Eltek Valere MU1000C User manual

DC-CONTROLLER

MU1000C Language

USER MANUAL

(Firmware version: V2.08)

UM_MU1000C_Language_E_R00

Control unit

MU1000C Language

USER MANUAL

Page 2 (38)

Eltek Valere Industrial GmbH ©2008

Information about the operation manual

IMPORTANT! Please read this operation manual very carefully before assembling

and starting this device!

The operation manual is a part of the delivery of this device, i.e. it should be

made available to each and every person involved with the starting, mainte-

nance or operation of the device. The device should be transported, mounted,

started, maintained and operated only by electro technical personnel.

The local specifications for the prevention of accidents as well as the general

guidelines according to IEC 364 should always be followed!

The functional descriptions in the operation manual correspond to those at the

time of the publication. Technical changes can be carried out by the Eltek

Valere Industrial GmbH without making any revisions or announcements.

There is no responsibility for the constant revision of the operation manual.

The device complies to the EN- and VDE-standards applicable at the time of the

publication. The CE symbol on the device confirms the conformation of the

EU-guidelines for 73/23 EWGLow voltage and for 89/339 EWG-Electromagnetic

compatibility.

The devices are delivered exclusively according to our delivery and sales

conditions. Alterations in the technical details in this operation manual as well as

the respective data sheets are reserved.

Complaints about the delivered goods should be made as soon as possible on

receiving them along with the packing invoice as well as the information about

the type, serial number and complaint.

Guarantee claims of the customer will not be entertained in the case of visible

external influences (e.g. absent or loose screws, welding, loose sheets, etc.),

that could be attributed to a non permitted opening of the device.

Eltek Valere Industrial GmbH does not undertake any responsibility for applica-

tions of the device, which have not been intended by the manufacturer.

It is the responsibility of the final consumer to take the necessary measures for

the prevention of damage to personnel and to goods (see upper text section).

Control unit

MU1000C Language

USER MANUAL

Page 3 (38)

Eltek Valere Industrial GmbH ©2008

Contact

ELTEK VALERE INDUSTRIAL GmbH

Schillerstraße 16

D-32052 Herford

+ 49 (0) 5221 1708-210

FAX + 49 (0) 5221 1708-222

Email Info.indust[email protected]

Internet http://www.eltekvalere-industrial.com

ATTENTION!

The duplication reproduction and/or adaptation of this document by electronic or

mechanical methods, also in parts, requires the previous authorization of the

Eltek Valere Industrial GmbH.

©Copyright Eltek Valere Industrial GmbH 2008. All rights reserved.

Control unit

MU1000C Language

USER MANUAL

Page 4 (38)

Eltek Valere Industrial GmbH ©2008

Revisions – MU1000C Language USER MANUAL

Revision: 00

Date: 2008-08-04

System: MU1000C

System voltage: 24 / 48 / 108 / 216 VDC

Revision Description Author Date

/00 Preliminary version (translation of the German version

…R02)

PS 2008-08-04

Control unit

MU1000C Language

USER MANUAL

Page 5 (38)

Eltek Valere Industrial GmbH ©2008

Directory

1. Applications, Functioning 6

2. Review of the types 7

3. Features 8

4. Description of the individual functions 9

4.1 Measuring inputs Udc1, Udc2, Udc3 9

4.2 Measuring inputs Idc1, Idc2, Idc3 9

4.3 Monitoring the insulation error 10

4.4 DC-Low voltage signal 10

4.5 DC- High voltage signal 10

4.6 Temperature control and temperature compensation of the charge voltage 11

4.7 Mains voltage control 11

4.8 Digital inputs 11

4.9 Additional Relays K1/K2 (K11-K18) 12

4.10 Monitoring: Battery unsymmetry 12

4.11 Boost charging 13

4.12 Bootloader 13

5. Operation 14

6. Menu- and display structure 15

6.1 General structure 15

6.2.1. Customer menu 16

6.2.2. Service menu 1 32

6.2.3. Service menu 2 / calibration menu 32

7. Connections 32

7.1 CAN-BUS-connector 34

8. Optional: Relay board DCC-RB6 35

9. Optional: Digital input board DCC-DIG8 35

10. Optional: Relay board MU1000C-I/O (RK1) 35

11. Technical Data MU1000C 37

Control unit

MU1000C Language

USER MANUAL

Page 6 (38)

Eltek Valere Industrial GmbH ©2008

1. Applications, Functioning

The Signalling and Monitoring unit MU 1000C (named MU 1000C in the

following) is used as a central monitoring- and signalling unit in DC–power

supply systems. These plants can be battery-powered or can operate as direct

supply for DC-bus bars.

They are used in all the places, where plant information is collected (such as

voltages and current at different intersections of the system), where

parameters have to be monitored and errors signalled or when a boost charge

function or a discharge test is required in a battery system.

The mounting of the monitoring unit can be very universal. Thus it is just as

possible to mount it in 19” – complete slide-in units (above 3HE) as in a

19”- partial slide-in unit (with 1/3-19” width).

The individual signal parameters, like voltages and current, are connected over

secured lines directly to the MU 1000 over a plug (DIN41612, R48).

The MU1000 receives these values, indicates them on the display, compares the

values with adjusted monitoring thresholds, gives disturbance signals (LED +

relay) and operates in the boost charge operation as well as discharge test op-

eration as a controlling device for the connected rectifier.

Additionally the output values of rectifier REC and inverter INV can be read out if

CAN-bus is connected.

The user language can be selected over a parametric menu. All the necessary

monitoring parameters can be read by the end-user directly at the site of

application and can be adjusted over a code-protected service menu. Special

software adaptations are not necessary for this.

The MU 1000C can be obtained for 2 different voltage ranges and can be

directly connected to the corresponding DC potential without any further

measures.

The software as well as the default values for the plant parameters for the MU

1000C is programmed in an EPROM. The current values (adaptations on site etc)

as well as the error data are stored in an EEPROM.

If due to a defect in the MU 1000C, there is cancellation in the EEPROM, then

when the device is switched on again, there is a reprogramming with the

default values of the plant from the EPROM. During this reprogramming, all the

functions, which have a control, function for external devices (boost charge op-

tion, discharge test) are deactivated in order to prevent damage due to false

values in the plant. These functions must be manually activated again in the

service menu.

Control unit

MU1000C Language

USER MANUAL

Page 7 (38)

Eltek Valere Industrial GmbH ©2008

2. Review of the types

MU1000C

Type designation Item Number Connection-/Measuring voltage in V DC

MU1000C-I Language 300-110-660.00 24 – 80 (Low Voltage Version)

MU1000C-II Language 300-110-770.00 80 – 300 (High Voltage Version)

Options and additional articles, which can be delivered:

•3-phase mains monitoring board: DCC-MM

•Battery monitoring: DCC-BM (old: MU1000C-BM)

•8 digital inputs: DCC-DIG8

•6 Relay outputs: DCC-RB6

optional: I/O-Relay board MU1000C-I/O RK1

•Profibus-accessibility with a unigate gateway CL

•Modbus-accessibility with a unigate gateway CL-RS

•1/3-19“ x 6 HE - Front plate for mounting of 1x MU1000; printed

•19“ x 3 HE – Front plate for mounting of 1x MU1000; printed

Control unit

MU1000C Language

USER MANUAL

Page 8 (38)

Eltek Valere Industrial GmbH ©2008

3. Features

The MU1000C has the following standard features:

•Real time clock(RTC) with date and Event History

•Measurement, announcement and supervision of 3 DC voltages in the system

•Measurement, announcement and supervision of 3 DC currents in the system

•Isolation mistake supervision

•Boost charge automatic (dependent on current, voltage and time)

BC switchable on digital input

•Battery test (dependent on time) and switchable on digital input

•Countercell Control

•Battery unsymmetric supervision

•Control for low discharge

•RS232- Interface to the parametrization with a configurator on a laptop / PC

•4 relay exits free of potential (K1-K4)

•8 digital measuring inputs for the evaluation of external registration loops

•CAN bus interface to the control and parameter query of electricity supply

modules

•Multilingual facility, 7 languages(3 at the same time): in English a. German

(always), French, Italian, Russian (Cyrillic), Swedish, Czech

•LED signals to the mistake announcement

•Free programming of announcement texts and error texts

•Free allocation of individual errors to urgent and not urgent alarms as well as

to the registration relays

•with BootLoader, i.e. firmware-update about CAN or RS232

Optional offers the MU1000C the following extension possibilities:

•Temperature compensation of the loading tension

(in connection with the temperature sensor LM335)

•Measurement, announcement and supervision from current and voltage of

3 phases net (in connection with extension board DCC-MM)

•8 additional relay registration contacts free of potential, freely programmable

(in connection with extension board MU1000C-I/O)

•8 additional digital measure inputs (DCC-DIG8- board)

•6 additional potential free relay contacts (DCC-RB6-board)

•Data distant query about modem

•Program software for the parametrization of the unity about RS232

•Connection to Profibus (with external gateway unigate CL)

•Connection to Modbus (with external gateway unigate CL-RS)

Control unit

MU1000C Language

USER MANUAL

Page 9 (38)

Eltek Valere Industrial GmbH ©2008

4. Description of the individual functions

4.1 Measuring inputs Udc1, Udc2, Udc3

•Voltage version 1 (LV): Operating voltage, measurement and indication of

24V-80VDC

•Voltage version 2 (HV): Operating voltage, measurement and indication

of 80V-300VDC

The supply lines have to be externally fused. If Udc3 is used for monitoring the

battery symmetry, pay attention to use the same reference connection point for

the minus connections of Udc1 and Udc3!

The clear text names for the display indication of the measuring inputs Udc1-Udc3

can be programmed via software (not included in this version) in the user menu.

The accuracy of the indication of the values corresponds to a class1 measuring

device.

Clear text terms:

•Udc1: freely programmable; designation in this version: Ubatt

•Udc2: not connected

•Udc3: not connected

4.2 Measuring inputs Idc1, Idc2, Idc3

The assignment of the nominal shunt values is done in the Service menu. The

following shunt magnitudes can be assigned to the individual measuring inputs:

•Idc1:(+/-)0-50A in 1A steps,50-1000A in 5A steps;0A means no sh.installed

•Idc2: 0-50A in 1A steps, 50-1000A in 5A steps; 0A means no shunt installed

•Idc3: 0-50A in 1A steps, 50-1000A in 5A steps; 0A means no shunt installed

The assigned maximum current of the shunt corresponds to a potential drop of

60mV.

As only the measuring input Idc1 can show negative current values, it should be

used for the reading of the battery charging- and discharging current.

The accuracy of indication of the values corresponds to a Class 1 measuring

instrument.

ATTENTION!

All shunts have to be referenced to the same DC-bar. A potential difference in

the current path of the shunts leads to failure of the measuring inputs.

A connection of the digital GND to the positive (in the direction of current flow)

connection at the current shunt is necessary for the correct indication of the

current measuring value. If more than one shunt is used in the system, then the

connection to one shunt is sufficient.

Control unit

MU1000C Language

USER MANUAL

Page 10 (38)

Eltek Valere Industrial GmbH ©2008

4.3 Monitoring the insulation error

The connection of the measuring and supply voltage Udc1 as well as of the

protective conductor is the minimum necessity for monitoring the DC-system for

insulation errors. While measuring the insulation error, it can be seen whether

there is an insulation error between the plus pole and the earth or the minus

pole and the earth.

Insulation errors are recognised only when they appear between the plus

potential/minus potential and the earth, not between the potentials.

The threshold value of the insulation resistance can be adjusted over the user

menu. The prefix indicates whether there is an earth-leakage against the plus or

minus.

Earth fault R = +(-)xxxkOhm

Factory setting: The error signal does not enter collective failure relay.

4.4 DC-Low voltage signal

A monitoring threshold U<Umin can be adjusted for each measuring voltage

(Udc1 to Udc3). The LED indication at the front side U>Umin and the relay K4 are

connected with the monitoring Udc1. In case of an error the Green LED U>Umin

goes out and the signalling relay K4 will switch over.

An external signal of the monitoring for Udc2 and Udc3 is possible over an

assignment of the signal to the reserve relay K1 or LED-signal S1 or S2.

A time-delay can be adjusted in the user-menu for these signals.

Indication: Udc1<Umin

Udc2<Umin

Udc3<Umin

4.5 DC- High voltage signal

A monitoring threshold U>Umax can be adjusted for each measuring voltage

(Udc1 to Udc3). The LED indication at the front side U>Umax and the relay K3 are

connected with the monitoring Udc2. In case of an error the red LED U>Umax

lights up and the signalling relay K3 pulls up.

An external signal of the monitoring for Udc2 and Udc3 is possible over an

assignment of the signal to the reserve relay K1 or to the LED-signals S1 and

S2.

A time-delay can be adjusted in the user-menu for these signals.

Indication: Udc1>Umax

Udc2>Umax

Udc3>Umax

Control unit

MU1000C Language

USER MANUAL

Page 11 (38)

Eltek Valere Industrial GmbH ©2008

4.6 Temperature control and temperature compensation of

the charge voltage

If an active temperature sensor (LM335) is connected to the monitoring unit,

then the temperature in the devices or the battery can be monitored. The signal

can be programmed as a collective failure (can be selected by the user) or be

conducted over the reserve relay K1 (can be programmed)

Thus the contact can be used for e.g. for a ventilation control. The temperature

monitoring can be activated in the service menu. The temperature threshold and

hysteresis can be similarly adjusted in the service menu.

Thus the contact can be used for e.g. for a ventilation control. The temperature

monitoring can be activated in the service menu. The temperature threshold and

hysteresis can be similarly adjusted in the service menu.

Indication: High temperature T>

The source tension of rectifier modules connected over CAN bus is steered

through choice of the option Temperature compensation dependent on tempera-

ture. The temperature coefficient as well as the start temperature and

final temperature of the loading tension regulation are programmable.

4.7 Mains voltage control

With additional board MU1000-MM (option) the unit monitors and displays the

mains voltages. The monitoring threshold is programmable in service menu.

Indication: UR US UT f

xxxV xxxV xxxV 50.0

and

IR IS IT

xxxA xxxA xxxA

Fault Indication: MM1 fault, mains fault V< or mains fault V>

With abandonment of the programmable supervision tension area a mistake

signal is generated. This mistake signal is filed in the event memory and can be

assigned to a Signal-LED (S1 or S2) as well as a registration relay.

The indicated frequency is measured by the phase L1.

4.8 Digital inputs

In total 8 digital inputs are available for different monitoring functions.

External relay contacts, like fuse monitoring are connectable to monitor and

signalling fault messages via MU1000C.

Control unit

MU1000C Language

USER MANUAL

Page 12 (38)

Eltek Valere Industrial GmbH ©2008

4.9 Additional Relays K1/K2 (K11-K18)

A signal can be assigned to the signalling relay K1 or K2 over the adjustments in

the service menu. If several signals are assigned, then the individual

signals are connected thus, the signalling relays switch when one or more of the

assigned signals appear. In the case of activated boost charge option, the relay

is assigned to the signal boost charge. Thus a battery compartment

ventilator can be operated over this contact. In this case, the other error

signals cannot be assigned to K1.

The falling-off of the relay is thereby delayed with entry of a mistake in the

opposed time. Put on the relay with discontinuation of the mistake condition

occurs against it undelayed.

All the individual signals can be assigned to the signalling relay K1.

For every relay a delay of 0-300 seconds can be programmed.

4.10 Monitoring: Battery unsymmetry

Defective battery cells can be recognised over the deviation of the mean voltage

of the battery (Ubatt/2) from the adjustment of the monitoring threshold dUbatt

and the mean voltage of the battery Ubatt/2 in the service menu. Only a very

high non-symmetry in the battery system is recognised and not the

position of the defective cell/s. The condition for this monitoring function is the

connection of the measuring voltage Udc3 between the minus potential and the

centre of the battery.

Setting occurs in % of the battery nominal tension (=cell count x 2.0V)

Fault indication: Battery unsymmetrical

Control unit

MU1000C Language

USER MANUAL

Page 13 (38)

4.11 Boost charging

There are different possibilities the boost charge (BC) to switch on.

Once about the manual activation. One must release the suitable point and then

can switch on in the main menu the BC with ENTER.

The BC can be also switched off so again.

To the second an automatic activation can occur.

One can let the BC by certain conditions one or also switch off.

e.g. BC switch On, if the battery tension is smaller of a certain one

Off tension value

or

if Ibatt (Ilade) > 200 A is.

The boost charge (BC) can be also released about a digital entrance (MU1000 or

I/O or DIG8).

The BC can be begun likewise automatically after a battery test.

If the BC is active, this is indicated in the main menu of the MU.

By a digital entrance one can switch off the BC or block also, so that the BC is

not switched on only at all.

There is furthermore a hand load where one can give by hand the tension.

Also a system charge is possible.

One can put a timer which switches off the BC after max. 1-24 hours.

4.12 Bootloader

From the firmware version MU 2.0 a Bootloader is integrated, i.e. you can carry

out over the CAN bus (with an USB-CAN-Dongle) or above the RS232

interface a firmware-update.

Eltek Valere Industrial GmbH ©2008

Control unit

MU1000C Language

USER MANUAL

Page 14 (38)

5. Operation

The MU 1000 is operated over the 4 keys at the front side (↑, ↓, ENTER,ESC).

The function of the individual key depends on the indication of the display and

on the respective menu level.

MU1000C

ENTER ESC

Down Up

Power

U>Umin

U>Umax

Isolation

S1

S2

Alarm A

Alarm B

RS232

CAN1

16

CAN2

16

Display

connection

interface RS232

different

LED's

connection

CAN-BUS

push-button switch

Picture 5.1:

Front view

MU1000C

Change in indication (scroll)

Pressing the keys ↑, ↓does the scrolling between the different indications,

whereby the previous indication appears when ↑is pressed and the next indica-

tion occurs with ↓. The serial order of the indications should be taken from the

sub-point Menu- and Indication structure.

Menu change

Indications, which contain a selectable sub-menu, are labelled with a star “*”.

By pressing the key “ENTER” for a short time one reaches the respective sub-

menu. The return to the above menu is done by simultaneously pressing the

“ESC” key.

Change of figure values / Assignment

For changing an indicated value, the key ↑should be pressed for increasing the

value and ↓should be pressed for decreasing the value. By touching the individ-

ual keys separately the value is changed by the smallest possible amount (usu-

ally one digit). If one key is pressed for a longer time, then the values change

continuously. The speed of change thereby increases with the duration for which

it is pressed.

Saving the changed values

After changing the adjustments the user can save the values by pressing the key

“ENTER” key.

Eltek Valere Industrial GmbH ©2008

Control unit

MU1000C Language

USER MANUAL

Page 15 (38)

Eltek Valere Industrial GmbH ©2008

6. Menu- and display structure

6.1 General structure

――――

Ç|

Indication * of Udc1 and Idc1

|

Indication * of Udc2 and Idc2

|

Indication * of Udc3 and Idc3

|

Indication * mains voltages, mains currents

|

Indication * of rectifier output voltage and current

|

Indication * of inverter output voltage and current

|

Indication * of temperature and R isol

|

Indication of the error status *

| ⎢

| ⎣present error x

| .

| .

|

error F19

|

error memory delete? Y / N

Indication of the event history (*)

| ⎢

| ⎣present event Å(come) Æ(goes)

| date time

|

Battery test* (One more test / Still no measuring value)

| ⎢

| ⎣Start? => Enter

|

Starkladung*

| ⎢

| ⎣Start? => Enter

|

Handladung*

| ⎢

| ⎣Start? => Enter

|

Indication Unit name and software version

|

Ç|

――――

wrap around

Custom menu* (press ENTER for 3sec)

Control unit

MU1000C Language

USER MANUAL

Page 16 (38)

Eltek Valere Industrial GmbH ©2008

6.2 Service menu

The service menu is used for changing parameters in the MU 1000. It is

protected against unauthorized access by a 3-digit access code. For the

calibration of the voltage and current measuring inputs, a calibration menu can

be selected with a second access code (see Pt. 6.2.3.)

Only authorised technical personnel should do changes in the service menu

because wrong adjustments could damage the system, the connected battery

and the load device. Eltek Valere Industries does not warrant damages caused

by

incorrect operation of the MU 1000C or by changes in the service menu. The

menu is shown with a star “ * “ , because it has the sub-menu s.

The indication values and possible parameters / adjustment fields are program-

mable only by service personnel.

6.2.1. Customer menu

The customer menu is a kind of reflection of the service menu, i.e. all valid

values of the system are indicated. However, these values cannot be changed in

contrast to service menu. The menu point should serve to give a topical over-

view about the investment parameters to the customer or to allow a

detailed distant diagnosis in the mistake case.

The menu is shown with a star “ * “ , because it has the sub-menu s.

Control unit

MU1000C Language

USER MANUAL

Page 17 (38)

Menu description MU1000C

1. Display at switching on

Vdc1: 53.5 V

Idc1: 0.0 A

1x press

Vdc2: 0.0 V

2. Display

Idc2: 0.0 A

1x press

3. Display Vdc3: 0.0 V

Idc3: 0.0 A

1xpress

4. Display

4a) 4b)

PSS1 Vo:----V

ENTER

CAN_ER

R

Io:----

A

E

N

T

E

R

CAN_ER

R

Io:----

A

PSS2 Vo:----V

4c)

CAN_ERR Io:---- A

PSS3 Vo:----V

1x press

Eltek Valere Industrial GmbH ©2008

Control unit

MU1000C Language

USER MANUAL

Page 18 (38)

UNV1 Vo:----V

CAN_ERR Io:---- A

5. Display

1x press

Temp.: 23.1 °C

Risol: >500kΩ

6. Display

1xpress

20.04.2006

No Errors

7. Display

1xpress

No Event

20.04.2006

8. Display

1xpress

9. Display Battery Test*

a) No test at all

a) & b) alternating

b) No test value visible on Display

1x press on ENTER

Boost ch. runs

Abort Boost cha*

Boost charge*

10. Display

1xpress

11. Display or System charge*

Manual charge *

1xpress

12. Display Texts freely configurable

Eltek-Valere

MU1000_C V2.08

1xpress

Display 1. appears

Eltek Valere Industrial GmbH ©2008

Control unit

MU1000C Language

USER MANUAL

Page 19 (38)

Call the customer menu

By pressing the ENTER – button for 4 sec the following menu will appear:

Customers menu ENTER

Exit ESC

By pressing the ENTER-button the Custumers menu appiers.

With the UP – button you move throw the menu step by step

The display shows the following menu:

Denotations Thresholds

Monitor.-delays Signal config

Mains monitor

Nominal values

System values Contact alloca

RS232 PC/Modem

Language

En

g

lish

(

GB

)

Date/Time

27.04.2008 08:27

shows new subrou-

tines

Manual charge

System test

Boost charge

LCD- illumination

Countercells

Ein

Thyristor loader

LCD-Contrast

75 %

Thursda

y

Weekday

St:0x0000 0x0000

IO- Contact alloca

Battery param.

IO-inp.delays

Signal delays Dig.inp.delays

a), b)

c), d)

e), f)

g), h)

i), j)

k), l)

m), n)

o), p)

q), r)

s), t)

u), v), w)

LCD/LED - test

Reset (boot)

x), y)

JJ000000-000.000

Version: 2.08

z), aa)

then display a) appears again

Eltek Valere Industrial GmbH ©2008

Control unit

MU1000C Language

USER MANUAL

Page 20 (38)

Items of the menu a) – z)

Press the ENTER-button to get into the menu.

With the UP-button you will run throw the menu.

to a) (press ENTER)

Denotations

a1) , a2) from MU1000

Udc1

:

Udc1=

Udc2 :

Udc2=

Udc3

:

Udc3=

Idc1 :

Idc1=

a3) , a4)

Eltek Valere Industrial GmbH ©2008

a5) , a6)

a7) , a8) from BM-card

a9), a10)

a11), a12)

a13), a14) from MU1000

Idc2=

Idc2

:

Idc3=

Idc3 :

input 1

3Idc1=

BMIdc1:

3Udc3=

BM2Udc3:

2Udc1=

BM1Udc1:

2Udc3=

BM1Udc3:

2Idc1=

BM1Idc1:

3Udc1=

BM2Udc1:

input 2

in

p

ut 2

in

p

ut 1

input 3

in

p

ut 3

input 4

in

p

ut 4

a15), a16)

input 5

in

p

ut 5

input 6

in

p

ut 6

a17), a18)

input 7

in

p

ut 7

a19), a20) input 8

in

p

ut 8

a21)-a28) from IO-card

bis

I/O- input 1

I/O- input 1

I/O - input 8

I/O - input 8

then display a1) appears again with ESC a level back

Table of contents

Popular Controllers manuals by other brands

SOMFY

SOMFY Animeo IB+ installation guide

National Instruments

National Instruments NI SMD-7613 user manual

KNX

KNX SATION-DM0101.0210 Technical manual

Festo

Festo CPX-FEC manual

Endress+Hauser

Endress+Hauser Liquiline CM442R technical information

Servomech

Servomech ATL 02 Installation, operation and maintenance manual

National Instruments

National Instruments PXIe-8881 Getting started guide

Johnson Controls

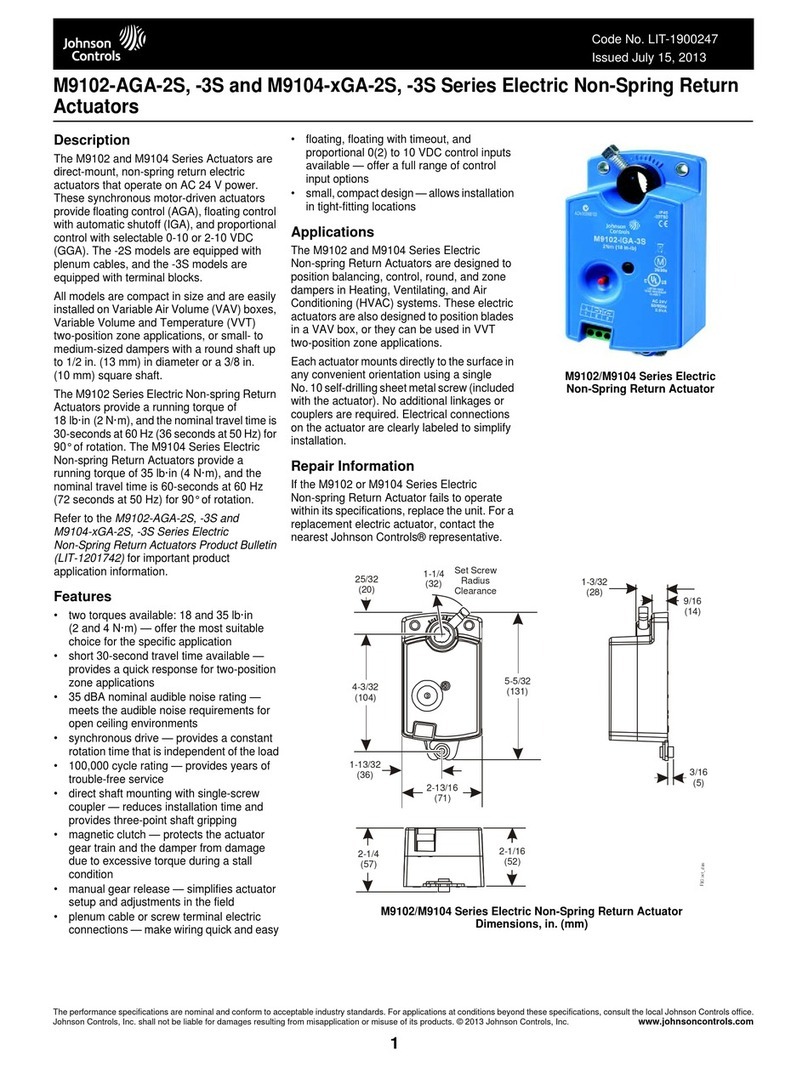

Johnson Controls M9102-AGA-2S Series quick start guide

Mitsubishi Electric

Mitsubishi Electric QX10 user manual

Condair

Condair HP manual

Mitsubishi Electric

Mitsubishi Electric FX3U-128ASL-M user manual

CLIVET

CLIVET TALK manual