S1CG/S1HG

in

le-Zone,

S2CG/S2H

Dual-Zone

•

nstallation,

eration and Maintenance Manual •

Comfort where it counts 2P/N 240007754, Rev. C [3/19/2010]

Contents

NOTICE

Shipping Damage

Shipping damage MUST be reported

to the carrier IMMEDIATELY.

Examine the exterior. Remove cover

and examine compressor and piping

for signs of damage.

Inspect each component for damage.

Concealed damage must be reported

to the carrier within 15 days of the

receipt of the shipment.

e carrier must make proper notation

on the delivery receipt of all damage

identied and complete a carrier inspec-

tion report.

e purchaser must notify ECR Inter-

national’s Customer Service Depart-

ment of all damage and is responsible

for ling any necessary claims with the

carrier.

Customer Service : (800) 228-9364

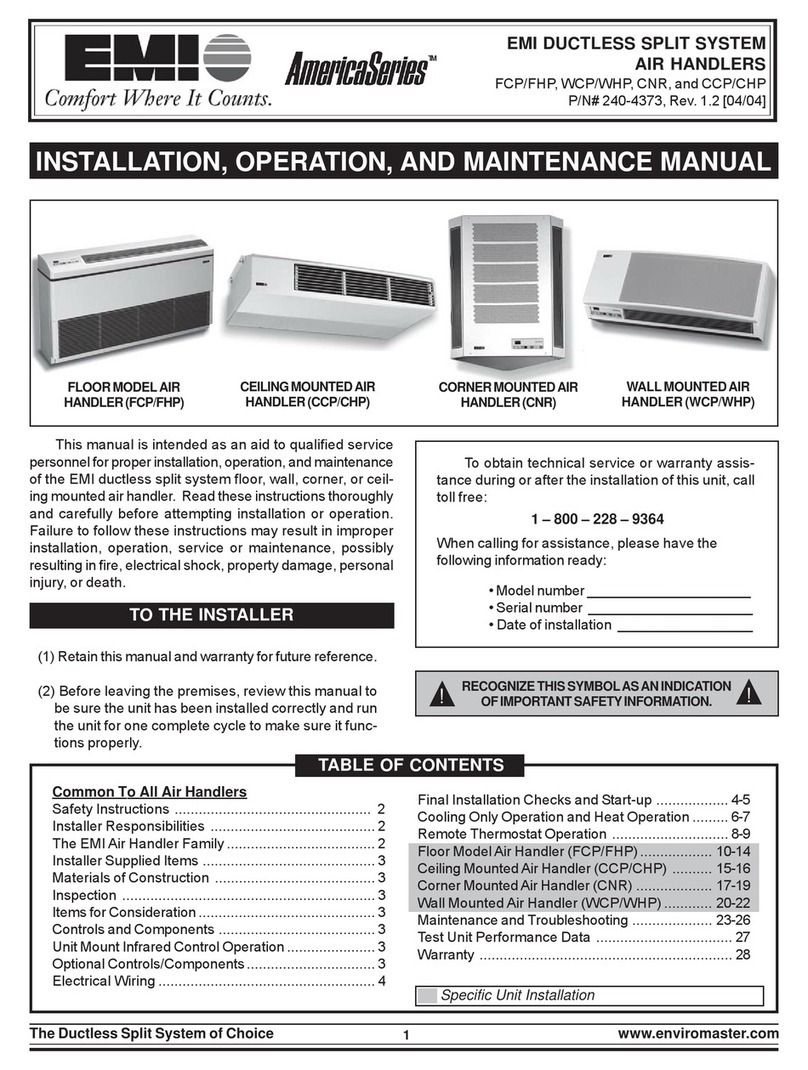

Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Verify unit before installing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Mounting the Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Electrical Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Refrigerant Piping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Refrigerant Processing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Operation Charts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Starting the Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Operation and Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Single-zone and Dual-zone Condenser Sequence of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Single-zone and Dual-zone Condenser Sequence of Operation,

Testing Defrost Operation Using Test Pins . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Specification and Dimensions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Test Unit Performance Data Sheet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

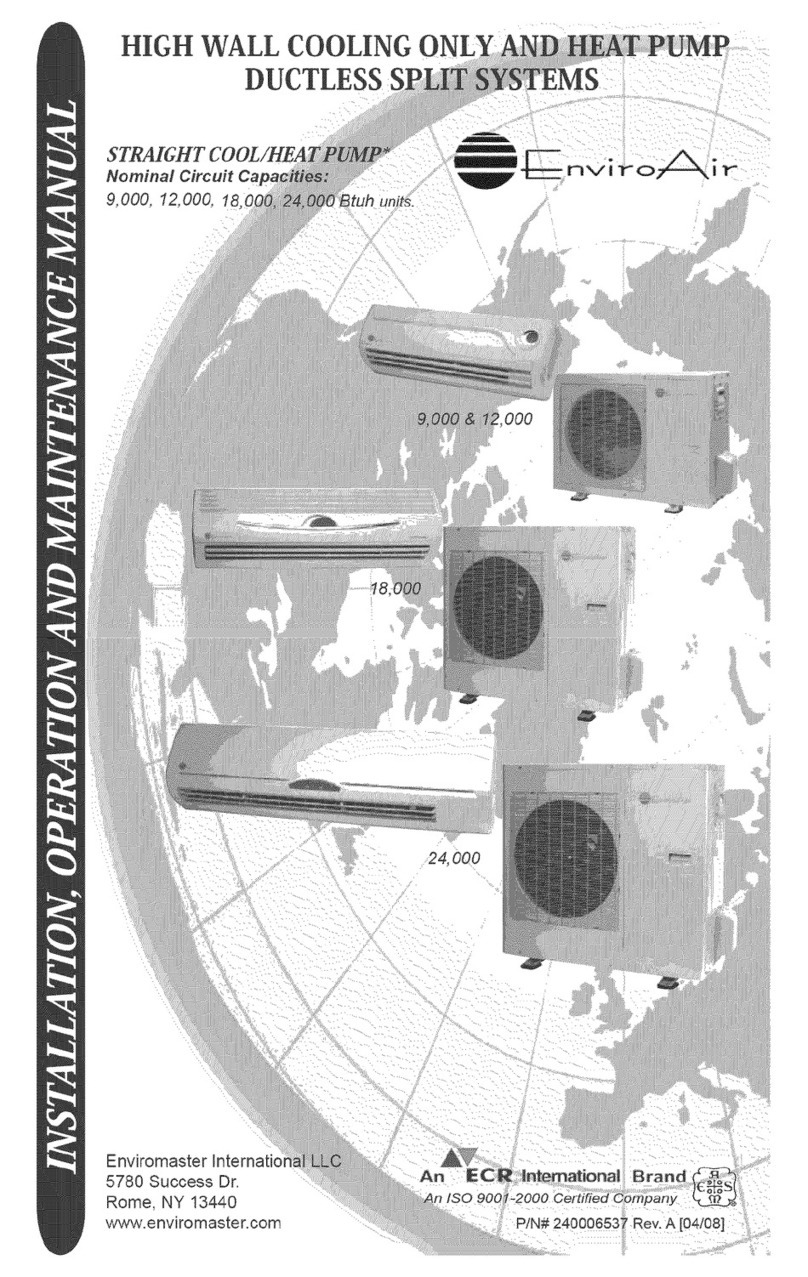

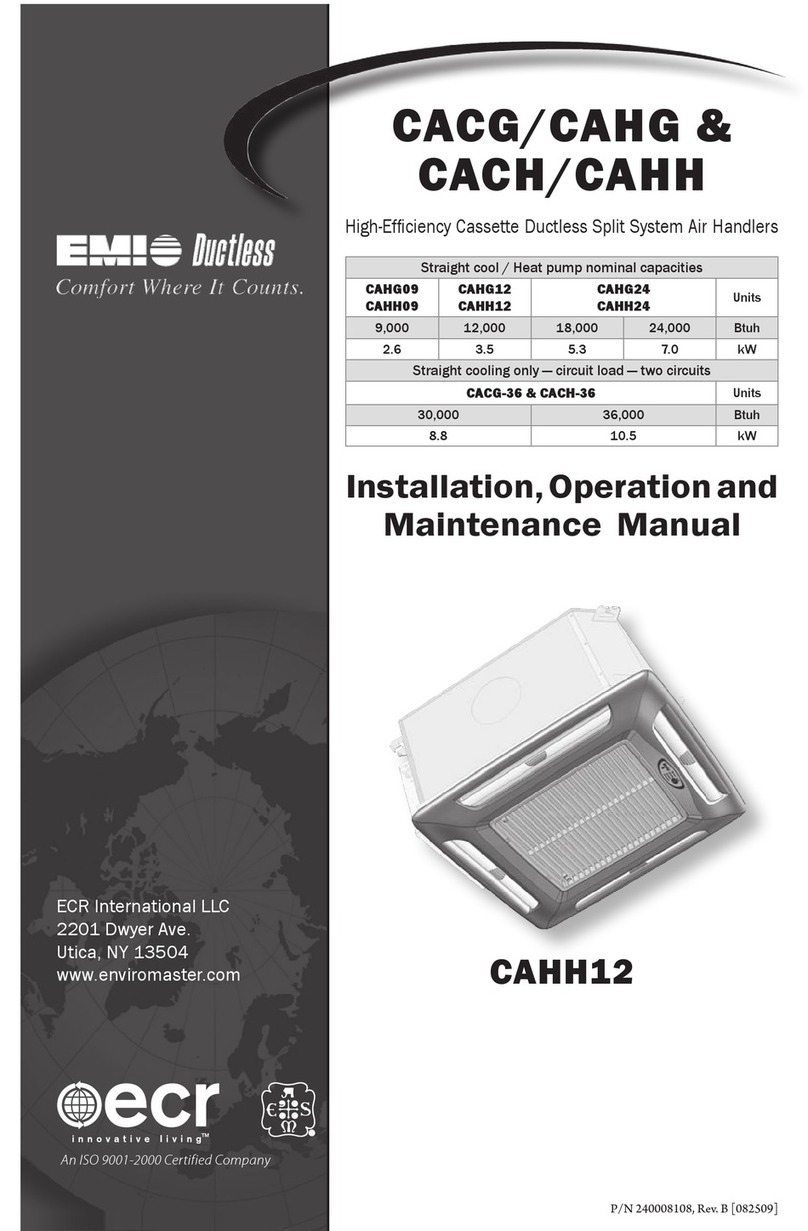

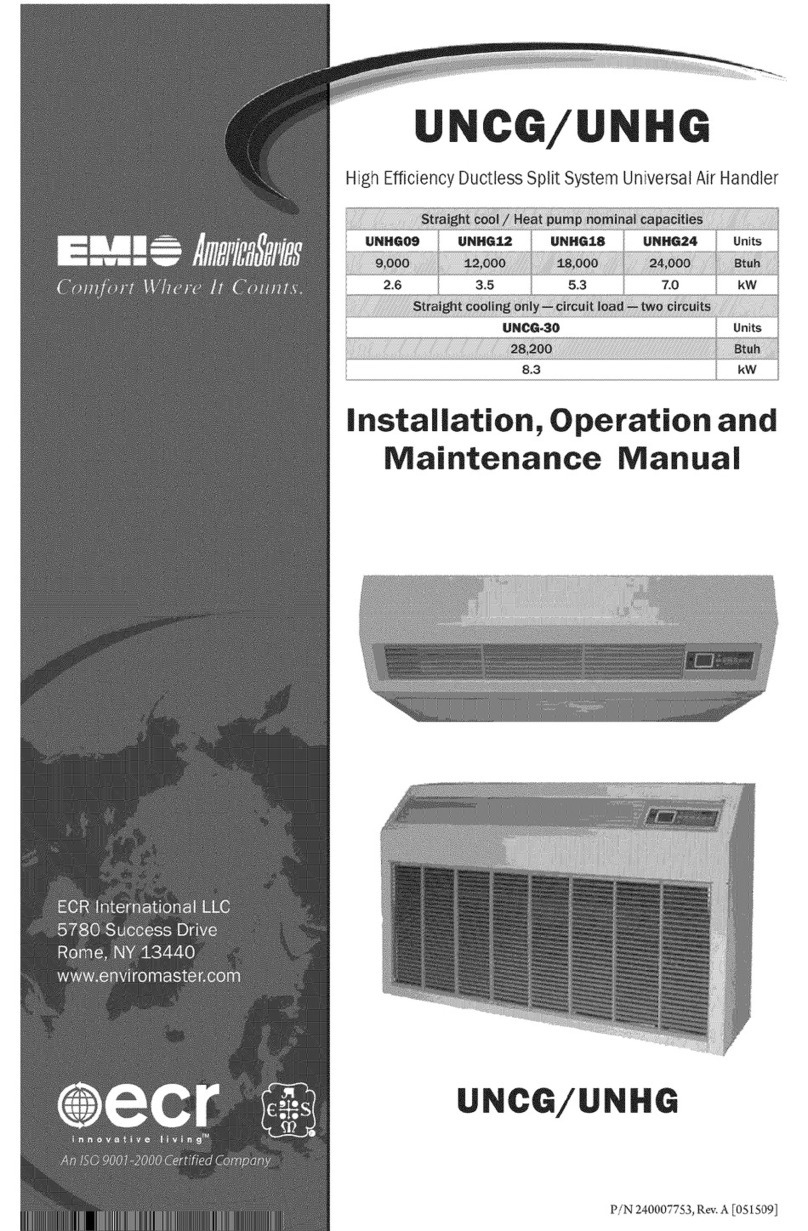

EMI’s Product Line . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

To the Installer

Retain this manual and warranty for

future reference. Before leaving the prem-

ises, review this manual to be sure the unit

has been installed correctly and run the

unit for one complete cycle to make sure

it functions properly.

To obtain technical service or warranty

assistance during or aer the installation

of this unit, contact your local representa-

tive. For a local representative listing, visit

our web site:

www.enviromaster.com

For further assistance call:

1-800-228-9364

When calling for assistance, please have

the following information ready:

Model Number _____________

Serial Number _____________

Date of installation ___________

NOTICE

e EMI series high eciency condensing unit is backed by EMI and ECR International

and is tested and rated in accordance with AHRI Standard 210/240-2008 and UL-1995.

Due to ongoing product development, product designs and specications may change

without notice. Please contact the factory for more information.