Elster GmbH

___________________________________________________________________________________________________________

EnCal 3000 Quad–Hardware Manual 22/06/2017

2/52

Contact Information...................................................................................................................................... 3

Safety Information ........................................................................................................................................... 4

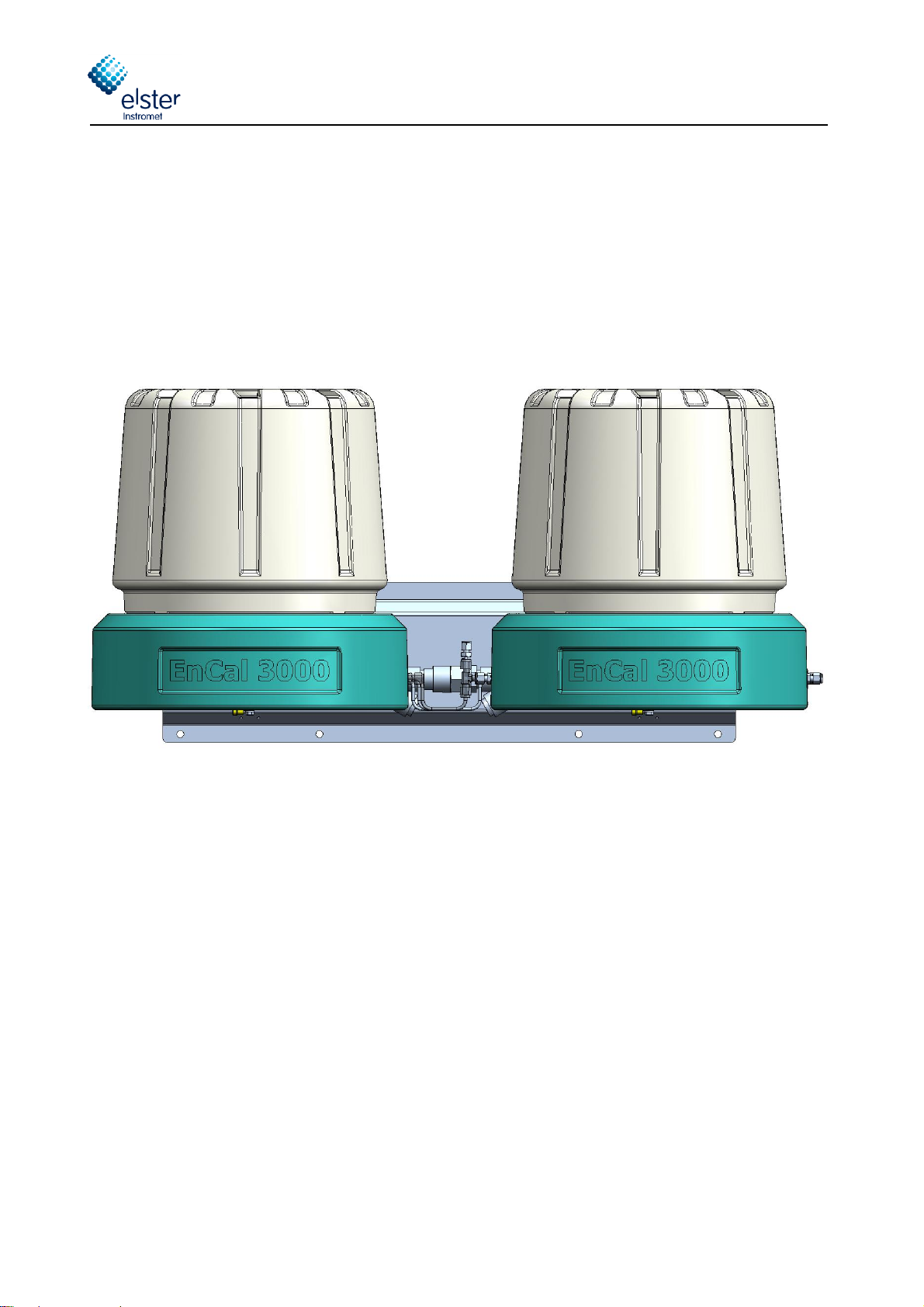

Gas quality measurement system EnCal 3000 Quad................................................................................... 5

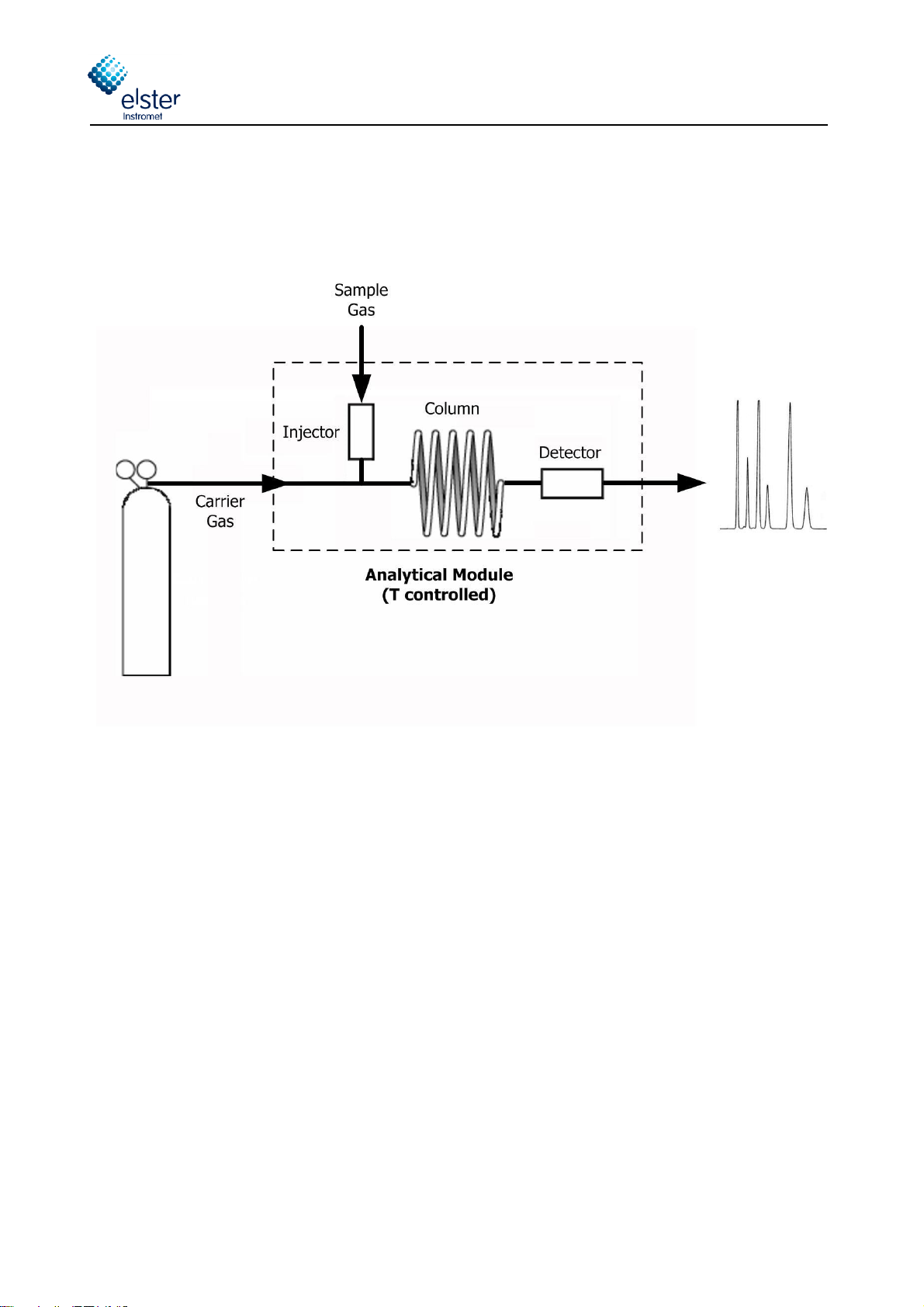

1Process Gas Chromatography –General Introduction....................................................................... 7

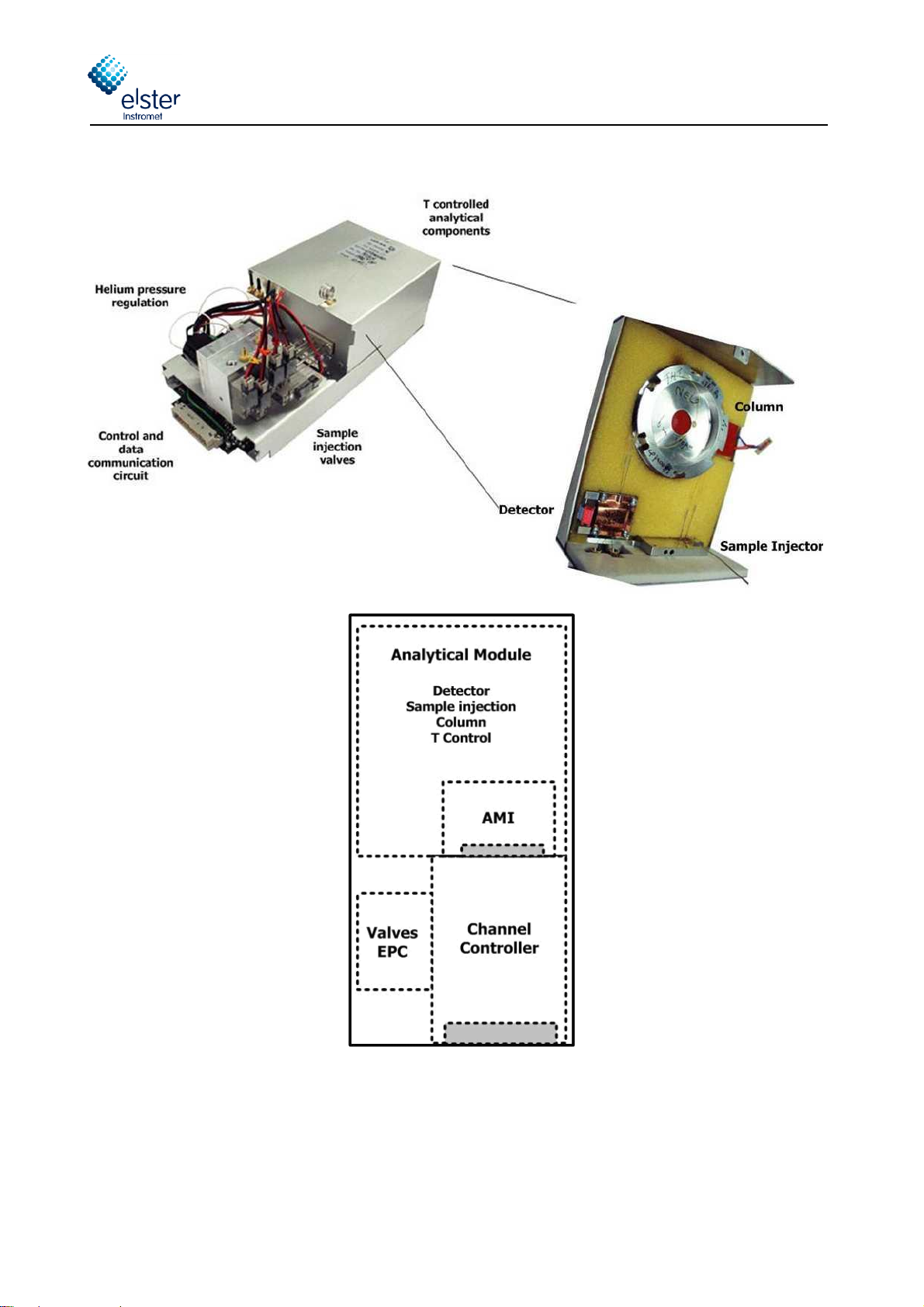

1.1 Analytical Principle................................................................................................................................7

1.1.1 Column .................................................................................................................................8

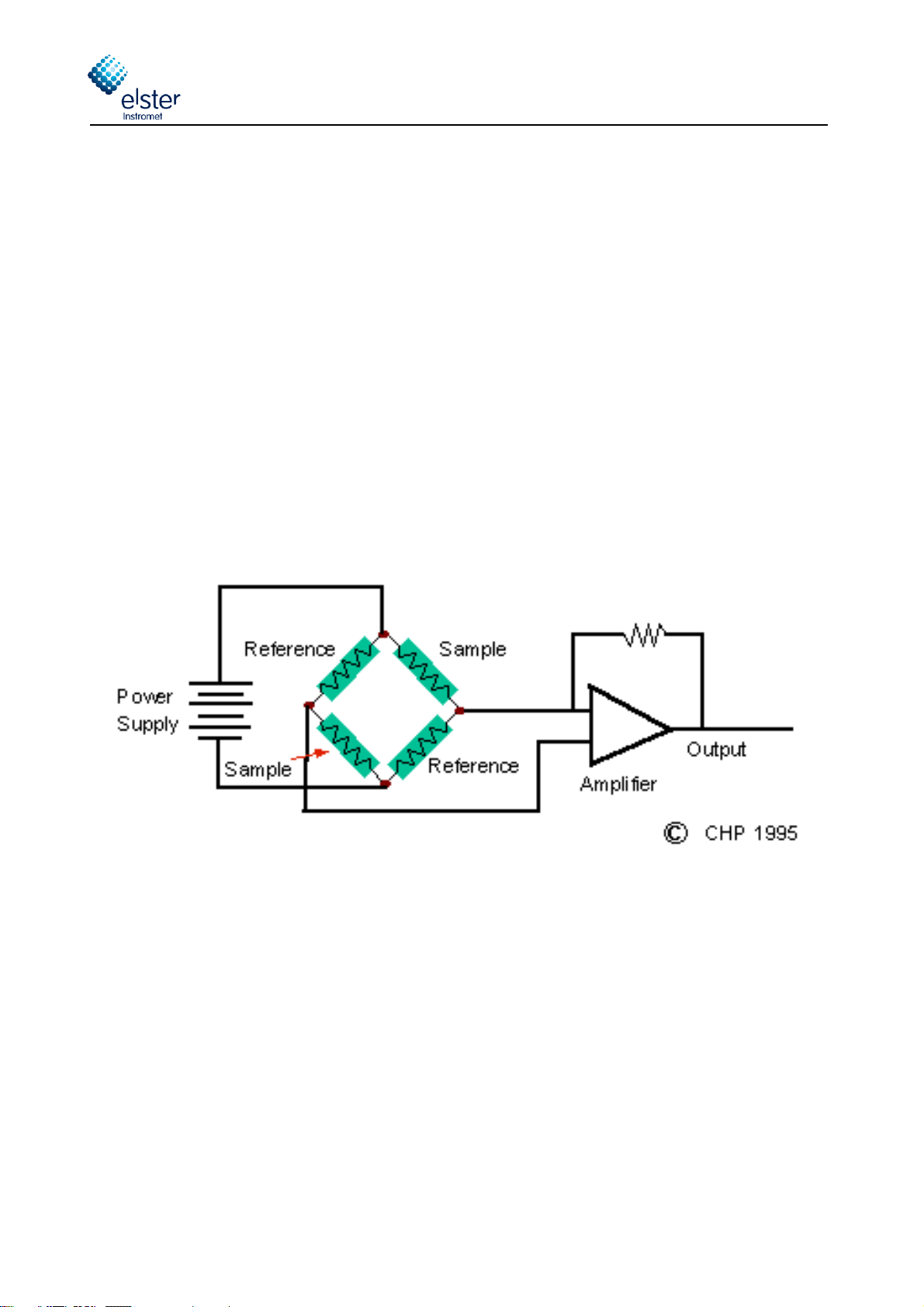

1.1.2 Detector................................................................................................................................9

1.1.3 Sample Injector ...................................................................................................................10

1.2 Process Gas Chromatography ..............................................................................................................11

2Functional Design ................................................................................................................................. 12

2.1 Introduction .......................................................................................................................................12

2.2 Enclosure...........................................................................................................................................13

2.3 Assembly of major components and internal components.......................................................................14

2.4 Channel .............................................................................................................................................15

2.5 Processor Board .................................................................................................................................19

2.6 Interconnection Board.........................................................................................................................22

2.7 Electrical connection ...........................................................................................................................23

2.8 Cabinet Heaters..................................................................................................................................24

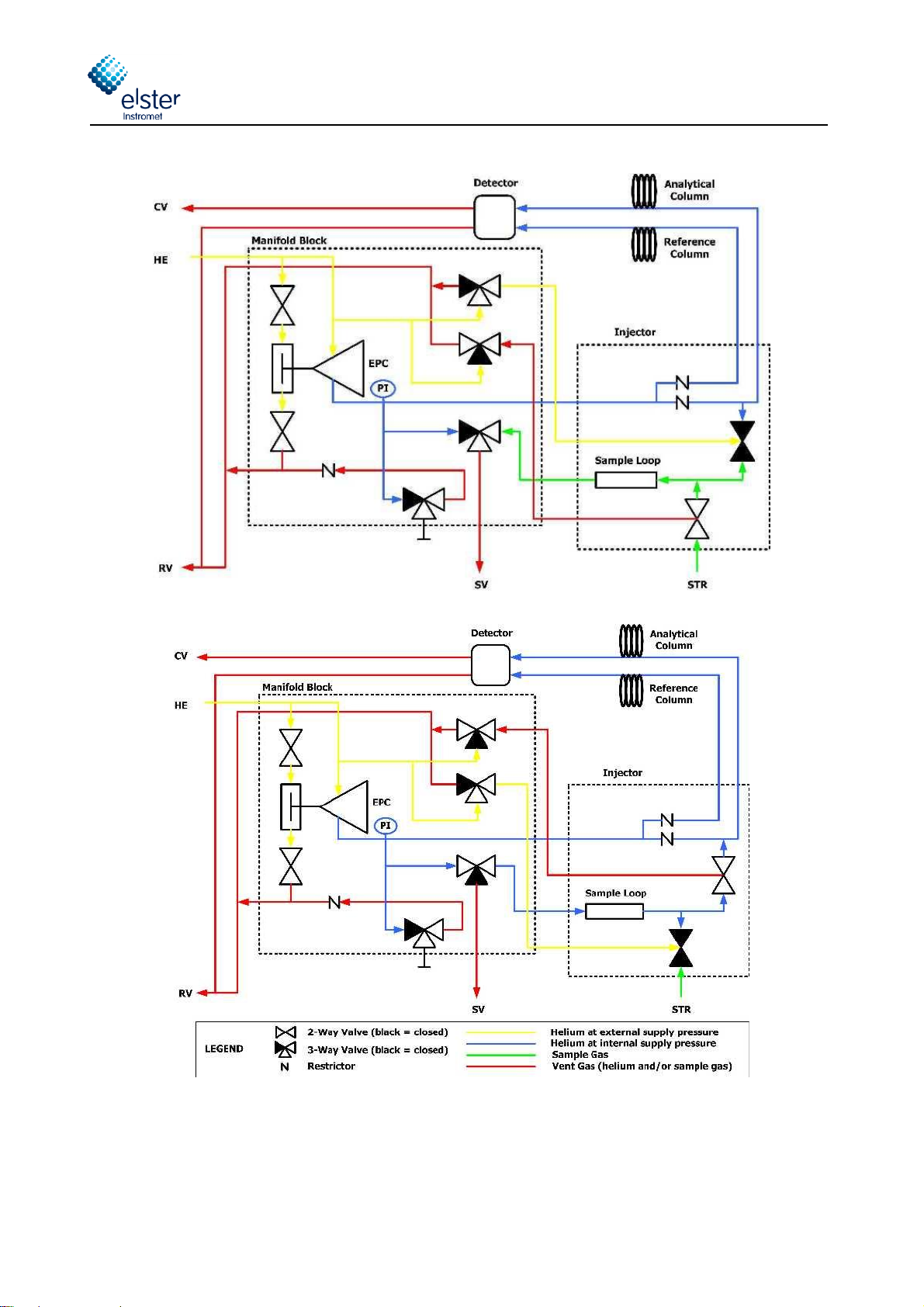

2.9 Internal sample system .......................................................................................................................25

2.9.1 Double Block and Bleed Function ...........................................................................................27

2.9.2 Internal Sample Bypass ........................................................................................................27

2.10 Gas Connections.................................................................................................................................28

2.11 Breather ............................................................................................................................................29

2.12 Cable Glands ......................................................................................................................................30

2.13 External Switch ..................................................................................................................................30

3Technical Specifications ..................................................................................................................... 31

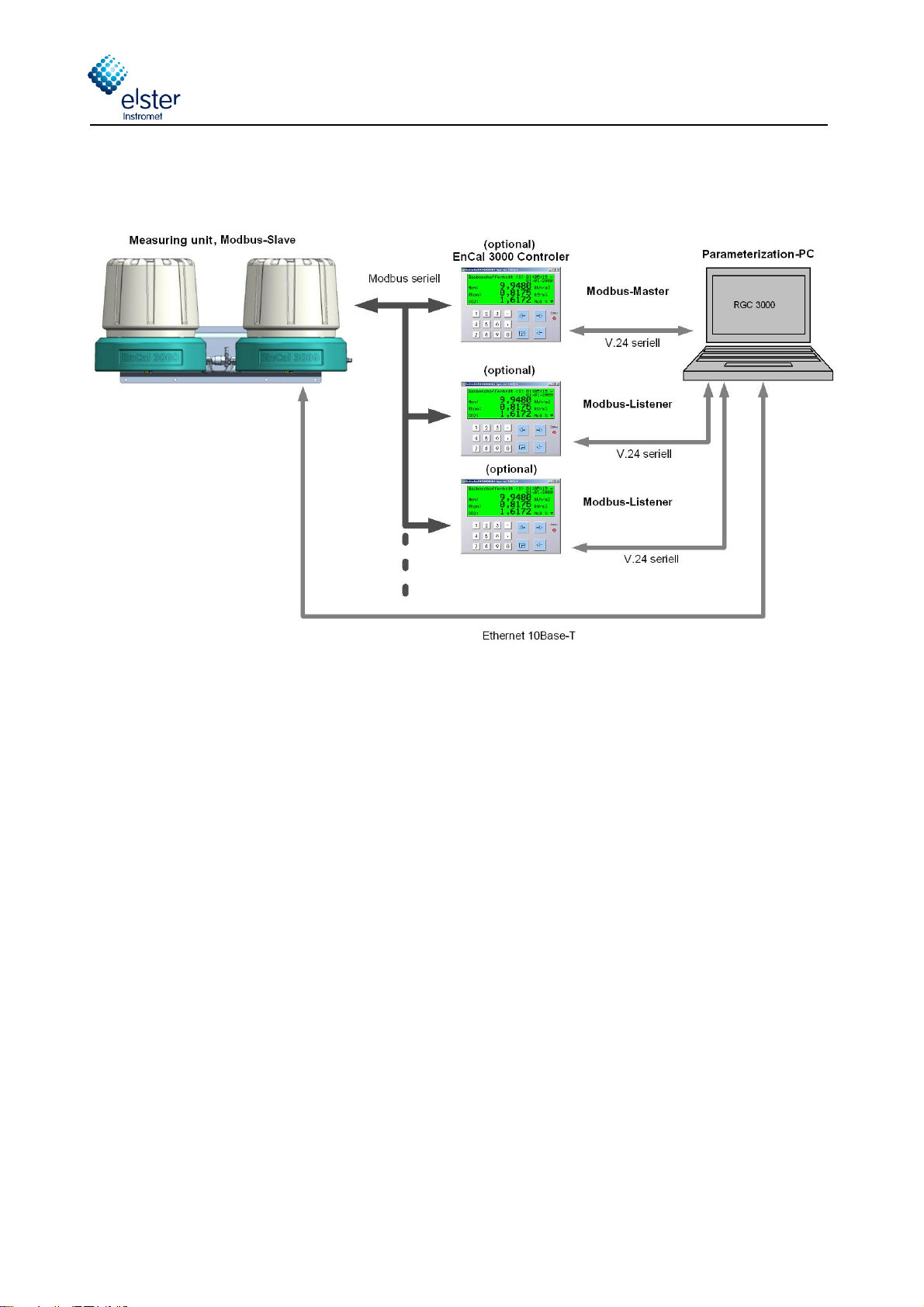

4Data Communication............................................................................................................................. 34

4.1 Local TCP/IP Data Communication .......................................................................................................34

4.2 Local Serial ModBus Data Communication .............................................................................................35

4.3 Remote Access ...................................................................................................................................36

4.4 ModBus Communication ......................................................................................................................37

5Hardware Installation ............................................................................................................................ 38

5.1 Installation specifications.....................................................................................................................38

5.1.1 Weight and Dimensions ........................................................................................................38

5.1.2 Installation clearance............................................................................................................38

5.1.3 Wall mounting .....................................................................................................................39

5.1.4 Connection of utilities ...........................................................................................................40

5.1.5 Connections to the EnCal 3000 Interconnection board .............................................................41

5.2 Hardware Start-up ..............................................................................................................................44

APPENDIX 1: CERTIFICATES ENCAL 3000 .............................................................................................. 46

APPENDIX 2: DECLARATION OF CONFORMITY ENCAL 3000 .............................................................. 52