6

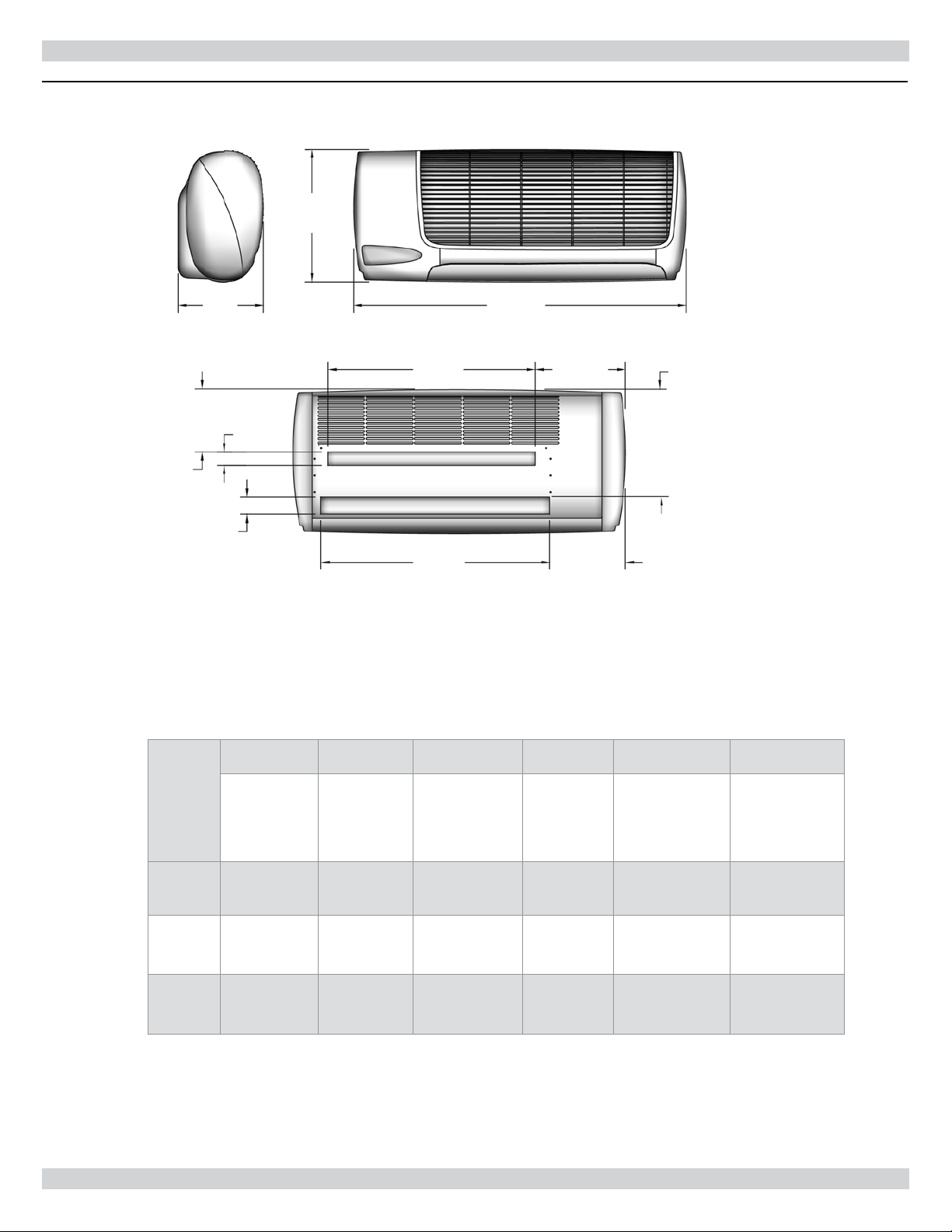

GENERAL PRODUCT INFORMATION

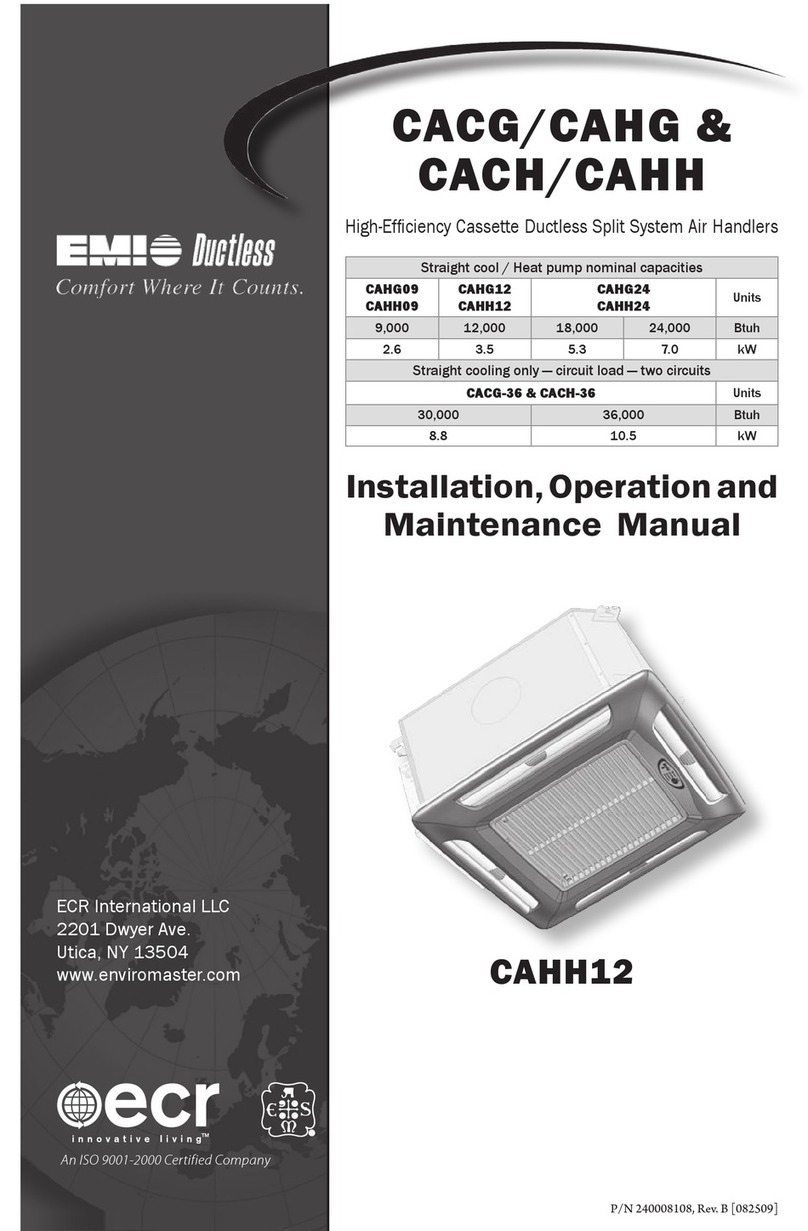

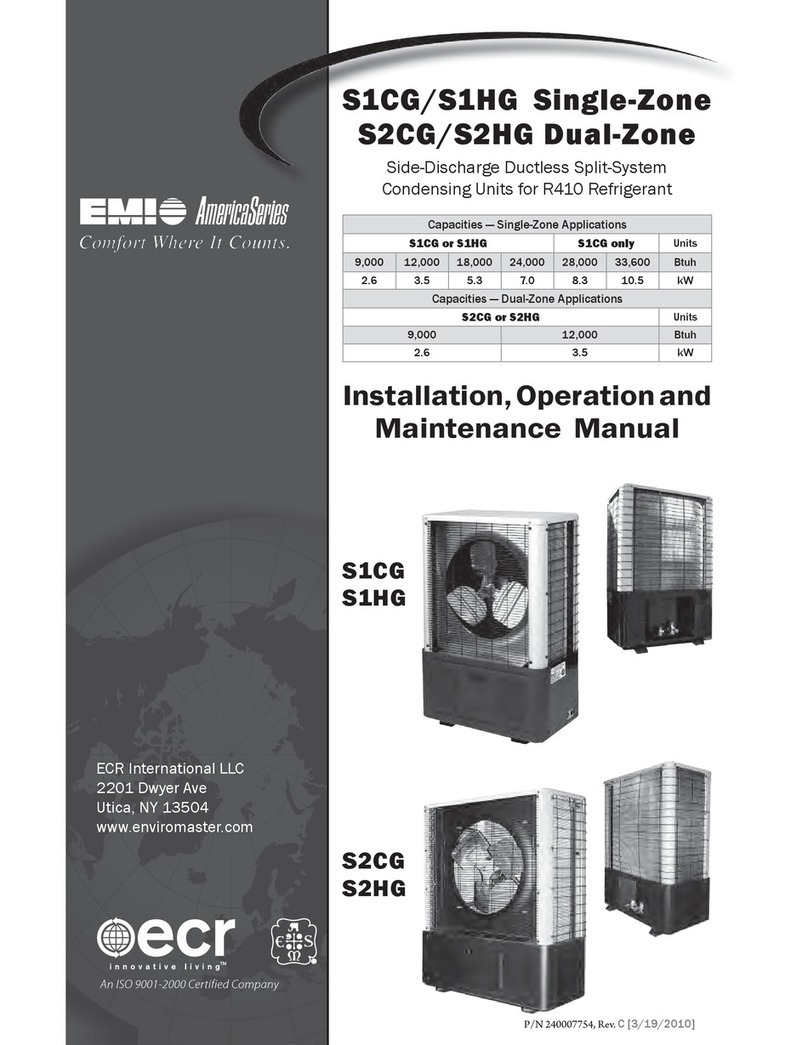

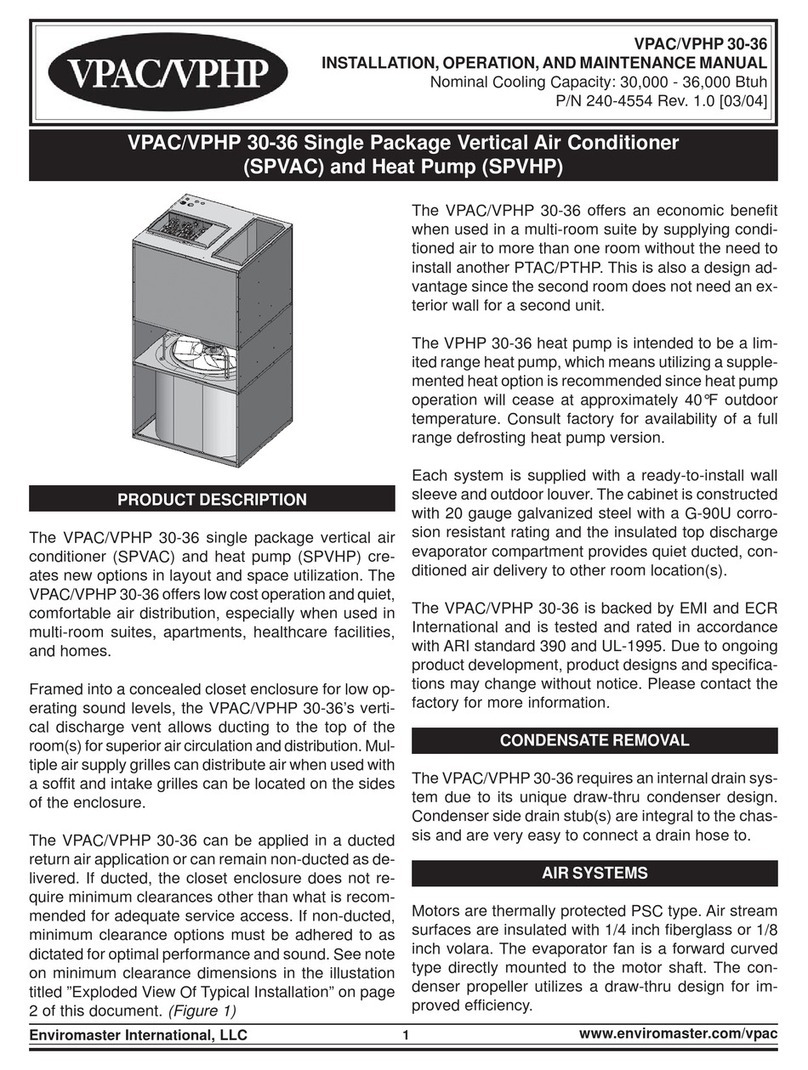

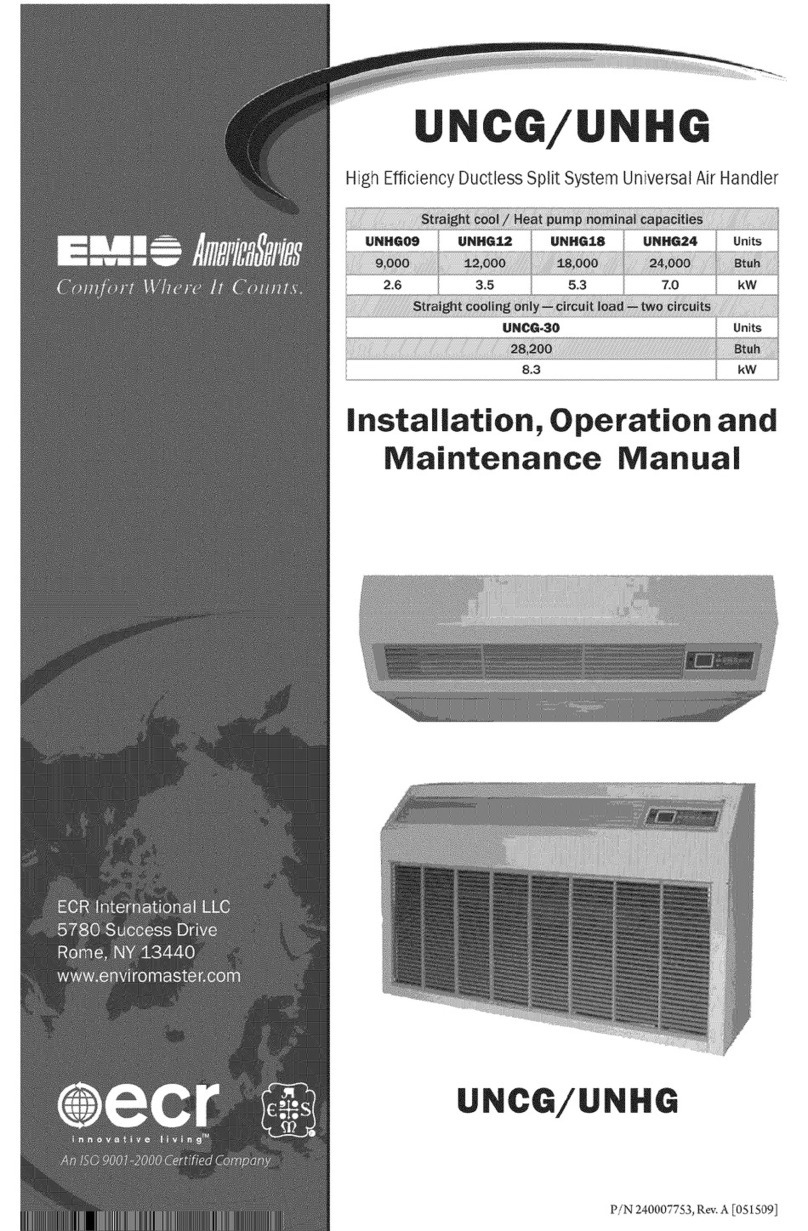

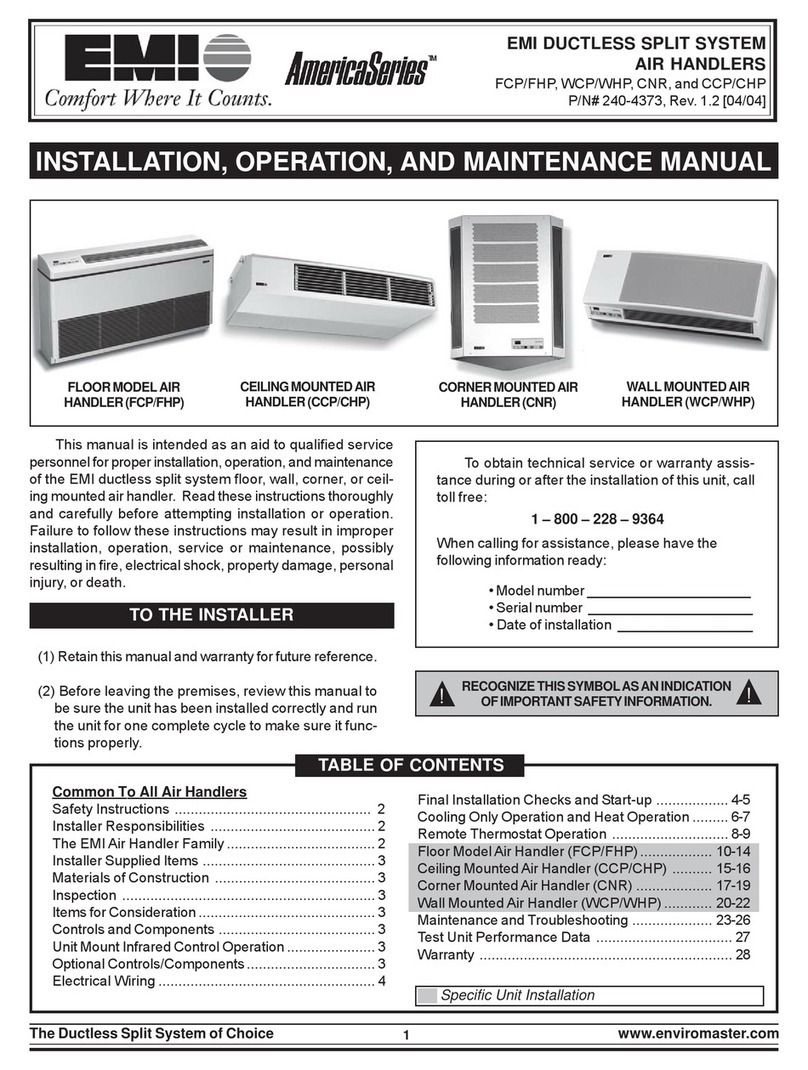

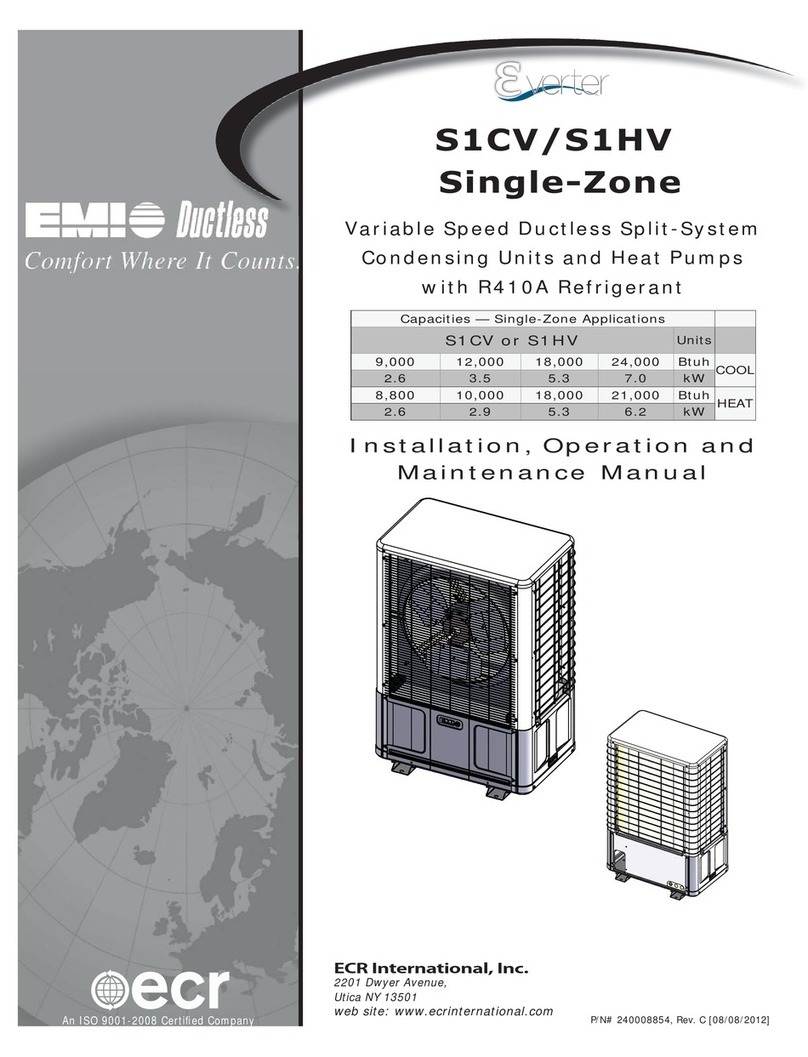

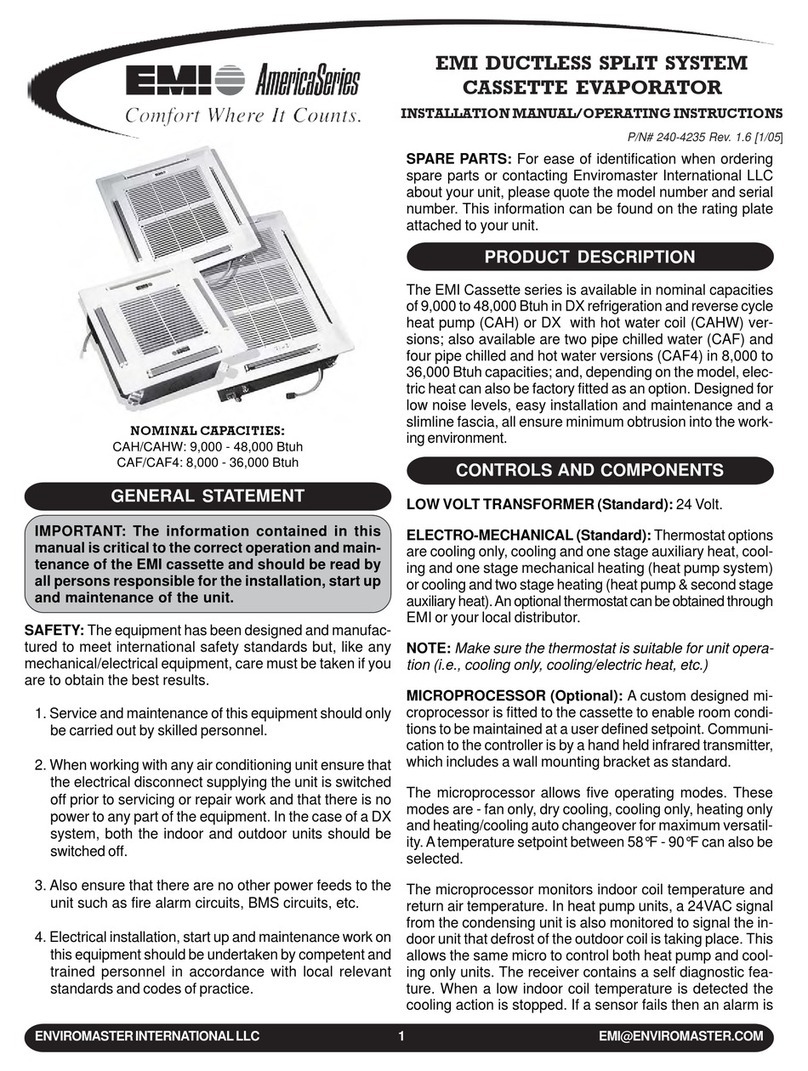

Product Description

Controls And Components

(Factory-Installed Or Supplied)

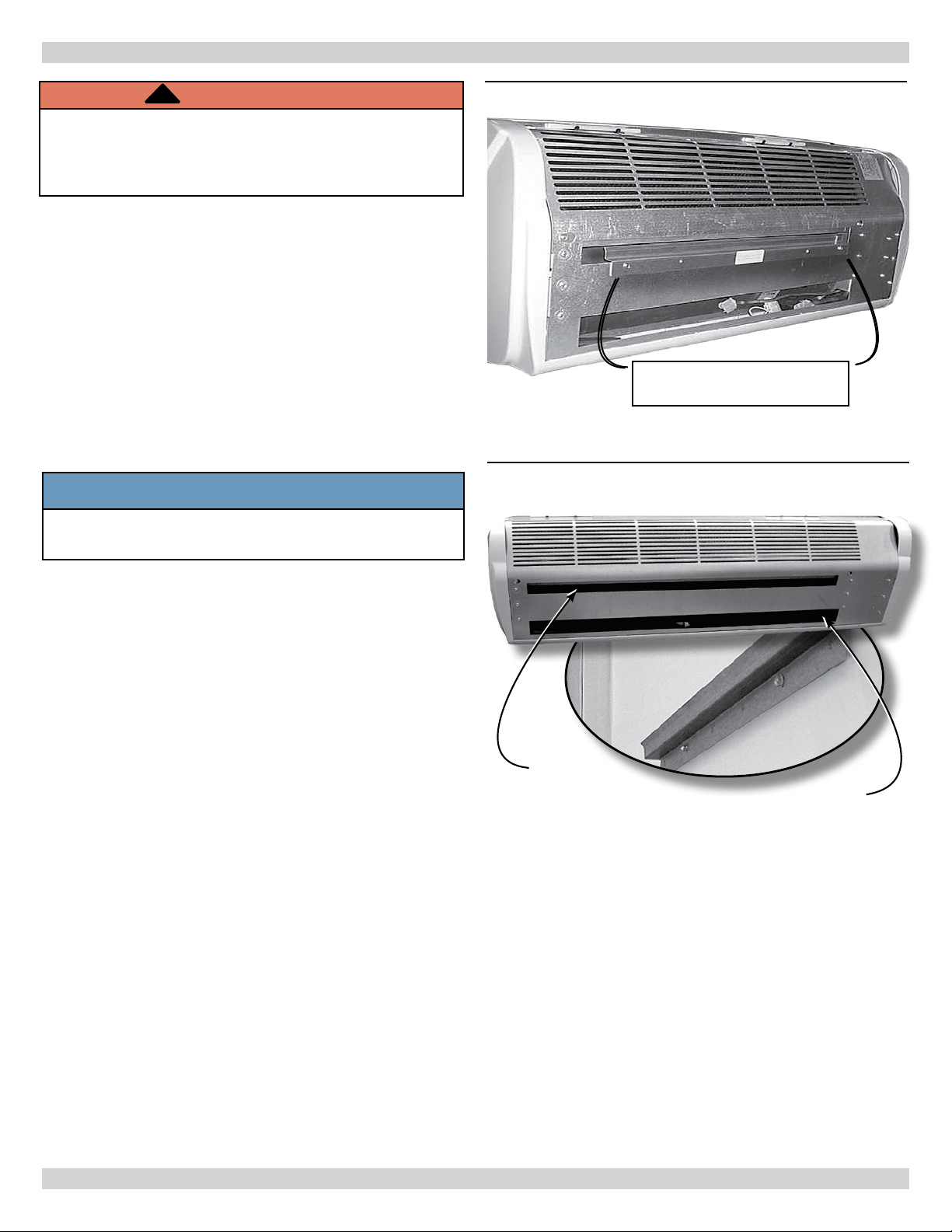

Cabinet Features:

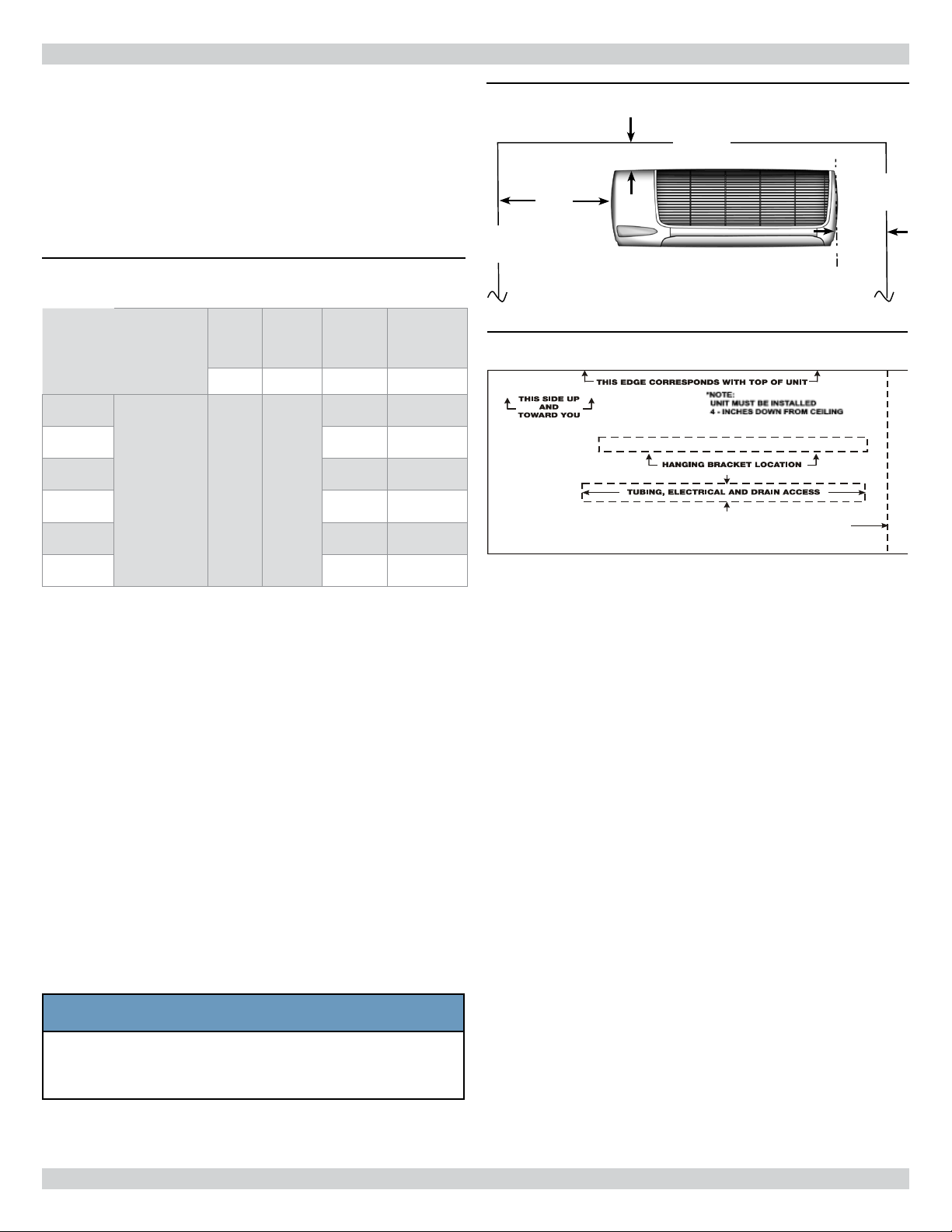

Optional Equipment

Installer Supplied Items

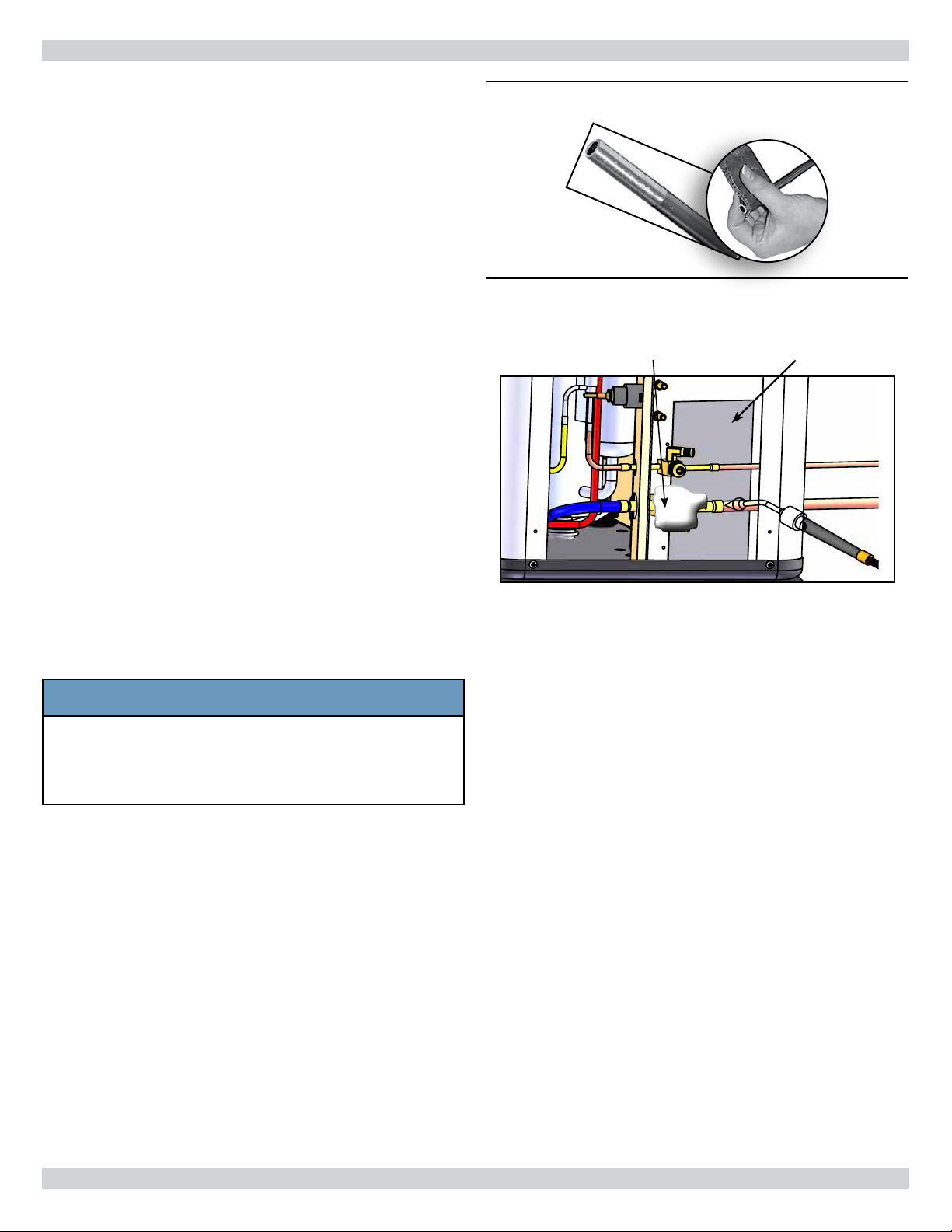

Both tubes need

to be insulated.