elsner elektronik KNX T-AP Guide

Temperature Sensor

KNX T-AP

Installation and Adjustment

Product Description ..........................................................................................3

Technical specifications................................................................................................. 3

Installation and Commissioning ........................................................................4

Installation position ....................................................................................................... 5

Layout KNX T-AP ........................................................................................................... 5

Connection of the temperature sensor........................................................................... 6

Notes on installation ............................................................................................................................. 6

Maintenance................................................................................................................... 6

Transmission protocol .......................................................................................7

Abbreviations ................................................................................................................. 7

Listing of all communication objects ............................................................................. 7

Setting of parameters......................................................................................11

General settings ........................................................................................................... 11

Temperature measured value ....................................................................................... 12

Temperature threshold values...................................................................................... 13

Temperature threshold value 1 / 2 / 3 / 4 ........................................................................................... 14

Temperature PI control ................................................................................................ 17

Logic............................................................................................................................. 24

AND Logic 1 / 2 / 3 / 4 .......................................................................................................................... 25

Linkage inputs of AND logic ............................................................................................................... 26

OR Logic 1 / 2 / 3 / 4 ............................................................................................................................. 27

Linkage inputs of OR logic .................................................................................................................. 28

KNX T-AP | from software version 0.2.0, ETS programme version 2.0 | Version: 29.03.2012.

Errors excepted. Subject to technical changes.

Elsner Elektronik GmbH Control and Automation Engineering

Herdweg 7 • D-75391 Gechingen • Germany

Phone: +49 (0) 70 56/93 97-0 • Fax: +49 (0) 70 56/93 97-20

2

3

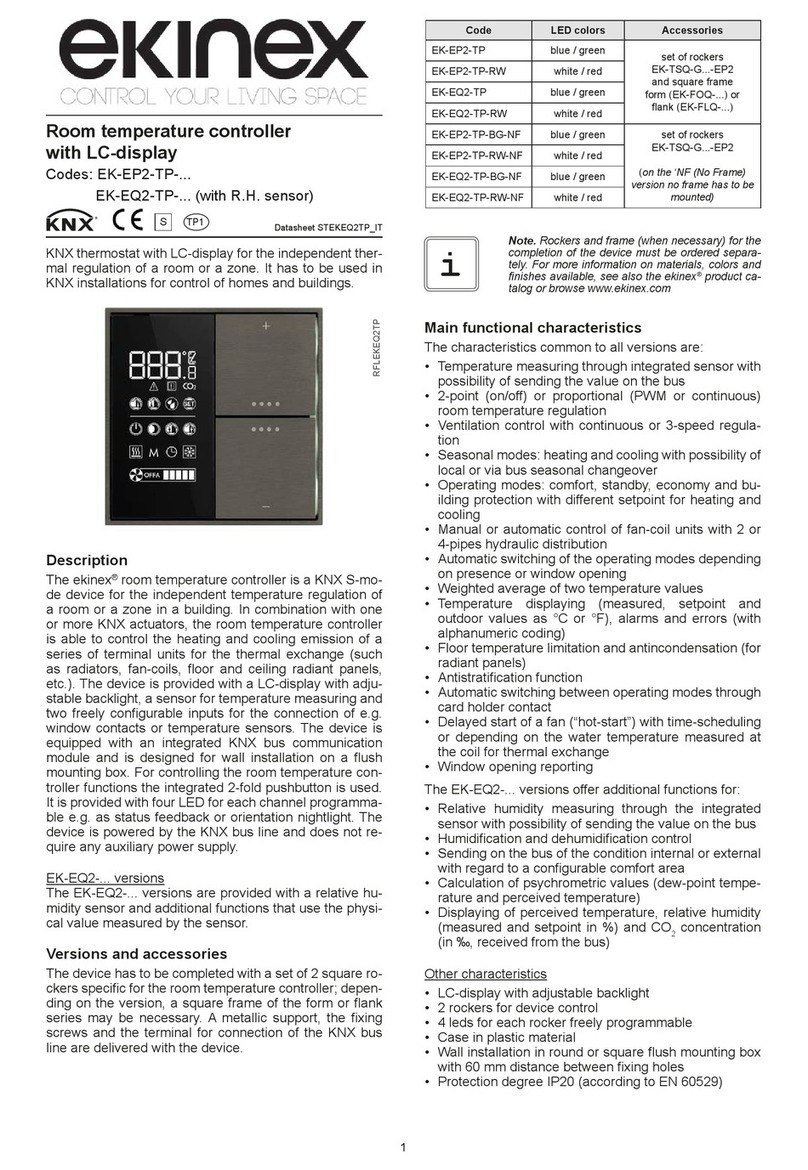

Product Description

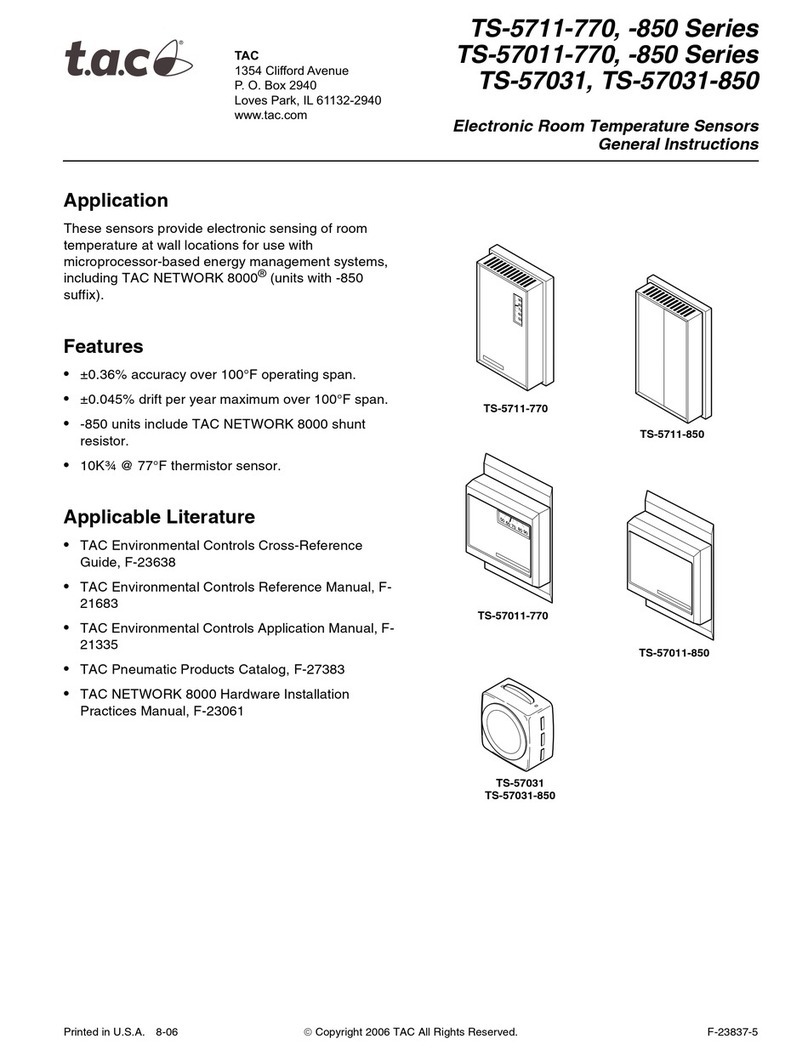

The Temperature Sensor KNX T-AP measures temperature in indoor and outdoor areas.

The sensor can receive an external measured value via the bus and process it with the

own data to an overall temperature (mixed value).

The KNX T-AP provides four switching outputs with adjustable threshold values as well

as additional AND and OR logic gates. The sensor has got a PI controller for heating and

cooling.

Functions:

•Measurement of temperature

•Mixed value from own measured value and external value (proportions can be set

in percentage)

•PI controller for heating (one or two step) and cooling (one or two step)

•4 switching outputs with adjustable threshold values (Threshold values can be

set by parameter or via communication objects)

•4 AND and 4 OR logic gates with each 4 inputs. Every switching incident as well

as 8 logic inputs (in the form of communication objects) may be used as inputs for

the logic gates. The output of each gate may optionally be configured as 1 bit or 2 x

8 bits

Configuration is made using the KNX software ETS. The programme file (format VD2)

and the manual can be downloaded from the Elsner Elektronik homepage on

www.elsner-elektronik.de in the “Service” menu.

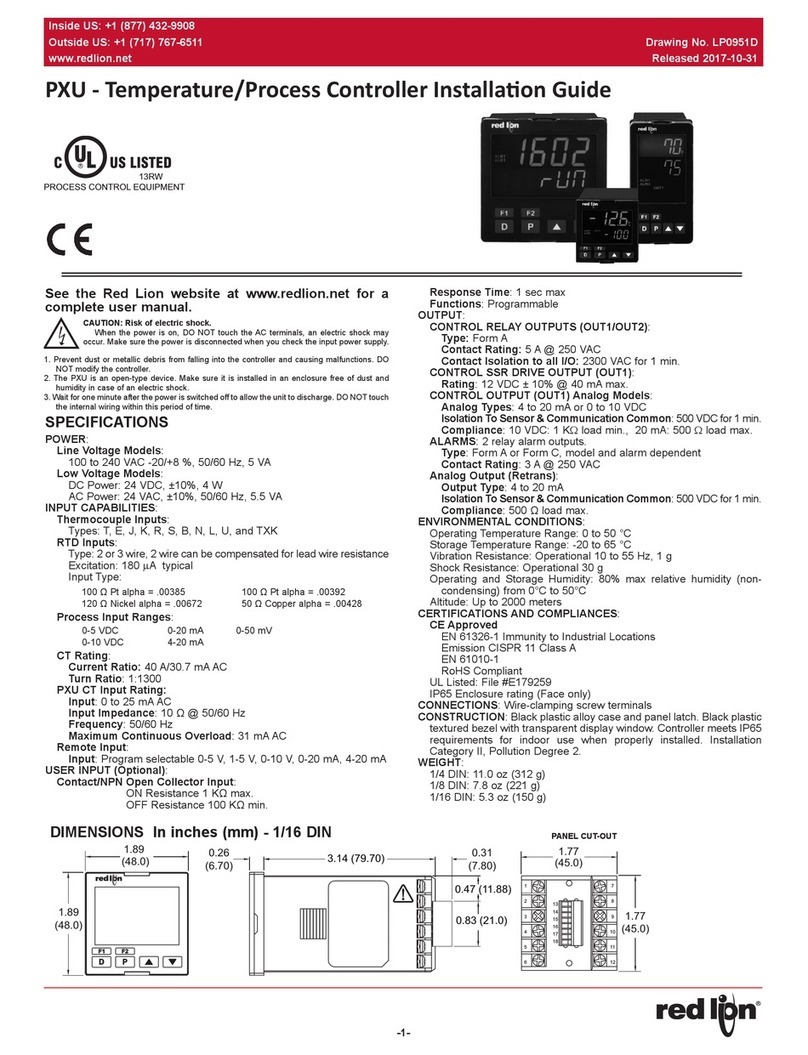

Technical specifications

Housing: Plastic material, sensor sleeve metal

Colour: Grey

Mounting: On-wall

Protection category: IP 65

Dimensions: approx. 65 x 93 x 38 (W x H x D, mm)

Weight: approx. 70 g

Ambient temperature: Operation -30…+85°C, Storage -55…+125°C

Operating voltage: KNX bus voltage

Bus current: max. 5.5 mA,

max. 15 mA when programming LED is active

Data output: KNX +/- bus terminal plug

BCU type: Own micro controller

PEI type: 0

Group addresses: max. 184

Allocations: max. 184

4

Communication objects: 80

Measurement range: -40…+80°C

Resolution: 0.1°C

Accuracy: ±1°C at -10…+85°C

±1.5°C at -25…+150°C

The following standards have been considered for the evaluation of the product in terms

of electro magnetic compatibility:

Transient emissions:

•EN 60730-1:2000 Section EMV (23, 26, H23, H26) (threshold category: B)

•EN 50090-2-2:1996-11 + A1:2002-01 (threshold category: B)

•EN 61000-6-3:2001 (threshold category: B)

Interference resistance:

•EN 60730-1:2000 Section EMV (23, 26, H23, H26)

•EN 50090-2-2:1996-11 + A1:2002-01

•EN 61000-6-1:2004

The product has been tested for the above mentioned standards by an accredited EMV

laboratory.

Installation and Commissioning

Installation, inspection, commissioning and troubleshooting

of the sensor must only be carried out by a competent electrician.

Disconnect all lines to be assembled, and take safety precautions against accidental

switch-on.

The sensor is exclusively intended for appropriate use. With each inappropriate change

or non-observance of the instructions for use, any warranty or guarantee claim will be

void.

After unpacking the device, check immediately for any mechanical damages. In case of

transport damage, this must immediately notified to the supplier.

If damaged, the sensor must not be put into

operation.

If an operation without risk may supposedly not be guaranteed, the device must be put

out of operation and be secured against accidental operation.

The sensor must only be operated as stationary system, i.e. only in a fitted state and after

completion of all installation and start-up works, and only in the environment intended

for this purpose.

5

Elsner Elektronik does not assume any liability for changes in standards after publication

of this instruction manual.

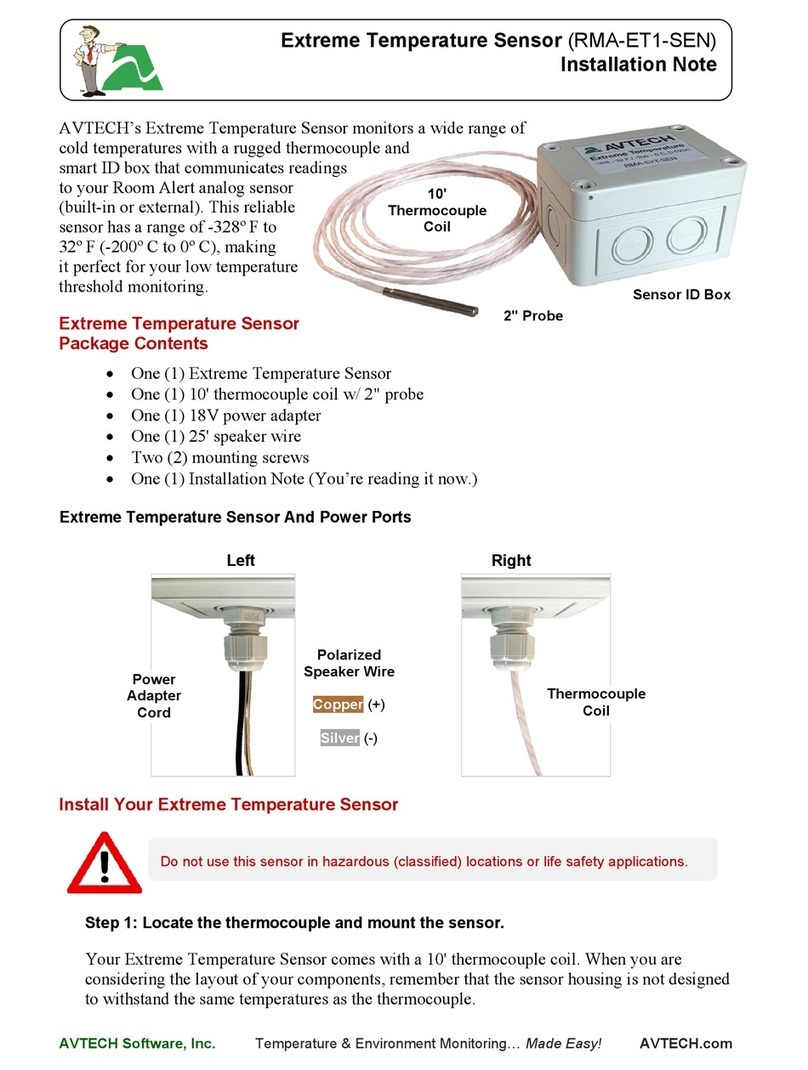

Installation position

The sensor is designed for surface mounting. When selecting an installation location,

please ensure that the measurement results are affected as little as possible by external

influences. Possible sources of interference include:

•Direct sunlight

•Drafts from windows and doors

•Warming or cooling of the building structure on which the sensor is mounted, e.g.

due to sunlight, heating or cold water pipes

•Connection lines which lead from warmer or colder areas to the sensor

Temperature variations from such sources of interference must be corrected in the ETS

in order to ensure the specified accuracy of the sensor (temperature offset).

For outdoor installation it must be ensured that a 60 cm gap is left below the sensor in

order to prevent it from being snowed during snowfall.

The sensor must be mounted vertically. The measurement probe and the cable outlet

must point downwards.

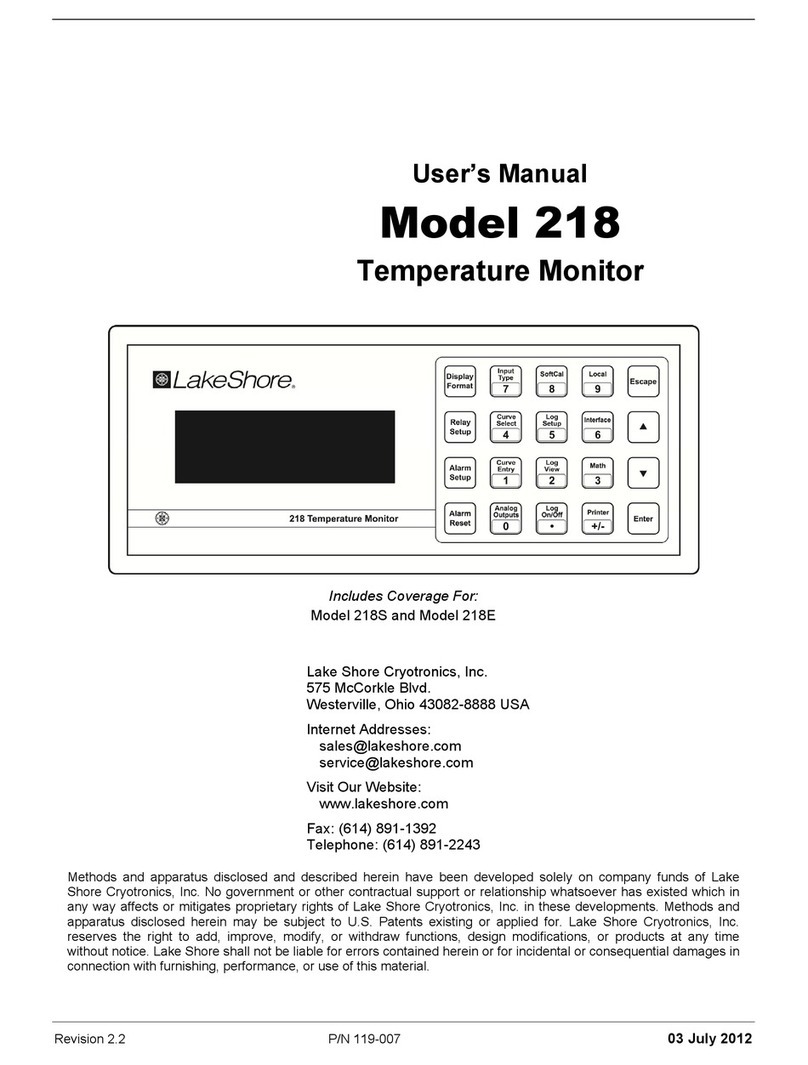

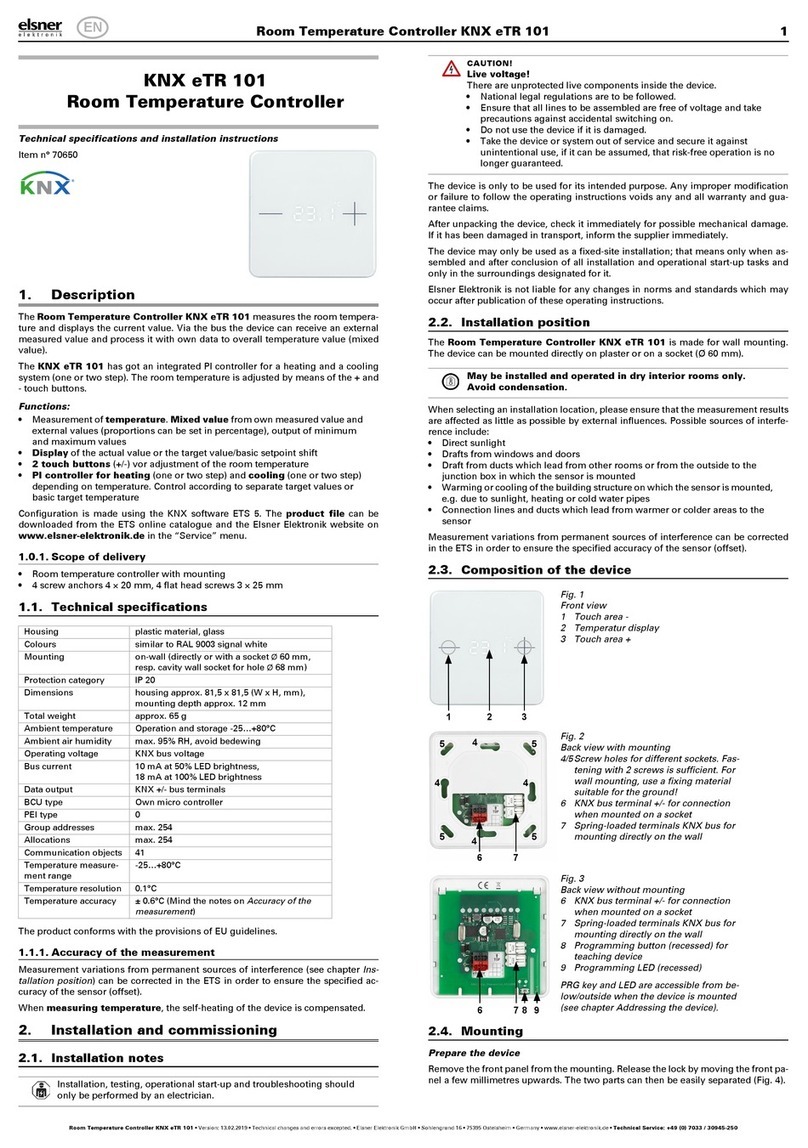

Layout KNX T-AP

Fig. 1: Opened casing, board Fig. 2: Rear view with dimensioning of

openings for mounting

1 Slot for KNX terminal +/-

2 Programming button for teaching the instrument

3 Programming LED

4 Cable entry with threaded joint

5 Temperature sensor tip

6

Connection of the temperature sensor

Remove the screwed on cover. Lead the KNX bus connection cable through the cable

entry on the bottom of the casing and connect the bus +/- to the terminal provided for

this purpose. Screw the cover back on.

Notes on installation

Do not open the temperature sensor if penetration of water (rain) is likely: Only a couple

of drops could damage the electronic.

Maintenance

The temperature sensor should regularly be checked for dirt and cleaned, if required.

Due to safety reasons, the sensor should always be

disconnected from the bus current when performing

maintenance and cleaning works (e.g. by deactivating/

removing fuse).

7

Transmission protocol

Abbreviations

Flags:

C Communication

R Read

W Write

T Transmit

U Update

Listing of all communication objects

No. Name Function DPT Flags

0 External measured value for temperature Input 9.001 C W

1 Internal measured value for temperature Output 9.001 C R T

2 Total measured value for temperature Output 9.001 C R T

3 Request min./max. measured value for

temperature

Input 1.017 C W

4 Minimum measured value for

temperature

Output 9.001 C R T

5 Maximum measured value for

temperature

Output 9.001 C R T

6 Reset min./max. measured value for

temperature

Input 1.017 C W

7 Temperature sensor malfunction Output 1.001 C R T

9 Temp. threshold value 1: Absolute value Input / Output 9.001 C R W T U

10 Temp. threshold value 1: (1:+ | 0:-) Input 1.006 C W

11 Temp. threshold value 1:

Switching output

Output 1.001 C R T

12 Temp. threshold value 1:

Switching output block

Input 1.006 C W

13 Temp. threshold value 2: Absolute value Input / Output 9.001 C R W T U

14 Temp. threshold value 2: (1:+ | 0:-) Input 1.006 C W

15 Temp. threshold value 2:

Switching output

Output 1.001 C R T

16 Temp. threshold value 2:

Switching output block

Input 1.006 C W

8

No. Name Function DPT Flags

17 Temp. threshold value 3: Absolute value Input / Output 9.001 C R W T U

18 Temp. threshold value 3: (1:+ | 0:-) Input 1.006 C W

19 Temp. threshold value 3:

Switching output

Output 1.001 C R T

20 Temp. threshold value 3:

Switching output block

Input 1.006 C W

21 Temp. threshold value 4: Absolute value Input / Output 9.001 C R W T U

22 Temp. threshold value 4: (1:+ | 0:-) Input 1.006 C W

23 Temp. threshold value 4:

Switching output

Output 1.001 C R T

24 Temp. threshold value 4:

Switching output block

Input 1.006 C W

25 Temp. control: Switching object

(0:heating | 1:cooling)

Input 1.002 C W

26 Temp. control: Target value current Output 9.001 C R T

27 Temp. control: Blocking object Input 1.006 C R W

28 Temp. control: Target value, day heating Input / Output 9.001 C R W T U

29 Temp. control: Target value, day heating

(1:+ | 0:-)

Input 1.002 C W

30 Temp. control: Target value, day cooling Input / Output 9.001 C R W T U

31 Temp. control: Target value, day cooling

(1:+ | 0:-)

Input 1.002 C W

32 Temp. control: Act. variable heating

1. stage

Output 5.001 C R T

33 Temp. control: Act. variable heating

2. stage

Output 5.001 C R T

34 Temp. control: Act. variable heating

2. stage

Output 1.001 C R T

35 Temp. control: Act. variable cooling

1. stage

Output 5.001 C R T

36 Temp. control: Act. variable cooling

2. stage

Output 5.001 C R T

37 Temp. control: Act. variable cooling

2. stage

Output 1.001 C R T

38 Temp. control: Night lowering activation Input 1.003 C W

9

No. Name Function DPT Flags

39 Temp. control: Target value heating,

night

Input / Output 9.001 C R W T U

40 Temp. control: TargetV heating, night

(1:+ | 0:-)

Input 1.002 C W

41 Temp. control: Target value cooling,

night

Input / Output 9.001 C R W T U

42 Temp. control: TargetV cooling, night (1:+

| 0:-)

Input 1.002 C W

43 Temp. control: Status heating 1

(1=ON | 0=OFF)

Output 1.001 C R T

44 Temp. control: Status heating 2

(1=ON | 0=OFF)

Output 1.001 C R T

45 Temp. control: Status cooling 1

(1=ON | 0=OFF)

Output 1.001 C R T

46 Temp. control: Status cooling 2

(1=ON | 0=OFF)

Output 1.001 C R T

47 Temp. control: Window status

(0: closed | 1: open)

Input 1.019 C W

78 Logic input 1 Input 1.006 C W

79 Logic input 2 Input 1.006 C W

80 Logic input 3 Input 1.006 C W

81 Logic input 4 Input 1.006 C W

82 Logic input 5 Input 1.006 C W

83 Logic input 6 Input 1.006 C W

84 Logic input 7 Input 1.006 C W

85 Logic input 8 Input 1.006 C W

86 AND logic 1: 1 bit Output 1.001 C R T

87 AND logic 1: 8 bit output A Output 5.010 C R T

88 AND logic 1: 8 bit output B Output 5.010 C R T

89 AND logic 2: 1 bit Output 1.001 C R T

90 AND logic 2: 8 bit output A Output 5.010 C R T

91 AND logic 2: 8 bit output B Output 5.010 C R T

92 AND logic 3: 1 bit Output 1.001 C R T

93 AND logic 3: 8 bit output A Output 5.010 C R T

94 AND logic 3: 8 bit output B Output 5.010 C R T

10

No. Name Function DPT Flags

95 AND logic 4: 1 bit Output 1.001 C R T

96 AND logic 4: 8 bit output A Output 5.010 C R T

97 AND logic 4: 8 bit output B Output 5.010 C R T

98 OR logic 1: 1 bit Output 1.001 C R T

99 OR logic 1: 8 bit output A Output 5.010 C R T

100 OR logic 1: 8 bit output B Output 5.010 C R T

101 OR logic 2: 1 bit Output 1.001 C R T

102 OR logic 2: 8 bit output A Output 5.010 C R T

103 OR logic 2: 8 bit output B Output 5.010 C R T

104 OR logic 3: 1 bit Output 1.001 C R T

105 OR logic 3: 8 bit output A Output 5.010 C R T

106 OR logic 3: 8 bit output B Output 5.010 C R T

107 OR logic 4: 1 bit Output 1.001 C R T

108 OR logic 4: 8 bit output A Output 5.010 C R T

109 OR logic 4: 8 bit output B Output 5.010 C R T

117 Software version Output 217.001 C R T

11

Setting of parameters

General settings

Transmission delays after

power-up and programming for:

Measured values 5 s

•

10 s • 30 s • 1 min • …

•

2 h

Threshold values and switching outputs 5 s

•

10 s • 30 s • 1 min • …

•

2 h

Target values and actuating variables 5 s

•

10 s • 30 s • 1 min • …

•

2 h

Logic outputs 5 s

•

10 s • 30 s • 1 min • …

•

2 h

Maximum telegram quota 1

•

2

•

3

•

5

•

10

•

20 Telegrams per second

Use malfunction object No

•

Yes

12

Temperature measured value

Temperature offset in 0.1°C -50 … 50

Use external measured value for temperature No

•

Yes

If no external measured value is used:

Use external measured value for temperature No

Temperature measured value

•

do not send

• send periodically

• send in case of change

• send in case of change and periodically

From change of

(only if sending “in case of change”)

2%

•

5%

•

10%

•

25%

•

50%

Send periodically all

(only if sending “periodically”)

5 s

•

10 s • 30 s • 1 min • …

•

2 h

Use min. and max. temperature values

(Values are not maintained after reset)

No

•

Yes

If an external measured value is used:

Use external measured value for temperature Yes

Ext. temperature measured value proportion

of the total measured value

5% … 100% (in steps of 5%)

13

Internal and total measured value for

temperature

•

do not send

• send periodically

• send in case of change

• send in case of change and periodically

All following settings refer to the total measured value

From change of

(only if sending “in case of change”)

2%

•

5%

•

10%

•

25%

•

50%

Send periodically all

(only if sending “periodically”)

5 s

•

10 s • 30 s • 1 min • …

•

2 h

Use min. and max. temperature values

(Values are not maintained after reset)

No

•

Yes

Temperature threshold values

Use temperature threshold value 1 /2 / 3 / 4 No

•

Yes

14

Temperature threshold value 1 / 2 / 3 / 4

Temperature threshold value:

……………………………

Temperature threshold value standard per Parameter • Communication object

If the threshold value is set per Parameter:

Temperature threshold value standard per Parameter

Temperature threshold value in 0.1°C -300 … 800

Hysteresis of the threshold value in % 0 … 50

If the threshold value is set per Communication object:

Temperature threshold value standard per Communication object

15

The value communicated last shall be

maintained

•

not

• after restoration of voltage

• after restoration of voltage and programming

(Do not use for first commissioning)

Start temperature threshold value in 0.1°C

valid until 1.communication

(only if the value communicated last is “not”

maintained or “after restoration of voltage”)

-300 … 800

Type of threshold change for temperature

•

Absolute value

• Increment/decrement

Step size

(only with “Increment/decrement”)

0.1°C

•

0.2°C

•

0.3°C

•

0.4°C

•

0.5°C

•

1°C • 2°C

•

3°C • 4°C • 5°C

Hysteresis of the threshold value in % 0 … 50

Temperature switching output:

……………………………

Output is at

(TV = temperature threshold value)

•

TV above = 1 | TV

–

Hyst. below = 0

• TV above = 0 | TV – Hyst. below = 1

• TV below = 1 | TV + Hyst. above = 0

• TV below = 0 | TV + Hyst. above = 1

Switching delay from 0 to 1 none

•

1s

•

2 s • 5 s • 10 s • …

•

2 h

Switching delay from 1 to 0 none

•

1 s

•

2 s • 5 s • 10 s • …

•

2 h

Temperature switching output sends

•

on change

• on change to 1

• on change to 0

• on change and periodically

• on change to 1 and periodically

• on change to 0 and periodically

Send temperature switching output

in the cycle of

(only if sending “periodically”)

5 s

•

10 s • 30 s • 1 min • …

•

2 h

Blocking:

……………………………

Use block of the temperature switching output No

•

Yes

Evaluation of the temperature blocking object

•

if value 1: block | if value 0: release

• if value 0: block | if value 1: release

Wert des Sperrobjekts

vor 1. Kommunikation

0 • 1

Behaviour of switching output

with blocking

•

do not send telegram

• send 0

• send 1

16

The behaviour with release of the switching output depends on the value of the

parameter “Temperature switching output sends …” (see ”Temperature switching

output”)

Value of parameter

“Temperature switching output sends”:

Setting options

“

Behaviour of switching

output with release”:

on change

•

do not send telegram

• send status of the switching output

on change to 1

•

do not send telegram

• if switching output = 1 Îsend 1

on change to 0

•

do not send telegram

• if switching output = 0 Îsend 0

on change and periodically send status of the switching output

(no selection)

on change to 1 and periodically if switching output = 1 Îsend 1

(no selection)

on change to 0 and periodically if switching output = 0 Îsend 0

(no selection)

17

Temperature PI control

Use control No

•

Yes

If the control is in use:

Control general:

……………………………

Type of control

•

One-stage heating

• Two-stage heating

• One-stage cooling

• One-stage heating + one-stage cooling

• Two-stage heating + one-stage cooling

• Two-stage heating + two-stage cooling

Behaviour of the blocking object with value

•

1 = block control |

0 = release control

• 0 = block control |

1 = release control

18

Value of the blocking object

before 1. communication

0

•

1

Send actuating variables

•

on change

• on change and periodically

Transmission cycle

(only if sending „periodically“)

5 s … 2 h

Status object/s send

•

on change

• on change to 1

• on change to 0

• on change and periodically

• on change to 1 and periodically

• on change to 0 and periodically

Transmission cycle

(only if sending „periodically“)

5 s … 2 h

Controller target value:

……………………………

Target value setpoint per Parameter • Communication object

If the target value is set per Parameter:

Target value setpoint per Parameter

Target value in 0.1°C -300 … 800

If the target value is set per Communication object:

Target value setpoint per Communication object

The value communicated last shall be

maintained

•

not

• after restoration of voltage

• after restoration of voltage and programming

(Do not use for first commissioning)

Start target value in 0.1°C

valid until 1.communication

(only if the value communicated last is “not”

maintained or “after restoration of voltage”)

-300 … 800

Limitation of object value (min) in 0.1°C -300 … 800

Limitation of object value (max) in 0.1°C -300 … 800

Type of the target value change

•

Absolute value

• Increment/decrement

Step size

(only with “Increment/decrement”)

0.1°C

•

0.2°C • 0.3°C

•

0.4°C • 0.5°C • 1°C • 2°C •

3°C • 4°C • 5°C

19

Heating control / Heating control 1. stage

(Appears only if heating control is used):

……………………………

Setting of the controller by

•

preset applications

• controller parameter

Application

(only if controller is set by “preset

applications”)

•

Hot water heating

• Floor heating

• Fan convector

• Electrical heating

Maximum actuating variable is reached at

target/actual difference of

(Attention: Can only be adjusted if “Setting of

the controller by controller parameter”)

1°C • 2°C • 3°C • 4°C • 5 °C

Re-setting time in mins

(Attention: Can only be adjusted if “Setting of

the controller by controller parameter”)

1 … 255

If blocked, the actuating variable shall

•

will not be sent

• send a specific value

Value in %

(not if a specific value is sent)

0 … 100

Other manuals for KNX T-AP

1

Table of contents

Other elsner elektronik Temperature Controllers manuals

elsner elektronik

elsner elektronik KNX eTR 101-BA2 Guide

elsner elektronik

elsner elektronik KNX T-UN 130 Guide

elsner elektronik

elsner elektronik Cala KNX T 101 User manual

elsner elektronik

elsner elektronik Arexa 230V Window Control Guide

elsner elektronik

elsner elektronik KNX T-AP Guide

elsner elektronik

elsner elektronik Cala KNX T 101 User manual

elsner elektronik

elsner elektronik KNX eTR 101 User manual

elsner elektronik

elsner elektronik KNX eTR 201 Sunblind User manual

elsner elektronik

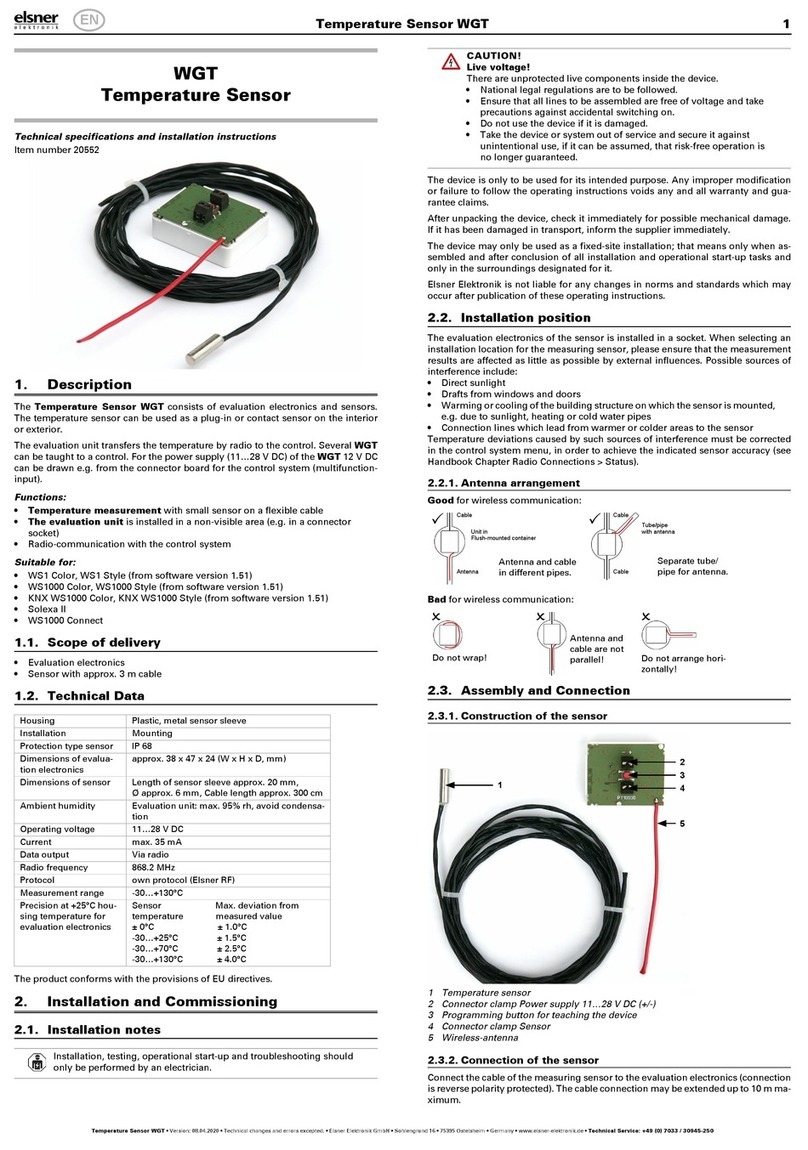

elsner elektronik 20552 User manual

elsner elektronik

elsner elektronik KNX TH65-AP User manual