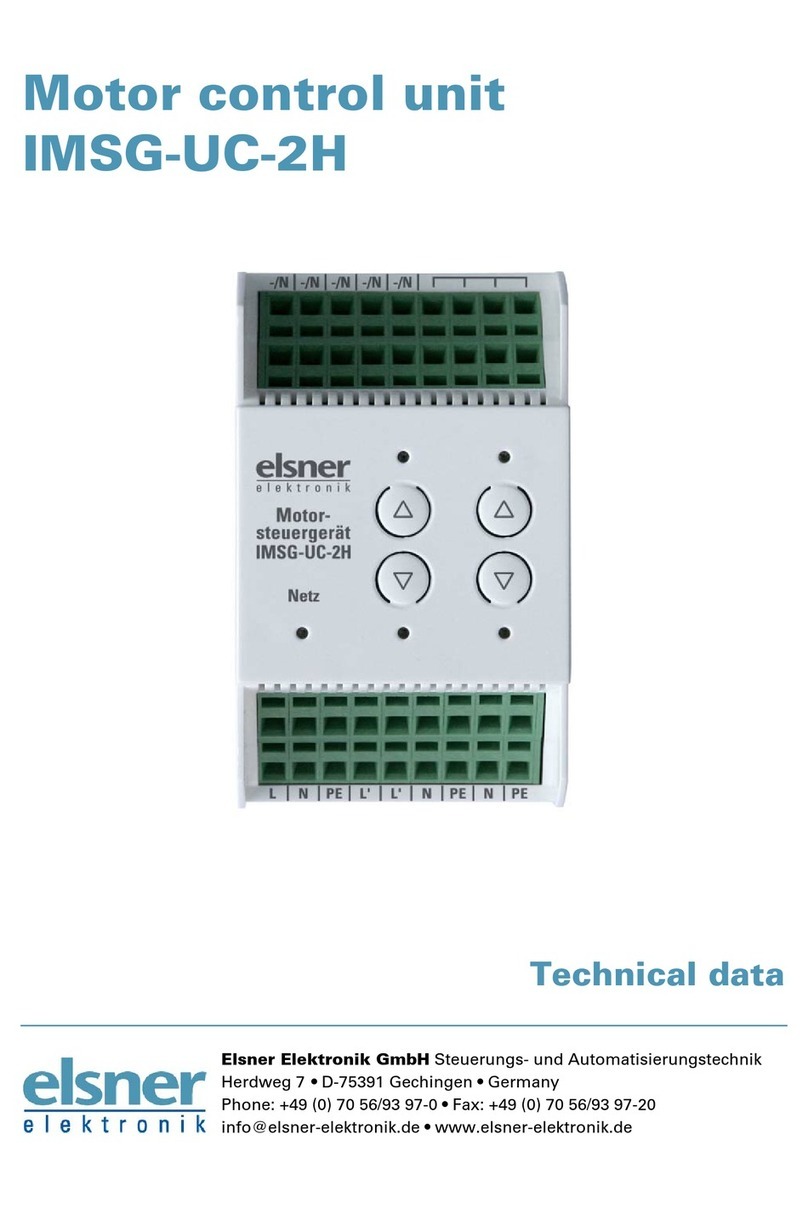

Motor control unit IMSG-UC-4H 2

Motor control unit IMSG-UC-4H • Version: 28.05.2020 • Technical changes and errors excepted. • Elsner Elektronik GmbH • Sohlengrund 16 • 75395 Ostelsheim • Germany • www.elsner-elektronik.de • Technical Service: +49 (0) 7033 / 30945-250

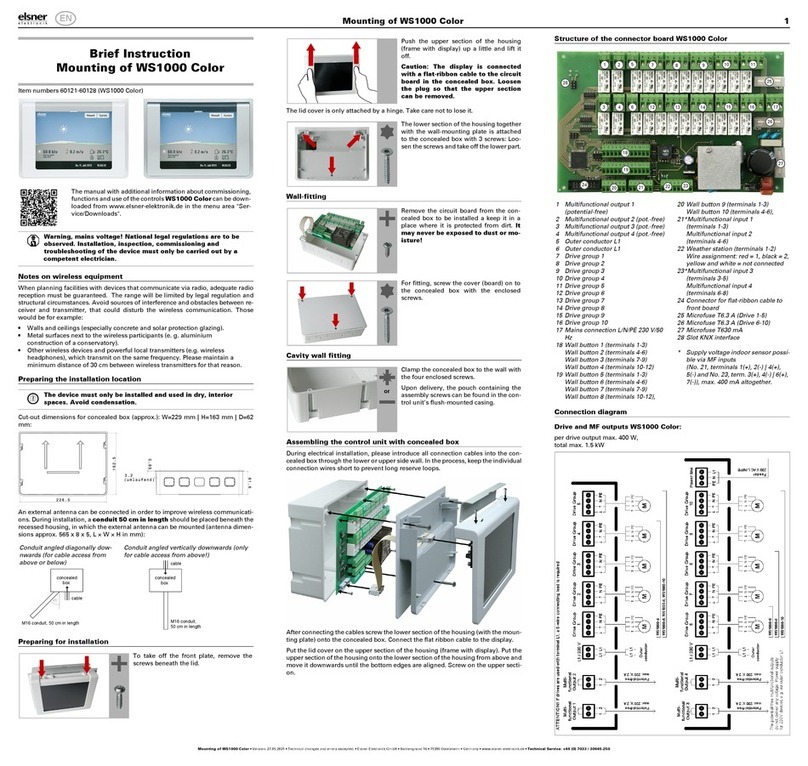

Control with 230V Connection example with several groups

2.4. Notes on mounting and commissioning

Device must not be exposed to water (rain). This could result in the electronic

being damaged. A relative air humidity of 95% must not be exceeded. Avoid bede-

wing.

Pay attention to the correct connection. An incorrect connection can lead to dama-

ge to the motor control unit or to any electronic device connected to it.

3. Operation

3.1. Central operation

The central input of the IMSG-UC-4H allows, for example, an automatic control

unit, a timeswitch or a normal, unlocked double button (Up/Down) to be connec-

ted. The central command (continuous voltage) always has priority over a move-

ment command from the extension inputs.

LED signals during central control (continuous voltage):

If there are "Up" and "Down" movement commands at the central input at the same

time, the drive moves up (secure position).

Set operating mode

The central control unit can be set to the operating modes "Latch" (defaulft) or "De-

adman". You can switch between the operating modes using the following buttons

integrated on the device:

If the Latch mode is active, the Network LED is on.

If the Deadman mode is active, the Network LED flashes every second.

Change the operating mode by pressing (channel 1) and (channel 2) again.

3.2. Individual operation

Manual individual operation of the drives can take place via the integrated Up/

Down buttons at the device or via unlocked double buttons (extension inputs). The

movement mode can be stopped via both buttons ( or ), regardless of the cur-

rent direction of movement.

LED signals during manual control:

Manual operation can be set to "Standard mode" or "Comfort mode":

3.2.1. Standard mode (default)

• If a button is pressed for less than 1 second, the drive will move in a step-by-

step fashion. This allows, for example, slats to be positioned precisely.

• If a button is held for longer than 1 second, the drive moves to its final

position (switching off after 240 seconds of maximum runtime)

This is how you set the Standard mode:

• Press the button on the channel to be set for 5 seconds and then

additionally the button for longer than 1 second

• To confirm the On LED on the channel flashes 5 times

3.2.2. Comfort mode

• If a button is held for less than 0.3 seconds, the drive moves to its final

position (switching off after 240 seconds of maximum runtime)

• If a button is held for longer than 0.3 seconds, but less than 2 seconds, the

drive moves only while the button is pressed and stops immediately when

it is released (deadman function)

• If a button is held for longer than 2 seconds, the drive moves to its final

position (switching off after 240 seconds of maximum runtime)

This is how you set the Comfort mode:

• Press the button on the channel to be set for 5 seconds and then

additionally the button for longer than 1 second

• To confirm the Off LED on the channel flashes 5 times

3.3. Individual movement position

The IMSG-UC-4H can store one movement position for each connected drive.

This allows fast and uncomplicated movement to a position that is needed often

(e.g. a shutter position or the partial opening of a window).

3.3.1. Storing a movement position

Storing a position is carried out as follows:

• Move the drive to the starting/zero position, i.e. close the window, retract the

awning or raise the blinds

• Press the and buttons for three seconds at the same time

• As feedback the drive moves briefly up and down. You are in now

Programming mode

• Move to the desired position

• Store the position by pressing the and buttons for 1 second long at the

same time

• As feedback the drive moves briefly up and down

• With blind slats, now open the slats to the desired angle. With awnings,

tighten the canvas with . For windows, you can skip this point.

• Store by again pressing the and buttons for 1 second long at the same

time

• As feedback the drive moves briefly up and down. The storage is complete

and the IMSG-UC-4H is again in normal mode

Note: As soon as a central command arrives (e.g. because of a wind or rain alarm),

the Programming mode will be interrupted! In this case, please carry out the posi-

tion storage again when the central command is no longer present.

3.3.2. Calling up a movement position

The stored position can be called up by pressing the button of the appropriate

channel for 3-6 seconds.

The drive will move to the movement position directly if it is in a secure position

and the runtimes of previous commands have expired. If the drive is in an interme-

diate position, it will move initially to the secure position and then to the stored po-

sition after expiry of the runtime.

4. Disposal

After use, the device must be disposed of or recycled in accordance with the legal

regulations. Do not dispose of it with the household waste!

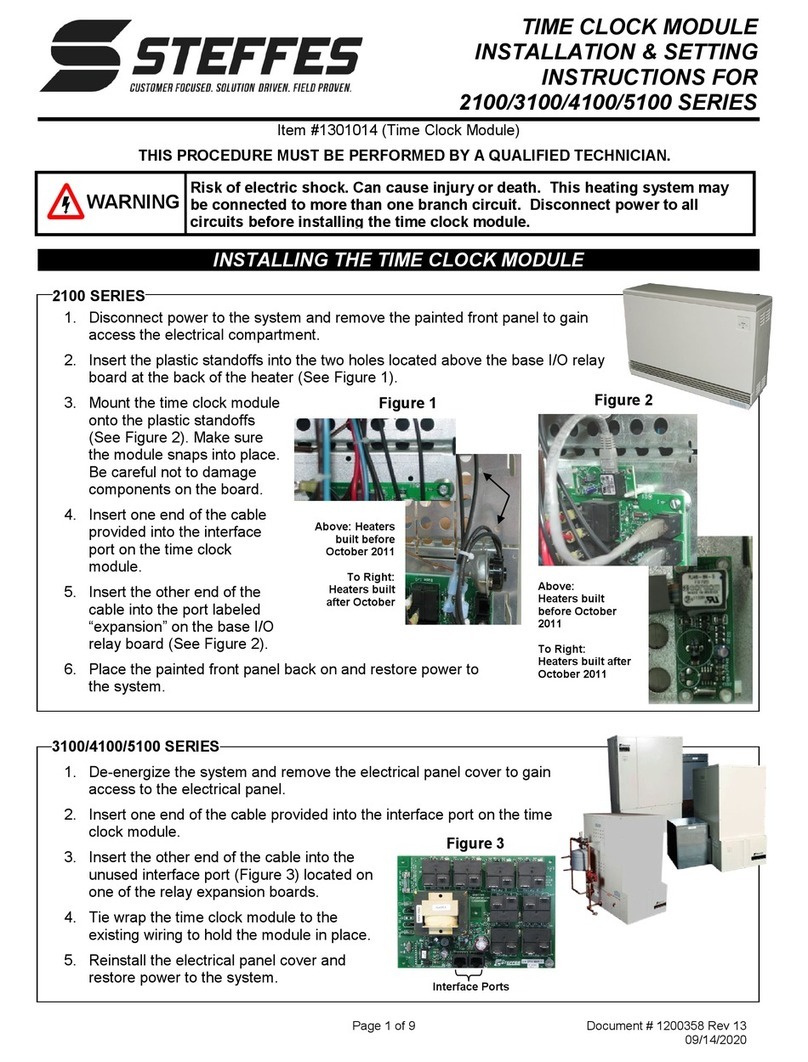

Fig. 2

Each terminal contact may be loaded with a

maximum of 10 A.

During movement: Channel LEDs in the direction of movement flash every 2

seconds

Runtime reached: Channel LEDs in the direction of movement continue to flash

every 2 seconds

Fig. 3

For IMSG-UC-2H

and/or -4H

Each terminal contact may

be loaded with a maximum

of 10 A.

Fig. 4

Press the button of channel

1 and the button of channel

2 for 5 seconds at the same

time

During movement: Channel LED in the direction of move-

ment flashes every second

Runtime reached without interruption: LED for the direction travelled remains on

Intermediate position reached: LEDs off