Type ACE97

2

To avoid such injury or damage,

provide pressurerelieving or pressure-

limiting devices (as required by

the appropriate code, regulation or

standard) to prevent service conditions

from exceeding limits.

Additionally, physical damage to the

valve could result in personal injury and

property damage due to escaping fluid.

To avoid such injury and damage, install

the valve in a safe location.

Clean out all pipelines before installation of the valve

and check to be sure the valve has not been damaged

or has collected foreign material during shipping. For

NPT bodies, apply pipe compound to the external pipe

threads. For flanged bodies, use suitable line gaskets

and approved piping and bolting practices.

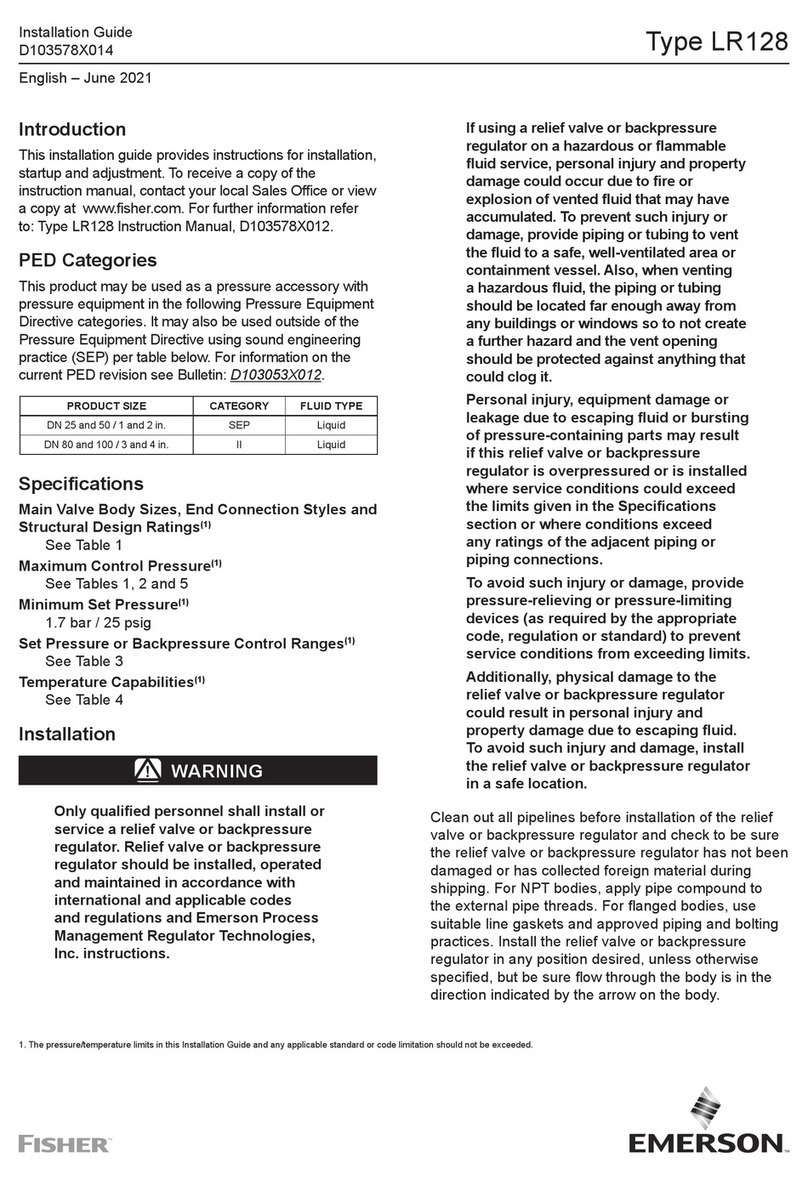

The valve must be mounted so the actuator case is

horizontal. The valve should be mounted above the

tank. For connections are required: a) blanketing

gas supply to the valve, b) vapor recovery/process

connection (vent), c) system tank connection and d)

sensing line to the tank.

Overpressure Protection

The recommended pressure limitations are stamped

on the valve nameplate. Some type of overpressure

protection is needed if the actual inlet pressure

exceeds the maximum operating outlet pressure

rating. Overpressure protection should also be

provided if the valve inlet pressure is greater than the

safe working pressure of the downstream equipment.

Valve operation below the maximum pressure

limitations does not preclude the possibility of

damage from external sources or debris in the line.

The valve should be inspected for damage after any

overpressure condition.

Startup

Slowly open the tank and sensing line shutoff valves

(between the Type ACE97 and the tank). A tank vapor

space pressure gauge should be installed and visible.

Slowly open the inlet shutoff valve (to the pad valve)

and leave it fully open.

Adjustment

The setpoint of this unit if factory set. If an adjustment

is to be made, it should be made in small increments

while the unit is controlling tank pressure. It is difficult

to make field adjustments due to the slow changes in

tank pressure.

Taking Out of Service (Shutdown)

!

WARNING

To avoid personal injury resulting from

sudden release of pressure, isolate

the valve from all pressure before

attempting disassembly.

Parts List

Key Description

16* O-ring

17 Bonnet (pad valve)

18 Body (pad valve)

19* O-ring (DN 25 and 50 / NPS 1 and 2pad valves only)

20 Round-Head Machine Screw (DN 25 and 50 / NPS 1 and 2

pad valves only)

21 Lock Washer (DN 25 and 50 / NPS 1 and 2 pad valves only)

22 Plug (DN 25 and 50 / NPS 1 and 2 pad valves)

23* O-ring (DN 25 and 50 / NPS 1 and 2 pad valves)

24* O-ring (DN 25 and 50 / NPS 1 and 2 pad valves)

25 Piston (main valve, DN 25 and 50 / NPS 1 and 2 pad valves)

26 Spring (Pad Main Valve)

27 Gasket (bonnet, pad valve)

28 Lock Washer

29 Hex-Head Machine Screw

31 Hex Nut

34 Spring Shim (DN 25 / NPS 1 pad valve)

35 Lower Cage (DN 25 and 50 / NPS 1 and 2 pad valves)

36 Spring (pad pilot valve)

37 Piston (pad pilot valve)

38* Diaphragm (pad and depad pilot valves)

39* O-ring

40 Upper Cage (DN 25 and 50 / NPS 1 and 2 pad valves)

41* O-ring

42 Poppet (pad pilot valve)

46 Seal Bushing

49 Spring Guide (pad valve)

50 Hex-Head Cap Screw

51 Lock Washer

52 Cage (DN 15 / NPS 1/2 pad valve)

75 Stem

76* O-ring

77 Cage (depad main valve)

78 Hex-Head Machine Screw

79 Lock Washer

80 Seal Retainer

81* Stem Seal

82* O-ring

83 Steal Retaining Plate

84 Spring (depad main valve)

85 Spring Guide (depad main valve)

86 Retaining Ring (1 and 2 NPT depad main valves)

87 Bonnet

88* O-ring (1 NPT depad main valve)

89 Retaining Ring

90 Cap (1 NPT depad main valve)

91 Body (depad main valve)