zone", the zones that will follow

the program are defined.

Headline

Window:

Actual Process Values

„Home“

Headline of the screen: “Actual Process Values”

Program controller active, Step2 is running.

Top picture: Program running.

Bottom picture: Program paused or stopped.

Course of program control:

Preliminary the time and temperature values for the desired steps have to be entered in the

window "program steps setting".

The time for the first step is the dwell time on the associated setpoint.

The time for the subsequent steps describes the duration, the program needs to reach from

the setpoint value of the previous step to the setpoint value of the current step.

For example.

Step 1: 0:20 h 80 ° C -> Initially set the setpoint of 80 ° C for 20min.

Step 2: 0:30 h 360 ° C -> After that the setpoint is continuously increased starting

at 80 ° C, so that after 30 minutes 360 ° C has been reached.

Step 3: 0:20 360 ° C -> Holding setpoint 360 ° C for 20 min.

Step 4: 00:40 55 ° C -

> Reducing the setpoint continuously within 40 minutes from

Manual: R4000-XX-X-000-X-X_EN Release: 1.08 ©Elotech GmbH Seite 19 36

360 ° C to 55 °

C.

Step 5: OFF 0 ° C -> This step is not executed.

The last step is the step before the step with time is set to OFF. If no time of the program is

turned "OFF", this is the Step 8.

After the total time of a started program the last setpoint is maintained.

After a power failure, during the program was running, the controller switches to the pro-

gram step again, in which the interruption happened.

5.4.6 Window: Parameter

This window is used as a display and input of all zone-parameters for all zones.

The header displays on the left the

zone number

and the window name, here “Main Parameter“.

The selected parameter is displayed in the middle

with light blue background.

By pressing the + - Buttons on the right (or

pressing the upper or lower areas of the list) the

list can slide up or down.

Pressing the selected parameter will switch to a

corresponding selection window.

“

+

”

switchover to the next zone.

Display of the current zone number

“ - ” switchover to the previous zone.

Hold down

< 2 se

c

. =

Return to previous window

Hold down > 2 sec. = Jump to window “Actual Process Value“

Jump to window “

Main

“

5.4.7 Zone – Parameter list

Zone On/Off On

Measuring

-

or controlling zone active

<§>

Off

Measuring

-

or controlling zone switched off

Setpoint

1 / 2

Setpoint

1 S

etpoint

2

Setpoint 1 Setpoint min …

Setpoint max

S

etpoint

1

<§> =

0

Setpoint 2 OFF(Setpoint min) …

Setpoint max

S

etpoint

2

<§> =

OFF

As soon as the logic input In_1 is on level 1, setpoint

2 will become active on all zones in which the ad-

justed value is unlike “Off“.

Manual: R4000-XX-X-000-X-X_EN Release: 1.08 ©Elotech GmbH Seite 20 36

utotune off

Switches off autotune

<§>

on

Ac

tivates autotune

The tuning algorithm determines the characteristic values within the controlled process

and calculates the valid feedback parameters (P, D, I) and the cycle time. (= 0.3 x D) of a

PD I- controller for a wide section of the range.

The autotune mode works during start-up shortly before the setpoint is reached. If acti-

vated after the setpoint has already been reached, the temperature will first drop by ap-

prox. 5% of the measuring range.

The tuning algorithm can be activated at any time by selecting the parameter

utotune = ”on”. After having calculated the feedback parameters, the controller will lead

the process value to the actual setpoint.

Selecting utotune = ”off” will stop the autotune function.

Autotune active: Indication in display “Zone synopsis“ and “Actual process values” as an

orange symbol:

Autotune duration > 2 hours: autotune stops with an error message.

Conditions for starting the autotune algorithm:

- The setpoint must amount to at least 5% of the measurement range

- The sensor must not have a failure.

- The softstart function must not be active

Configuration

Heating-

Cooling

Heating

Two

-

point controller: "Heating

"

<§>

Cooling

Two

-

point controlle

r: "

Cooling

"

Non-lin. Cooling

Two

-

point controller

: "

Cooling

" ,

with non

-

linear

characteristic curve for evaporation cooling

Heating-Cooling

Three

-

point controller: ”Heating

–

Off

–

Cooling”

Hints for adjusting the control parameters:

As standard the controller operates in PD I control mode, i.e. controlling without deviation

and with practically no overshoot during start-up.

The control action can be altered in its structure by adjusting the following parameters:

t

X

t

X

Set

OPT on

self tune during start-up OPT on

self tune, after the setpoint has

already been reached

self tune start

Set

Other manuals for R4000

2

Table of contents

Other Elotech Temperature Controllers manuals

Popular Temperature Controllers manuals by other brands

Multi Channel Systems

Multi Channel Systems TC01 user manual

Fire-Lite

Fire-Lite H355 Installation and maintenance instructions

Samwontech

Samwontech TEMP880S Instuctions for installation and use

Ink Bird

Ink Bird ITC-306A manual

Fuji Electric

Fuji Electric PUMCE instruction manual

Hunter

Hunter 44758 owner's manual

netvox

netvox RA0715 user manual

DigiQ

DigiQ DX3 user guide

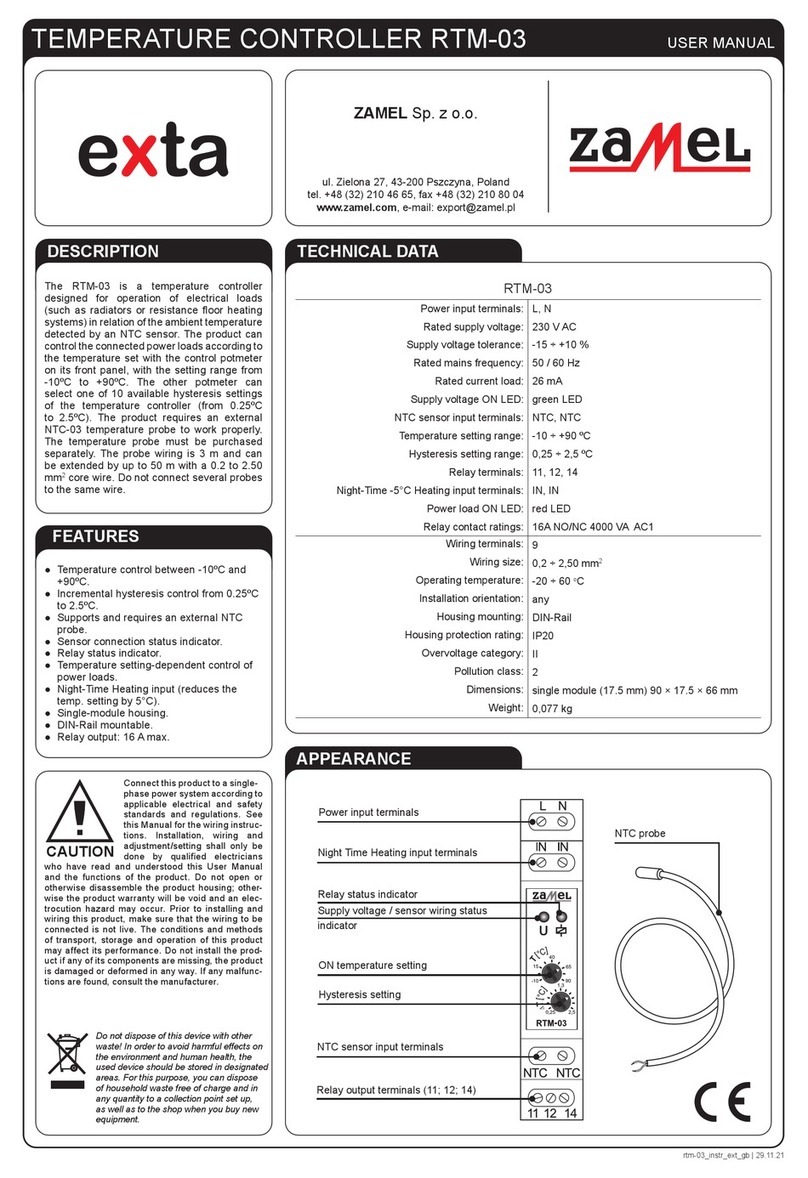

Zamel

Zamel exta RTM-03 user manual

28 GORILLA

28 GORILLA 28-0010038 user manual

S+S Regeltechnik

S+S Regeltechnik HYGRASGARD AFTF Series Operating Instructions, Mounting & Installation

HomeMatic

HomeMatic HMIP-STHD Mounting instruction and operating manual