Eltorque QT Series User manual

ID 2021 2.0 July 2018

User Manual QT250 and QT800

with Dual CAN and Failsafe options

Table 1: Document history for User Manual QT250 and QT800

Document

ID

Revision

Author

Changes

Approved

by

Date

2021

1.0

SKO

Based on 1372 with

adjustments.

Updated version

with Failsafe option

May 2018

2021

2.0

SKO

Added information

on Dual CAN

July 2018

Copyright © 2018, Eltorque AS

This document is submitted in confidence and contains proprietary information which shall not be

reproduced or transferred to others for the purpose, tender or any other intensions without written

permission of Eltorque AS

User Manual QT250 and QT800, ID 2021 2.0 July 2018

Page 3 of 86

Table of Contents

Chapter 1 Introduction ...............................................................................................................................................................7

1.1 System Overview ........................................................................................... 7

1.2 Description .................................................................................................... 8

1.3 Features ......................................................................................................... 9

1.4 Area of use .................................................................................................... 9

1.5 Technical support information .................................................................. 10

1.6 Reader groups ............................................................................................. 10

1.7 Notation used in this manual..................................................................... 10

1.8 Related documentation .............................................................................. 11

1.9 Disclaimer.................................................................................................... 11

1.10 Terms and abbreviations............................................................................ 11

1.11 About this user manual .............................................................................. 13

Chapter 2 HSE Information....................................................................................................................................................15

2.1 Care and cleaning of actuator.................................................................... 15

2.2 Disposal and waste handling ..................................................................... 15

Chapter 3 Product Description ...........................................................................................................................................17

3.1 QT250 and QT800 actuators ..................................................................... 17

3.2 Actuator control system examples ............................................................ 18

3.3 Technical specification ............................................................................... 19

3.4 Actuator components ................................................................................. 21

3.4.1 QT250 Actuator --------------------------------------------------------------------- 21

3.4.2 QT800 Actuator --------------------------------------------------------------------- 21

3.5 Communication interface box ................................................................... 22

3.6 Labelling ...................................................................................................... 22

3.7 Cabling......................................................................................................... 23

3.8 Storage......................................................................................................... 23

3.9 Engineering information............................................................................. 24

3.9.1 Power circuit design --------------------------------------------------------------- 24

3.9.2 Duty performance ------------------------------------------------------------------ 24

3.9.3 Endurance ------------------------------------------------------------------------------ 25

3.9.4 Shielding considerations -------------------------------------------------------- 25

3.9.5 Communication interface considerations ------------------------------- 25

3.9.6 Installations with Eltorque Hybrid Marine Cable --------------------- 27

3.9.7 Orientation----------------------------------------------------------------------------- 28

3.9.8 Space requirements---------------------------------------------------------------- 28

3.9.9 Mounting-------------------------------------------------------------------------------- 31

3.9.10 Additional information adaption actuator/valve --------------------- 31

3.9.11 Torque considerations for valve and actuator------------------------- 31

3.9.12 Closing time--------------------------------------------------------------------------- 31

3.9.13 Configuration ------------------------------------------------------------------------- 32

Chapter 4 Mounting and Installation..............................................................................................................................33

4.1 Mounting the actuator on the valve .......................................................... 33

4.2 Mounting procedure QT250 and QT800................................................... 33

4.3 Valve flange fastening holes ...................................................................... 34

4.4 Cable connection overview......................................................................... 35

Table of Contents

Page 4 of 86

User Manual QT250 and QT800, ID 2021 2.0 July 2018

4.5 Cable glands................................................................................................ 36

4.6 Power supply connection............................................................................ 37

4.7 Grounding (earthing) .................................................................................. 39

4.8 Communication connection interfaces...................................................... 39

4.8.1 Connection procedure ------------------------------------------------------------ 39

4.8.2 CANopen interface connection ----------------------------------------------- 39

4.8.3 Digital interface connection --------------------------------------------------- 41

4.8.4 Analog interface connections ------------------------------------------------- 42

Chapter 5 Operation..................................................................................................................................................................43

5.1 Manual operation ........................................................................................ 43

5.2 Error alarms and error handling ................................................................ 44

5.2.1 GENERAL alarm ---------------------------------------------------------------------- 44

5.2.2 POSITION UNDEFINED alarm --------------------------------------------------- 44

5.2.3 TEMPERATURE alarm -------------------------------------------------------------- 45

5.2.4 TORQUE alarm------------------------------------------------------------------------ 45

5.3 Troubleshooting.......................................................................................... 46

Chapter 6 Maintenance............................................................................................................................................................49

6.1 Maintenance overview ................................................................................ 49

6.2 Inspection .................................................................................................... 49

6.3 Tightening of bolts ..................................................................................... 49

6.4 Lubrication................................................................................................... 49

6.5 Care and cleaning of anodizing ................................................................. 49

Chapter 7 Technical Details..................................................................................................................................................51

7.1 Surface treatment ....................................................................................... 51

7.2 Communication interface ........................................................................... 51

7.2.1 CANopen interface ----------------------------------------------------------------- 51

7.2.2 Digital interface---------------------------------------------------------------------- 51

7.2.3 Analog interface --------------------------------------------------------------------- 53

Chapter 8 Ordering Information and Recommended Spare Parts ................................................................55

Dual CAN Option..................................................................................................................................................59

A.1Terms and abbreviations............................................................................ 59

A.2 Product description..................................................................................... 59

A.2.i. Differences from standard to Dual CAN actuator-------------------- 60

A.3 Actuator control system examples ............................................................ 60

A.4 Engineering information............................................................................. 61

A.4.i. Cabling considerations----------------------------------------------------------- 61

A.5 Mounting and installation .......................................................................... 61

A.6 Operation..................................................................................................... 62

A.7 Ordering information.................................................................................. 62

A.8 Technical details ......................................................................................... 63

A.8.i. Dual CAN ------------------------------------------------------------------------------- 63

Failsafe Option......................................................................................................................................................65

B.1Terms and abbreviations............................................................................ 66

B.2 Disposal and waste handling ..................................................................... 66

B.3 Product Description .................................................................................... 66

B.3.i. Differences from standard to failsafe actuator ----------------------- 67

B.3.ii. Failsafe actuator components------------------------------------------------- 67

B.4 Planning ....................................................................................................... 68

B.4.i. Installation plan --------------------------------------------------------------------- 68

Table of Contents

User Manual QT250 and QT800, ID 2021 2.0 July 2018

Page 5 of 86

B.4.ii. Maintenance plan ------------------------------------------------------------------- 68

B.4.iii. Storage----------------------------------------------------------------------------------- 68

B.4.iv. Battery charge ------------------------------------------------------------------------ 69

B.4.v. Space requirements---------------------------------------------------------------- 69

B.5 System interface.......................................................................................... 71

B.6 Mounting and installation .......................................................................... 71

B.6.i. Opening the actuator to access connectors ---------------------------- 72

B.7 Operation..................................................................................................... 72

B.7.i. Operation of the hand-wheel -------------------------------------------------- 72

B.7.ii. Actuator states----------------------------------------------------------------------- 72

B.7.iii. LED indication ------------------------------------------------------------------------ 73

B.7.iv. Troubleshooting overview ------------------------------------------------------ 74

B.8 Maintenance ................................................................................................ 74

B.8.i. Battery discharge and charge ------------------------------------------------- 74

B.8.ii. Changing battery on the UPS unit------------------------------------------- 75

B.9 Ordering information.................................................................................. 79

Torque and Screw Recommendations ....................................................................................................81

C.1 Eltorque torque recommendations............................................................ 81

C.2 Mounting screws and lubrication .............................................................. 81

C.3 M4 screws on communication interface box ............................................ 82

Earthing Methods in Maritime Installations .......................................................................................83

Table of Contents

Page 6 of 86

User Manual QT250 and QT800, ID 2021 2.0 July 2018

This page is left intentionally blank

User Manual QT250 and QT800, ID 2021 2.0 July 2018

Page 7 of 86

The Eltorque Lifelong Intelligent control concept provides maintenance-free,

configurable eco-friendly and fully electric actuators with real-time feedback.

The Eltorque actuators are divided in two main families:

•QT-series of actuators are ideal for quarter-turn valves such as butterfly and

ball-valves.

•MT-series of actuators are multi-turn actuators optimized for linear valves

such as globe valves, and with a form factor that make the MT-series ideal for

manifold actuation.

The Eltorque actuators are fully electric and can be connected in series. They

offer a plug and play solution with low installation costs and high level of

security. By combining the Eltorque actuators with the Eltorque Hybrid Marine

Cable, the cost of installation is even further reduced.

The Electric bus connected actuator installation eliminates the cable clutter,

transportation loss, air or oil leakage associated with conventional actuator

The use of permanent magnet-based motor technology and efficient electric,

mechanics and firmware design guarantee an eco-friendly and cost-efficient

ownership.

Eltorque actuators have a proven track record of lifelong maintenance-free

operation with 15 years of proven operation.

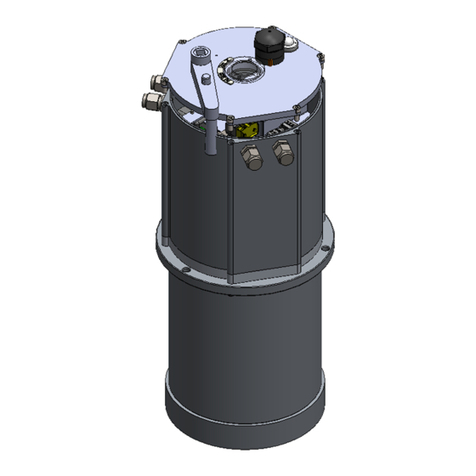

Figure 1: System overview example

Introduction

Page 8 of 86

User Manual QT250 and QT800, ID 2021 2.0 July 2018

The QT250 and QT800 described in this manual are part of the QT series. This

series is characterized by their quarter-turn movement and low energy

consumption along with their small footprint. They are suited for butterfly, ball

and other quarter-turn valves.

The QT250 and QT800 actuators are available in different versions with

corresponding User Manuals:

Table 2: Product overview

A= Plain actuator, B= with Failsafe option, R1= with Dual CAN, R2= with Failsafe

and Dual CAN, H= Actuator with cable glands for Eltorque Hybrid Marine Cable.

Product

Product id

User Manual

QT250 2.5 CANopen Actuator

250.120.5A and 250.120.5AH

Doc ID 2021

QT250 2.5 Digital/Analog Actuator

250.150.5A

QT800 2.5 CANopen Actuator

800.120.5A and 800.120.5AH

QT800 2.5 Digital/Analog Actuator

800.150.5A

QT250 2.5 CANopen Failsafe Actuator

250.120.5B and 250.120.5BH

QT800 2.5 CANopen Failsafe Actuator

800.120.5B and 800.120.5BH

QT250 2.5 Dual CAN Actuator

250.120.5R1 and 250.120.5R1H

QT800 2.5 Dual CAN Actuator

800.120.5R1 and 800.120.5R1H

QT250 2.5 Dual CAN and Failsafe

Actuator

250.120.5R2 and 250.120.5R2H

QT800 2.5 Dual CAN and Failsafe

Actuator

800.120.5R2 and 800.120.5R2H

QT250 1.0 CANopen Actuator

250.120.1and 250.120.1H

Doc ID 1372

QT250 1.0 Digital Actuator

250.110.1

QT250 1.0 Analog Actuator

250.130.1,

QT250 1.0 Modbus Actuator

250.140.1 and 250.140.1H

QT800 1.0 CANopen Actuator

800.120.1and 800.120.1H

QT8001.0 Digital Actuator

800.110.1

QT800 1.0 Analog Actuator

800.130.1

QT800 1.0 Modbus Actuator

800.140.1and 800.140.1H

QT250 1.0 CANopen Actuator - Open

Deck

250.121.1 and 250.121.1H

QT250 1.0 Digital Actuator- Open Deck

250.111.1

QT250 1.0 Analog Actuator- Open Deck

250.131.1

QT250 1.0 Modbus Actuator- Open

Deck

250.141.1 and 250.141.1H

QT800 1.0 CANopen Actuator- Open

Deck

800.121.1 and 800.121.1H

Introduction

User Manual QT250 and QT800, ID 2021 2.0 July 2018

Page 9 of 86

Product

Product id

User Manual

QT800 1.0 Digital Actuator- Open Deck

800.111.1

QT800 1.0 Analog Actuator- Open Deck

800.131.1

QT800 1.0 Modbus Actuator- Open

Deck

800.141.1 and 800.141.1H

QT250 CANopen 2.4 EX Actuator

EX250.125.4 and EX250.125.4H

Doc id 1193

QT800 CANopen 2.4 EX Actuator

EX800.125.4 and EX800125.4H

This User Manual describes the standard 2.5 version with the options for Dual

CAN and Failsafe.

The Eltorque actuators provides a wide range of attractive features:

•Optimized single-axis architecture, ensuring a compact and low-weight

actuator.

•Accurate real-time magnetic position control with no mechanical limit

switches, ensuring maintenance-free operation.

•Few spare parts - low lifetime costs.

•Easy setup and commissioning –low installation cost.

•Specific alarms including over-torque and temperature –providing high

operation safety.

•Robust implementation of CANbus protocol ensuring a reliable bus

connection.

•Reduced power consumption that gives a greener profile.

•Self-lock feature which allows movements from the motor, but immediately

locks movements from the valve side.

•Fast and precise motor that reduces the closing time.

•Low start-up load which enables a high number of actuators per power fuse.

•Remote programming via the CAN bus protocol on the Hybrid Marine Cable.

•Specific alarms including over-torque and temperature –providing high

operation safety.

•Option for Dual CAN see Appendix A on page 59.

•Option for Failsafe operation see 0 on page 64

Eltorque actuators are an ideal choice in a wide range of Maritime and Onshore

systems such as:

•Cargo handling

•Bilge and ballast

Introduction

Page 10 of 86

User Manual QT250 and QT800, ID 2021 2.0 July 2018

•Tank gauging

•SPS system

•Anti-heeling systems

•RSW systems

•Bulk handling

•Fuel systems

•Hydro power and district heating

•Waste water treatment

•HVAC system

•Fire water system

•Oil Production system, oil transfer line

If you require technical support outside of this manual, we recommend that you

use the support functions available on the web-site or contact us via e-mail.

If you have feedback to this manual, that should also be routed through e-mail.

Eltorque AS

Julianus Holms veg 34

7071 Trondheim

Norway

Web: www.eltorque.no

e-mail: info@eltorque.no

Phone: +47 74 85 55 20

Fax: +47 74 85 55 12

The following reader groups have been defined for this User Manual:

•Project and engineering personnel

•Installation personnel

•Operators

•Supervisors

•Technical support personnel

•Technical management personnel

The following notations have been used in this manual:

Bold is used for commands and menu selection.

Italic is used to give emphasis to information. It is also used for names of

documents referred to in the manual.

Note! Note is used to draw attention to important or helpful information

Caution! A caution is used when there is a danger that the equipment is damaged

if you do not follow the instructions.

Introduction

User Manual QT250 and QT800, ID 2021 2.0 July 2018

Page 11 of 86

Warning is used to draw attention to information of very high importance,

for example to avoid injuries to personnel.

This User Manual QT250 and QT8001is related to the following documentation:

Table 3: Related documentation

Document

Document ID

Hybrid Marine Cable product datasheet

Eltorque document ID 1946

Eltorque E3C Manual

Eltorque document ID 1687

Guidelines for earthing in maritime

installations

Published by the Norwegian Electrical

Safety Directorate. Available on net or

supplied by Eltorque on request.

System Integrators Manual CANopen

Interface

Eltorque document ID 1691

User Manual

QT250 2.4 EX

QT800 2.4 EX

Eltorque document ID 1193

User Manual QT250 and QT800 1

Eltorque document ID 1372

Note! 1 See Table 2: Product overview on page 8 for specification of the relevant User

Manuals for the QT250/QT800 series.

The information contained in this document is subject to change without prior

notice. Eltorque AS shall not be liable for errors contained herein or for incidental

or consequential damages about the furnishing, performance, or use of this

document. It is the customer’s responsibility to verify that he has the latest

revision available by checking the document area of www.eltorque.no

Table 4: Terms and abbreviations

Term

Description

ABS

American Bureau of Shipping.

AFD

Asbestos Free Declaration.

Analog Control

Step-less control utilizing analog signals, e.g. 4-20 mA. Allows positioning of the

valve actuator between Open and Closed.

BTO

Break to open. The torque required to unseat the closed valve.

Introduction

Page 12 of 86

User Manual QT250 and QT800, ID 2021 2.0 July 2018

Term

Description

CAN/CAN bus

Controller Area Network.

CAN bus is a fieldbus which allows communication between a maximum of 127

actuators connected to the same network. It is not a “master-slave” network (ref.

Modbus), hence all the nodes in the network can actively send messages at their

own initiative. Communication is prioritized meaning that urgent messages are

transmitted and received before information with lower priority. Compared to

Modbus, CAN bus has quite a few advantages:

−More reliable communication

−More nodes per network

−More control and configuration features are available

−Higher performance

CANopen

CANopen is a higher-level protocol and is running on top of the CAN protocol for

all Eltorque actuators.

The standard consists of an addressing scheme for the nodes on the CAN bus

and several small protocols for communicating with each node. In terms of the

OSI model, CANopen implements the levels above, including the network layer.

CCS

Central Control System.

Communication

Interface Box

Electronic device controlling the actuator according to signals from an overall

control system such as a PLC or other type of electronic controller.

Configuration

The set-up of parameters, which affects the actuator’s performance and

behavior.

Digital Control

Simple control utilizing relays, on/ off switches and indicators. Allows only Open

or Closed functionality for a valve actuator.

DNV GL

Det Norske Veritas Germanischer Lloyd.

E3C

Eltorque Common Configuration Controller.

E-VCI

Eltorque Valve Control Interface

E-VCS

Eltorque Valve Control System offers a dedicated control system

for operation of Eltorque actuators.

Eltorque Valve Control System is suitable for installations where the operator

requires full control of all valves and pumps, and in addition monitor level,

temperature, flow and pressure.

Hazardous area

Area in which the permanent or periodical presence of explosive substances

causes a risk of explosion.

Products described in this manual are not suitable for use in hazardous areas.

Eltorque can deliver actuators for use in such areas if required. Please contact

your local representative for further details.

HMI

Human Machine Interface.

HSE

Health, Safety and Environment.

HVAC

Heath, ventilation and air condition

IACS

International Association of Classification Societies

IAS

Integrated Automation System.

ICS

Integrated Control System.

IMO

International Maritime Organization

LR

Lloyd’s Register.

MAST

Maximum allowable stem torque/thrust.

MD

Material Declaration.

MEPC

The Marine Environment Protection Committee

Introduction

User Manual QT250 and QT800, ID 2021 2.0 July 2018

Page 13 of 86

Term

Description

OSI model

Open Systems Interconnection model. The model is a conceptual model that

standardizes communication systems without regard to the underlying internal

structure. The model partitions a communication system into abstraction layers.

Out of range

Definition of position. The outgoing shaft is outside the defined position area.

PF

Power factor

PCB

Printed circuit board.

PLC

A Programmable Logic Controller is a digital computer used for automation of

industrial processes, such as control of machinery on factory assembly lines,

measurement and control of process plants etc.

RSW

Refridgerated sea water system

SDoC

Supplier Declaration of Conformity.

SOLAS

Safety Of Life At Sea –conversion under IMO concerning safety for personnel and ships at

sea.

SPC

Statistical process control

VA

Voltampere

UPS

Uninterruptable power supply.

Valve

A valve is a device that controls the flow of materials (gases, fluidized solids,

slurries, or liquids) by opening, closing, or partially obstructing various

passageways.

Actuator

A device for control of valves in various process control systems.

Valve top

flange

The flange on top of the valve which integrates the actuator. Key parameters to

be aware of are summarized in 3.3 Technical specification on page 19. As an

example, butterfly valves typically comprise four screw holes for the flange

integration and a square stem for valve operation.

Within range

Definition of position. The outgoing shaft is within the defined position area.

This user manual describes the guidelines for installation, setup and operation of

QT250 and QT800 in a valve control system. The valid products for this manual

are listed in Table 2: Product overview on page 8.

Chapter 1 introduces the product and this manual.

This chapter is intended for all reader groups.

Chapter 2 informs on health, safety and environment issues.

The reader group for this chapter is for supervisors, technical support and

technical management personnel.

Chapter 3 gives a product description including the mechanical construction of

the actuator, technical specifications and a functional description. There is also

an overview of technical issues that should be considered in the design and

planning phase for the installation.

The reader group for this chapter is supervisors, project and planning personnel.

Introduction

Page 14 of 86

User Manual QT250 and QT800, ID 2021 2.0 July 2018

Chapter 4 covers the mechanical installation on valves and the electrical

installation of power and control signal.

The reader group for this chapter is installation personnel.

Chapter 5 covers the use of the actuator such as how to use the manual

emergency operation. There is also an overview of error messages and a

troubleshooting overview.

The reader group for this chapter is operators.

Chapter 6 covers maintenance, inspection and repair of the actuator.

The reader group for this chapter is operators, technical support and

management personnel.

Chapter 7 gives more in-depth technical information on the product.

The reader group for this chapter is technical support and management

personnel.

Chapter 8 gives ordering information.

The reader group for this chapter is technical support and management

personnel.

Appendix A describes the Dual CAN option, how to install and operate an

actuator with this option. The reader group for this chapter is installation

personnel, operators, support personnel and management personnel.

Appendix B describes the Failsafe option, how to install and operate an actuator

with this option. The reader group for this chapter is installation personnel,

operators, support personnel and management personnel.

Appendix C gives an overview of torque recommendations for actuator bolts.

The reader group for this chapter is installation personnel.

Appendix D includes the document “Earthing Methodology in Maritime

Installations” The reader group for this chapter is installation personnel,

technical support and technical management personnel.

User Manual QT250 and QT800, ID 2021 2.0 July 2018

Page 15 of 86

This chapter includes safety information that the user needs to know to operate

the equipment without doing harm to personnel or the environment.

The operation of the equipment is safe provided that the recommended

operating procedures are followed. There are specific hazards however

that need to be addressed so that the user knows how to deal with them.

Electrical installations shall be designed and installed by personnel with

certifications according to applicable laws and regulations. Ensure that all

such work is done according to applicable laws and regulations.

Service must always be performed by trained personnel.

All batteries and electronic equipment may contain substances harmful to the

environment. After removing used equipment, return them for disposal

according to local governmental guidelines.

Caution! Do not use ammonia, alkaline cleaners, lye or strong acid for cleaning as

this can damage the protective anodized layer of the product surface.

Caution! Do not use high pressure power washer directly on the actuators as the

product is not IP69K rated.

HSE Information

Page 16 of 86

User Manual QT250 and QT800, ID 2021 2.0 July 2018

This page is left intentionally blank

User Manual QT250 and QT800, ID 2021 2.0 July 2018

Page 17 of 86

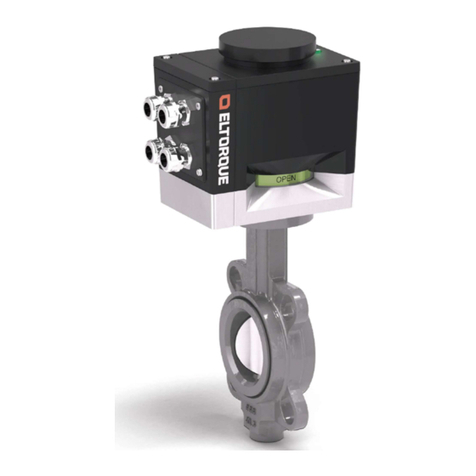

The QT250 and QT800 are the most sold products in the Eltorque portfolio. They

have been used on a various of vessel types on butterfly and ball valves. The

QT800 is based on the QT250, with an additional gearbox to further increase the

output torque. They are equipped with a magnetic position sensor that gives a

correct position feedback, even after a power outage. Both can be manually

operated by the means of a fixed hand wheel located under the cover on top of

the actuator without the need for external tools. Both QT250 and QT800 can be

delivered with the Failsafe option described in 0 on page 64 and the CAN Dual

option described in Appendix A on page 59.

The QT250 actuator is suitable for valves with torque requirements between 100-

250 Nm, while the QT800 is suitable for 320-800 Nm. Both can be delivered with

CANopen, Analog and Digital communication.

Note! For actuators equipped with Failsafe and/or Dual CAN options, these are only

available with the CANopen communication interface.

The actuators are designed to be operational during a temporary submerged

situation, see details for housing in Table 5: System performance parameters for

QT250 and QT800 actuators on page 19.

Figure 2: Actuator mounted on a valve

Caution! Remember to have the actuator checked by Eltorque after all submerged

situations to keep the warranty.

Product Description

Page 18 of 86

User Manual QT250 and QT800, ID 2021 2.0 July 2018

The actuator must be integrated with the main control system in one of two

ways:

•Directly to the main control system. In this case it is important to consider

the communication protocol.

•Through a stand-alone sub-system delivered by Eltorque. This is a

standardized hardware and software platform tailored for Eltorque actuators.

The solutions illustrated below show a bus connection with the Eltorque Hybrid

Marine Cable. This cable can be used with the CANopen and Dual CAN

communication interface. In addition, Eltorque actuators support Digital and

Analog connections.

Figure 3 below shows Eltorque actuators that are connected to a cabinet with

Eltorque valve control system (E-VCS). In this example, pump starters are also

connected to the E-VCS. Other equipment, such as sensors can also be connected

to the E-VCS. The E-VCS includes an HMI interface on the cabinet and can also

support an HMI interface on main control level.

Figure 3: Eltorque Valve Control System (E-VCS) with valve and pump control

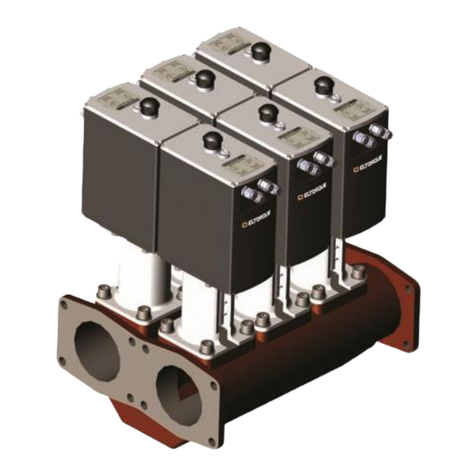

Figure 4 below shows Eltorque actuators that are connected directly to a

customer specific PLC, PC or other control unit. In addition, Eltorque actuators

support digital and analog connections. On system level, the PLC, PC or

Controller must be compliant with Eltorque communication protocol according to

Eltorque System Integrators Manual.

Product Description

User Manual QT250 and QT800, ID 2021 2.0 July 2018

Page 19 of 86

Figure 4: Eltorque actuator loop connected to Integrated Automation Control System (IAS

or ICS)

Table 5: System performance parameters for QT250 and QT800 actuators

QT250

QT800

Valve flange and max

allowed rated torque

options

100, 150 or 250 Nm

320, 480 or 800 Nm

Closing time options

0-90movement:

12, 15, or 20 seconds

0-90movement:

42, 52.5 or 70 seconds

Valve spindle adaptor

SQ17

depth 38 mm/1.50 in

SQ27

depth 45 mm/1.77 in

Max. allowed valve

flange and related

torque

(Ref. ISO5211) 2001E

F05

F07

F10

F10

F12

125

250

500

500

1000

Valve applications

Quarter-turn

Examples:

Butterfly DN50-DN200 PN16

Floating Ball DN65-DN100 CL150

Quarter-turn

Example:

Butterfly DN150-DN200 CL150

Weight

11 kg/24.3 lb

20 kg/44.1 lb

Dimensions (HxWxD)

229 x 156 x 209 mm

9.02 x 6.14 x 8.23 in

333 x 200 x 239 mm

13.11 x 7.87 x 9.41 in

Manual operation –

number of turns

21 turns on hand wheel =

90movement on valve

73 turns on hand wheel =

90movement on valve

Color

Black

Housing

IP66 and IP x8 (10 m –100 hours/32 ft 9.7 in –100 hours).

Corrosion protected aluminum and steel enclosure.

Should not be exposed to corrosive chemicals.

Storage temperature

5 –35C/41 –95F

Product Description

Page 20 of 86

User Manual QT250 and QT800, ID 2021 2.0 July 2018

QT250

QT800

Operating temperature

With Failsafe option

-25 to 55C/-13 to 131F

0 to 45C/32 to 113F

Temperature protection

Motor current is switched off in case of over-heating.

Power supply

1-phase,110 –240V AC, 50/60 Hz, Max 240 VA

Power consumption

Opening and closing

with max torque1

100 VA, PF 0.79

Power consumption

Standby1

9 VA, PF 0.37

Duty performance

According to AN 15714-

1 / IEC 60034-1

Class A –10 cycles per hour/52 –15 min.

Endurance

According to EN 15712-

2

Classes A and B –10 000 cycles per lifetime.

Cable glands

Up to five M20 glands allows bus connection of power supply and

signal wiring. Use IP68 (10 m 72 hours) cable glands for all wires.

Communication

Interfaces options

CANopen allows positioning and other extended control of the

actuator. The absolute maximum theoretical number of devices allowed

on the bus is 127, but the actual number of nodes is limited by the

baud-rate and the cable quality. Eltorque recommends a maximum of

80 nodes on 500 m/1660ft cable.

Digital 2 DI (Open-Close) and 3 D0 (Open-Close-Alarm.)

Analog Al (Set position) A0 (Feedback position) and D0 (Alarm) (4-20

mA) AI/A0 signal.

Position sensor

Resolution: 360°/12bit = 0.35156°/bit

Integral Non-Linearity (INL): typ. ± 0.8°

Differential Non-Linearity (DNL): ± 0.176°

Output shaft accuracy: 1%

Position feedback not corrupted by power outage.

Configuration

USB connection to PC with Eltorque E3C. Special configuration cable is

needed, see E3C User Manual.

Configurable parameters

Open and Closed positions. Actuator speed, torque and valve position

regions. Inverted IO or bus parameters depending on the applied

communication interface.

Manual operation

Standard feature using fixed hand-wheel. Mechanical valve position

indicator. No need for external tools.

Cover of handwheel

Can be removed and refitted without tools. Protects mechanism against

mechanical damage and foreign objects. The actuator must not be

lifted by the top cover.

Self-lock

The QT250 and QT800 are equipped with a mechanical self-locking

device that locks the valve to the target position when the actuator

movement command is completed.

Certification/type

approval

All valid certificates are listed on www.eltorque.no –support –technical

support –certificates.

1 Earlier versions of the QT250 and QT800 have other values for power consumption, see Table 2:

Product overview on page 8 for information on the correct documentation to consult.

Other manuals for QT Series

1

This manual suits for next models

2

Table of contents

Other Eltorque Controllers manuals

Popular Controllers manuals by other brands

nVent RAYCHEM

nVent RAYCHEM Elexant 450c Installation and operation manual

TSi Power

TSi Power ATS-500 Series installation instructions

Thermo Scientific

Thermo Scientific ALPHA PH 560 manual

SMC Networks

SMC Networks AR20S 02E-Y 15V Series Operation manual

REACIONA

REACIONA AVR-A-OPT-03 18A Installation and operation manual

Epson

Epson BO-IC400 user guide