4Instruction manual V 1.6 – 07/2005

Table of contents

1. Important Notes................................................................................................................................................ 5

2. Safety ................................................................................................................................................................. 6

2.1 Safety instructions .......................................................................................................................................................................... 6

2.2 Warnings........................................................................................................................................................................................... 6

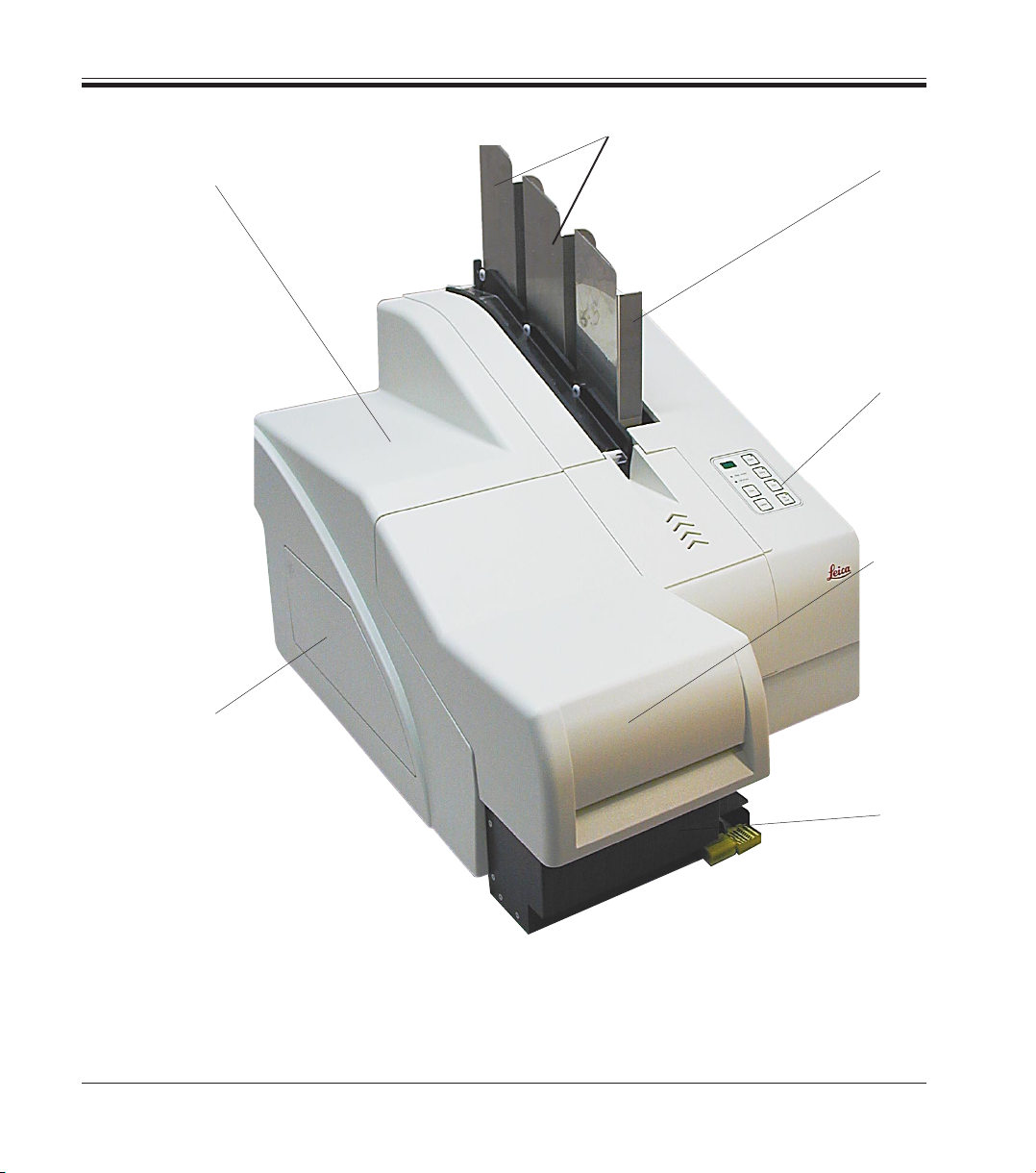

3. Instrument components and specification ................................................................................................. 8

3.1 Overview - instrument .................................................................................................................................................................... 8

3.2 Technical data ............................................................................................................................................................................... 10

3.3 Print specifications ....................................................................................................................................................................... 12

3.3.1 Requirements for microscope slides ......................................................................................................................................... 12

3.3.2 Print specifications ....................................................................................................................................................................... 14

3.3.3 Printing bar code ........................................................................................................................................................................... 15

3.3.4 Resistance against reagents ....................................................................................................................................................... 17

4. Setup ................................................................................................................................................................ 18

4.1 Site requirements .......................................................................................................................................................................... 18

4.2 Installing the printer ...................................................................................................................................................................... 18

4.3 Standard delivery - packing list .................................................................................................................................................. 19

4.4 Installing the manual unload system .......................................................................................................................................... 20

4.5 Automated unload station (optional) .......................................................................................................................................... 21

4.6 Installing/exchanging the flashtube ........................................................................................................................................... 22

4.7 Filling and inserting the magazines ............................................................................................................................................ 24

4.8 Electrical connection .................................................................................................................................................................... 25

4.9 Exchanging the cartridge ............................................................................................................................................................. 26

4.10 Installing the printer driver .......................................................................................................................................................... 29

5. Operation ......................................................................................................................................................... 32

5.1 Control panel functions ................................................................................................................................................................ 32

5.2 Display indications ........................................................................................................................................................................ 37

5.3 Alarm functions.............................................................................................................................................................................. 39

5.4 Printer driver settings ................................................................................................................................................................... 40

6. Cleaning and maintenance .......................................................................................................................... 43

6.1 Cleaning the instrument ............................................................................................................................................................... 43

6.2 Print head cleaning ....................................................................................................................................................................... 46

6.3 General maintenance ................................................................................................................................................................... 47

7. Troubleshooting ............................................................................................................................................. 48

7.1 General ............................................................................................................................................................................................ 48

7.2 Status messages ........................................................................................................................................................................... 49

7.3 Error messages .............................................................................................................................................................................. 50

7.3 Changing the flash bulb ................................................................................................................................................................ 53

7.4 Power failure .................................................................................................................................................................................. 53

7.5 Replacing the secondary fuses ................................................................................................................................................... 54

8. Warranty and service.................................................................................................................................... 55