2

• Do not immerse the device or its parts in water or other liquids.

• Turn off the main switch whenever a malfunction is detected or in case of cleaning/maintenance.

• For installation an omnipolar switch should be incorporated in the xed wiring, in accordance with the wiring regulations, to provide a full

disconnection under overvoltage category III conditions (contact opening distance equal to or greater than 3mm).

• Do not obstruct the fan or exhaust grille to ensure optimum air passage.

• Ensure adequate air supply into the room in compliance with existing regulations in order to ensure proper device operation

• If the environment in which the product is installed also houses a fuel-operating device (water heater, methane stove etc., that is not a “sealed

chamber” type), it is essential to ensure adequate air intake, to ensure good combustion and proper equipment operation.

• Install the product so that the impeller is not accessible from the air outlet side as veried by contact with the Test Finger (test probe “B” of the

norm EN61032) in compliance with the current safety regulations.

Unit Setting

The SANO PIV WALL unit runs continuously a low ventilation level supplying fresh clean air into your home. This fresh air dilutes the stale and humid

air in your home and is a great way to prevent and even cure condensation dampness and mould problems.

The unit setting is selected by the installer to suit the size, layout, thermal properties and moisture production in the home. Getting this setting right

is very important and is often based on the experience of the installer. It is as important not to over ventilate as it is to under ventilate a home. Elta

Fans Residential team has much experience in setting PIV units and can be contacted anytime for advice.

The unit has numerous automatic speed adjustments to optimise ventilation and energy use.

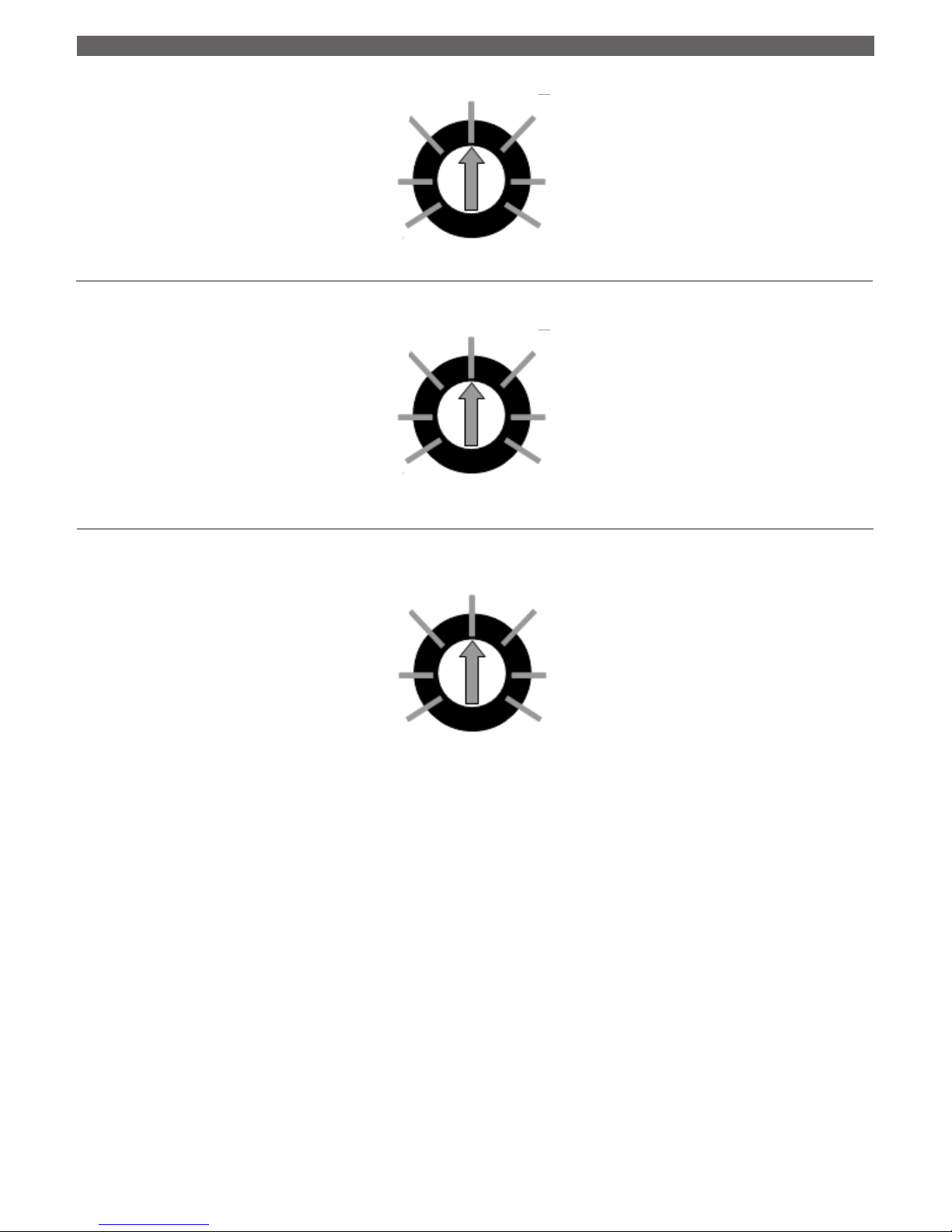

Normal Mode

The unit will run in this mode for the vast majority of its time supplying until the unit’s integral temperature sensor switches it to “Standby” mode,

or the “Override Boost” mode (if connected via a suitable switch) is activated by the occupants.

This rate is set via 3 RATE dip switches shown in the wiring diagram, when leaving the factory this is set to 21l/s.

Energy Saving Mode

When the temperature of air being brought into the home is above an adjustable temperature the unit will automatically switch to a lower speed.

This lower speed will reduce the energy used by the ventilation unit and the amount of uncomfortably warm air being brought in. This temperature

can be selected for conditions where condensation is less likely to occur such as the summer months.

This trigger temperature is adjustable between 15-25°C, via V1 trimmer (shown in the wiring diagram). The default when leaving the factory is

19°C. It is usually adjusted to 1°C above the temperature the home is heated to

The fan speed is adjustable between via the HY trimmerand can be set to between -50% and 50% of the trickle speed.

FOR EXAMPLE: The trickle is set at 21l/s, HY trimmer set to -20%: when triggered the boost will be 21+(-4.2)=16.8l/s.

It is recommended that the Heat Recovery Mode (boost above 0%) is not used for the WALL mounted PIV and the boost increase is set at or below

0% (default).

Summer Standby Mode

The summer shutdown function limits the chance of the house overheating when temperatures outside reach a level that is uncomfortable. The unit

will essentially switch off when the temperature reaches a “Standby” trigger temperature to save energy and prevent undesirable warm air being

introduced unnecessarily in to the home.

Some customers wish to have their unit operating all year round e.g. for Radon Gas control or pollen ltration during summer. That’s why an

adjustable trigger temperature has been incorporated.

This temperature set point is adjustable via V2 trimmer (shown in the wiring diagram) between 20° and 40°C, the default when leaving the factory

is 26°C.

Override Boost Mode

The unit’s automatic controls can be overridden to operate the unit at its maximum airow by means of a user switch.

The override boost can be triggered via a dedicated external volt free switch connecting GND and S3 terminals (shown in diagram). Purge operation

overrides any other speed settings.

This function can be incorporated at installation stage or later. The unit will function automatically with or without it.

To prevent excessively warm air being supplied to the home and to protect the components of the unit, the purge will not operate above 40°C.

OPERATION