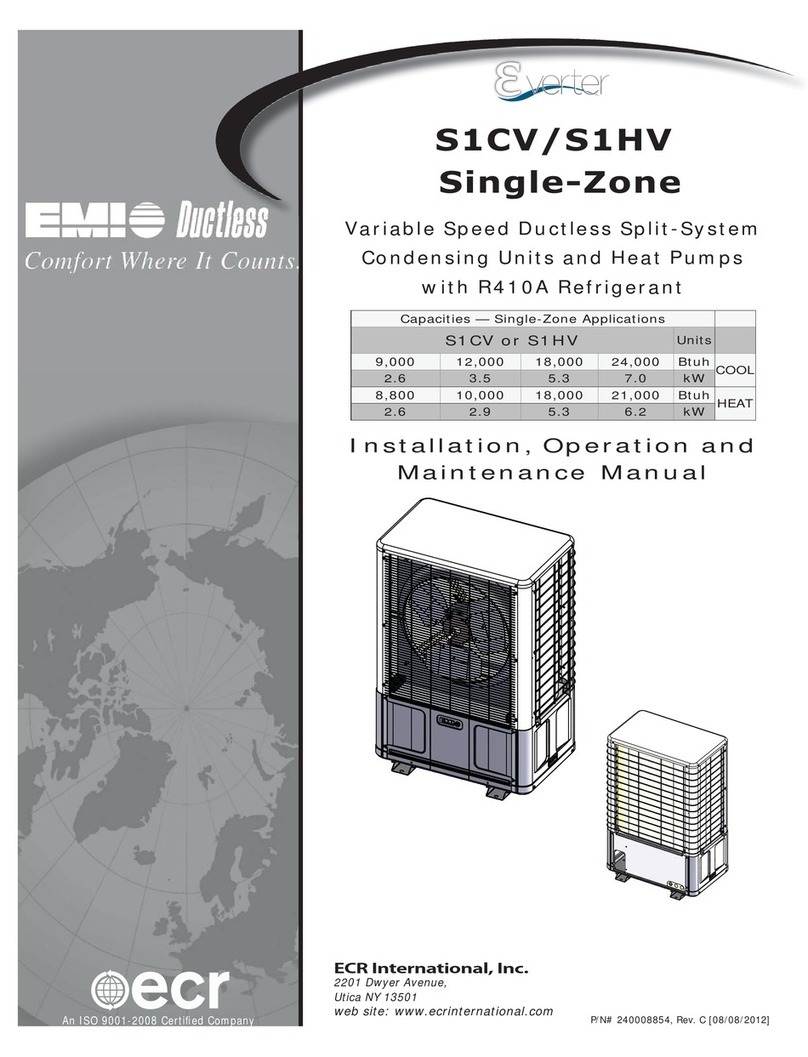

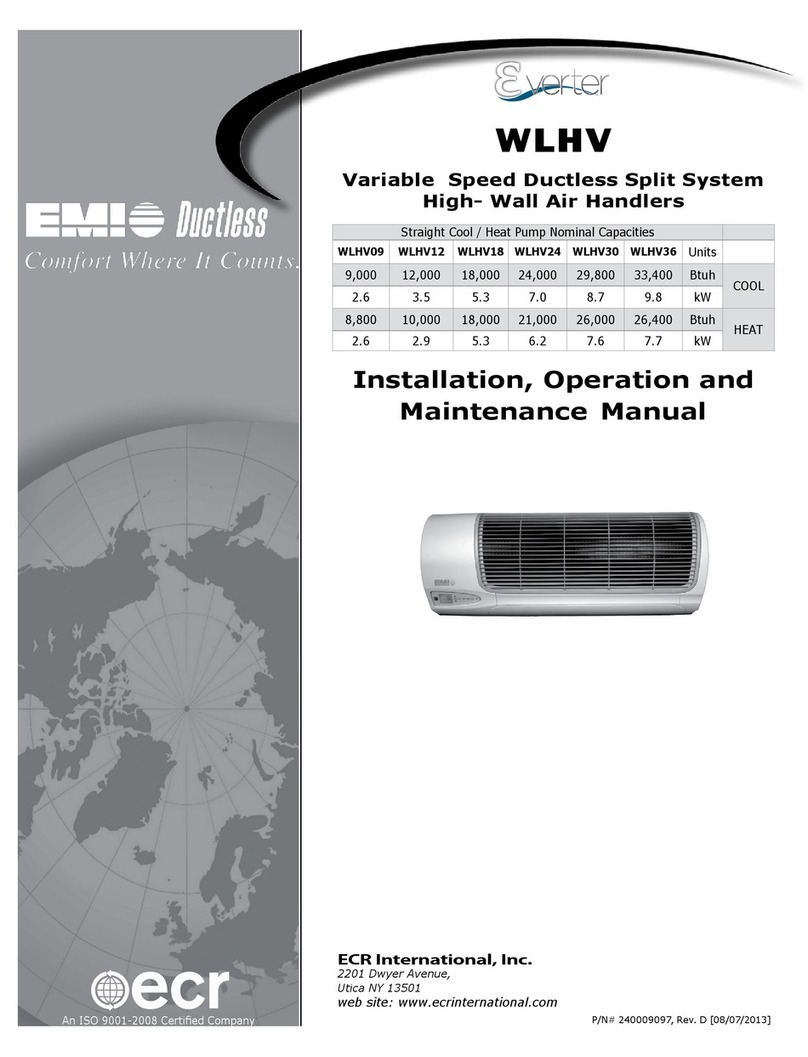

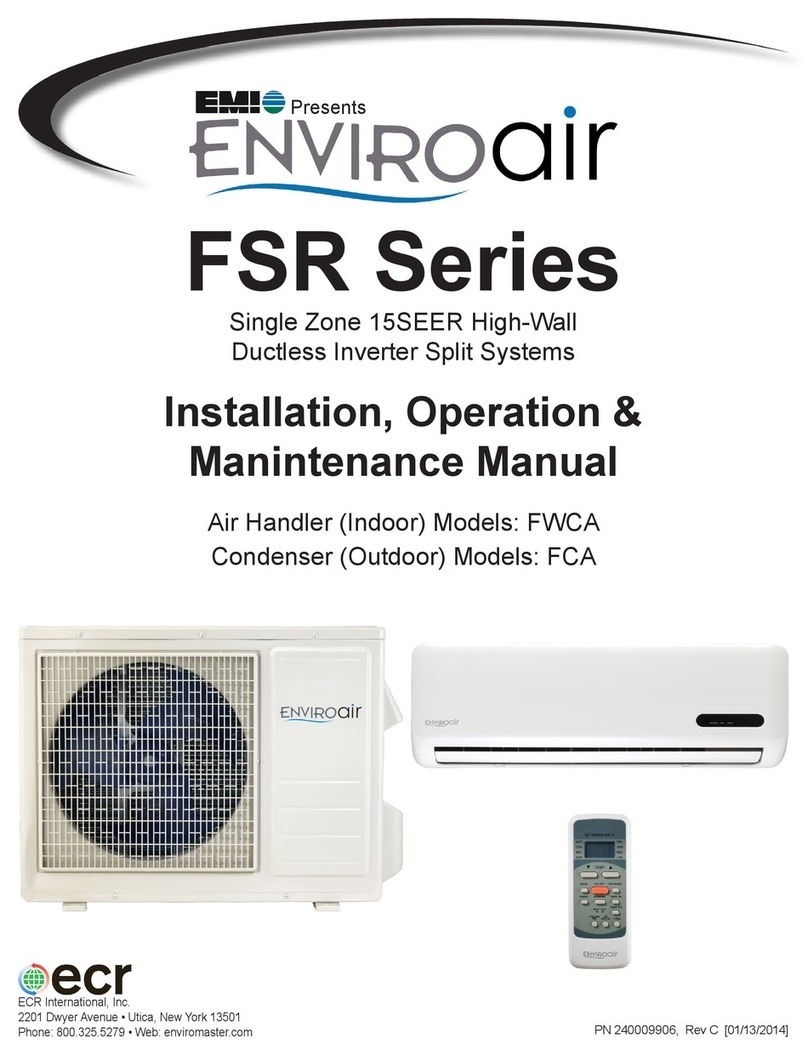

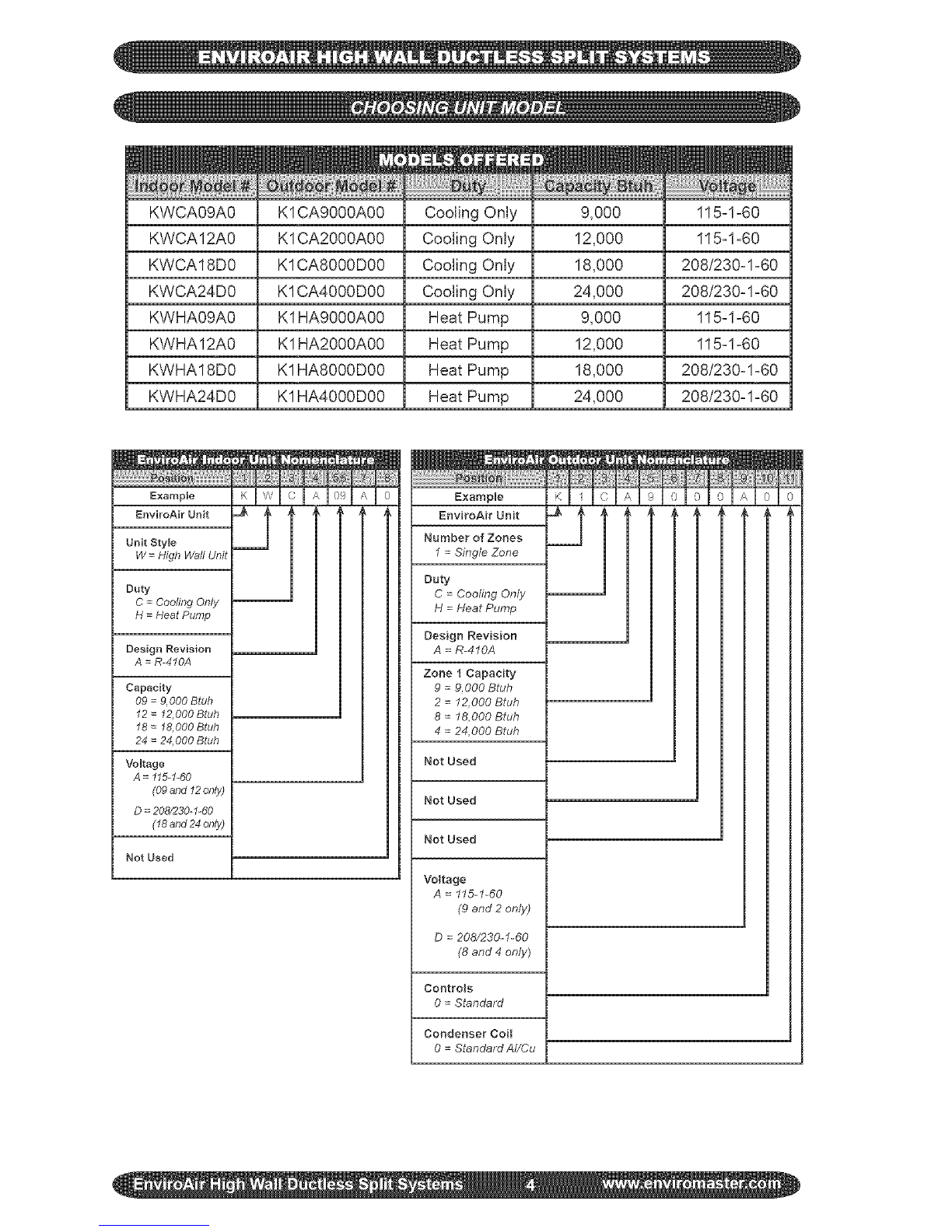

TheEnviroAirsystemisanefficientduct-

lesssplitairconditioningsystemwithcooF

ingcapacitiesfrom9,000-24,000Btuhand

heatpumpcapacityof9,000-24,000Btuh.

Designedforquietoperationandboasting

compactdimensions,theEnviroAirsys-

temincludesadvancedfeatureslikeauto-

restart,fullfeatureremotecontrol.

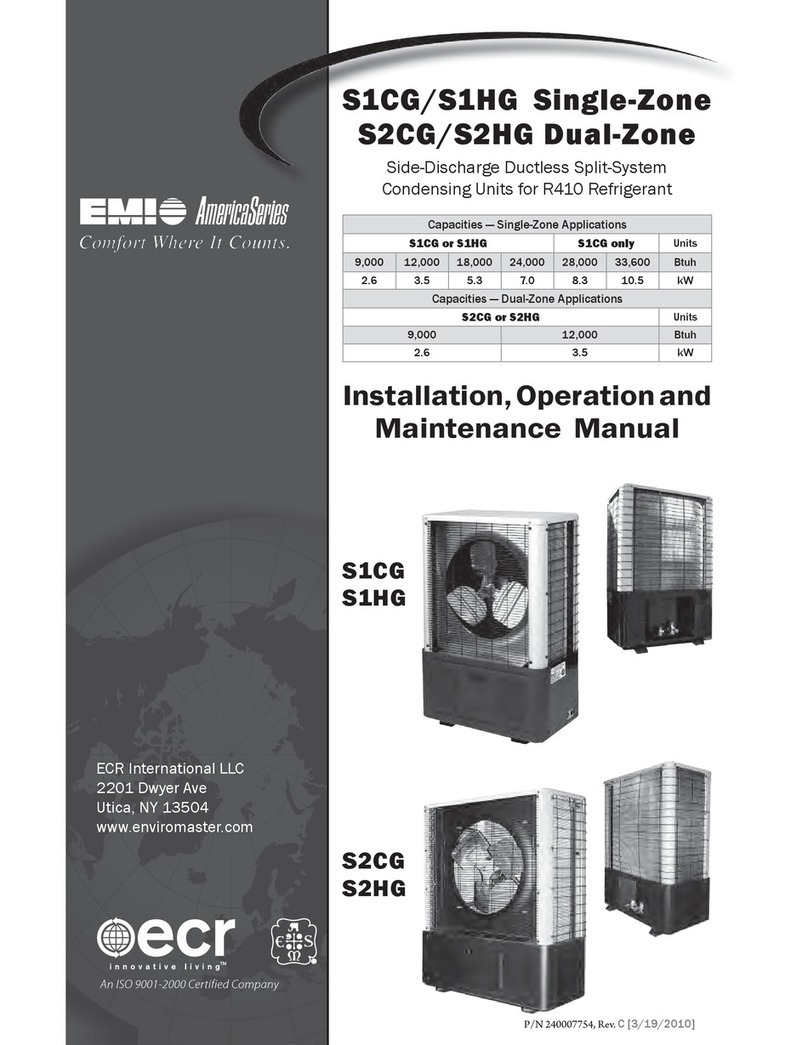

oMain System Breaker: Sized per unit

requirements, to be mounted adjacent

to outdoor unit.

oMounting Hardware: Wall anchors,

condenser pad.

oVacuum Pump

oGauge Set: R-410 specific.

oHigh Vo#age interconnect Wiling:

14 AWG wiring from outdoor unit to in-

door unit for power and control. *

oRefrigerant :R-410A required for addi-

tional line sets beyond 16 ft=

• Can be purchased through the factory asan

accessory, (partof the Tube Set Kit below)

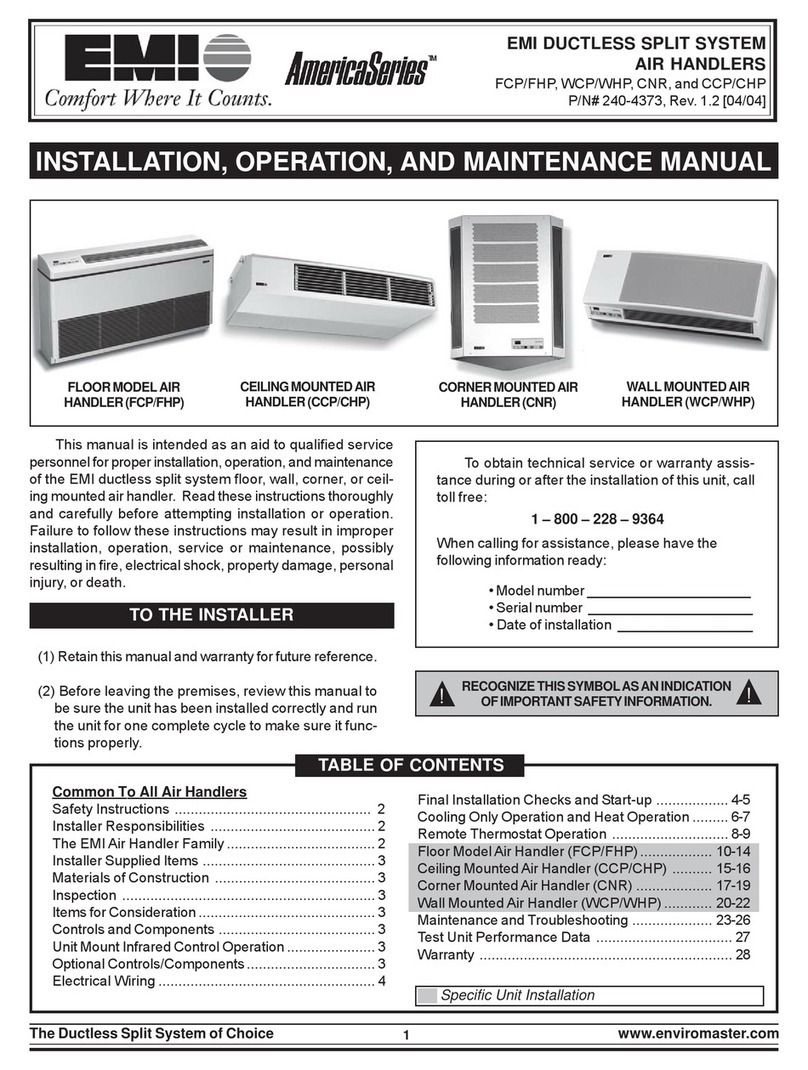

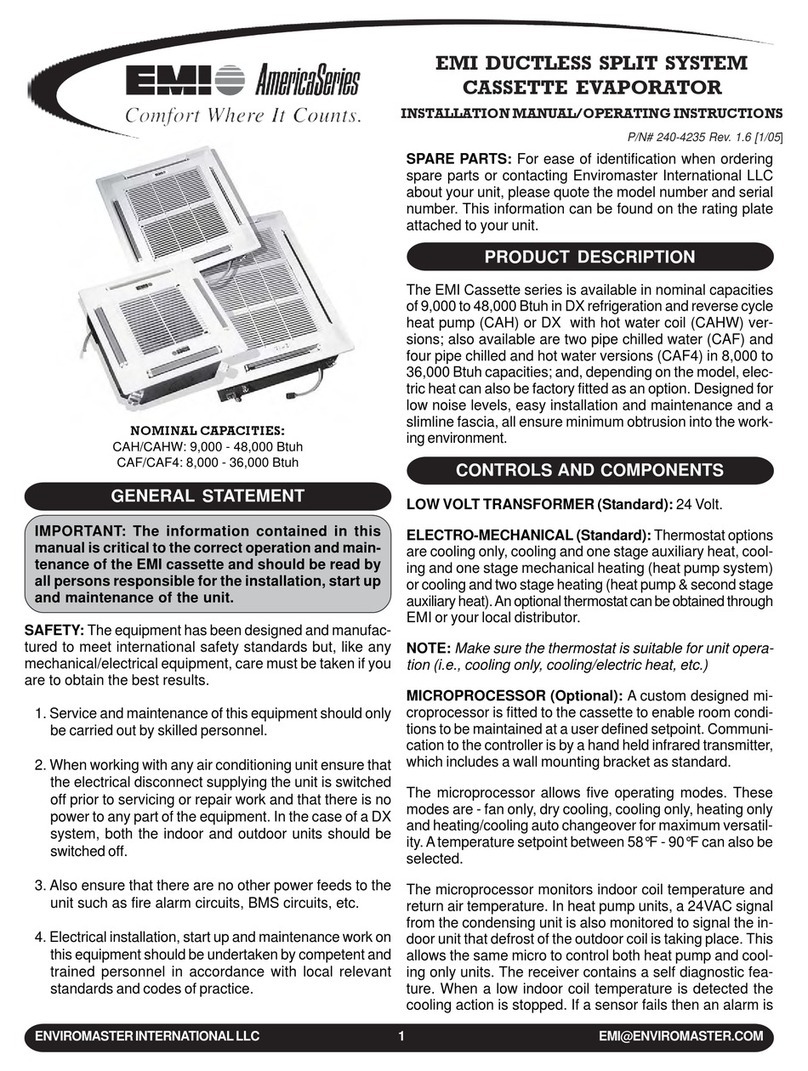

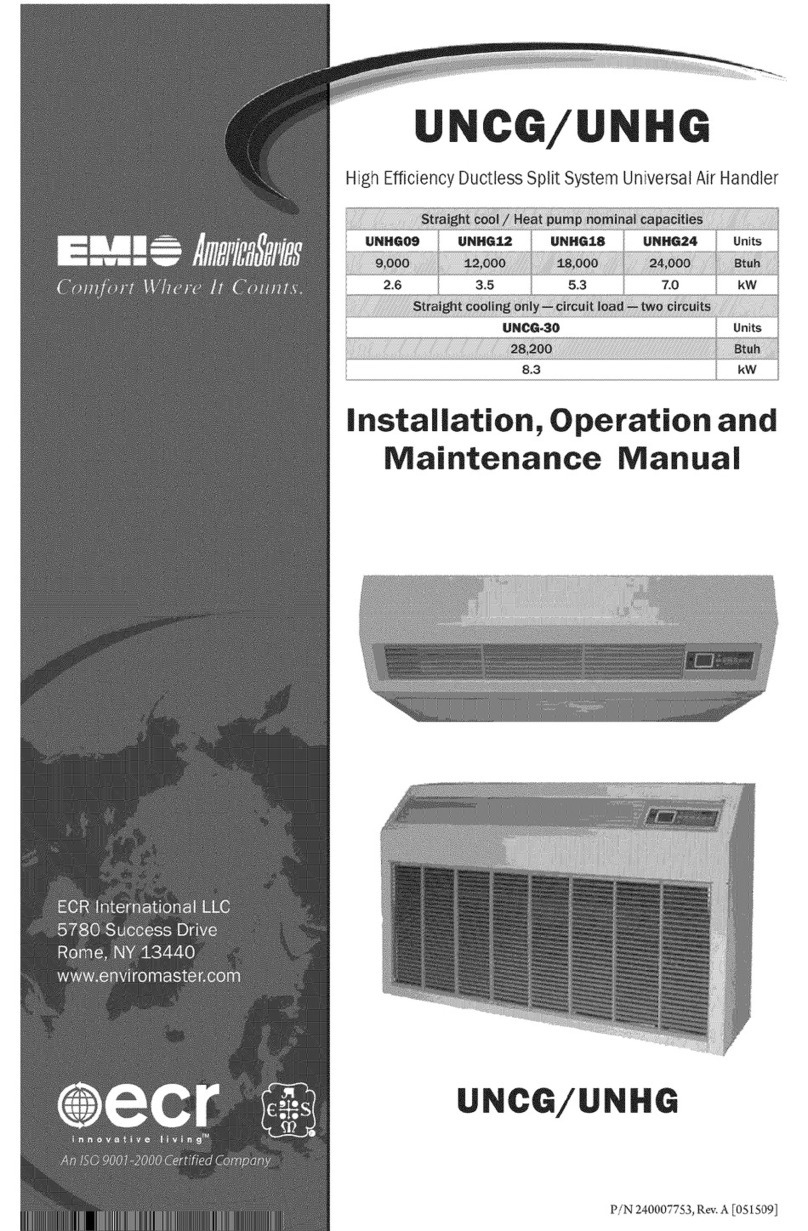

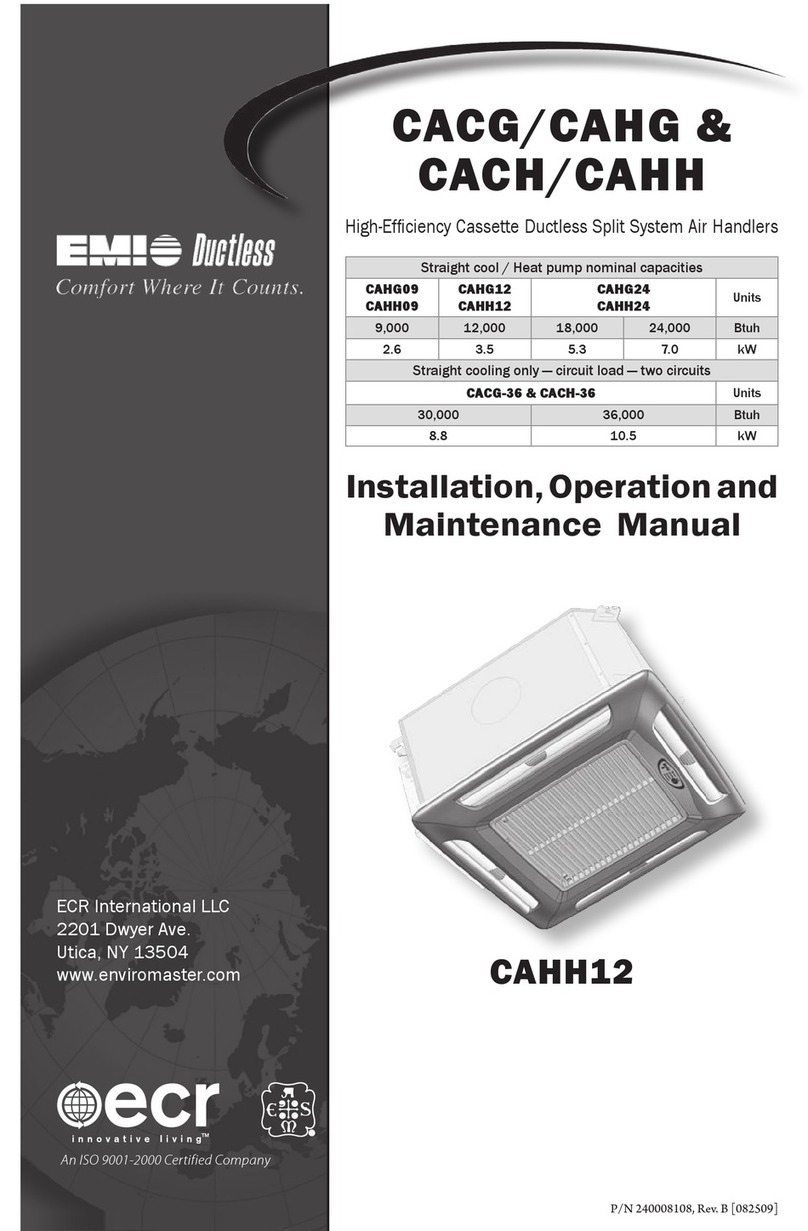

Comprised of three standard components

the indoor high wall evaporator, the out

door condensing unit, and an infrared

handheld remote contro!. The EnviroAir

system is engineered to the highest per-

formance and reliability standards. The

evaporator is equipped with permanent

washable air filters as well as motorized

air sweep for enhanced air circulation, and

the condensing unit is equipped as stan-

dard with a high efficiency rotary compres-

sor.

Tube-Set Kit consisting of:

oRefrigerant Line Set - 25 feet of

suction and liquid line, both fully in-

sulated, and flare fittings supplied

on both ends.

ointerconnecting High Vo#age Wiring

- 25 feet supplied.

oAdd#ional Condensate Tubing - 6feet

extra supplied.

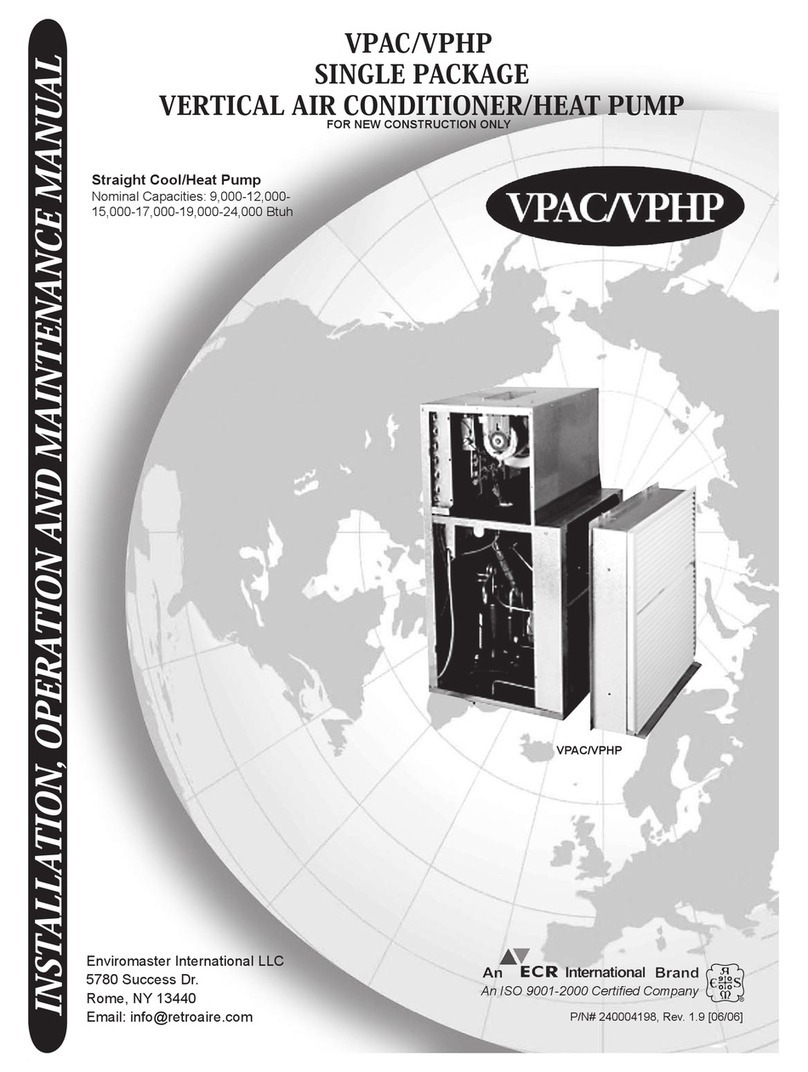

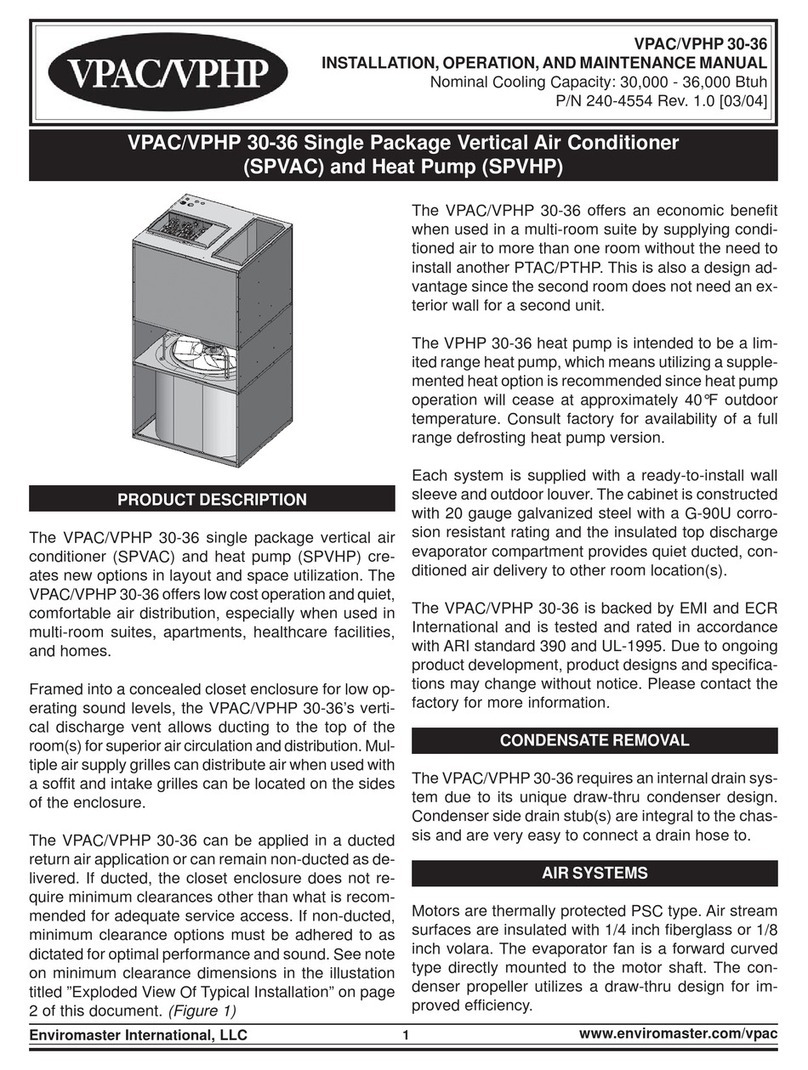

EMI recommends the EnviroAir system

for residential and light commercial cool-

ing applications. The EnviroAir system will

operate in standard cooling mode down to

60°F outdoor temperature.

oMatched System Consisting Of:

Evaporator section and condenser sec-

tion with remote control.

The EnviroAir system is backed with the

standard limited warranty that applies

to all EMI equipment. For a copy of this

limited warranty, please contact EMI cus-

tomer service or refer to the website at

_,_Nw.enviromaster, com.

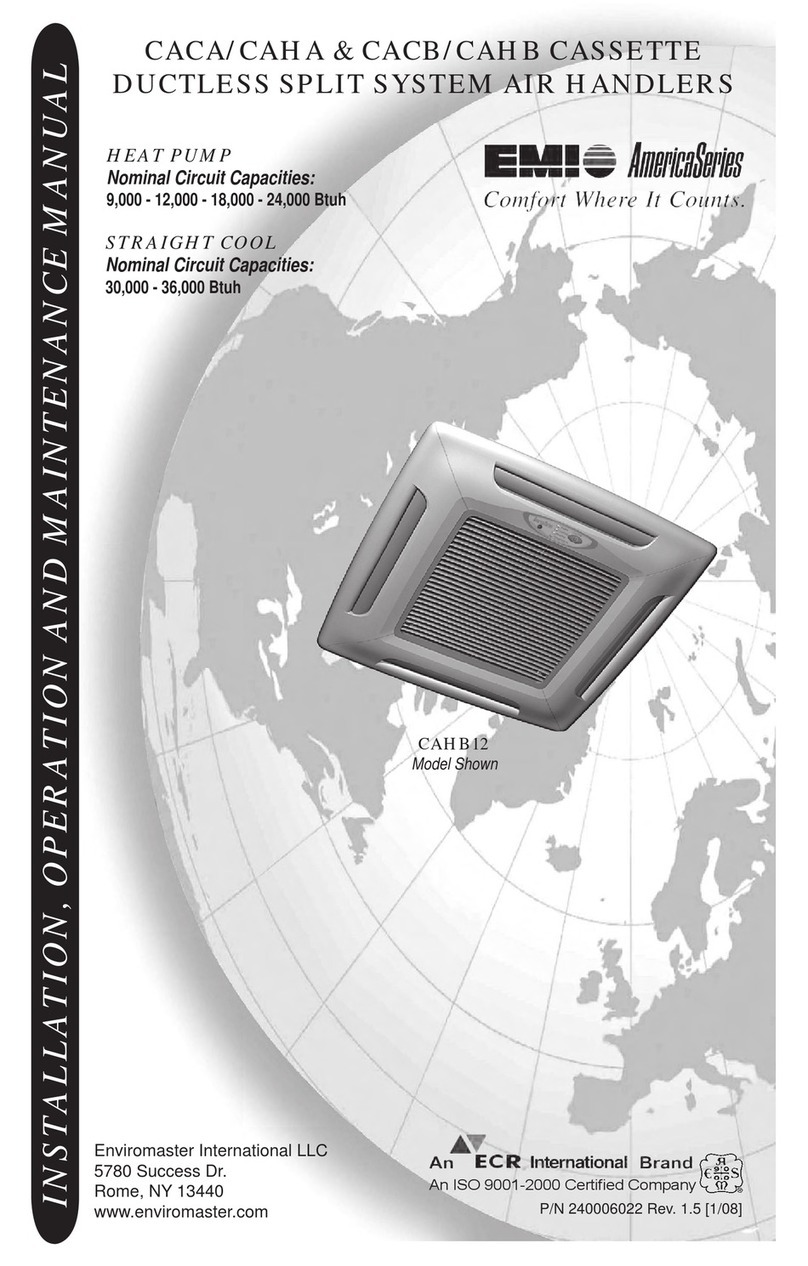

Application:

Check the application of the unit prior to

installation, certain applications require

additional components or installation pa-

rameters, such as the need for external

condensate pump or if the system will

need to perform low ambient cooling at

outdoor temperatures below 6O°F.