Table of Contents

1 Introduction ..............................................................................................................................................................3

1.1 References ........................................................................................................................................................3

1.2 Abbreviations....................................................................................................................................................3

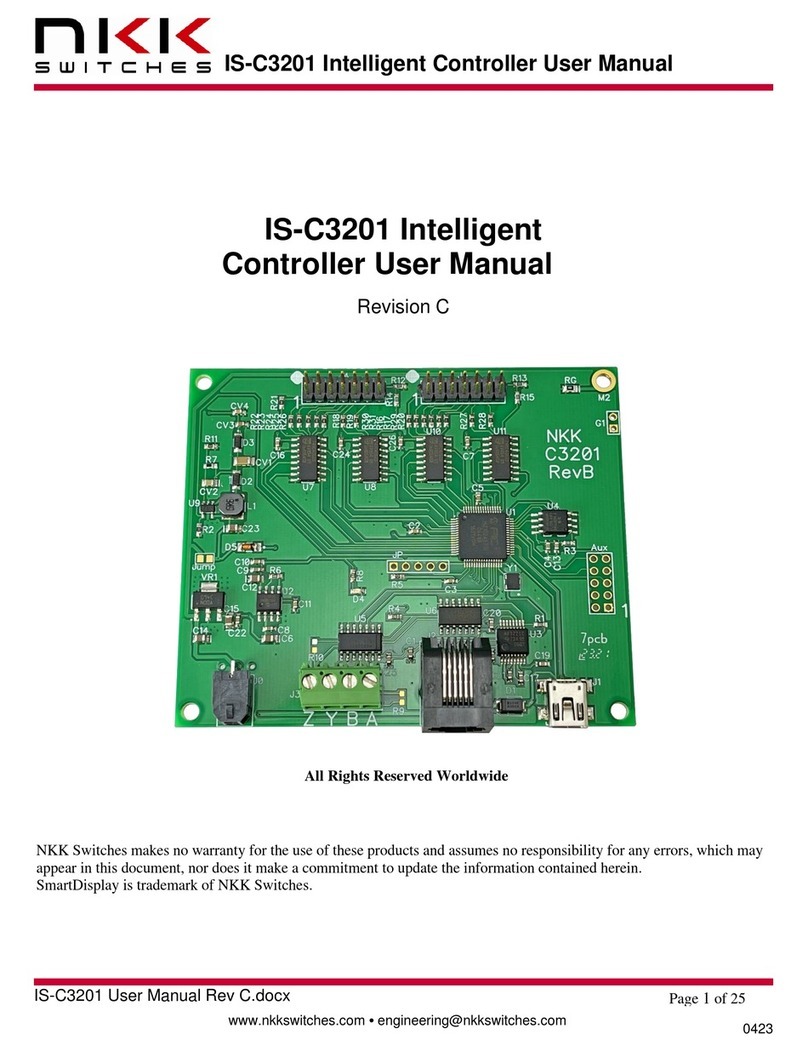

2 Electrical installation.................................................................................................................................................4

2.1 Interface Pinout ................................................................................................................................................4

2.1.1 Analog Interface........................................................................................................................................5

2.1.2 Digital Interface.........................................................................................................................................6

2.1.3 Modbus Interface......................................................................................................................................7

2.1.4 CAN Interface............................................................................................................................................8

2.1.5 Dual CAN Interface....................................................................................................................................9

2.2 Earthing of product...........................................................................................................................................9

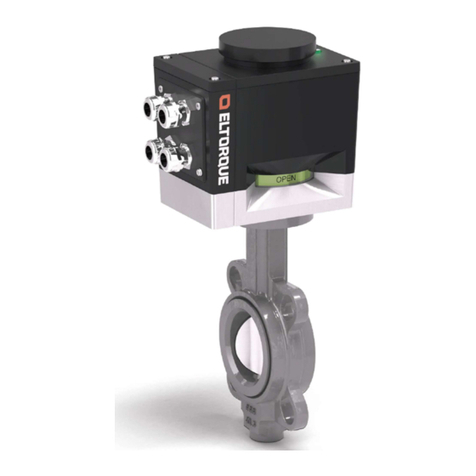

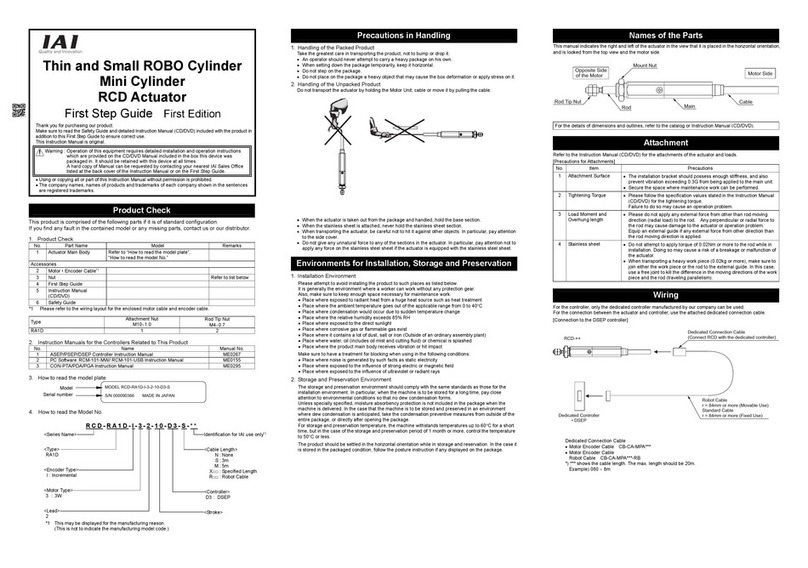

2.3 Configuration of actuator .................................................................................................................................9

3 Maintenance, service and troubleshooting............................................................................................................10

3.1 Maintenance...................................................................................................................................................10

3.2 Internal construction.......................................................................................................................................10

4 Ordering information..............................................................................................................................................12