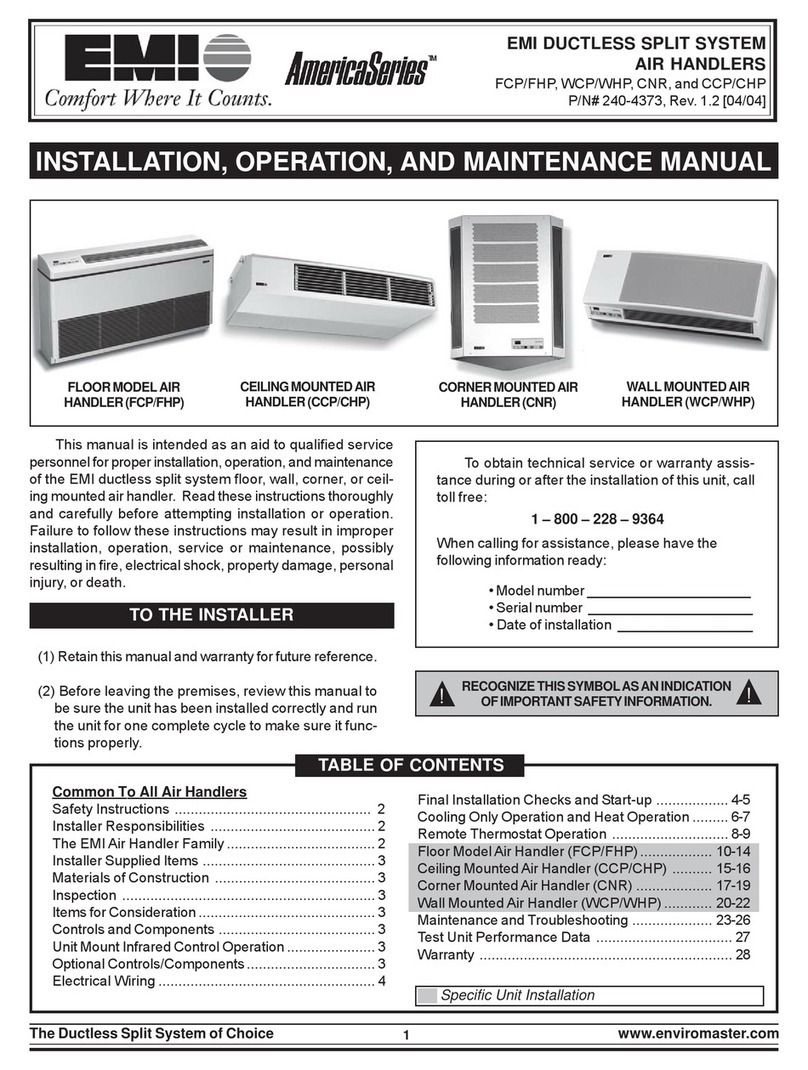

+ The AmericaSeries UNCG/UNHG

is available as a (Dx) direct expansion

straight cool and heat pump.

+ It offers a contemporary design in a

ductless type air handlers and combines

attractive appearance with high eNciency

conditioning for small to medium size

commercial or residential spaces.

The UNCG/UNHG is equipped with

unit mounted infrared compatible con-

trols which also supports 24V remote wall

thermostat operation. Optional handheld

remote is available.

Heat pump models provide up to

23,800 Bmh of cooling and 20,800 Btuh

of heating. Electric heat options are

available for up to S kW of supplemental

heat.

This American-made air handler of+

fers ease of installation, operation, and

service.

it can be matched with EMI's:

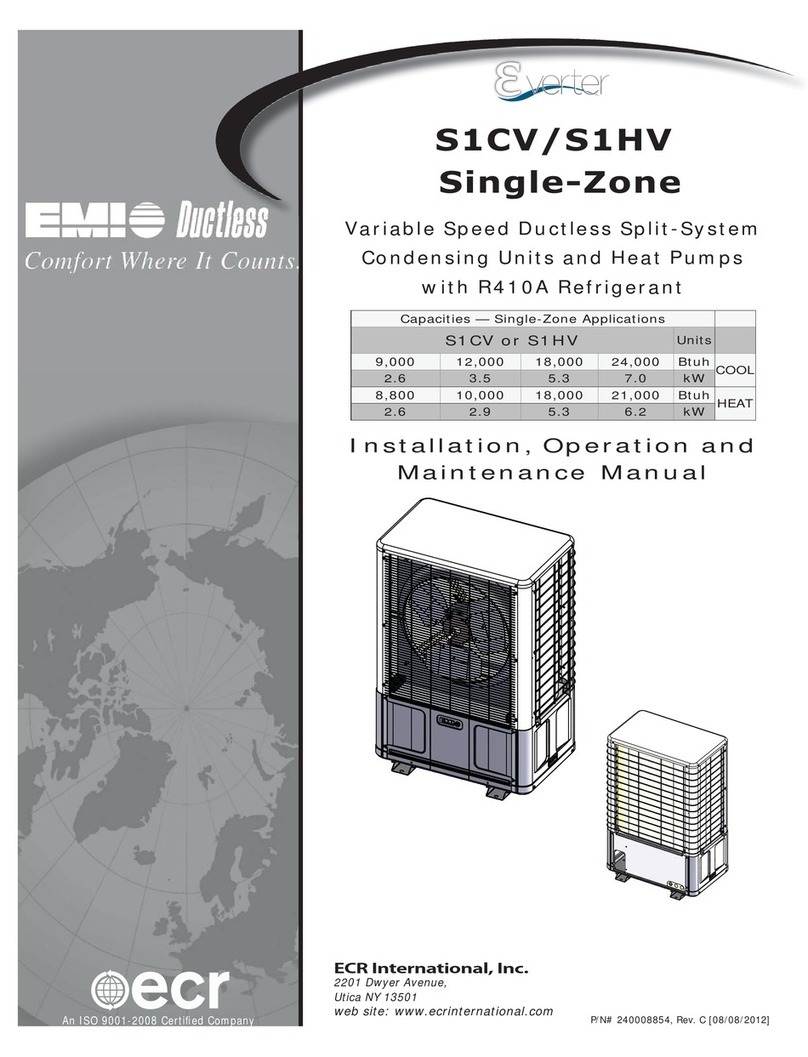

- Single-zone condensing units --

S1CG/SIHG 09-24 and $1CG 30.

Controls and components

{Factory-instaRed or supplied)

+ Large LCD Bacldit Display

Single unit-mounted control package,

configurable to either unit mount or re-

mote wall thermostat operation, increas-

ing installation flexibility.

Urlit mourfl: control -- Ifthe control is

configured for unit mount control DO

NOT connect a wall thermostat to the

unit. See Figure 27, Page 26+

+ Unit control can be used in cooling only,

cooling with electric heat, heat pump, or

heat pump with second stage electric heat

applications.

Operational range set point temperature

adjustable between SS°F and 90°F in one-

degree increments+

+ Infrared-compatible controller allows use

of optional IR hand held controller.

11111111111111111

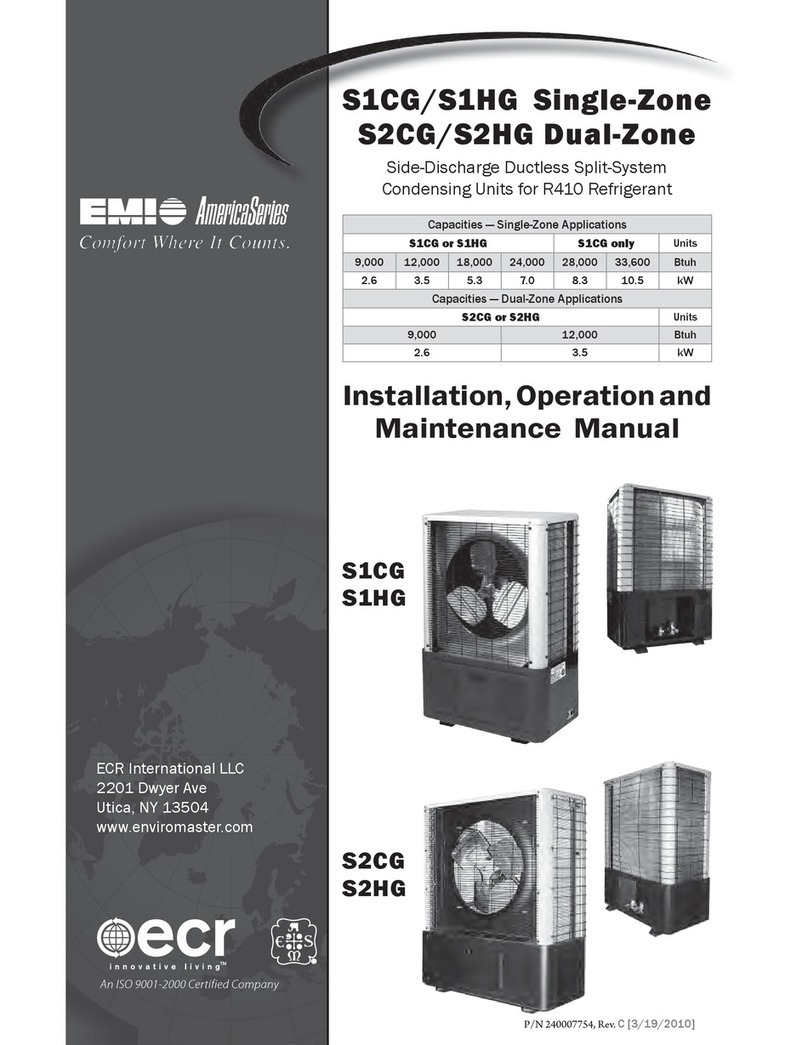

S2CG/S2HG side discharge.

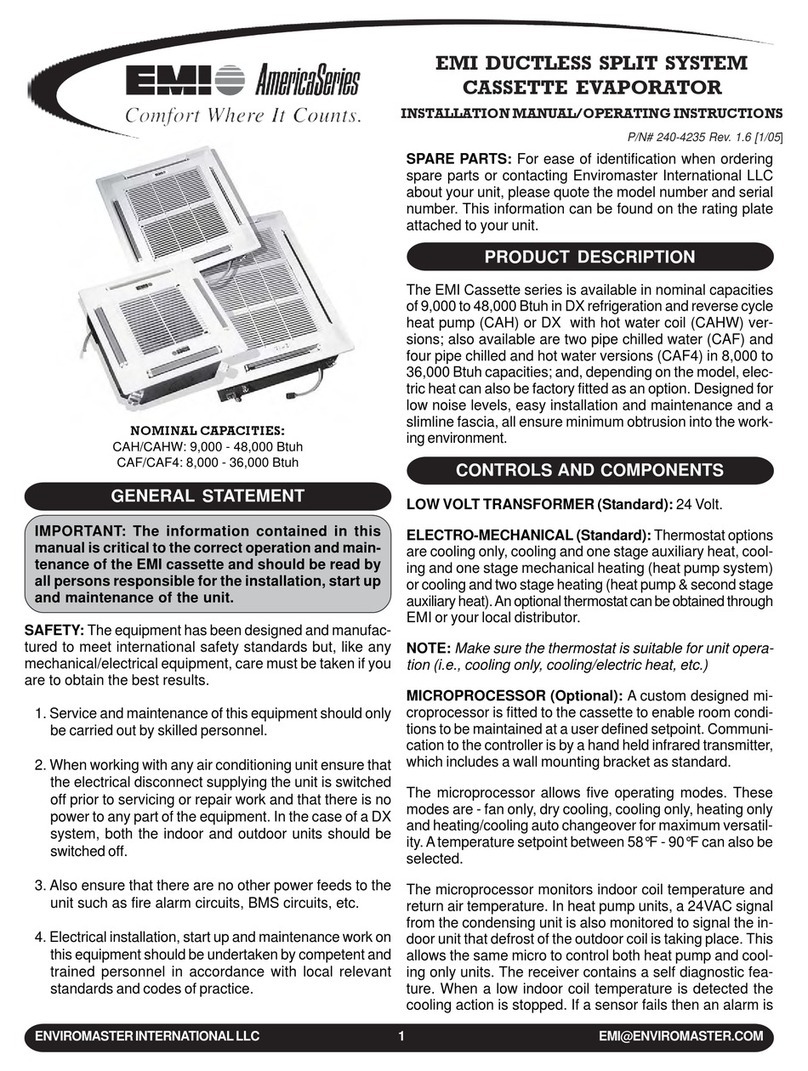

- Multi-zone, top discharge condens-

ing units -- T2CG/T2HG, T3CG/

T3HG, or T4CG/T4HG+

All EMI air handlers are backed by En-

viromaster international LLC and are

tested and rated in accordance with AR1

standards 210/240 and UL 199S+

Dual-zone condensing units -- +++++++++++++++++Unit-mounted controls are fhlly l_nc-

+++++++++++++++++tional without the handheld remote.

+ Operation modes include Heat, Cool,

Dry, Fan and Auto Change-over+

Fan Operation - Auto/On+ High or Low

speed fan

Fan Purge - Fan remains on for 60 sec-

onds after Heat/Cool call is dropped for

improved eNciency (Auto mode only)

Room air sampling -- Selectable time

intervals ensure the fan will cycle on peri-

odically, in Auto Fan Mode to help elimi-

nate room temperature stratification+

•Selectable Fahrenheit (°F) orCelsius (°C)

temperature scale.

•Drymode- Operates coolingand electric

heat simultaneously to remove humidity.

Optional electric heat must be selected.

•Anti-Short Cycle Compressor Protec-

tion.

c

:_/N 240007753, Bey A [05150% 5 Made i_ the OoA