Elvaco CMi6160 User manual

CMi6160 User’s Manual English

CMi6160

User’s Manual

English

V1.4

CMi6160 User’s Manual English

CMi6160 User’s Manual English

page | 2 (38)

[2022-10]

v1.4

Contents

1DOCUMENT NOTES .....................................................................................................4

1.1 COPYRIGHT AND TRADEMARK.........................................................................................4

1.2 CONTACTS..................................................................................................................... 4

2IMPORTANT USAGE AND SAFETY INFORMATION...................................................5

3USING THIS MANUAL ..................................................................................................6

3.1 PURPOSE AND AUDIENCE ............................................................................................... 6

3.2 ONLINE RESOURCES ...................................................................................................... 6

3.3 SYMBOLS.......................................................................................................................6

4INTRODUCTION............................................................................................................7

4.1 PURPOSE....................................................................................................................... 7

4.2 APPLICATION DESCRIPTION.............................................................................................7

4.3PRODUCT FEATURES......................................................................................................7

4.4 COMPATIBILITY...............................................................................................................7

5GETTING STARTED......................................................................................................8

5.1 PURPOSE....................................................................................................................... 8

5.2 PRODUCT OVERVIEW CMI6160......................................................................................8

Mount and start-up the device..................................................................................... 8

5.2.1 .................................................................................................................................... 8

5.2.2 Antenna connection..................................................................................................... 9

5.2.3 Mounting battery power............................................................................................... 9

5.2.4 Start-up and LED indications....................................................................................... 9

5.2.5 Switch off/reboot module........................................................................................... 10

6INTEGRATION GUIDE ................................................................................................11

6.1 PURPOSE..................................................................................................................... 11

6.2 INTRODUCTION.............................................................................................................11

6.3 STATUS AND CONFIGURATION PARAMETERS.................................................................. 11

DIEHL METERING SHARKY & SCYLAR error codes.............................................. 16

6.3.1 16

CHANGING APN VIA THE DM SYSTEM...........................................................................18

6.4 18

7ADMINISTRATION REFERENCE................................................................................19

7.1 PURPOSE..................................................................................................................... 19

7.2 SECURITY AND ACCESS CONTROL................................................................................. 19

7.3 SCHEDULING READOUTS /TRANSMISSIONS ...................................................................19

7.3.1 Synchronization......................................................................................................... 19

7.3.2 Randomized transmissions....................................................................................... 19

7.3.3 Data retransmission .................................................................................................. 20

Example 1............................................................................................................................... 20

Example 2............................................................................................................................... 21

7.4 CONFIGURATION OPTIONS ............................................................................................29

7.5TIME HANDLING............................................................................................................33

7.6 METER DATA TRANSMISSIONS....................................................................................... 33

7.7 MESSAGE FORMATS..................................................................................................... 33

7.8 MESSAGE ENCODING.................................................................................................... 33

7.8.1 M-Bus........................................................................................................................ 33

CMi6160 User’s Manual English

CMi6160 User’s Manual English

page | 3 (38)

[2022-10]

v1.4

7.8.2 JSON......................................................................................................................... 33

7.8.3 SenML/CBOR encoded telegram.............................................................................. 33

8TECHNICAL SPECIFICATIONS..................................................................................34

9TYPE APPROVALS.....................................................................................................36

10 DOCUMENT HISTORY................................................................................................37

10.1 VERSIONS....................................................................................................................37

11 REFERENCES.............................................................................................................38

11.1 TERMS AND ABBREVIATIONS .........................................................................................38

11.2 NUMBER REPRESENTATION ..........................................................................................38

CMi6160 User’s Manual English

CMi6160 User’s Manual English

page | 4 (38)

[2022-10]

v1.4

1 Document notes

All information in this manual, including product data, diagrams, charts, etc. represents information on

products at the time of publication, and is subject to change without prior notice due to product

improvements or other reasons. It is recommended that customers contact Elvaco AB for the latest

product information before purchasing a CMi Series product.

The documentation and product are provided on an “as is” basis only and may contain deficiencies or

inadequacies. Elvaco AB takes no responsibility for damages, liabilities or other losses by using this

product.

1.1 Copyright and trademark

© 2021, Elvaco AB. All rights reserved. No part of the contents of this manual may be transmitted or

reproduced in any form by any means without the written permission of Elvaco AB. Printed in Sweden.

CMi Series is a trademark of Elvaco AB, Sweden.

1.2 Contacts

Elvaco AB

Kabelgatan 2T

434 37 Kungsbacka

SWEDEN

Phone: +46 300 30250

E-Mail: [email protected]om

Elvaco AB Technical Support

Phone: +46 300 434300

E-Mail: support@elvaco.se

Online: http://www.elvaco.com

CMi6160 User’s Manual English

CMi6160 User’s Manual English

page | 5 (38)

[2022-10]

v1.4

2 Important usage and safety information

The following safety precautions must be observed during all phases of the operation, usage, service or

repair of any CMi Series product. Users of the product are advised to convey the information to users and

operating personnel and to incorporate these guidelines into all manuals supplied with the product.

Failure to comply with these precautions violates safety standards of design, manufacture and intended

use of the product. Elvaco AB assumes no liability for customer’s failure to comply with these

precautions.

CMi6160 receives and transmits radio frequency energy while switched on. Remember that interference

can occur if the product is used close to TV sets, radios, computers or inadequately shielded equipment.

Follow any special regulations and always switch off the product wherever forbidden, or when you

suspect that it may cause interference or danger.

The device or antenna of the product must not be mounted closer than 0.5 m from areas where people

are staying permanently in order not to risk exposing people to RF fields.

To use the product's NFC TAG, follow the instructions issued by the manufacturer of the NFC reader for

safe and efficient operation.

Ensure yourself that power supply and/or battery-unit connected to CMi6160 fulfil EN 62368-1 or

equivalent safety standard.

For guaranteed lifetime of a battery-operated device, configuration and settings must be approved by

Elvaco and not changed during the lifetime of the device.

CMi6160 User’s Manual English

CMi6160 User’s Manual English

page | 6 (38)

[2022-10]

v1.4

3 Using this manual

3.1 Purpose and audience

This manual provides all information needed to mount, deploy and configure CMi6160 and targets

installers and system integrators.

This manual will provide device-specific information for CMi6160, such as status/configuration

parameters and message formats, needed to integrate the module with a DM system and a receiving

MDM server.

It is meant to be used along with the common “Elvaco NB-IoT Module Integrators Manual”, which

provides information about the bootstrapping process, device management, data transport and

encryption.

3.2 Online resources

To download the latest version of this user’s manual, or to find information in other languages, please

visit https://www.elvaco.com/.

3.3 Symbols

The following symbols are used throughout the manual to emphasize important information and useful

tips:

The Note symbol is used to mark information that is important to take into consideration for

safety reasons or to assure correct operation of the meter connectivity module.

The Tip symbol is used to mark information intended to help you get the most out of your

product. It can for example be used to highlight a possible customization option related to the

current section.

The following symbols are used to provide information on how the product should be used:

Symbol

Description

Waste electrical products should not be disposed of with household waste. Please recycle

where facilities exist. Contact your Local Authority for recycling advise.

Electrostatic-sensitive device. Please observe the necessary ESD protective measures when

installing the MCM.

CMi6160 User’s Manual English

CMi6160 User’s Manual English

page | 7 (38)

[2022-10]

v1.4

4 Introduction

4.1 Purpose

This chapter provides a general description of CMi6160. In the next-coming sections you will learn more

about possible applications for the product and how CMi6160 can be combined with other products to

build versatile solutions.

4.2 Application description

CMi6160 is a cost-effective NB-IoT meter connectivity module, which is mounted inside a DIEHL

metering SHARKY & SCYLAR heat meter. As soon as the device has been mounted and deployed, it will

start to deliver meter data to a receiving system via the NB-IoT (LPWAN) network. The product is ideal

for applications where long range and high energy-efficiency are required and a lower bandwidth is not a

concern.

4.3 Product features

Key features of CMi6160 include:

•IoT-ready

As soon as the meter connectivity module has been mounted and started up, it will automatically

initiate transmission of meter data without any manual steps needed. The CMi6160 is prepared

for seamless integration with all leading IoT platforms.

•Battery operated

CMi6160 has several options for power supply. It can be battery operated for up to 13 years with

daily transmission of meter data.

•One-Touch Commissioning

The product uses the Elvaco One-Touch Commissioning (OTC) to configure and deploy products

quickly and securely. Using the Elvaco OTC App, simply enter your desired settings and place

your mobile phone on the right side of the SHARKY & SCYLAR meter. New settings will be

applied instantaneously via NFC.

•Flexible message scheme

CMi6160 has different message formats to choose from, which makes it easy to setup the device

for your specific project.

4.4 Compatibility

CMi6160 is compatible with DIEHL metering SHARKY 775 and SCYLAR 548 meters. CMi6160 is

supplied with external DIEHL battery pack.

CMi6160 User’s Manual English

CMi6160 User’s Manual English

page | 8 (38)

[2022-10]

v1.4

5 Getting started

5.1 Purpose

This chapter provides instructions on how to get started with the CMi6160. After reading and carefully

following each step of this chapter, the MCM will be mounted and deployed.

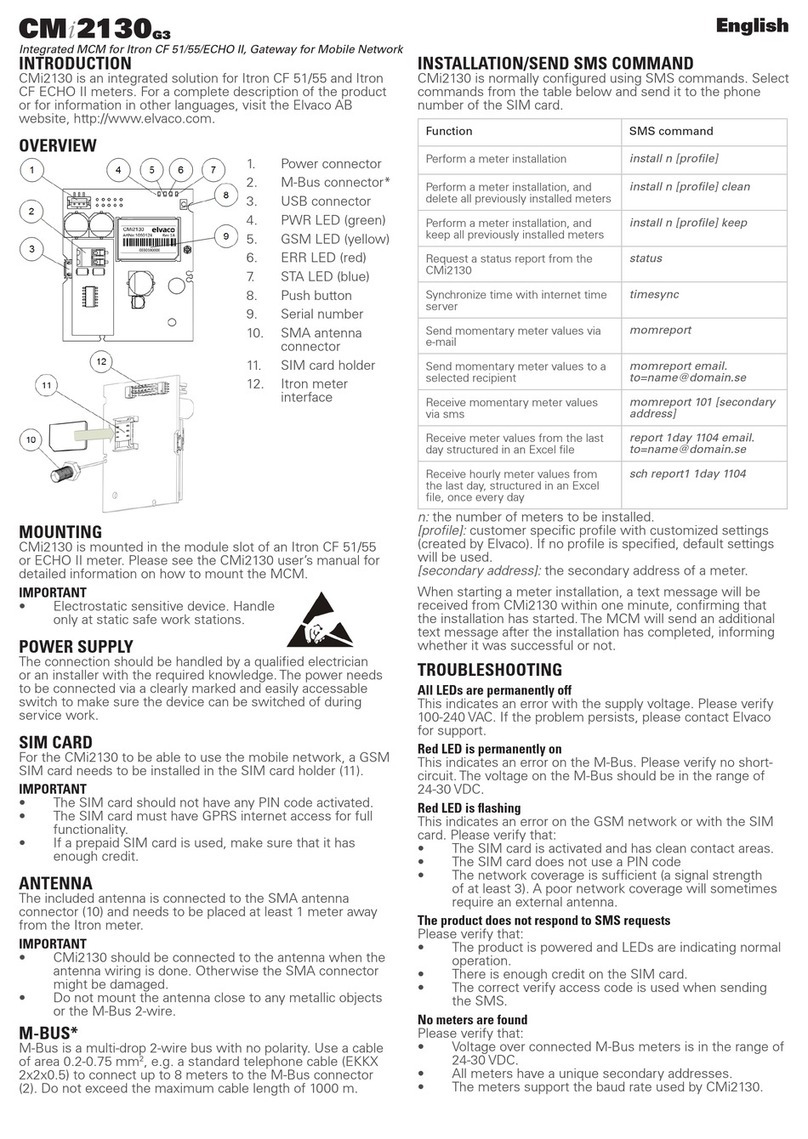

5.2 Product overview CMi6160

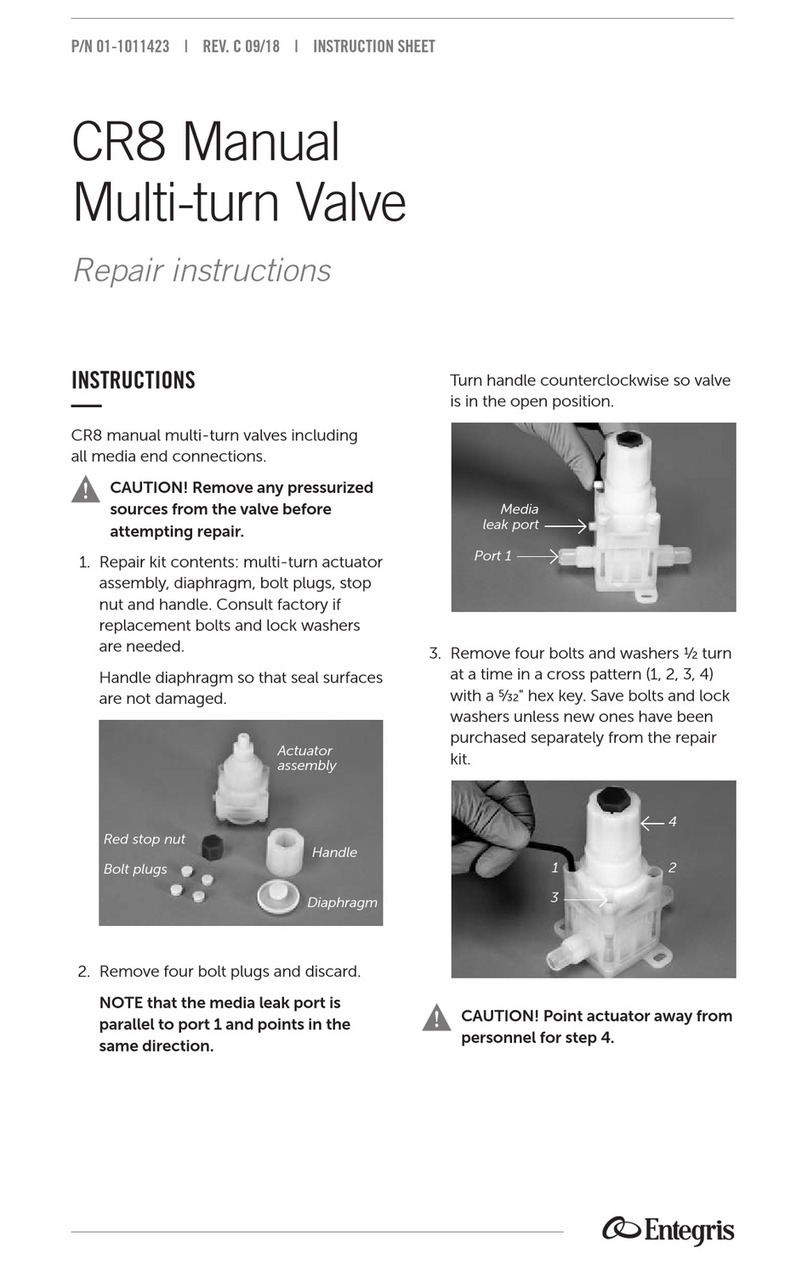

Figure 1: CMi6160 frontside

1. Meter Interface

2. LED - Green

3. LED - Red

4. Power Connector

5. SIM (Nano)

6. Push Button

7. Antenna Connector (MCX female)

8. NFC Antenna

5.2.1 Mount and start-up the device

Before mounting the module in the meter, make sure that a SIM card is installed in the SIM card slot ((5)

in Figure 1), as illustrated in Figure 2.

Figure 2: SIM-card installation

CMi6160 User’s Manual English

CMi6160 User’s Manual English

page | 9 (38)

[2022-10]

v1.4

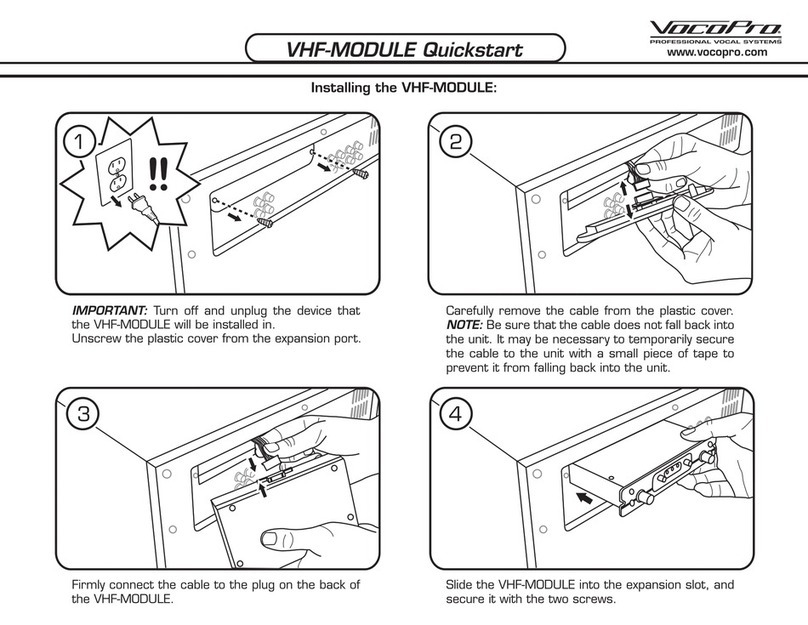

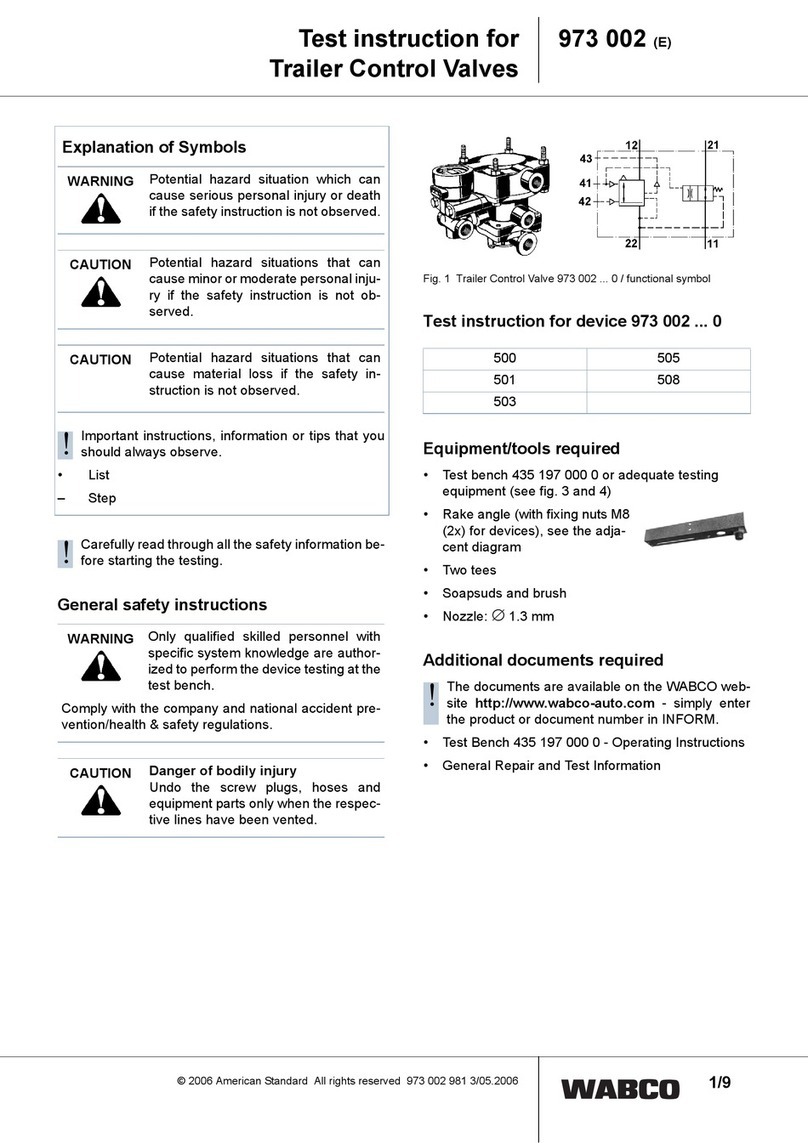

When the SIM card has been mounted, open the calculator by folding down the side catches. Lock the

module into the appropriate slot (preferable slot 2, see Figure 3, mandatory when internal antenna is

used) and carefully connect the pre-formed ribbon cable at both ends.

Figure 3: Module slots - SHARKY 775 (Left) & SCYLAR 548 (Right)

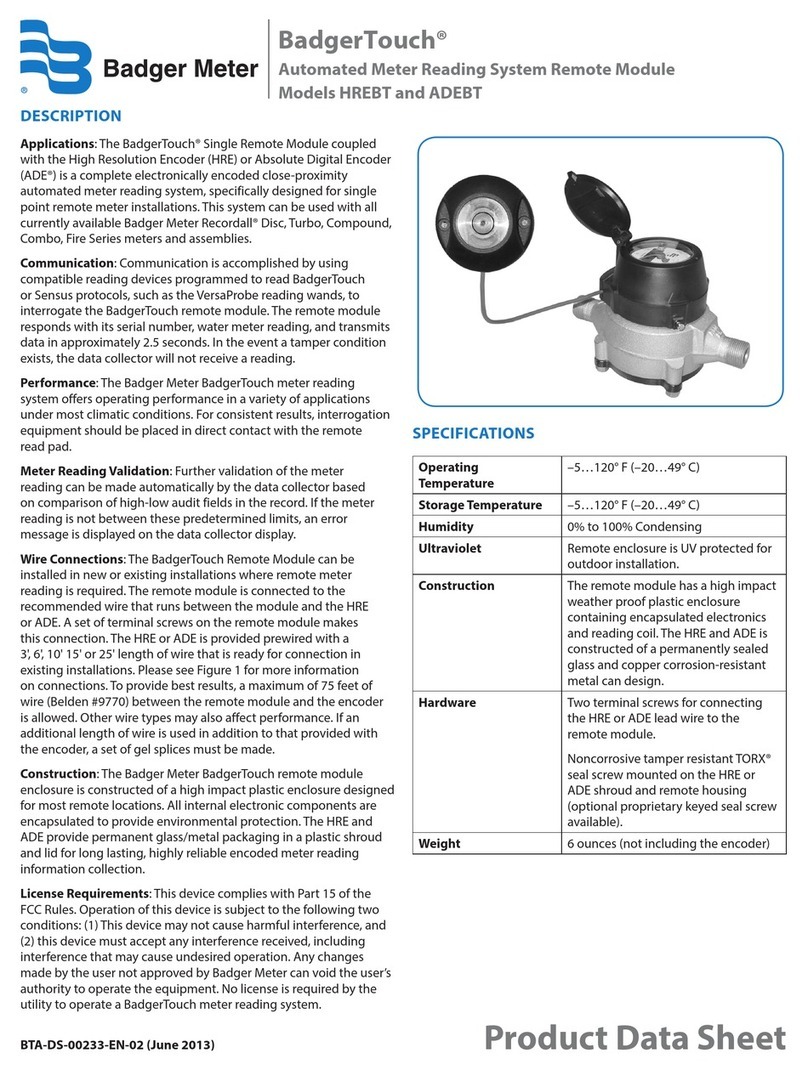

5.2.2 Antenna connection

If the CMi6160 is equipped with internal antenna no additional actions need to be taken. If external

antenna is used, disconnect the internal antenna (if it is mounted) from MCX connector of CMi6160. See

Figure 4 below for internal antenna positioning.

Connect an external antenna (released by the supplier) with MCX connector to the module CMi6160 in

the meter. Make a hole in rubber gromets/sealing and push the mcx connector through the

gromet/sealing. Make sure thicker part of antenna cable is in gromet/seal. Push the connector gently into

the antenna connector (7) on the module.

Figure 4: Antenna connection.

5.2.3 Mounting battery power

See manual for external battery pack. Connect power cable from external battery back to battery power

connector (4) of the CMi6160.

5.2.4 Start-up and LED indications

Module activation

Upon delivery, CMi6160 will be set to passive mode, which means that no messages will be transmitted

from the module. Please make sure a SIM card (size: Nano) has been mounted before activating the

module. There are two ways to activate the module:

1. Press down the push button for at least 5 seconds until the green LED lights up, then release the

button. CMi6160 will confirm start-up by flashing its red and green LEDs for one second.

CMi6160 User’s Manual English

CMi6160 User’s Manual English

page | 10 (38)

[2022-10]

v1.4

2. Open the Elvaco OTC app available in Google Play or App Store and scan the module (make

sure NFC is activated on the phone). Go to Apply mode, set the power mode to “active” and

press Apply settings.The NFC is reachable from backside of meter or front if meter cover is

removed. The mobile phone should vibrate three times. This indicates that settings have

successfully been applied.

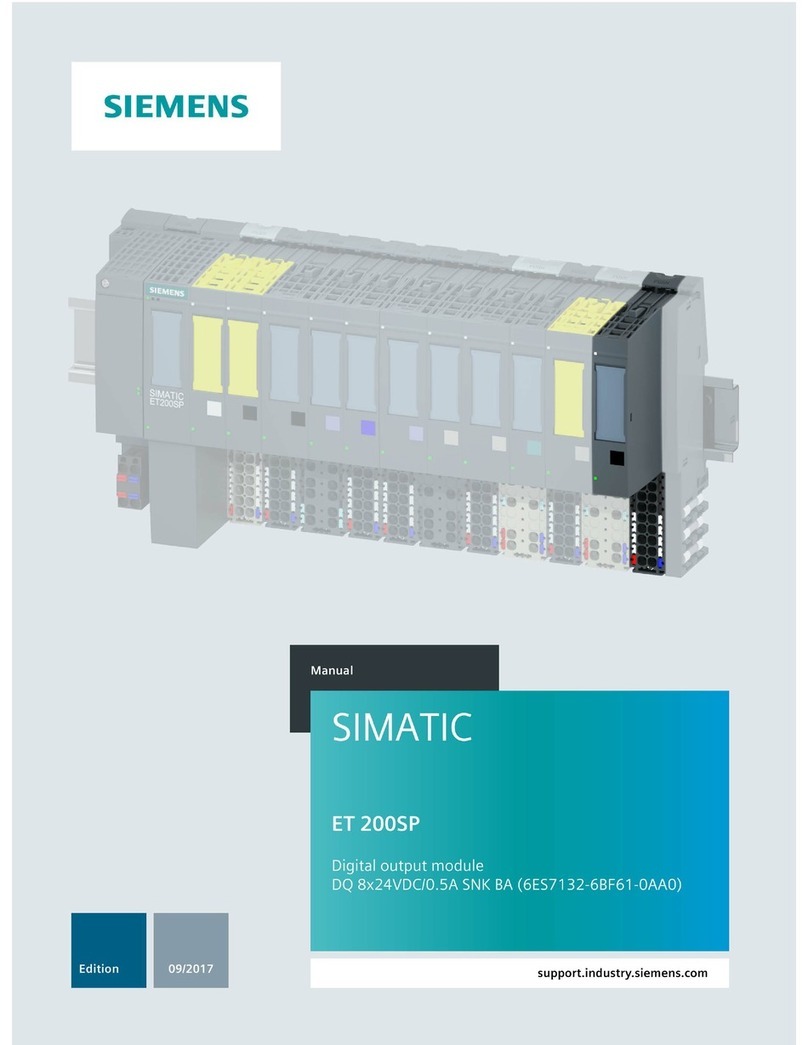

Network Connection

When activated, CMi6160 will attempt to connect to the mobile network. The phase is indicated by the

green and red LED lights up for 1 second, followed by short flashes on the green LED until the module

has joined the mobile network. When CMi6160 succeeds in connecting to the mobile network, the green

LED will lighten up for 8 seconds, as illustrated by 2.

If the module fails to join the mobile network, it will perform retries until it succeeds. The time between

each attempt will increase for every attempt until it is performed once every day. A new join attempt cycle

can be manually started anytime by using the push button to reboot the module or by deactivating and

activating the module using the Elvaco OTC App.

Figure 5: LED indicators, network connection

5.2.5 Switch off/reboot module

To reboot the module, press and hold the push button for 5-15 seconds. Release the button when the

green LED is lit.

To switch off the module, press and hold the push button for 15-20 seconds. Release the button when

the red LED is lit.

Figure 6: LED indication, reboot / switch-off

CMi6160 User’s Manual English

CMi6160 User’s Manual English

page | 11 (38)

[2022-10]

v1.4

6 Integration guide

6.1 Purpose

This chapter provides the technical details needed to integrate an Elvaco NB-IoT module with a MDM

and/or DM server.

Note that this section will provide device-specific information and is meant to be used with the

common “Elvaco NB-IoT MCM Integrator’s guide”.

6.2 Introduction

For device management, the module will act as a LWM2M device connecting to a LwM2M server. The

Device Management system enables configuration and monitoring of a CMi6160 module remotely. This

includes setting configuration parameters, update the firmware and trigger momentaneous/historical

readouts of the module. For meter data transport, the module uses the MQTT-SN protocol.

Upon activation, the device will attempt to connect to its configured bootstrap server via the mobile (NB-

IoT) network. When successful, the module will receive connection credentials, i.e. IP addresses to the

DM server and the meter data server.

The module will thereafter connect to the DM server and perform a DTLS handshake to generate the

session key used to encrypt the data that is transmitted between DM server and module. Note that using

DTLS is optional, and the product also support unencrypted communication.

The module will thereafter connect to the MQTT-SN gateway and perform a DTLS handshake to

generate the sessions keys used to encrypt the meter data transport.

Each module has a security chip where a device-unique set of keys are stored. These are provisioned to

the module during production. The UDP transport of both DM and MDM can be secured using DTLS 1.2.

Either the pre-provisioned keys can be used, or new keys can be provisioned during the bootstrap phase.

6.3 Status and configuration parameters

Table 1 below provides a list of all CMi6160 status and configuration parameters accessible on LwM2M.

Op.

LwM2M object

LwM2M resource

ID

Type

Range or

Enumeration

Comment

R

LwM2M Security

LWM2M Server

URI

0/0/0

String

Bootstrap URI

R

LwM2M Security

Bootstrap server

0/0/1

Bool

TRUE

R

LwM2M Security

Security Mode

0/0/2

Integer

0..4

BS Security

mode

0 = PSK mode

3 = No security

R

LwM2M Security

PSK Identity

0/0/3

Opaque

DevEUI

-

LwM2M Security

Secret Key

0/0/4

Opaque

Bootstrap PSK

R

LwM2M Security

Short Server ID

0/0/10

Integer

1..65534

R

LwM2M Server

Short Server ID

1/0/0

Integer

1..65534

R

LwM2M Server

Lifetime

1/0/1

Integer

E

LwM2M Server

Bootstrap-

Request Trigger

1/0/9

R(W)

LwM2M Security

LWM2M Server

URI

0/1/0

String

DM ServerURI

Writable by

Bootstrap server

R

LwM2M Security

Bootstrap server

0/1/1

Bool

FALSE

CMi6160 User’s Manual English

CMi6160 User’s Manual English

page | 12 (38)

[2022-10]

v1.4

Op.

LwM2M object

LwM2M resource

ID

Type

Range or

Enumeration

Comment

R(W)

LwM2M Security

Security Mode

0/1/2

Int

0..4

DM Security

mode

Writable by

Bootstrap server

R

LwM2M Security

PSK Identity

0/1/3

Opaque

DM PSK identity

(DevEUI)

(W)

LwM2M Security

Secret Key

0/1/4

Opaque

DM PSK

Writable by

Bootstrap server

R

LwM2M Security

Short Server ID

0/1/10

Integer

1..65534

R

LwM2M Server

Short Server ID

1/1/0

Integer

1..65534

R

LwM2M Server

Lifetime

1/1/1

Integer

DM lifetime

E

LwM2M Server

Registration

Update Trigger

1/1/8

R

Device

Manufacturer

3/0/0

String

Manufacturer

("Elvaco")

R

Device

Model Number

3/0/1

String

Product model

("CMi6160")

R

Device

Serial Number

3/0/2

String

DevEUI

R

Device

Firmware Version

3/0/3

String

Firmware

version

E

Device

Reboot

3/0/4

Reboot

R

Device

Available Power

Sources

3/0/6/0

Integer

0..7

Power source

1: Internal

battery

2: External

battery

6: AC (Mains)

power

R

Device

Power Source

Voltage

3/0/7/0

Integer

Power source

voltage

(Millivolt)

R

Device

Battery level

3/0/9

0..100

Battery level (in

%)

R

Device

Error Code

3/0/11/0

0..8

Error codes,

according to

LwM2M 1

RW

Device

Current Time

3/0/13

Time

Current time

RW

Device

UTC Offset

3/0/14

String

UTC Offset

UTC+X (ISO

8601)

R

Device

Hardware version

3/0/18

String

Hardware

version

R

Connectivity

Monitoring

Network Bearer

4/0/0

Integer

0..50

7 = NB-IoT

R

Connectivity

Monitoring

Available Network

Bearer

4/0/1/0

Integer

0..50

7 = NB-IoT

R

Connectivity

Monitoring

Radio Signal

Strength

4/0/2

Integer

RSRP

(NRSRP)

R

Connectivity

Monitoring

APN

4/0/7/0

String

APN

R

Connectivity

Monitoring

Cell ID

4/0/8

Integer

Cell ID

R

Connectivity

Monitoring

SMNC

4/0/9

Integer

0..999

MNC

PLMN = SMNC

+ SMCC

CMi6160 User’s Manual English

CMi6160 User’s Manual English

page | 13 (38)

[2022-10]

v1.4

Op.

LwM2M object

LwM2M resource

ID

Type

Range or

Enumeration

Comment

R

Connectivity

Monitoring

SMCC

4/0/10

Integer

0..999

MCC

PLMN = SMNC

+ SMCC

W

Firmware

Update

Package URI

5/0/1

Firmware

Update URI

E

Firmware

Update

Update

5/0/2

Firmware

Update Trigger

R

Firmware

Update

State

5/0/3

Integer

0..3

Firmware

Update Status

0: Idle

1: Downloading

2: Downloaded

3: Updating

R

Firmware

Update

Update result

5/0/5

Integer

Firmware

Update Result

R

Firmware

Update

Firmware Update

Protocol Support

5/0/8/0

Integer

0..5

0 = CoAP

R

Firmware

Update

Firmware Update

Delivery Method

5/0/9

Integer

0..2

0 = Pull only

R

LwM2M Cellular

Connectivity

PSM Timer

10/0/4

Integer

NB-IoT T3412.

Will be writeable

in future

releases.

R

LwM2M Cellular

Connectivity

Active Timer

10/0/5

Integer

NB-IoT T3324.

Will be writeable

in future

releases.

R

LwM2M Cellular

Connectivity

eDRX parameters

for NB-S1 mode

10/0/9

Opaque

8 bit

NB-IoT eDRX.

Will be writeable

in future

releases.

"This resource is

encoded as

octet 3 in

[3GPP-

TS_24.008,

clause

10.5.5.32]."

R

LwM2M Cellular

Connectivity

Activated Profile

names

10/0/11

ObjLink

Link to APN

Connection

Profile object

RW

LwM2M APN

Connection

Profile

Profile name

11/[0,1]/0

String

RW

LwM2M APN

Connection

Profile

APN

11/[0,1]/1

String

Manual APN

Writable in

object resource

1.

RW

LwM2M APN

Connection

Profile

Auto select APN

by device

11/[0,1]/2

Boolean

Auto APN Mode

Writable in

object resource

1.

RW

LwM2M APN

Connection

Profile

Authentication

Type

11/[0,1]/4

Integer

0..3

3 = None,

Writing currently

not supported

RW

Elvaco MDM

Server

URI

33905/0/

0

String

MDM Server

URI

CMi6160 User’s Manual English

CMi6160 User’s Manual English

page | 14 (38)

[2022-10]

v1.4

Op.

LwM2M object

LwM2M resource

ID

Type

Range or

Enumeration

Comment

RW

Elvaco MDM

Server

Protocol

33905/0/

1

Integer

0..

MDM Server

Protocol

0 = MQTT-SN

RW

Elvaco MDM

Server

Transport Security

Mode

33905/0/

2

Integer

0..4

MDM Server

Transport

Security Mode

0 = PSK mode

3 = No security

W

Elvaco MDM

Server

Transport Secret

Key

33905/0/

5

Opaque

MDM Server

Transport Secret

Key

RW

Elvaco MDM

Server

Connection config

33905/0/

10

Integer

0..1

MDM Server

Connection

Config

0: Optimized

1: Compliant

RW

Elvaco MDM

Server

Topic

33905/0/

11

String

MDM Server

Topic

RW

Elvaco MCM

Config

Meter readout

interval

33906/0/

0

Integer

5..1440

Meter Readout

Interval

RW

Elvaco MCM

Config

Report data

encoding

33906/0/

1

Integer

Report Data

Encoding

0: Reserved

1: JSON

2: MBus

3. SenML/CBOR

RW

Elvaco MCM

Config

Report frame type

33906/0/

2

Integer

CMi6160:

42: Standard

43: Extended

RW

Elvaco MCM

Config

Eco mode

Enabled

33906/0/

3

Boolean

Not used

RW

Elvaco MCM

Config

NFC Enabled

33906/0/

4

Boolean

R

Elvaco MCM

Config

NFC Config-

locked

33906/0/

5

Boolean

W

Elvaco MCM

Config

Adjust time

33906/0/

6

Integer

E

Elvaco MCM

Config

Instantaneous

readout trigger

33906/0/

10

Trigger a meter

readout

instantaneously.

E

Elvaco MCM

Config

Historic resend

trigger

33906/0/

13

Execute arguments given as Unix timestamps:

0=’<start-time>’,1=’<stop-time>’,2=’<min-

interval>’

R

Elvaco MCM

Config

Historic resend

status

33906/0/

14

Integer

0..50

Number of

measurements

queued for

uplink

E

Elvaco MCM

Config

Apply APN

changes

33906/0/

15

Stages changes in APN and APN mode,

resets the device and tries to use those

changes.

R

Elvaco NB-IoT

Status

Uptime

33907/0/

0

Integer

[s]

R

Elvaco NB-IoT

Status

Average current

consumption

33907/0/

1

Integer

[uA]

R

Elvaco NB-IoT

Status

Network

classification

33907/0/

2

Integer

0: Excellent

1: Good

2: Fair

3: Poor

CMi6160 User’s Manual English

CMi6160 User’s Manual English

page | 15 (38)

[2022-10]

v1.4

Op.

LwM2M object

LwM2M resource

ID

Type

Range or

Enumeration

Comment

R

Elvaco NB-IoT

Status

ECL

33907/0/

3

Integer

0..2

R

Elvaco NB-IoT

Status

RSSI

33907/0/

4

Integer

[dBm *10]

R

Elvaco NB-IoT

Status

SNR

33907/0/

5

Integer

[dB*10]

R

Elvaco NB-IoT

Status

MDM connection

status

33907/0/

10

Integer

0: OK

1: Connecting

2: No

credentials

3: DTLS

Rejected

4: MQTT-SN

Failed

5: MQTT-SN

Rejected

R

Elvaco Meter

Info

Meter Model

33908/0/

0

String

-

R

Elvaco Meter

Info

Meter ID

33908/0/

1

Integer

R

Elvaco Meter

Info

Comm status

33908/0/

2

Integer

0: OK

1: No meter

detected

2: Error

R

Elvaco Meter

Info

Error flags

33908/0/

3

Opaque

Meter Error flags

R

Elvaco NB-IoT

Info

IMSI

33909/0/

0

Integer

SIM IMSI

R

Elvaco NB-IoT

Info

ICCID

33909/0/

1

Integer

SIM ICCID

R

Elvaco NB-IoT

Info

Registrations

33909/0/

2

Integer

NB-IoT

Registrations

R

Elvaco NB-IoT

Info

Last Registration

duration

33909/0/

3

Integer

NB-IoT Last

Regsitration

Duration

R

Elvaco NB-IoT

Info

Modem Model

33909/0/

4

String

NB-IoT Modem

Model

R

Elvaco NB-IoT

Info

Modem Firmware

33909/0/

5

String

NB-IoT Modem

Firmware

Table 1: CMi6160 status/configuration parameters

CMi6160 User’s Manual English

CMi6160 User’s Manual English

page | 16 (38)

[2022-10]

v1.4

6.3.1 DIEHL METERING SHARKY & SCYLAR error codes

The error codes transported from an MCM is the status byte of the M-Bus header. Bits 71:64 of M-Bus

header.

Meaning of Error Codes

The following information is from the documentation received from Diehl Metering. It has only been

enhanced by formatting, contents is as-is straight from the document. For latest error description please

use the latest documentation available from DIEHL Metering. Table 2 corresponds to Table 7 of EN

13757-3:2013 for M-Bus.

Bit

Description

Usage

0

reserved

-

1

any application error

-

2

power low

E-8, E-9

3

permanent error

C-1, E-4

4

temporary error

E-1, E-3, E-6, E-7, leak error

5

manufacturer specific

see table below

6

manufacturer specific

see table below

7

manufacturer specific

see table below

Table 2: DIEHL error codes

Table 3 explains the position of error codes from the User’s Manual of the meter.

Error

C-1

E-8

E-4

E-1

E-7

E-9

E-3

E-6

Leak

error

E-5

Mbus

status

Byte

0x08

0x04

0x28

0x50

0x70

0x84

0xB0

0xD0

0xF0

0x10

Prio

Highest

Lowest

Table 3: Error code positioning

CMi6160 User’s Manual English

CMi6160 User’s Manual English

page | 17 (38)

[2022-10]

v1.4

Table 4 contains error display codes and corresponding explanations.

Error display

Meaning

C-1

Basic parameter error in flash or RAM

E-1

Temperature measurement error

Temperature range exceeded [-9.9 °C … 190 °C]

Sensor short-circuit

Sensor break

E-3**

Temperature sensors reversed in hot and cold lines

E-4

Hardware error in ultrasonic measurement

Ultrasonic transducer defective

Short-circuit in ultrasonic transducer

E-5

Reading too frequently

M-Bus communication not possible for short time

E-6**

Wrong direction of flow

Flow sensor incorrectly installed

E-7

No meaningful ultrasonic receive signal

Air in the measuring path

E-8

No primary voltage (only if mains unit used)

Powered by back-up battery

E-9

Warning: battery nearly exhausted

E-A*

Leakage: pipe break detected

E-b*

Leakage: leakage detected in energy meter

E-C*

Leakage: leakage pulse input 1

E-d*

Leakage: leakage pulse input 2

Table 4: Error code translation

* Optional

** application-dependent

When the module is unable to read a data field, that data field will be excluded in the payload.

CMi6160 User’s Manual English

CMi6160 User’s Manual English

page | 18 (38)

[2022-10]

v1.4

6.4 Changing APN via the DM system

Since changing APN is a potentially hazardous operation that may render the device disconnected from

the mobile network, there is a rollback functionality in place when changing the APN.

To change APN, write the APN to the resource /10/1/1 and set APN mode to manual in /10/1/2. Once

done, stage the changes by executing /33906/0/15. When executed, the device will reset and try to use

the new APN. If the device manages a successful bootstrapping, the new APN will be saved as the

default. If a successful bootstrapping has not happened for some time, the device will roll back to the old

APN and reset again.

CMi6160 User’s Manual English

CMi6160 User’s Manual English

page | 19 (38)

[2022-10]

v1.4

7 Administration reference

7.1 Purpose

This chapter contains detailed information about configuring options for CMi6160.

7.2 Security and access control

CMi6160 has a configuration lock feature, which prevents unauthorized access to the module. When

configuration lock has been enabled, a Product Access Key (PAK) will be needed to access the device

via NFC. The Product Access Key is claimed by the end-user to his One-Touch Commissioning (OTC)

account via the Elvaco OTC App or the OTC web interface.

Note that the default setting of the CMi6160 is Open, meaning the user must set it to Lock

to activate the configuration lock. In section 7.5, all default configurations are listed.

7.3 Scheduling readouts and transmissions

A Readout refers to a readout of meter data and storing the information locally in the device memory.

A Transmission refers to a sending a set of readouts from the device over NB-IoT network to a LWM2M

or MQTT-SN server.

A combination of above is set to achieve the functionality specified by the project/customer.

7.3.1 Time handling

The module relies on the meter’s clock for keeping time. Time in the meter is assumed to be in standard

local time (no DST). When synchronizing time in the meter using the OTC App, timeserver or network

time. Local standard time is always used, even if DST is in effect. The timestamped meter data sent from

the module can be adjusted to be sent in UTC by specifying the “UTC offset” configuration parameter.

The UTC offset will be subtracted from the timestamp prior to transmission. If the meter is in Sweden,

which uses CET (Central European Time), it should have UTC offset set to +60 (+1h). In this case at time

12.00 a telegram is sent with timestamp 11.00 as this is the corresponding UTC time. A meter in New

York (USA) should have a UTC offset of -300 (-5h) etc. A UTC offset of 0 means the meter time is used

as-is.

7.3.2 Synchronization

All schedules are based on a synchronization with a clock. That means that if a readout schedule of 60

minutes is used, it is synchronized on top of the hour, so 11:00, 12:00, 13:00 etc. 120 minutes will give

12:00, 14:00, 16:00 etc.

When time in the module (or meter) is synchronized a rescheduling takes place such that the next meter

readout is made according to an updated time.

To handle the case where time synchronization “moves time” past a previously planned readout (like

23.58 → 00.02) the module will always make a readout and transmission of a new value when time is

synchronized. The device will therefore send an additional readout which can be masked on the server-

side.

7.3.3 Randomized transmissions

In order to prevent a large population of devices from transmitting data at exactly the same time the

devices should have a random delay before transmitting data. The delay should be configurable via

NFC/DM.

Readouts from the meter are always performed on top of the hour, 11.00, 13.00 etc. Transmissions can

CMi6160 User’s Manual English

CMi6160 User’s Manual English

page | 20 (38)

[2022-10]

v1.4

be carried out at other times but are planned at full ours given a set transmission interval (Ttransmit). The

figure below illustrates this. The transmissions are planned at time T1. The actual Ttransmit is a random time

between (T1+ Toffset) and (T1+ Toffset + Tdelay).

Ttransmit, Toffset and Tdelay are parameters in the product.

Conditions

•Toffset + Tdelay <= Ttransmit

oThis should be checked by the device and the OTC App.

•If Ttransmit is reduced below Toffset + Tdelay, then Toffset should be set to 0 and Tdelay.= Ttransmit.

7.3.4 Data retransmission

If data cannot be sent, due for instance to network issues, there will be a number of retries after which the

device will give up and leave the readout as “unsent” in its storage. Next time a transmission is attempted

unsent data will be resent (if possible). Retransmission can be done by FIFO or LIFO.

Rules for retransmissions include maximum age of data, order of data, number of retransmitted data /

transmission interval,

Example 1

A device is configured the following way:

•Message encoding: M-Bus

•Auto upload order: FIFO

•Measurement interval: 60 minutes

•Transmit interval: 60 minutes

•Transmit offset: 15 minutes

•Transmit delay: 30 minutes

•Maximum uploads per transmission: 4

•Upload maximum age 72h

A network issue caused the module to be offline for 5 days, while still reading and storing measurement

data. When the device manages to go online the following scenario takes place.

•The device will start by transmitting measurement data that is 3 days old (FIFO order)

•The device will send 4 measurement telegrams per hour, at a randomly chosen time between

minute 15 and 45

•Each telegram contains a single readout, totaling 4 readouts per transmission

•The device will take approximately 1 day to “catch up” and start sending one measurement per

hour

Other manuals for CMi6160

1

This manual suits for next models

4

Table of contents

Other Elvaco Control Unit manuals

Popular Control Unit manuals by other brands

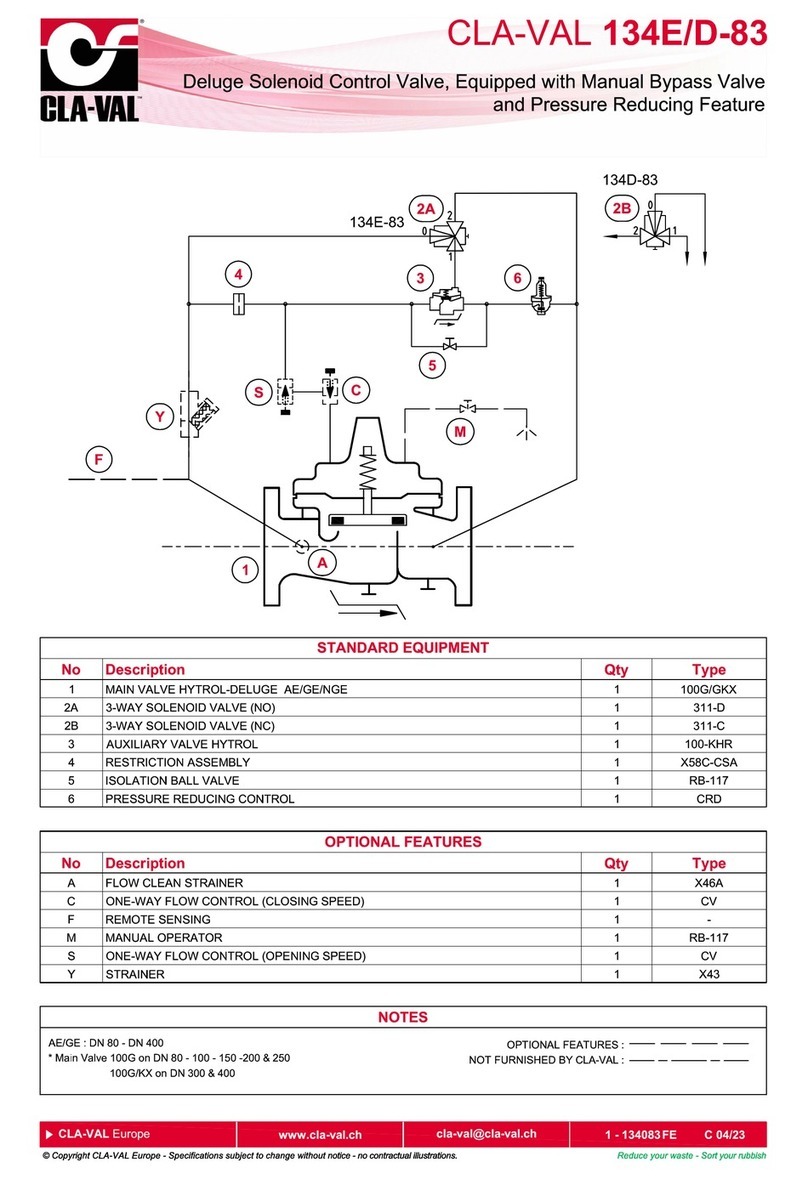

CLA-VAL

CLA-VAL 134E-83 manual

KONTRONIK

KONTRONIK TelMe Futaba Operation manual

Eaton

Eaton Power XL SmartWire-DT DX-NET-SWD Series manual

Crane

Crane KROMBACH TUFSEAT Performance Series Installation, operation and maintenance manual

Roger Technology

Roger Technology B70/1DCHP Instructions and warnings for installation

OMC

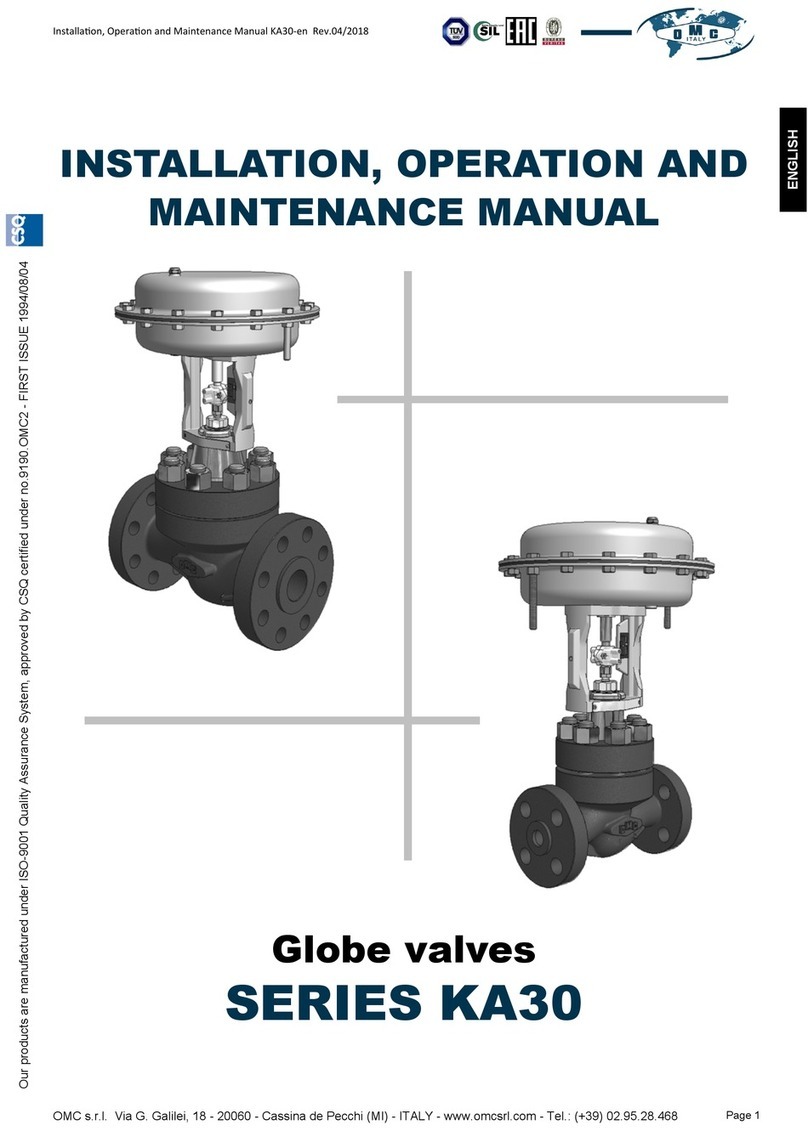

OMC KA30 Series Installation, operation and maintenance manual