Elvo E911D User manual

ELVO E911D/E911A/E912A 1

ELVO

SOLDERING STATIONS

INSTRUCTION MANUAL

ELVO.010.5001.E

Pb-Sn

E912A

E911A

E911D

32 ELVO E911D/E911A/E912A

Switzerland

ELVO ELECTRONICS AG

Hauptstrasse 93

CH-2552 Orpund

Tel: ++41

/

(0)32

/

356 04 31

Fax:++41

/

(0)32

/

356 04 32

I: www.elvo.ch

The future belongs to quality and excellence

2ELVO E911D/E911A/E912A

INTRODUCTION

0

Warranty

The equipment has been carefully tested both

mechanically and electrically prior to shipment.

It has also been verified, as far as possible, that

the equipment is in good working order. For a

period of 12 months (6 months if the equipment

operates day and night, even if only occasion-

ally), beginning on the day the equipment is

ready to be shipped at our plant (in cases where

we undertake assembly and/or initial operation,

from the day of initial operation), we guarantee

good working of the equipment delivered and

we promise to repair or replace at will, as quickly

and reasonably as possible, any parts which

are proven to be faulty in design, material or

workmanship. If, during operation and within

the period of warranty, any discrepancy appears

between the equipment contracted for and the

one actually supplied by us, we shall bear the

costs incurred in repairing or replacing the faulty

parts at our plant. We shall supply and ship at

our expense "FOB factory" the replacement

material necessary for carrying out the repairs

under this warranty on the site. We shall pay

the salary and wages of our employees, but the

buyer shall pay for the travelling time, as well

as their transportation and out of pocket ex-

penses.

Our liability is limited to direct damages.

Our warranty shall not cover replacements or

repairs which are due to normal wear and tear,

faulty or negligent maintenance, disregard of

operating instructions in this manual, overload-

ing, use of unsuitable materials, faulty construc-

tion of buildings, incorrect assembly work, faulty

electrical connections, acts of God, and any

other cause beyond our control.

Our "General Terms and Conditions of Sale",

of which the above text is an excerpt, are bind-

ing for all warranty cases.

This document, its contents, and the technology described are strictly

confidential. It is provided for assistance to ELVO customers only. It

may not be copied, repro-duced or passed on to third parties with-

out express, written permission from ELVO ELECTRONICS.

Dear customer

We thank you for selecting one of our ELVO

clean-o-point®

soldering stations, the new

standard in soldering technology. The solder-

ing stations answer the need for increased qual-

ity control in the soldering process. With the

hundred thousands of clean-o-point®

tip clean-

ers sold in the past number of years all over the

world, satisfied customers urged us to integrate

this extraordinary tip cleaning system into these

new stations.

Please read the operating instructions carefully

to maximize the advantages of using your new

soldering station.

Responsibility for shipment

The moment the equipment is shipped from our

plant, the buyer assumes all risks regarding it,

in particular but not limited to the risk for dam-

age, loss, theft or confiscation. We are liable

only for damages which can undeniably be

traced to gross negligence of our personnel.

Inspection of goods upon arrival

Remove packing material carefully and keep it

for possible storing or return of the unit.

After unpacking, check the equipment for pos-

sible damage due to transportation. Should this

be the case, inform immediately both the for-

warder and the carrier. The buyer must exam-

ine the equipment within a reasonable period

of time and notify us immediately in writing of

any defects. Failing such notification the equip-

ment is deemed to be accepted.

ELVO E911D/E911A/E912A 31

Subject to change without notice.

Printed in Switzerland

ZUMBACH Electronic AG

P.O. Box

CH-2552 Orpund

December 2006

ELVO E911D/E911A/E912A 3

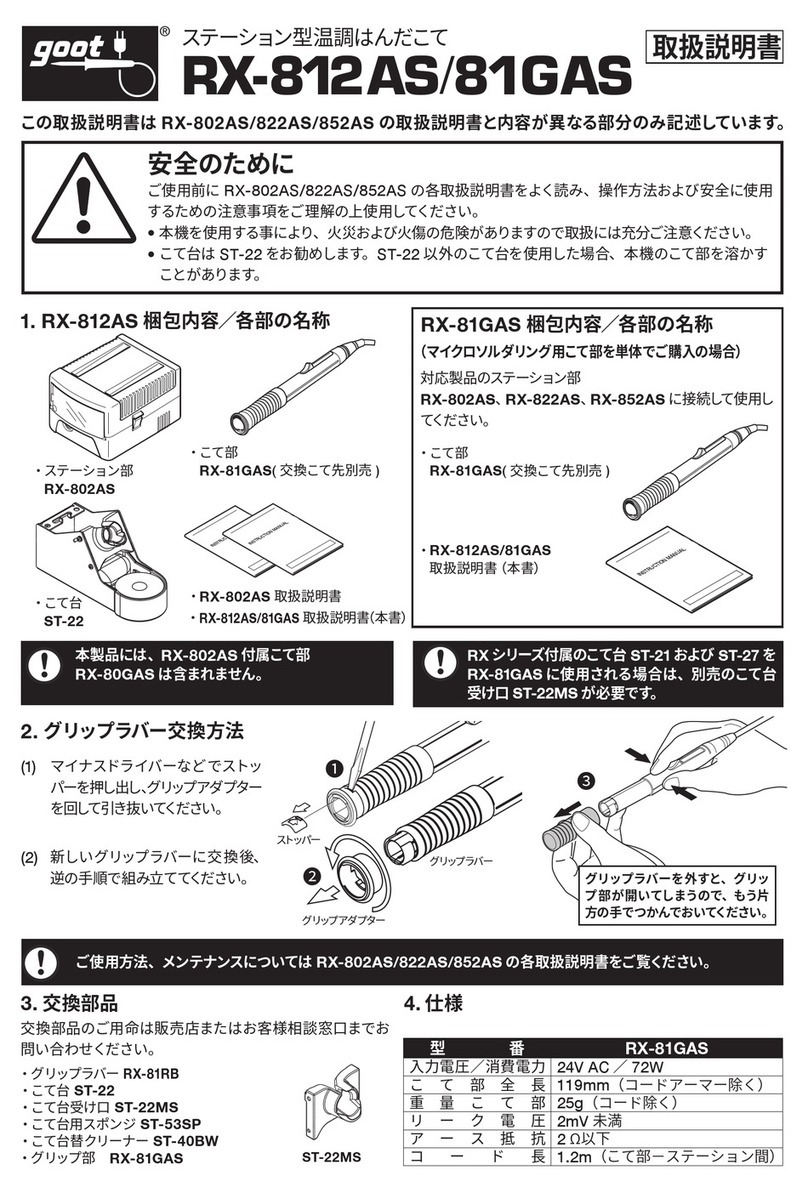

13

4

7

2

10

5

7

E911D

9

8

12

10

2

11

14

▼

1

▼

6

4

3

9

8

14

▼

10

11

2

6

12

1

▼

14

▼

1

9

8

E911A

E912A

4

6

11

7

▼

30 ELVO E911D/E911A/E912A

S

SAFETY CAUTIONS 9

SERVICING 19

Spare Parts 19, 21

Sponges 12, 18, 19, 21

T

Technical data 8

Temperature 4, 7, 8, 13, 14

Temperature range 8, 13

Temperature Stability 13

Tip Replacement 17

TIP SELECTOR CHART 17, 20

W

Working place overview 11

Working Temperature 13

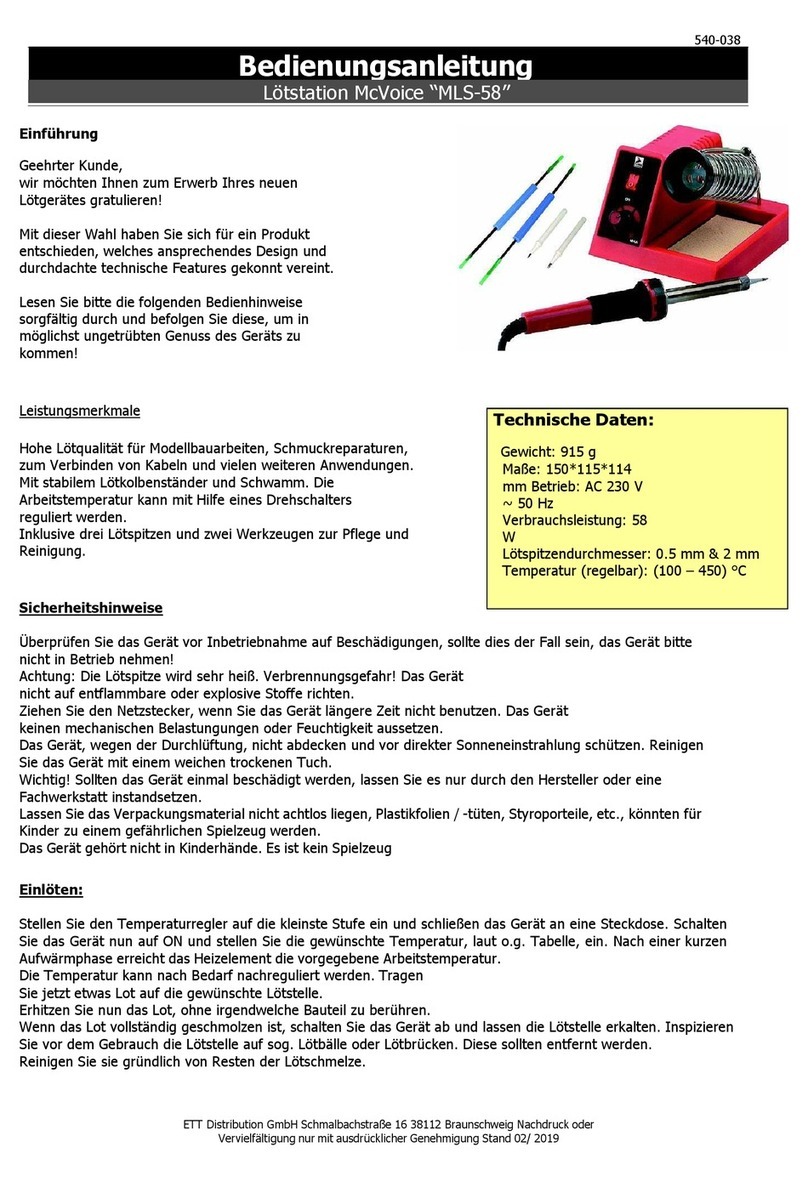

4ELVO E911D/E911A/E912A

Legend

Main switch

Potentiometer for electronic temperature adjustment

"SET" tumbler switch

"Heater/Stand-by" tumbler switch

Digital read-out (with E911D only)

"Heater" LED heating control lamp

Temperature resistant silicon-cable

Iron holder

Soldering iron with high-efficency ceramics heating element and removable sol-

dering tips (for tip selector chart see chapter 6.1)

clean-o-point®

Automatic patented soldering tips cleaning system.

The motorized moist sponge rollers are self-cleaning.

Round motorized sponge rollers

Stop/Go switch

Automatic for E911D and E911A

The self-cleaning motorized round sponges are only beginning to work when

soldering iron is taken out of holder.

Standard switch

Manual for E912A

Connector socket (24 V) for mains supply unit

1

2

3

4

5

6

7

8

9

10

11

12

13

14

ELVO E911D/E911A/E912A 29

INDEX

10

A

ACCESSORIES 21

ADDRESSES 20, 25

B

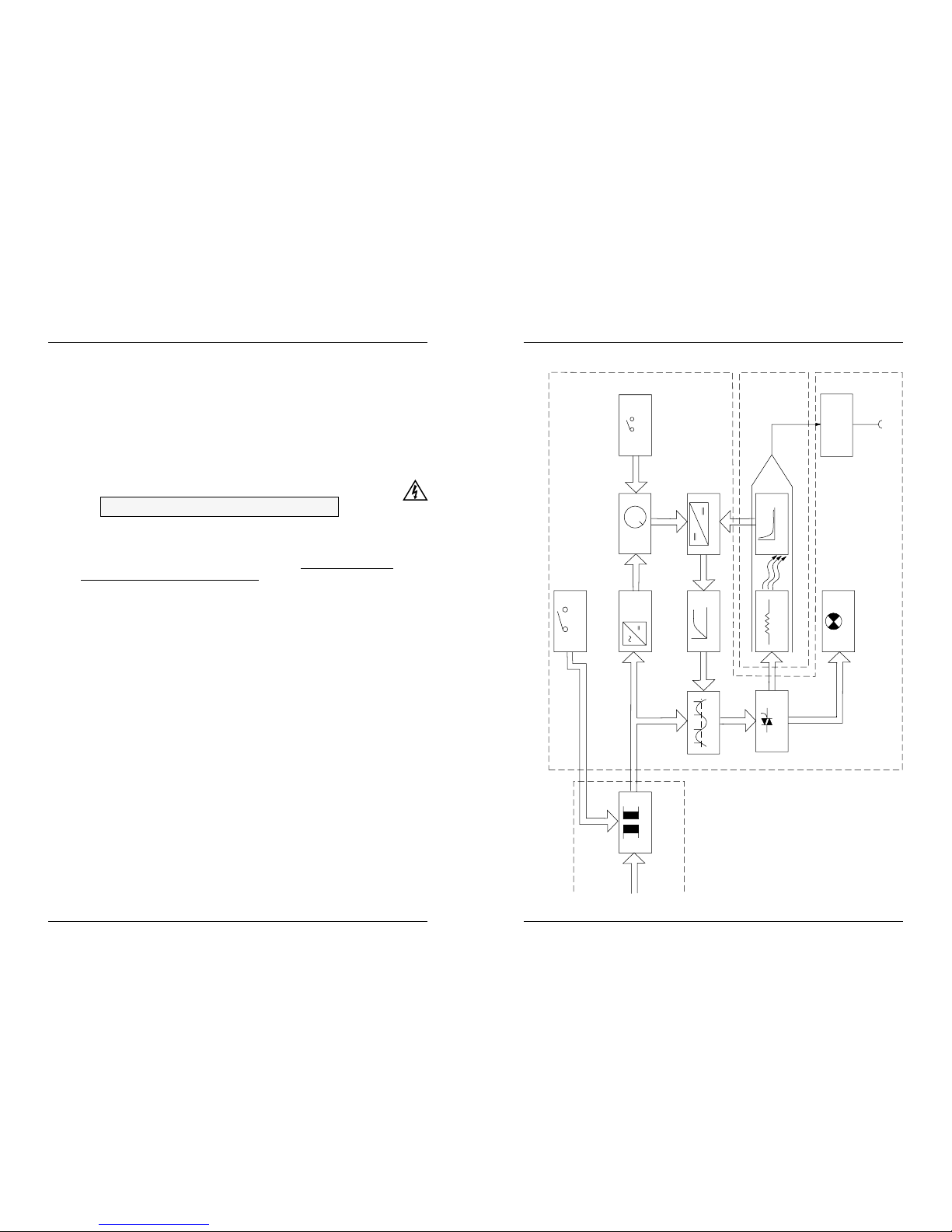

Block diagram 22, 23, 24

C

Care of tips 16

Clean-o-point 2, 4, 7, 12, 15, 16, 18

Cleaning 2, 4, 7, 15, 16, 18, 19

Components Assembly 12

D

Dimensioned drawing 8

E

ESD 10, 11, 12, 19

F

Features 7, 9, 12

G

General Cleaning 16

M

Maintenance 2, 15, 16, 18

Mains protection 10

MOS 7, 10, 13

O

Operation 2, 12, 13,

P

Product Features 7

R

Recycling 18, 28

ELVO E911D/E911A/E912A 5

CONTENTS

2

1PRODUCT DESCRIPTION 7

1.1 PRODUCT FEATURES ................................................................ 7

1.2 TECHNICAL DATA TYPE E911D / E911A / E912A .................... 8

1.3 DIMENSIONED DRAWING .......................................................... 8

3INITIAL OPERATION 12

3.1 GENERAL FEATURES ............................................................... 12

3.1.1 Feature Description ................................................................ 12

3.2 COMPONENTS ASSEMBLY ..................................................... 12

3.3 TEMPERATURE RANGE ........................................................... 13

3.3.1 Temperature Stability .............................................................. 13

3.3.2 Working Temperature ............................................................. 13

3.4 OPERATING INSTRUCTIONS ................................................... 14

3.4.1 clean-o-point®- How it works .............................................. 15

SAFETY CAUTIONS 9

2.1 SAFETY INFORMATION .............................................................. 9

2.2 SAFETY CAUTIONS .................................................................... 9

2.3 OPERATING PRECAUTIONS ...................................................... 9

2.4 MECHANICAL PRECAUTIONS ................................................ 10

2.5 ELECTRICAL PRECAUTIONS .................................................. 10

2.6 MAINS PROTECTION ............................................................... 10

2.7 THE ESD WORKING PLACE..................................................... 10

2.7.1 ESD - Working place overview .................................... 11

!

▲

!

▲

!

▲

!

▲

!

▲

!

28 ELVO E911D/E911A/E912A

RECYCLING

9

9.1 GENERAL RECYCLING

All individual components of the unit described in this manual have to be

treated according to the local regulations for recycling (batteries, metals

etc.) or for safe disposal ( printed circuit boards etc).

Pb-Sn

6ELVO E911D/E911A/E912A

6ACCESSORIES 21

6.1 SOLDERING TIPS ...................................................................... 21

6.2 SPARE SPONGES ..................................................................... 21

DIAGRAMS 22

7.1 BLOCK DIAGRAM E911D ......................................................... 22

7.2 BLOCK DIAGRAM E911A ......................................................... 23

7.3 BLOCK DIAGRAM E912A ......................................................... 24

7

8ADDRESSES 25

8.1 THE ELVO SALES-AND SERVICE SUPPORT .......................... 25

RECYCLING 28

9.1 GENERAL RECYCLING ............................................................ 28

INDEX 29

9

10

4MAINTENANCE 16

4.1 GENERAL CLEANING ............................................................... 16

4.2 CARE OF TIPS ........................................................................... 16

4.3 TIP REPLACEMENT AND DRESSING ..................................... 17

4.3.1 Commissioning of New Tips ............................................... 17

4.4 CLEAN-O-POINT®MAINTENANCE ......................................... 18

5SERVICING 19

5.1 RETURN FOR REPAIRS ............................................................ 19

5.2 CONDITIONS APPLYING TO SPARE PARTS........................... 19

5.3 SPARE PARTS LIST ................................................................... 20

ELVO E911D/E911A/E912A 27

Sweden Cyncronica AB

Tomtbergavägen 2

SE-14567 Norsborg

Tel ++46

/

853 194 300

Fax ++46

/

853 194 310

Filtronic AB

Box 2284

Hissgatan 2

SE-531 40 Lidköping

Tel ++46

/

510 208 10

Fax ++46

/

510 210 40

Taiwan KINGYOUP ENTERPRISES CO.

4F-16., No.16, Lane 609, Sec. 5

Chung Hsin Road

TW-Taipei County

Tel ++886

/

2 999 17 50

Fax ++886

/

2 999 17 47

UK Link Hamson Ltd.

5 The Gateway Centre

Coronation Road

Cressex Bus Park

GB-High Wycombe HP12 3SU

Tel ++ 44

/

1494 439 786

Fax ++ 44

/

1494 526 222

USA ELVO Division of

Zumbach Electronics Corp.

140 Kisco Avenue

Mount Kisco, NY 10549-1412

Phone ++1

/

914 241 7080

Fax ++1

/

914 241 7096

e-mail: [email protected]

ELVO E911D/E911A/E912A 7

ELVO Electronics Temperature Controlled Soldering Stations Type E911D /

E911A / E912A with integrated Automatic Soldering Tip Cleaning are the new

high performance standard for soldering equipment.

•Soldering of electronic components with electric or thermic

sensitiveness like C-MOS-circuits, FET-transistors, LCD-read-outs

•Soldering with high requirements to the soldering connection,

Military, Aviation and Space research

•Soldering with special solder (high and low melting) and connection

within exact tolerances

1.1 PRODUCT FEATURES

•clean-o-point®

,automatic soldering tip cleaner

•Accurate, stable temperature setting and control

•Variable temperature control

from 140-450°C (280-850°F) for digital version

from 150-400°C (300-840°F) for analog version

•Rapid heat up and instant recovery

•Digital read-out models

•Zero-voltage thyristor power switching

•Ultra-low tip leakage

•Comply with DOD and ML Specs

PRODUCT DESCRIPTION

1

Mains supply unit:

Suspend outside the working

zone using the assembly kit

provided for this way you can

avoid most efficently any elec-

tromagnetic radiation.

26 ELVO E911D/E911A/E912A

Hungary Ferrumino

Királi utca 9

HU-1042 Budapest

Tel ++36 1 379 0417

Fax ++36 1 379 0418

Nóniusz Kft.

Köbanyai u. 47/b

HU-1101 Budapest

Tel ++36 1 350 4326

Fax ++36 1 350 6459

Italy COFILI MACCHINE

Via Privata Schiatti

I-20057 Vedano al Lambro / MI

Tel ++39

/

39 49 20 15

Fax ++39

/

39 49 15 79

Japan CLAY & COMPANY LTD

4-6-8 Kawara-Machi, Chuo-Ku

Osaka Kagaku Seni Kaikin 3a

J-Osaka City

Tel ++81

/

6 204 43 55

Fax ++81

/

6 204 43 62

Korea SE HAN Electools Ltd.

B-508-1, Bundang Techno Park

Yatap-dong 148, Bundang KU

Songnam. Kyonggi-DO

Korea 463-070

Tel ++82

/

2 277 48 72

Fax ++82

/

2 272 93 73

Malaysia Broad-line Corp. SDN BHD

25, Jalan Radin Anum 2

Seri Petaling

MY-57000 Kuala Lumpur

Tel ++65

/

3 9057 0091

Fax ++65

/

3 9059 3273

Netherlands Unitek Eapro

Schootensee Dreef 21

NL-5700 AD Helmond

Tel ++ 31

/

4925 42 225

Fax ++ 31

/

4925 36 222

Norway KREPRO AS

Bonsdalsvn. 32

Postboks 233

N-2070 Raholt

Tel ++ 47

/

639 953 320

Fax ++ 47

/

639 953 933

Philippines MVENT

Market Venture Philippines Inc.

523 Santissima Trinidad St.

San Antonio Valley 6

PH-1707 Paranoque City

Tel ++63

/

2 825 97 84

Fax ++63

/

2 825 43 44

Singapore CHIP HUA EQUIPMENT

AND TOOLS PTE Ltd.

701 Sims Drive

#02-04 LHK Building

SG-Singapore 337383

Tel ++65

/

6298 30 88

Fax ++65

/

6297 00 29

Slovakia Mikrona Mkroelektronické

Prvky Systémy

Ku Bratke 1

SK-93505 Levice

Tel ++421/

366 310 430

Fax ++421/

366 312 497

Slovenia Atech Elektronika

Bac pri Meteriji 30

SL-6242 Materija

Tel ++386/

568 000 01

Fax ++386/

568 742 441

Spain Bielec Electronics S.L.

Portugal Carme Karr, 13

E-08034 Barcelona

Tel ++34

/

932 802 989

Fax ++34

/

932 804 113

8ELVO E911D/E911A/E912A

1.3 DIMENSIONED DRAWING

Power supply 115 or 230 V~, 50/60 Hz

Heater voltage 24 V

Power of iron (wattage) 55 W

Temperature range 140-450°C (280-850°F) digital

150-400°C (300-840°F) analog

Tip leakage < 2 mV

Standard Tip Type ET 4520 S 2.0

Dimensions See dimensioned drawing (below)

Weight Mains supply unit: 1.4 kg (3.09 lbs)

Soldering station: 1.1 kg (2.43 lbs)

1.2 TECHNICAL DATA TYPE E911D / E911A / E912A

Dimensions in mm (inch)

▲

98(3.86)

176(6.93)

▲

▲

▲

▲

91(3.58)

▲▲

189(7.44)

▲

ELVO E911D/E911A/E912A 25

ADDRESSES

8

8.1 THE ELVO SALES- AND SERVICE SUPPORT

Austria JI+C WarenvertriebsgesmbH

Theresianumgasse 13

A-1040 Wien

Tel ++43

/

1 812 27 39

Fax ++43

/

1 812 10 81

FAIR-TRADE

Mittelstrasse 63

A-2203 Manhartsbrunn

Tel ++43

/

224 583 9900

Fax ++43

/

224 583 9903

Belgium Arcoss BVBA

Bremheidelaan 8

B-2300 Tunrhout

Tel ++32

/

144 201 51

Fax ++32

/

144 225 51

Czech. ABE TEC s.r.o.

Republic Prumyslova 387

CZ-53003 Pardubice

Tel ++ 420

/

466 670 192

Fax ++ 420

/

466 655 127

Denmark Hin Horsen A/S

Langmarksvej 29

DK-8700 Horsen

Tel ++ 45

/

7625 90 90

Fax ++ 45

/

7625 90 91

France A. Jahnichen

38, Rue de Peupliers

F-92008 Nanterre Cedex

Tel ++33

/

1 47 86 84 40

Fax ++33

/

1 47 86 16 01

Germany Technisches Büro KULLIK &

Partner Vertriebs GmbH

Mettgenberg 3

D-58540 Meinerzhagen

Tel ++ 49

/

235 790 9510

Fax ++ 49

/

235 790 9595

Switzerland ELVO Electronics AG

(H.Q.) Hauptstrasse 93

CH-2552 Orpund

Schweiz

Tel ++ 41

/

(0)32

/

356 04 31

Fax ++ 41

/

(0)32

/

356 04 32

www.elvo.ch

Brütsch/Ruegger AG

Postfach

CH-8010 Zürich

Tel ++41

/

(0)44/736 63 63

Fax ++41

/

(0)44/736 63 60

EGLI, FISCHER & CO. AG

Gotthardstrasse 6

CH-8022 Zürich

Tel ++41

/

(0)44

/

209 81 11

Fax ++41

/

(0)44

/

201 22 75

Ernst Hess AG / SES-Sterling

Metzerlenstrasse 38

CH-4115 Mariastein

Tel ++41

/

(0)61

/

731 34 16

Fax ++41

/

(0)61

/

731 34 89

NEUTEC

Mettlenbachstrasse 29

CH-8617 Mönchaltorf

Tel ++41

/

(0)44

/

948 17 11

Fax ++41

/

(0)44

/

948 17 37

Simpex Electronic AG

Binzackerstrasse 33

CH-8622 Wetzikon

Tel ++41

/

(0)44

/

931 10 10

Fax ++41

/

(0)44

/

931 10 11

SIBALCO

W. Siegrist & Co. AG

Birmannsgasse 8

CH-4009 Basel

Tel ++41

/

(0)61

/

264 10 10

Fax ++41

/

(0)61

/

264 10 15

ELVO E911D/E911A/E912A 9

SAFETY CAUTIONS

2.2 SAFETY CAUTIONS

Heeding the recommendations within the present manual will allow

this apparatus to perform its highest capacity with maximum security.

2.3 OPERATING PRECAUTIONS

Following the instructions will enable high performance of the opera-

tions and ensure many long years of use.

Adhere to following suggestions :

• Handling the AC and other cables

When connecting and disconnecting the cables, take hold of

the plug section and not the cord. Pulling the cord may caused

damage to the cable and create hazards.

•Preventing electric shocks and fire hazards

If the cable is broken or damaged, or if the wires are exposed,

have it replaced !

•The buyer has to install this appliance in such a way, that the

security of the operator is guaranteed. Special care has to be

taken with features, which are not mounted in a rack or

similar.

2

▲

!

▲

!

!

2.1 SAFETY INFORMATION

Before installing and commissioning the soldering

station, please study this instruction manual carefully.

The enclosed measures and recommendations have to

be followed.

Do never touch the soldering tip when the appliance

is switched on (danger of burning)

When the the soldering station is open, it should always

be handled when not under power (mains connection

plugged off) and by authorized service personnel only

▲

▲

!

!

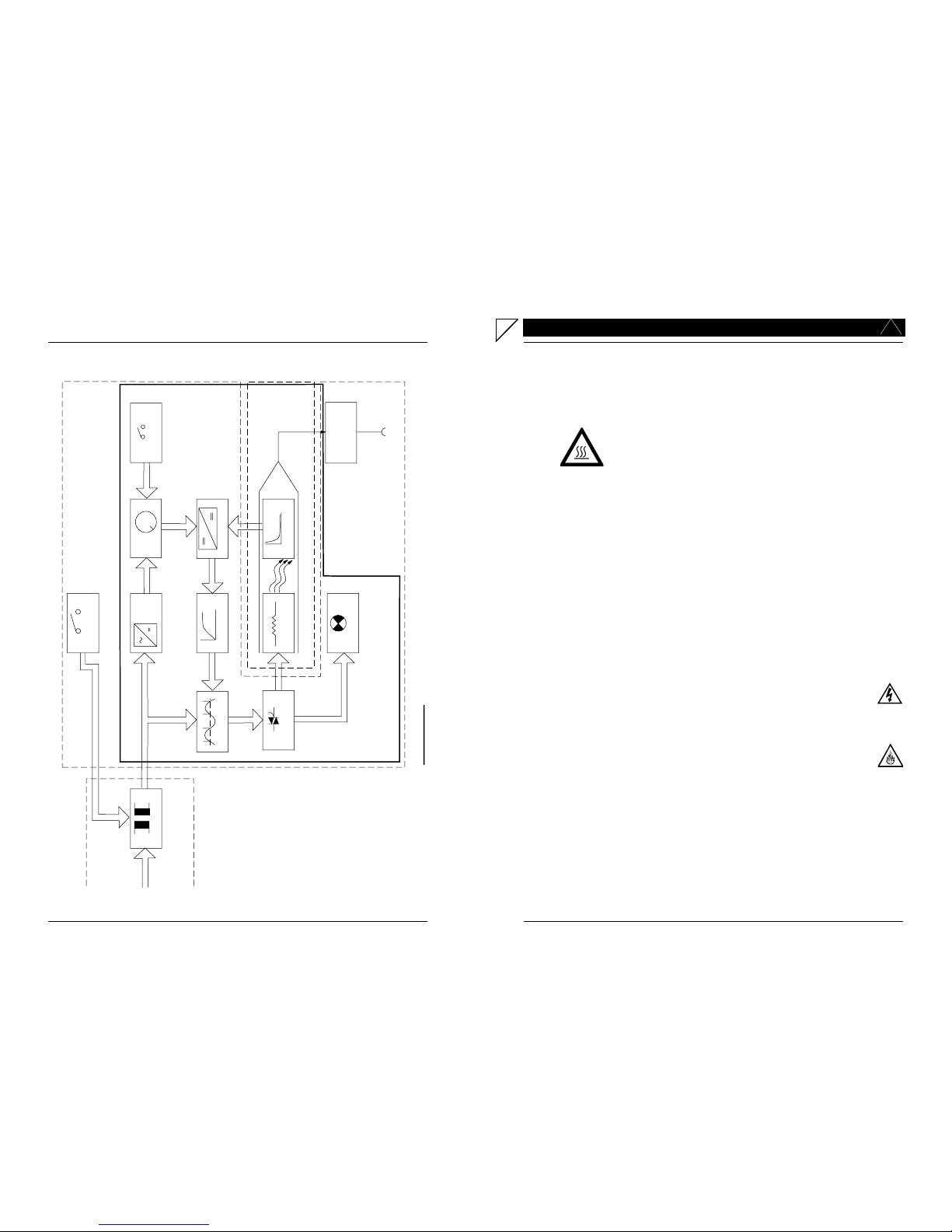

24 ELVO E911D/E911A/E912A

7.3 BLOCK DIAGRAM E912A

0

20

40 60

80

100 %

IST

Mains supply

Transformer

Separate mains transformer

Zero voltage detector

Switch

Heat display

Soldering iron

Heater element Temp. - Sensor

Controller Comparator

Standby

Nominal

Mains remote

control

Rectifier

Potential equalization

on housing and

working base

Connector

Tip point

Soldering station

This part is installed twice in Type 912A

10 ELVO E911D/E911A/E912A

2.6 MAINS PROTECTION

ELVO soldering stations comply with the requirements of DOD-STD-

2001-1, MIL-S-45743E, WS6536E and more. Electronic zerovoltage

thyristor switching protects voltage and currentsensitive units and com-

ponents against transient voltage spikes (computer, C-MOS compo-

nents). Soldering tip is grounded to ensure a voltage leakage of less

than 2 millivolt.

2.7 THE ESD WORKING PLACE

The ELVO technology includes a series of precautions for unproble-

matic soldering of MOS-electronic elements.

For working on high integrated MOS-elements with very fine struc-

tures like VLSI we recommend to build up a working place as men-

tioned below.

☞Please do not use the SL as service ground because it may

be connected with the neutral conductor and consequently

may not be free from disturbing voltages (e. g. unsymmetrical

three phase mains).

☞Please note that a short in a defective instrument can induce

a high pulse with voltage peaks of more than 100 V.

▲

!

2.4 MECHANICAL PRECAUTIONS

Avoid subjective procession !

To guarantee a long standing stability in accordance to international

rules, referring to security and reliability, all spare parts listed within

this manual must be replaced with original items only.

In case of a component failure, only the assembly of an original, recog-

nized component, will further the longevity.

2.5 ELECTRICAL PRECAUTIONS

AN ELECTRICAL SHOCK CAN BE FATAL !

It is at the own risk of the operator of an opened appliance, to under

stand the resulting danger of the above and to take the corresponding

measures to protect third parties. Memorize the dangerous areas, which

are exactly described in this manual. You should never touch simulta-

neously circuits and earth connections, during the installation or when

servicing.

▲

!

▲

!

ELVO E911D/E911A/E912A 23

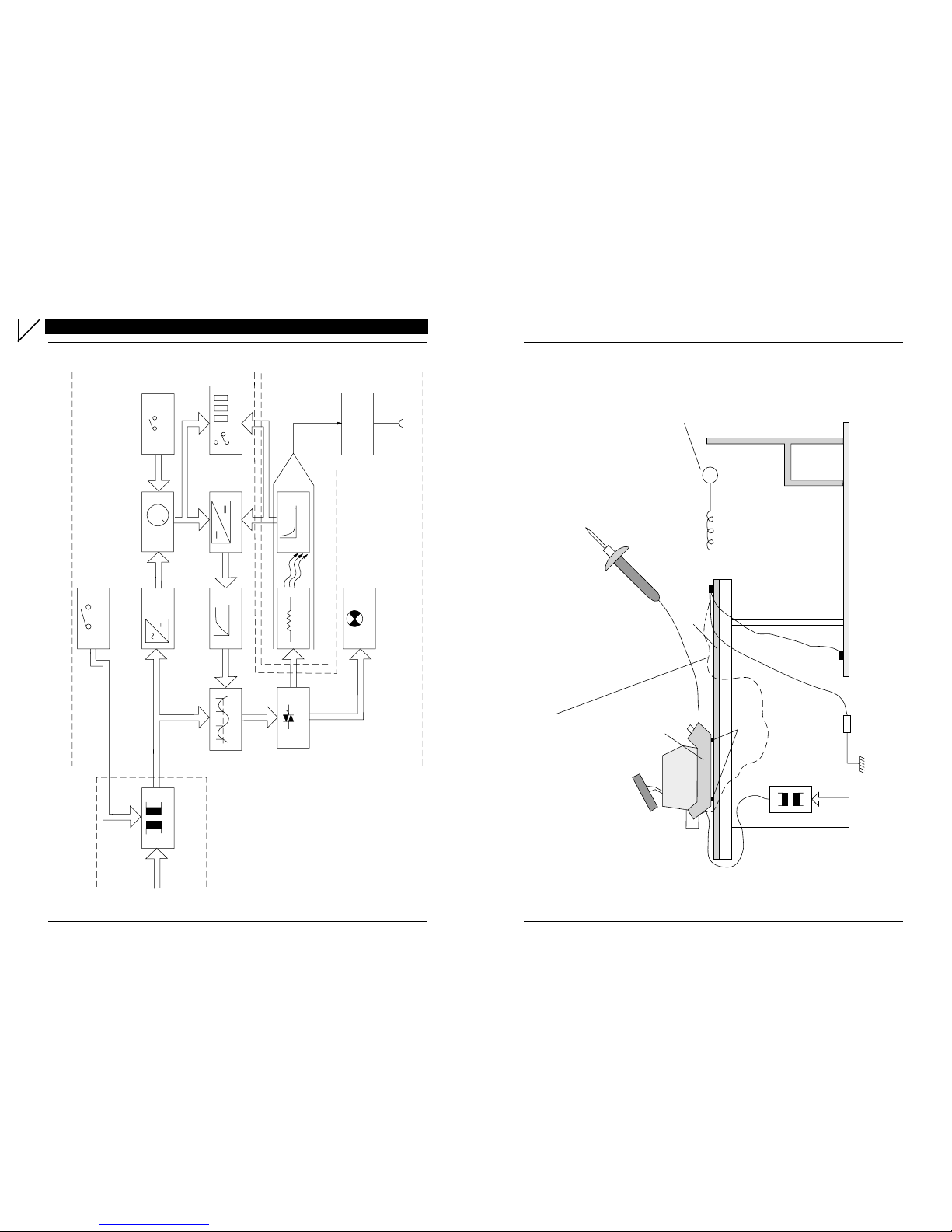

7.2 BLOCK DIAGRAM E911A

0

20

40 60

80

100 %

IST

Mains supply

Transformer

Separate mains transformer

Zero voltage detector

Switch

Heat display

Soldering iron

Heater element Temp. - Sensor

Controller Comparator

Standby

Nominal

Mains remote

control

Rectifier

Potential equalization

on housing and

working base

Connector

Tip point

Soldering station

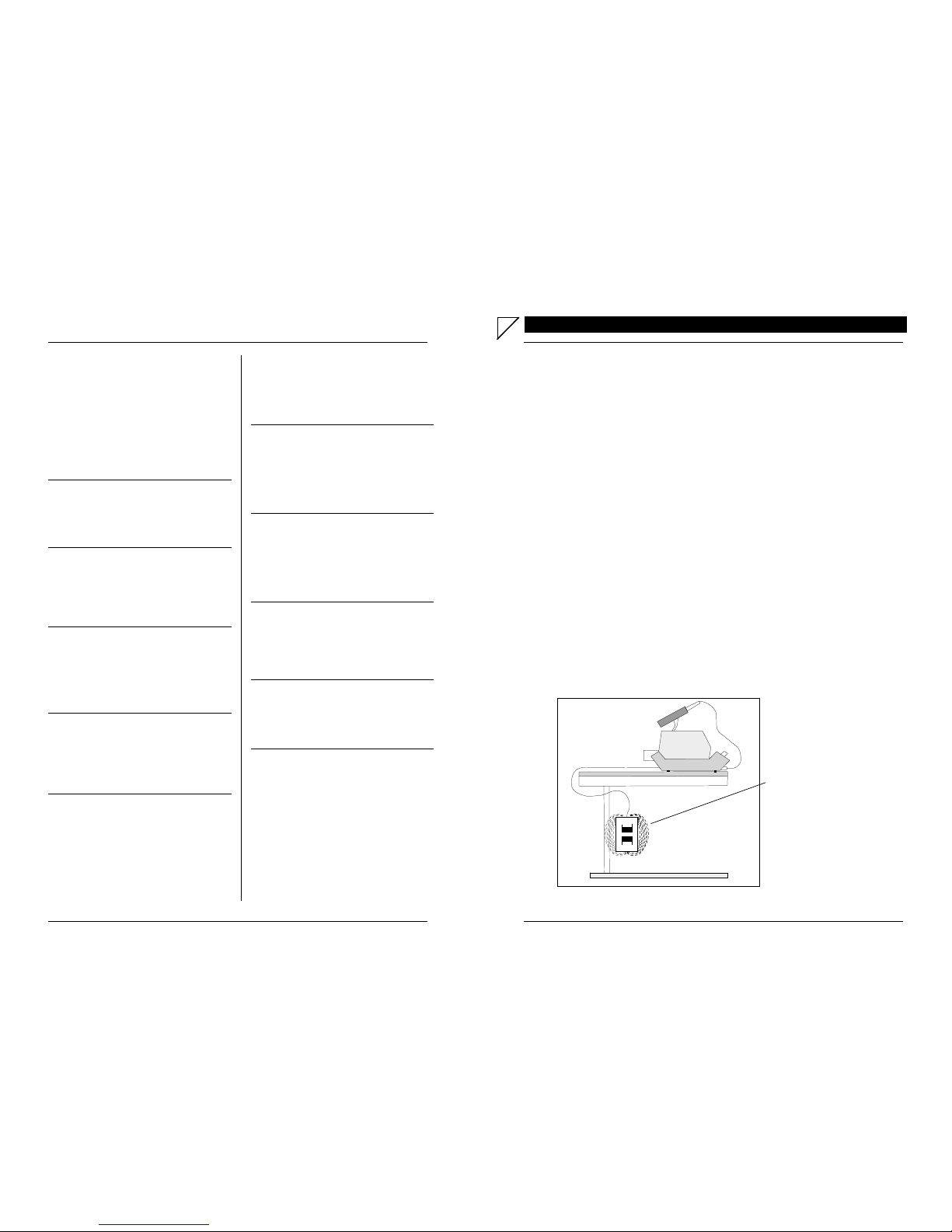

ELVO E911D/E911A/E912A 11

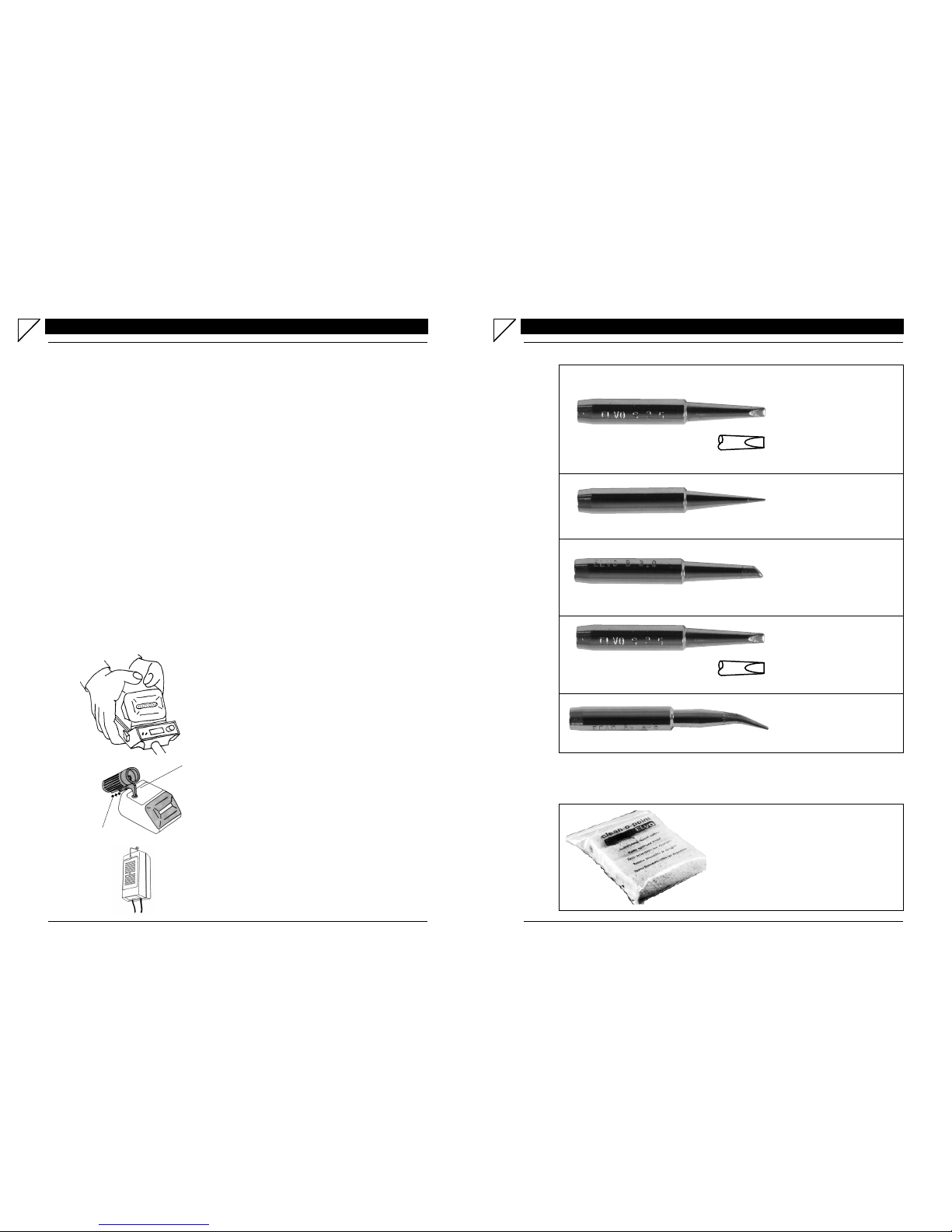

2.7.1 ESD - Working place overview

Clean-o-point

24 V AC approx. 100 kΩ

Soldering iron

Antistatic working floor (isoelectric)

Potential equalization

(workshop internal)

Rv

Mains supply

Mains transformer

Galvanic separation

Conducting rubber feet

approx. 10Ω- 2kΩ

Soldering station

ESD wristlet

Clean-o-point and soldering

station have the same potential

as the working base

Tip point

(same potential

as soldering station

and working base)

Hand lever (10 - 50 kΩ) thereby

no shock discharge of the user

(same potential is adjusted

automatically)

Antistatic working base

Additional potential equalization possible

22 ELVO E911D/E911A/E912A

DIAGRAMS

7

7.1 BLOCK DIAGRAM E911D

0

20

40 60

80

100 %

IST

Mains supply

Transformer

Separate mains transformer

Zero voltage detector

Switch

Heat display

Soldering iron

Heater element Te mp. - Sensor

Controller Comparator Nominal/Actual display

Standby

Nominal

Mains remote

control

Rectifier

Potential equalization

on housing and

working base

Connector

Tip point

Soldering station

12 ELVO E911D/E911A/E912A

INITIAL OPERATION

3

3.1 GENERAL FEATURES

•Soldering stations E911D / E911A / E912A

•clean-o-point®

•Soldering iron 55 Watt

•Iron holder

•Transformer

•Suspension device with hock screw

•Bag with spare sponges

•Copper cleaning brush

•Instruction manual

3.1.1 Feature Description

•Socket for potential equalization is installed on the rear side

(to avoid leakage of static charges)

•The soldering station is isolated from AC line by a transformer and

only 24 V AC isolated voltage is used to drive the heating element

•All housing parts are molded of high impact and high heat resistant

polycarbonate.

•The soldering iron is connected to the soldering station using a

temperature resistant and antistatic silicone rubber sheathed cable

with a five pin heavy duty plug with locking ring

3.2 COMPONENTS ASSEMBLY

Assembly:

Press the station and the clean-o-point®firmly

together with both hands.

Iron holder:

Insert until it snaps in (1).

With the models E911A and E911D, the Stop +

Go switch can be blocked (if desired) by pushing

the corresponding slide lever backwards (2).

1

2

Transformer with suspension device

!

ELVO E911D/E911A/E912A 21

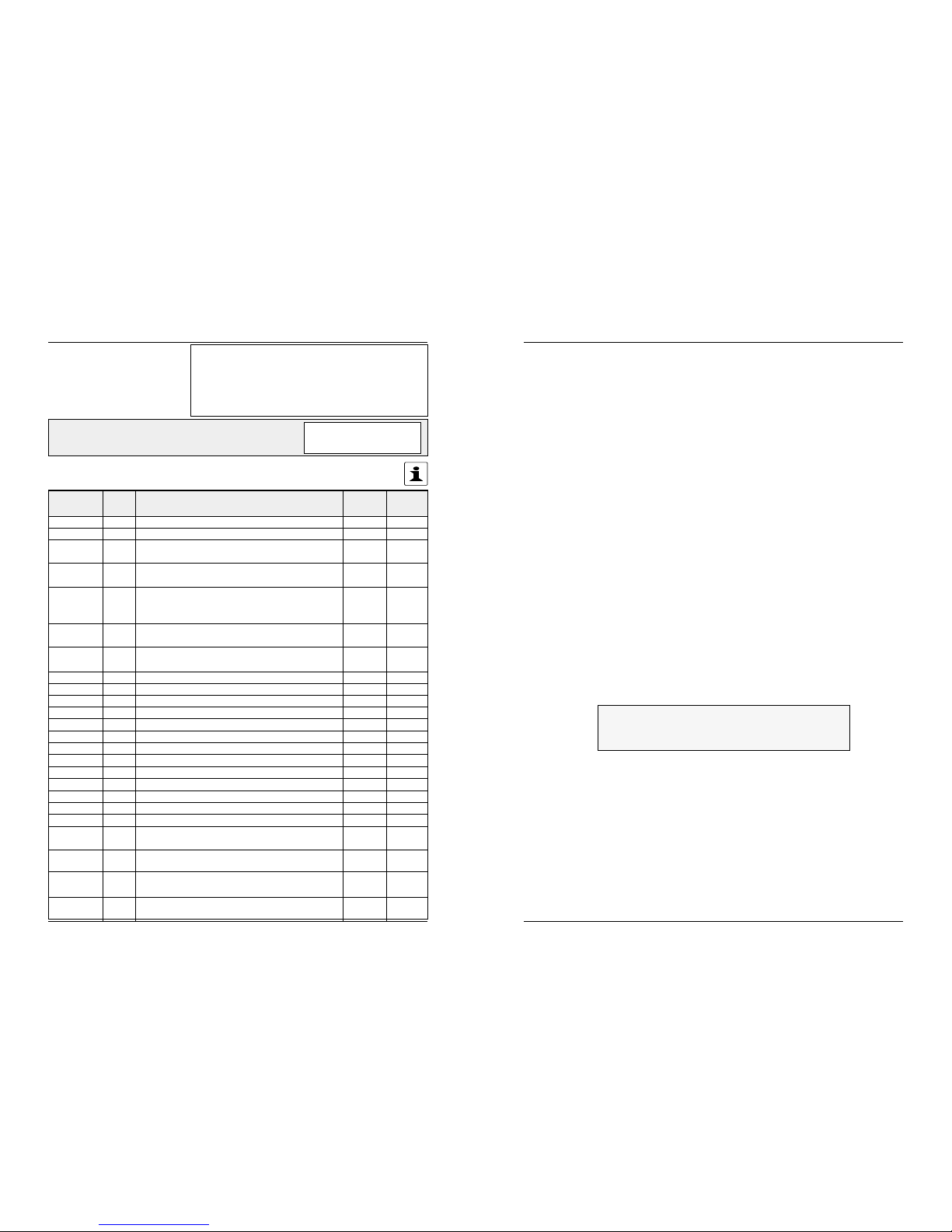

ACCESSORIES

6

Screw Driver Shape

Order number Dim.

4520 S 1.0 ≥1/32"

4520 S 1.5 1/16"

4520 S 2.0 5/64"

4520 S 2.5 3/32"

4520 S 3.0 1/8"

4520 S 3.6 ≤5/32"

4520 S 4.8 3/16"

Conical Shape

Order number Dim.

4520 C 0.3 1/64"

4520 C 0.6 .025"

4520 C 0.8 1/32"

Screw Driver Shape

Order number Dim.

4521 SL 1.2 1/32"

4521 SL 1.6 1/16"

4521 SL 2.0 5/64"

4521 SL 3.2 1/8"

Conical cranked

Order number Dim.

4521 CA 0.8 1/32"

Pointed Shape

Order number Dim.

4520 B 1.6 1/16"

4520 B 2.5 3/32"

4520 B 3.0 1/8"

4520 B 4.8 3/16"

Length = 46 mm (1.81")

Length = 46 mm (1.81")

Length = 46 mm (1.81")

Length = 52 mm (2.05")

Length = 52 mm (2.05")

6.2 SPARE SPONGES

6.1 TIPS

☞For SMT tips, ask for additional information

Spare sponges

8 pieces

Order number F3008

ELVO E911D/E911A/E912A 13

3.3 TEMPERATURE RANGE

ELVO soldering station delivers the full operating range of 140-450°C (280-

850°F) in the digital version and 150-400°C (300-840°F) in the analog ver-

sion without changing tip or heating element. The ceramics heating element

ensures the accurate temperature close to the surface of the tip. This results

in rapid heat up time of about 45 seconds and instant recovery.

3.3.1 Temperature Stability

Tip idling temperature stability is smaller than ±3°C (±10°F), corresponding

to MIL requirements. This is accomplished by embedding the thermocouple

sensing unit in the bevel of the heating element barrel. The measuring point is

nearest to the soldering tip. Only this method allows the closest possible moni-

toring of the temperature.

3.3.2 Working Temperature

A too low temperature will slow the solder flow; a high temperature will burn

the flux in the solder, which in turn will emit a heavy white smoke in a dry joint,

or damage the PCB. When the tip working temperature is set within the cor-

rect parameters suited to the particular solder being used a good joint is as-

sured. The most common solder alloys used in the electronic industry is 60%

tin, 40% lead (60/40). The tip working temperature of the solder is detailed

below and can vary from manufacturer to manufacturer:

Melting point: 188°C (370°F)

Normal operation: 270-320°C (518-608°F)

Production line operation: 320-380°C (608-716°F)

☞The temperature above 380°C (716°F) should not be used for normal

soldering functions but can be used for short periods of time when ex-

cessive heat is required.

Consider the recommendations of the manufacturers of

the diffrent components ! ▲

!

20 ELVO E911D/E911A/E912A

5.3 SPARE PARTS LIST Sender (Company name):

...................................................................................................

...................................................................................................

Send, ATTENTION to:

....................................................................

ORDER FORM Unit serial number:

(on the technical label)

For a quick response to your spare parts requirement kindly use the list below.

Just fill in the quantity of each part you require and send it to us - Thank you.

You will find the addresses at the end of this manual.

Part no.

ET4500 9 Soldering iron 55 W 1

ET4550 Heating element 1

ET4520 Soldering tips

Type S, B, C 1

ET4521 Soldering tips

Type SL, SS, CA 1

ET4522 Soldering tips SMD

Type SM8

SM14 1

Type SM16

SM23 1

Type SM0805

SM1206 1

Type SM5588 1

ET4523 SMD-Adapter 1

ET4524 Cleaning brush,Copper 1

ET3008 Spare sponges,(bag of 8 pieces) 1

ET3010 Front cover, black 1

ET3011 Tinbox, axe standards included 1

ET3012 8 Iron holder assembly 1

ET3015 Axe standards to tinbox ET3011 1

ET3016 Box ESD, black 1

ET3017 Box, green 1

ET3019 Holder 1

ET3020 Rocker switch 1

ET3021 Complete switch to "Stop & Go" 1

TR4200 Supply unit to E911D/A

230 VAC / 50 VA 1

TR4220 Supply unit to E912A

230 VAC / 100 VA 1

TR4111 Supply unit to E911D/A

115 VAC / 50 VA 1

TR4121 Supply unit to E912 A

115 VAC / 100 VA 1

Pos. Description Qty Order-

qty

14 ELVO E911D/E911A/E912A

3.4 OPERATING INSTRUCTIONS

E911D

1. Connect unit to mains.

Switch unit on. Green "Heater"

light will turn on.

2. The temperature will be read

on digital LED display.

3. Set nominal temperature by

holding "SET" switch

4. Rotate temperature control

knob until digital display reads

desired temperature (resolu-

tion ±1°)

5. Release "SET" switch. Tip

temperature is now rising

and being displayed.

6. During any work breaks,

move the switch on the

left to "Standby". When start-

ing work again, move it back

to "Heater" so that the tem-

perature last used will be re-

set automatically.

E911A / E912A

Connect unit to mains.

Switch unit on. Green "Heater"

light will turn on.

-

-

Rotate temperature control

knob to the desired tempera-

ture

-

During any work breaks,

move the switch on the

left to "Standby". When start-

ing work again, move it back

to "Heater" so that the tem-

perature last used will be re-

set automatically.

3

ELVO E911D/E911A/E912A 19

5.1 RETURN FOR REPAIRS

Should it prove necessary in the future to send the equipment back

for repair, please proceed as follows :

-enclose an exact description of the failure, including the

operational mode in which the failure or breakdown first occurred

-indicate clearly the person that should be contacted in your com-

pany and indicate the telephone and fax number

-for transportation, please use the original packing material (as far

it is still available). Should this no longer be available, please make

sure that the package protects the equipment adequately.

-assuming it is necessary and possible, send the entire equip-

ment back (soldering station and mains supply unit, accessories

etc.)

You can of course contact our service or sales departments by

telephone, telex or telefax. Our customer service will gladly

assist you. Addresses are listed in chapter 8

In order to assure best performance in function of your ELVO solder-

ing station, please consider following points. In case of a function

failure, please contact your next ELVO specialist.

5.2 CONDITIONS APPLYING TO SPARE PARTS

Only use original spare parts. Chapter 5.1 contains a list of standard

spare parts.

To use products from another source could harm

•safety,

•reliability and

•performance.

SERVICING

5

ELVO E911D/E911A/E912A 15

3.4.1 clean-o-point®- How it works

The clean-o-point®cleans tips with a remarkable self-cleaning motorized

wiping system that keeps tips clean, prolongs tip life, removes and collects

excess solder. Fast 1 second cleaning with damp sponges means no tem-

perature loss at the tip, no cold solder points to destroy PC boards.

☞see also chapter 4.4 - clean-o-point ®maintenance

Pb-Sn

▼

18 ELVO E911D/E911A/E912A

4.4 clean-o-point® MAINTENANCE

1. Before using for the first time, wash sponges carefully under

running water.

2. Rinse sponges under running water once only before begin-

ning the shift, and wring well. If the soldering tips are very

fine, wring more thoroughly. The sponges retain uniform hu-

midity for about 8 hours.

3. Do not wet the sponges by pouring water over them

in the unit. Overly wet sponges will cause excessive

cooling of soldering tips.

4. Replace sponges when incrusted with rosin (after about

1 month of all-day shifts).

☞Sponges are much cheaper than soldering tips !

5. Empty solder container before starting each 8-hour shift.

Wash and wring sponge rollers well.

☞Collect solder for recycling !

6. To clean the soldering tip, insert it with a steady movement

between the wet rotating sponge rollers. Cleaning takes less

than 1 second !

7. Soldering tips cleaned with clean-o-point®have a service

life

up to 10 times longer than tips cleaned with common flat

sponges.

▲

!

Pb-Sn

16 ELVO E911D/E911A/E912A

MAINTENANCE

4

▲

!

▲

!

4.1 GENERAL CLEANING

The outer case of iron or station may be cleaned with a damp cloth

using little amounts of liquid detergents.

☞Never submerge the unit in liquid or allow any to enter

the case of the station.

Never use any solvent to clean the case.

(Decomposition of the writing and / or deformation on

the housing)

4.2 CARE OF TIPS

The tips supplied are iron plated copper and if used properly will

give a long life.

1. Always keep tips tinned before switching off or storing for a

long period of time; Wipe tip using clean-o-point.

Caution with long hair!

2. Don't keep iron set at high temperature for long periods

as this will break down the surface of the tip.

3. Never clean tips with abrasive materials or files.

4. If any oxide film is formed, this can be cleaned with the clean-

ing brush, isoproyl alcohol or equivalent, and then imme-

diately reheat and retain the tip to prevent oxidation of

wettable surface.

5. Remove the tip and clean every twenty-four hours or at least

once a week. Remove any loose build up in the barrel.

6. Do not use fluxes containing chloride or acid.

Use only rosin or activated resin fluxes.

7. Do not use any compound or antiseize materials on

the wettable surface.

▲

!

ELVO E911D/E911A/E912A 17

4.3 TIP REPLACEMENT AND DRESSING

Tip can be replaced simply by unscrewing the knurled nut barrel

assembly. The station must be switched off and allowed to cool during

this operation, as damage may result if the system is left on

without the tip inserted. After removing tip, blow out any oxide

dust that may have formed in the tip retaining area of the barrel. Be

careful to avoid getting dust in your eyes. Replace the tip and screw

back the retaining knurled nut barrel assembly using only firm hand

pressure to tighten. Pliers should only be used to tighten the nut to

avoid burning your fingers.

Wear protection spectacles!

☞Care should be taken not to overtighten as this

would damage the heating element.

4.3.1 Commissioning of New Tips

☞The following procedures should be followed when a new

tip has been installed at any time. It will give the tip much

longer life.

1. Set temperature to the minimum, then switch power to "ON".

2. After approx. 1 minute set temperature to 200°C (392°F).

(Beginning of scale)

3. Tinn the surface with resin core solder containing

collophonium after having reached 200°C (392°F).

4. Set to desired temperature and let it heat for approx. 5

minutes.

5. Ready for use after reaching the present desired tempera-

ture.

☞Important: Remove tip and clean daily if a new tip is

installed and removed any loose build up

in the barrel !

(For Tip Selector Charts, see chapter 6 !)

▲

!

▲

!

This manual suits for next models

2

Table of contents