Eltron Strata Series User manual

User’s Manual No. 980181-001 Rev. B

©1998 Eltron International Inc.

Strata

Thermal Printers

User’s Manual

User’s Manual No. 980181-001 Rev. B

©1998 Eltron International Inc.

Strata

Thermal Printers

User’s Manual

FOREWORD

This manual provides installation and operation information for the Eltron Strata LP (LP2684) and

Strata TLP (TLP2684) printers, manufactured by Eltron International Incorporated, Simi Valley,

California.

COPYRIGHT NOTICE

This document contains information proprietary to Eltron International Incorporated. This docu-

ment and the information contained within is copyrighted by Eltron International Incorporated and

may not be duplicated in full or in part by any person without written approval from Eltron. While

every effort has been made to keep the information contained within current and accurate as of the

date of publication, no guarantee is given or implied that the document is error-free or that it is ac-

curate with regard to any specification. Eltron reserves the right to make changes, for the purpose of

product improvement, at any time.

TRADEMARKS

Strata, Strata LP , Strata TLP, LP2684 and TLP2684 are service marks and Eltron is a trademark of

Eltron International Incorporated. Windows and MS-DOS are registered trademarks of Microsoft

Corp. All other marks are trademarks or registered trademarks of their respective holders.

FCC NOTICE:

This equipment has been tested and found to comply with the limits of a Class A digital device, pur-

suant to Part 15 of the FCC Rules. These limits are designed to provide reasonable protection

against harmful interference when the equipment is operated in a commercial environment. This

equipment generates, uses and can radiate radio frequency energy and, if not installed and used in

accordance with the instructions, may cause harmful interference to radio communications. How-

ever, there is no guarantee that interference will not occur in a particular installation. Operation of

this equipment in a residential area is likely to cause harmful interference in which case the user will

be required to correct the interference at his own expense.

INDUSTRY CANADA NOTICE:

This device complies with Industry Canada ICS-003 class A requirements.

Cet equipement est conforme a l’ICS-003 classe A de la norm Industrielle Canadian

980181-001 Rev.B iii

FOREWORD

This manual provides installation and operation information for the Eltron Strata LP (LP2684) and

Strata TLP (TLP2684) printers, manufactured by Eltron International Incorporated, Simi Valley,

California.

COPYRIGHT NOTICE

This document contains information proprietary to Eltron International Incorporated. This docu-

ment and the information contained within is copyrighted by Eltron International Incorporated and

may not be duplicated in full or in part by any person without written approval from Eltron. While

every effort has been made to keep the information contained within current and accurate as of the

date of publication, no guarantee is given or implied that the document is error-free or that it is ac-

curate with regard to any specification. Eltron reserves the right to make changes, for the purpose of

product improvement, at any time.

TRADEMARKS

Strata, Strata LP , Strata TLP, LP2684 and TLP2684 are service marks and Eltron is a trademark of

Eltron International Incorporated. Windows and MS-DOS are registered trademarks of Microsoft

Corp. All other marks are trademarks or registered trademarks of their respective holders.

FCC NOTICE:

This equipment has been tested and found to comply with the limits of a Class A digital device, pur-

suant to Part 15 of the FCC Rules. These limits are designed to provide reasonable protection

against harmful interference when the equipment is operated in a commercial environment. This

equipment generates, uses and can radiate radio frequency energy and, if not installed and used in

accordance with the instructions, may cause harmful interference to radio communications. How-

ever, there is no guarantee that interference will not occur in a particular installation. Operation of

this equipment in a residential area is likely to cause harmful interference in which case the user will

be required to correct the interference at his own expense.

INDUSTRY CANADA NOTICE:

This device complies with Industry Canada ICS-003 class A requirements.

Cet equipement est conforme a l’ICS-003 classe A de la norm Industrielle Canadian

980181-001 Rev.B iii

WARRANTY INFORMATION

We Need To Hear From You!

To Establish Your Warranty Period And Provide Access To Technical Support,

Send Us Your Product Registration Card Today!

Eltron warrants the mechanism, control electronics and power supply, under normal use and serv-

ice, to be free from defects in material and workmanship for a period of twelve (12) months from the

date of purchase by the end user. Eltron warrants the print head, under normal use and service, to

be free from defects in material and workmanship for a period of ninety (90) days or 30KM of print-

ing (whichever occurs first) from the date of purchase by the end user. Proof of purchase or product

registration is required. If proof of purchase or product registration cannot be established, shipment

date to the original buyer (dealer or distributor) will be used to establish the warranty period.

Failure to exercise caution to protect the equipment from electrostatic discharge damage, adverse

temperature and humidity conditions or physical abuse may void the warranty. Failure to use only

Eltron approved media may void the warranty. Eltron will, at it’s option, repair or replace the

equipment or any parts which are determined to be defective within this warranty period, and

which are returned to Eltron F.O.B. factory of origin.

The warranty set forth above is exclusive and no other warranty, whether written or oral, is ex-

pressed or implied. Eltron specifically disclaims the implied warranties of merchantability and fit-

ness for a particular purpose.

RETURN MATERIALS AUTHORIZATION

Before returning any equipment to Eltron for in warranty or out of warranty repair, contact Repair

Administration for a Return Materials Authorization (RMA) number. Repack the equipment in the

original packing material and mark the RMA number clearly on the outside. Ship the equipment,

freight prepaid, to the address listed below:

Eltron Repair Administration, USA

41 Moreland Road

Simi Valley, CA. 93065

Phone: +1 (805) 579-1800

FAX: +1 (805) 579-1808

Label Printers: Card Printers:

Eltron International, Europe Eltron International, Europe

Eltron House Zone Indutrielle, Rue d'Amsterdam

Molly Millars Lane 44370 Varades, France

Wokingham RG41 2QZ England Phone: +33 (0) 240 097 070

Phone: +44 (0) 1189 770 300 FAX: +33 (0) 240 834 745

FAX: +44 (0) 1189 895 762

iv 980181-001 Rev.B

WARRANTY INFORMATION

We Need To Hear From You!

To Establish Your Warranty Period And Provide Access To Technical Support,

Send Us Your Product Registration Card Today!

Eltron warrants the mechanism, control electronics and power supply, under normal use and serv-

ice, to be free from defects in material and workmanship for a period of twelve (12) months from the

date of purchase by the end user. Eltron warrants the print head, under normal use and service, to

be free from defects in material and workmanship for a period of ninety (90) days or 30KM of print-

ing (whichever occurs first) from the date of purchase by the end user. Proof of purchase or product

registration is required. If proof of purchase or product registration cannot be established, shipment

date to the original buyer (dealer or distributor) will be used to establish the warranty period.

Failure to exercise caution to protect the equipment from electrostatic discharge damage, adverse

temperature and humidity conditions or physical abuse may void the warranty. Failure to use only

Eltron approved media may void the warranty. Eltron will, at it’s option, repair or replace the

equipment or any parts which are determined to be defective within this warranty period, and

which are returned to Eltron F.O.B. factory of origin.

The warranty set forth above is exclusive and no other warranty, whether written or oral, is ex-

pressed or implied. Eltron specifically disclaims the implied warranties of merchantability and fit-

ness for a particular purpose.

RETURN MATERIALS AUTHORIZATION

Before returning any equipment to Eltron for in warranty or out of warranty repair, contact Repair

Administration for a Return Materials Authorization (RMA) number. Repack the equipment in the

original packing material and mark the RMA number clearly on the outside. Ship the equipment,

freight prepaid, to the address listed below:

Eltron Repair Administration, USA

41 Moreland Road

Simi Valley, CA. 93065

Phone: +1 (805) 579-1800

FAX: +1 (805) 579-1808

Label Printers: Card Printers:

Eltron International, Europe Eltron International, Europe

Eltron House Zone Indutrielle, Rue d'Amsterdam

Molly Millars Lane 44370 Varades, France

Wokingham RG41 2QZ England Phone: +33 (0) 240 097 070

Phone: +44 (0) 1189 770 300 FAX: +33 (0) 240 834 745

FAX: +44 (0) 1189 895 762

iv 980181-001 Rev.B

Table of Contents

Installation . . . . . . . . . . . . . . . . . . . . . . . . . 1

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Unpacking Your Printer . . . . . . . . . . . . . . . . . . . . 2

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Your Printer . . . . . . . . . . . . . . . . . . . . . . . . . . 8

The FEED Control . . . . . . . . . . . . . . . . . . . . . . . 9

The STATUS Indicator. . . . . . . . . . . . . . . . . . . . . 11

Loading Labels or Tags . . . . . . . . . . . . . . . . . . . . 12

Loading Transfer Ribbons . . . . . . . . . . . . . . . . . . . 24

Removing A Partially Used Transfer Ribbon . . . . . . . . . . 30

Top Of Form Sensing . . . . . . . . . . . . . . . . . . . . . 31

Using AutoSense. . . . . . . . . . . . . . . . . . . . . . . . 32

Cleaning Your Printer . . . . . . . . . . . . . . . . . . . . . 34

Cleaning the Print Head . . . . . . . . . . . . . . . . . . . . 35

Cleaning Under the Sensor Bracket . . . . . . . . . . . . . . 36

Trouble Shooting . . . . . . . . . . . . . . . . . . . . . . 37

Where to Start . . . . . . . . . . . . . . . . . . . . . . . . . 37

Other Support Resources . . . . . . . . . . . . . . . . . . . 40

Serial Interface Communication Configuration. . . . . . . . . 41

Serial Interface Cable Wiring. . . . . . . . . . . . . . . . . . 41

Tag Media Sensing . . . . . . . . . . . . . . . . . . . . . . 42

Printer Features . . . . . . . . . . . . . . . . . . . . . . . 43

Supplies and Accessories . . . . . . . . . . . . . . . . . . 49

Windows Printer Driver . . . . . . . . . . . . . . . . . . . 53

980181-001 Rev.B v

Table of Contents

Installation . . . . . . . . . . . . . . . . . . . . . . . . . 1

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Unpacking Your Printer . . . . . . . . . . . . . . . . . . . . 2

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Your Printer . . . . . . . . . . . . . . . . . . . . . . . . . . 8

The FEED Control . . . . . . . . . . . . . . . . . . . . . . . 9

The STATUS Indicator. . . . . . . . . . . . . . . . . . . . . 11

Loading Labels or Tags . . . . . . . . . . . . . . . . . . . . 12

Loading Transfer Ribbons . . . . . . . . . . . . . . . . . . . 24

Removing A Partially Used Transfer Ribbon . . . . . . . . . . 30

Top Of Form Sensing . . . . . . . . . . . . . . . . . . . . . 31

Using AutoSense. . . . . . . . . . . . . . . . . . . . . . . . 32

Cleaning Your Printer . . . . . . . . . . . . . . . . . . . . . 34

Cleaning the Print Head . . . . . . . . . . . . . . . . . . . . 35

Cleaning Under the Sensor Bracket . . . . . . . . . . . . . . 36

Trouble Shooting . . . . . . . . . . . . . . . . . . . . . . 37

Where to Start . . . . . . . . . . . . . . . . . . . . . . . . . 37

Other Support Resources . . . . . . . . . . . . . . . . . . . 40

Serial Interface Communication Configuration. . . . . . . . . 41

Serial Interface Cable Wiring. . . . . . . . . . . . . . . . . . 41

Tag Media Sensing . . . . . . . . . . . . . . . . . . . . . . 42

Printer Features . . . . . . . . . . . . . . . . . . . . . . . 43

Supplies and Accessories . . . . . . . . . . . . . . . . . . 49

Windows Printer Driver . . . . . . . . . . . . . . . . . . . 53

980181-001 Rev.B v

General Cautions and Warnings

These pages describe general safety and maintenance warnings and cautions for the printer.

They are referenced throughout the manual. The manual may also include other warnings and

cautions not displayed here.

Warning - Shock Hazard

The printer should never be operated in a location where it can

get wet. Personal injury could result.

Warning - Static Discharge

The discharge of electrostatic energy that accumulates on the

surface of the human body or other surfaces can damage or

destroy the print head or electronic components used in this

device. DO NOT TOUCH the print head or the electronic

components under the print head assembly.

Caution - Printer Setup & Handling

1)When installing or modifying the printer setup or

configuration, ALWAYS TURN POWER OFF Before:

A) Connecting any cables.

B) Performing any cleaning or maintenance operations.

C) Moving the printer.

2) Damage to the printer interface connector, accessories or

door may result from placing the printer on it’s front bezel or

backside during unpacking or handling.

vi 980181-001 Rev.X3

General Cautions and Warnings

These pages describe general safety and maintenance warnings and cautions for the printer.

They are referenced throughout the manual. The manual may also include other warnings and

cautions not displayed here.

Warning - Shock Hazard

The printer should never be operated in a location where it can

get wet. Personal injury could result.

Warning - Static Discharge

The discharge of electrostatic energy that accumulates on the

surface of the human body or other surfaces can damage or

destroy the print head or electronic components used in this

device. DO NOT TOUCH the print head or the electronic

components under the print head assembly.

Caution - Printer Setup & Handling

1)When installing or modifying the printer setup or

configuration, ALWAYS TURN POWER OFF Before:

A) Connecting any cables.

B) Performing any cleaning or maintenance operations.

C) Moving the printer.

2) Damage to the printer interface connector, accessories or

door may result from placing the printer on it’s front bezel or

backside during unpacking or handling.

vi 980181-001 Rev.X3

Media Cautions & Tips

1) Always use high quality Eltron approved labels and tags.

Eltron approved supplies can be ordered from your ELTRON

dealer. For the name of a dealer in your area, call Eltron

Customer Service at one of the numbers listed on the back page

of this manual.

2) If poor quality, adhesive backed labels are used, that DO

NOT lay flat on the backing liner, the exposed edges may stick

to the label guides and rollers inside the printer, causing the

label to peel off from the liner and jam the printer.

3) DO NOT use non-Eltron transfer ribbon. Permanent damage

to the print head may result if a non-Eltron ribbon is used.

Non-Eltron ribbons maybe wound incorrectly for the printer or

contain chemicals that may damage the print head.

4) IMPORTANT - If a transfer ribbon is installed incorrectly by

the operator, damage to the print head may result.

5) DO NOT use a ribbon when printing with direct thermal

media.

Media Reload Tip

If you should run out of labels or ribbon while printing, DO NOT

turn the power switch OFF (0) while reloading or data loss may

occur. The printer will automatically resume printing when a

new label or ribbon roll is loaded.

Print Mode Control (TLP2684)

The printer is reconfigured for direct thermal (or thermal

transfer) printing with the “O” command for the Strata TLP

thermal transfer printer. See the EPL2 programmer's manual

for details.

Print Quality Tip

Print density (darkness) is affected by the heat energy (density

setting) applied and by the print speed. Changing both Print

Speed and Density may be required to achieve the desired

results.

980181-001 Rev.B vii

Media Cautions & Tips

1) Always use high quality Eltron approved labels and tags.

Eltron approved supplies can be ordered from your ELTRON

dealer. For the name of a dealer in your area, call Eltron

Customer Service at one of the numbers listed on the back page

of this manual.

2) If poor quality, adhesive backed labels are used, that DO

NOT lay flat on the backing liner, the exposed edges may stick

to the label guides and rollers inside the printer, causing the

label to peel off from the liner and jam the printer.

3) DO NOT use non-Eltron transfer ribbon. Permanent damage

to the print head may result if a non-Eltron ribbon is used.

Non-Eltron ribbons maybe wound incorrectly for the printer or

contain chemicals that may damage the print head.

4) IMPORTANT - If a transfer ribbon is installed incorrectly by

the operator, damage to the print head may result.

5) DO NOT use a ribbon when printing with direct thermal

media.

Media Reload Tip

If you should run out of labels or ribbon while printing, DO NOT

turn the power switch OFF (0) while reloading or data loss may

occur. The printer will automatically resume printing when a

new label or ribbon roll is loaded.

Print Mode Control (TLP2684)

The printer is reconfigured for direct thermal (or thermal

transfer) printing with the “O” command for the Strata TLP

thermal transfer printer. See the EPL2 programmer's manual

for details.

Print Quality Tip

Print density (darkness) is affected by the heat energy (density

setting) applied and by the print speed. Changing both Print

Speed and Density may be required to achieve the desired

results.

980181-001 Rev.B vii

viii 980181-001 Rev.B viii 980181-001 Rev.B

1

Installation

This section provides information on the

installation of the printer and software.

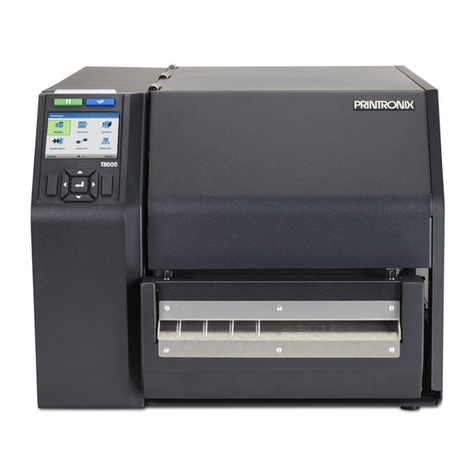

Introduction The Strata printer models are low cost, manu-

facturing oriented, thermal desktop printers.

The Strata LP is a direct thermal printer. The

Strata TLP is a thermal transfer and direct ther-

mal printer. The printers have been specifically

designed for printing large labels, hazardous

material labels, small signs, fan-fold media, and

shipping and receiving labels while operating in

office to industrial environments.

The printer features a tough, steel-case con-

struction, a small footprint, a heavy-duty motor,

and sharp, reliable printing up to 8.5 inches

(216 mm) wide. The print head resolution of a

Strata printer is 203 dpi (8 dots/mm).

The printer can print letter (8.5”x 11”) and A4

(210mm x 297mm) sizes. Print forms up to 8.5

inches (216 mm) wide and 22 inches (558.8

mm) long or two times A4 (210mm x 594mm)

size with optional memory added.

980181-001 Rev.B 1

Installation

1

Installation

This section provides information on the

installation of the printer and software.

Introduction The Strata printer models are low cost, manu-

facturing oriented, thermal desktop printers.

The Strata LP is a direct thermal printer. The

Strata TLP is a thermal transfer and direct ther-

mal printer. The printers have been specifically

designed for printing large labels, hazardous

material labels, small signs, fan-fold media, and

shipping and receiving labels while operating in

office to industrial environments.

The printer features a tough, steel-case con-

struction, a small footprint, a heavy-duty motor,

and sharp, reliable printing up to 8.5 inches

(216 mm) wide. The print head resolution of a

Strata printer is 203 dpi (8 dots/mm).

The printer can print letter (8.5”x 11”) and A4

(210mm x 297mm) sizes. Print forms up to 8.5

inches (216 mm) wide and 22 inches (558.8

mm) long or two times A4 (210mm x 594mm)

size with optional memory added.

980181-001 Rev.B 1

Installation

Unpacking Your

Printer Open the shipping carton and remove the

printer and it’s accessories.

Check List 1) Printer

2) Power Cord

3) Media Holder and Retainers

4) Cleaning Pen

5) User’s & Programmer’s Manuals

6) Sample Label Roll

7) Sample Transfer Ribbon Roll (TLP only)

8) Ribbon Core (TLP only)

9) Software: CAL Tools for Windows™

& Windows™ drivers

2980181-001 Rev.B

Installation

WindowsDrivers

CREATE-A-LABEL

Tools

Strata

User' Manual

Models

LP2684 & TLP 2684

EPL2

Programmer's

Manual

Unpacking Your

Printer Open the shipping carton and remove the

printer and it’s accessories.

Check List 1) Printer

2) Power Cord

3) Media Holder and Retainers

4) Cleaning Pen

5) User’s & Programmer’s Manuals

6) Sample Label Roll

7) Sample Transfer Ribbon Roll (TLP only)

8) Ribbon Core (TLP only)

9) Software: CAL Tools for Windows™

& Windows™ drivers

2980181-001 Rev.B

Installation

WindowsDrivers

CREATE-A-LABEL

Tools

Strata

User' Manual

Models

LP2684 & TLP 2684

EPL2

Programmer's

Manual

Installation The following steps will guide you through the

installation of the printer and software.

Step ➊

Attach Power

See Warnings - Page vi

980181-001 Rev.B 3

Installation

O

PartNo. : 120XXX-XXX

SerialNo. : XXXXXXXX

InputPower: 115VAC 6.3A 50/60Hz

Part No. : 120XXX-XXX

Serial No. : XXXXXXXX

Input Power: 115VAC 6.3A 50/60Hz

Check Voltage

O = Off

O

Installation The following steps will guide you through the

installation of the printer and software.

Step ➊

Attach Power

See Warnings - Page vi

980181-001 Rev.B 3

Installation

O

PartNo. : 120XXX-XXX

SerialNo. : XXXXXXXX

InputPower: 115VAC 6.3A 50/60Hz

Part No. : 120XXX-XXX

Serial No. : XXXXXXXX

Input Power: 115VAC 6.3A 50/60Hz

Check Voltage

O = Off

O

Step ➋Attach

Interface Cable

Parallel Interface

Serial Interface

For additional information on serial cable wir-

ing, refer to Appendix A.

4980181-001 Rev.B

Installation

Step ➋Attach

Interface Cable

Parallel Interface

Serial Interface

For additional information on serial cable wir-

ing, refer to Appendix A.

4980181-001 Rev.B

Installation

Step ➌Apply

Power

If the indicator fails to light, refer to

Appendix A - Trouble Shooting.

980181-001 Rev.B 5

Installation

On

O

O

I=On

Step ➌Apply

Power

If the indicator fails to light, refer to

Appendix A - Trouble Shooting.

980181-001 Rev.B 5

Installation

On

O

O

I=On

Step ➍Install

Software Start your computer. Follow the installation in-

structions on the diskette label to install the soft-

ware.

Refer to Section 2 - Operation, for information

on loading labels and using your printer.

6980181-001 Rev.B

Installation

Step ➍Install

Software Start your computer. Follow the installation in-

structions on the diskette label to install the soft-

ware.

Refer to Section 2 - Operation, for information

on loading labels and using your printer.

6980181-001 Rev.B

Installation

2

Operation

This section provides information on the opera-

tion of the printers.

All user control (and adjustment) printer

features are identified by green parts.

980181-001 Rev.B 7

2

Operation

This section provides information on the opera-

tion of the printers.

All user control (and adjustment) printer

features are identified by green parts.

980181-001 Rev.B 7

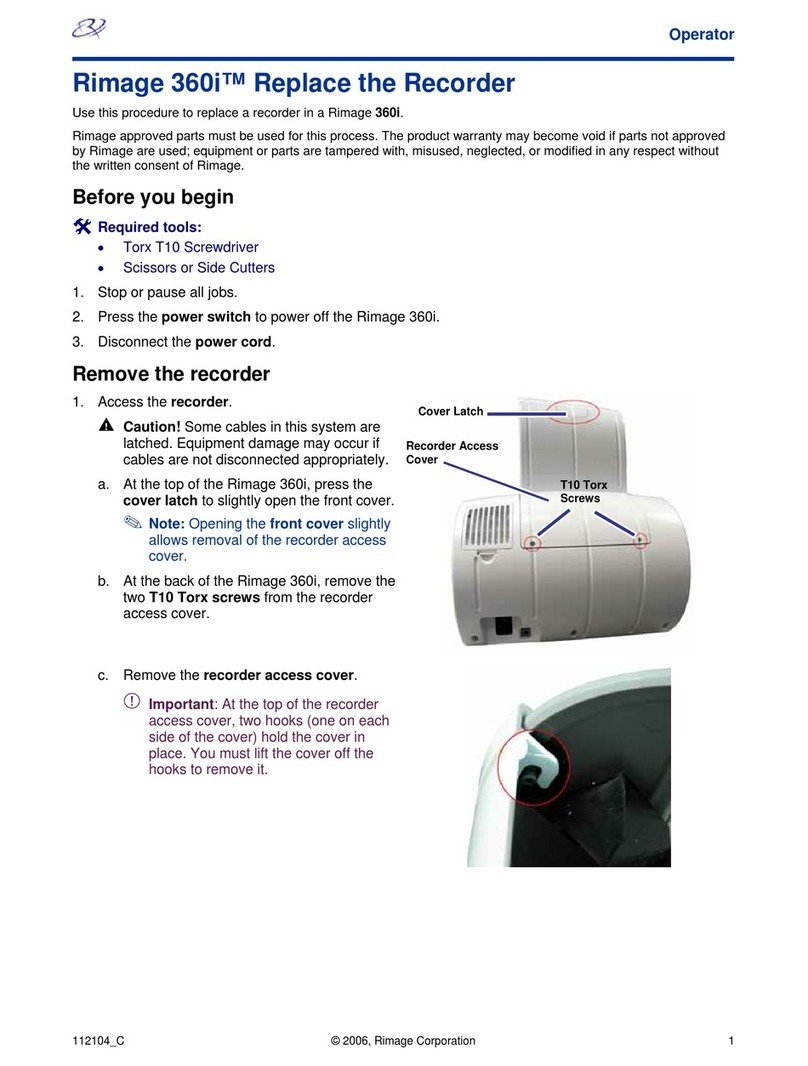

Your Printer

8980181-001 Rev.B

Operation

A) Cover Release Button

B) Upper Media Bracket

C) Lower Media Bracket

D) Media Guide Adjustment

E) Transmissive (Gap) Sensor

Adjustment

F) Print Carriage Release Lever

G) Print Head

H) Transmissive (Gap) Sensor

Swivel Bracket

I) Reflective (black mark) Sensor

J) Label Taken Sensor

K) Label Backing Exit

L) Peel Bar

M) FEED Button

N) STATUS Indicator

O) Bezel Release

P) Platen Roller

Q) Media Guide (behind print

head carriage)

R) Media Roll Holder

S) Tear Bar

T) Media Roll Holders

Strata Your Printer

8980181-001 Rev.B

Operation

A) Cover Release Button

B) Upper Media Bracket

C) Lower Media Bracket

D) Media Guide Adjustment

E) Transmissive (Gap) Sensor

Adjustment

F) Print Carriage Release Lever

G) Print Head

H) Transmissive (Gap) Sensor

Swivel Bracket

I) Reflective (black mark) Sensor

J) Label Taken Sensor

K) Label Backing Exit

L) Peel Bar

M) FEED Button

N) STATUS Indicator

O) Bezel Release

P) Platen Roller

Q) Media Guide (behind print

head carriage)

R) Media Roll Holder

S) Tear Bar

T) Media Roll Holders

Strata

The FEED Control The FEED button controls specific printer

functions: feeding media (labels, tags or

continuous media), loading media, pausing

printing, and initiating AutoSense (Dump

Mode).

Use the FEED control button in normal opera-

tion by tapping or holding the button.

•Tapping the FEED Button with labels

loaded will cause the paper to advance to the

top of the next label. This action is referred to

as a “Form Feed”.

•While Printing, Tapping the FEED Button

will pause batch printing (at the next label

gap) with indicator green flashing red. Press-

ing the FEED Button again will resume print-

ing with the next label in the batch process.

980181-001 Rev.B 9

Operation

FEED Switch

The FEED Control The FEED button controls specific printer

functions: feeding media (labels, tags or

continuous media), loading media, pausing

printing, and initiating AutoSense (Dump

Mode).

Use the FEED control button in normal opera-

tion by tapping or holding the button.

•Tapping the FEED Button with labels

loaded will cause the paper to advance to the

top of the next label. This action is referred to

as a “Form Feed”.

•While Printing, Tapping the FEED Button

will pause batch printing (at the next label

gap) with indicator green flashing red. Press-

ing the FEED Button again will resume print-

ing with the next label in the batch process.

980181-001 Rev.B 9

Operation

FEED Switch

•Holding the FEED button down will cause

the printer to continuously Form Feed until

the button is released. The printer will feed

the media until the next top of form is

reached.

•Holding the FEED button without media

loaded will cause the printer to continuously

(line) feed until the button is released or me-

dia is detected. This is useful when reloading

media in the printer and is also know as

“Power Media Loading”.

•Holding the FEED button down while pow-

ering up the printer with media loaded will

cause the printer to enter the AutoSense

mode. See AutoSense on page 32 for impor-

tant details.

Always run the AutoSense procedure when

loading new media. Media from the same

manufacturing lot and having identical

dimensions do not need to have the AutoSense

procedure run every time new media is loaded.

The Form Feed length is set by printer

programming (Q) command in EPL2

programming language) or the AutoSense

feature, an automatic label and gap length

sensing operation. See AutoSense, page 32.

Continuous media with no label gaps, black

mark mark or notch hole, require programming

to set the form length and feed distance.

10 980181-001 Rev.B

Operation

•Holding the FEED button down will cause

the printer to continuously Form Feed until

the button is released. The printer will feed

the media until the next top of form is

reached.

•Holding the FEED button without media

loaded will cause the printer to continuously

(line) feed until the button is released or me-

dia is detected. This is useful when reloading

media in the printer and is also know as

“Power Media Loading”.

•Holding the FEED button down while pow-

ering up the printer with media loaded will

cause the printer to enter the AutoSense

mode. See AutoSense on page 32 for impor-

tant details.

Always run the AutoSense procedure when

loading new media. Media from the same

manufacturing lot and having identical

dimensions do not need to have the AutoSense

procedure run every time new media is loaded.

The Form Feed length is set by printer

programming (Q) command in EPL2

programming language) or the AutoSense

feature, an automatic label and gap length

sensing operation. See AutoSense, page 32.

Continuous media with no label gaps, black

mark mark or notch hole, require programming

to set the form length and feed distance.

10 980181-001 Rev.B

Operation

The STATUS

Indicator The STATUS indicator is a power and status in-

dicator. When the printer power is first switched

ON (1), the STATUS indicator will glow

GREEN, indicating that the printer is ready for

operation.

Indicator Color Meaning

GREEN 1) Power ON, ready for use.

2) Printing, operation normal.

GREEN Blinking Interface Activity

GREEN with RED

Blinking Twice Printer PAUSED

(during a batch print operation)

AMBER 1) Command Error condition

2) Command Syntax Error

RED

1) Media Out (printing)

2) Ribbon Out (printing)

3) Print Carriage Open

4) Power-up failure

DARK Power OFF.

Refer to Appendix A for additional information

on trouble shooting error conditions.

980181-001 Rev.B 11

Operation

STATUS

Indicator

The STATUS

Indicator The STATUS indicator is a power and status in-

dicator. When the printer power is first switched

ON (1), the STATUS indicator will glow

GREEN, indicating that the printer is ready for

operation.

Indicator Color Meaning

GREEN 1) Power ON, ready for use.

2) Printing, operation normal.

GREEN Blinking Interface Activity

GREEN with RED

Blinking Twice Printer PAUSED

(during a batch print operation)

AMBER 1) Command Error condition

2) Command Syntax Error

RED

1) Media Out (printing)

2) Ribbon Out (printing)

3) Print Carriage Open

4) Power-up failure

DARK Power OFF.

Refer to Appendix A for additional information

on trouble shooting error conditions.

980181-001 Rev.B 11

Operation

STATUS

Indicator

Loading Labels

or Tags Your printer can print on adhesive backed la-

bels, non-adhesive tags or continuous media

(typically paper). The printer is capable of using

media on a roll or fan fold media.

Step 1 Open the printer. Press the two green release

buttons on the sides of the printer to open the

cover.

12 980181-001 Rev.B

Operation

Loading Labels

or Tags Your printer can print on adhesive backed la-

bels, non-adhesive tags or continuous media

(typically paper). The printer is capable of using

media on a roll or fan fold media.

Step 1 Open the printer. Press the two green release

buttons on the sides of the printer to open the

cover.

12 980181-001 Rev.B

Operation

This manual suits for next models

2

Table of contents

Other Eltron Printer manuals

Eltron

Eltron LP2022 User manual

Eltron

Eltron LP2642 User manual

Eltron

Eltron P210 Guide User manual

Eltron

Eltron P2242 Series User manual

Eltron

Eltron LP2642 User manual

Eltron

Eltron TLP2046 User manual

Eltron

Eltron PRIVILEGE P500 User manual

Eltron

Eltron TLP2046 User manual

Eltron

Eltron Eclipse LP2344 User manual