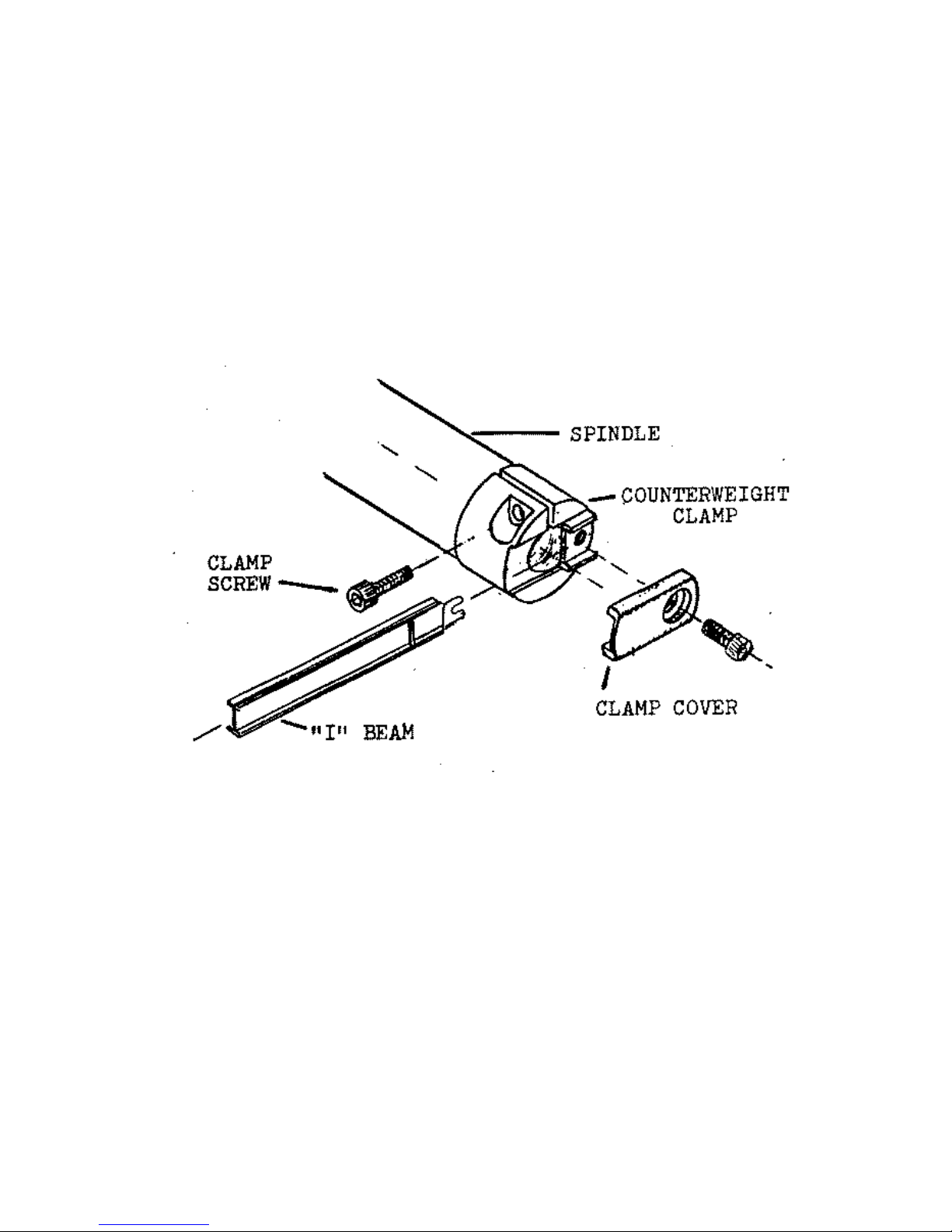

A very rigid coupling occurs with only a small amount of torque on this screw because of

the close tolerances. Overtorquing this screw can distort the air bearing spindle and crack the

counterweight clamp.

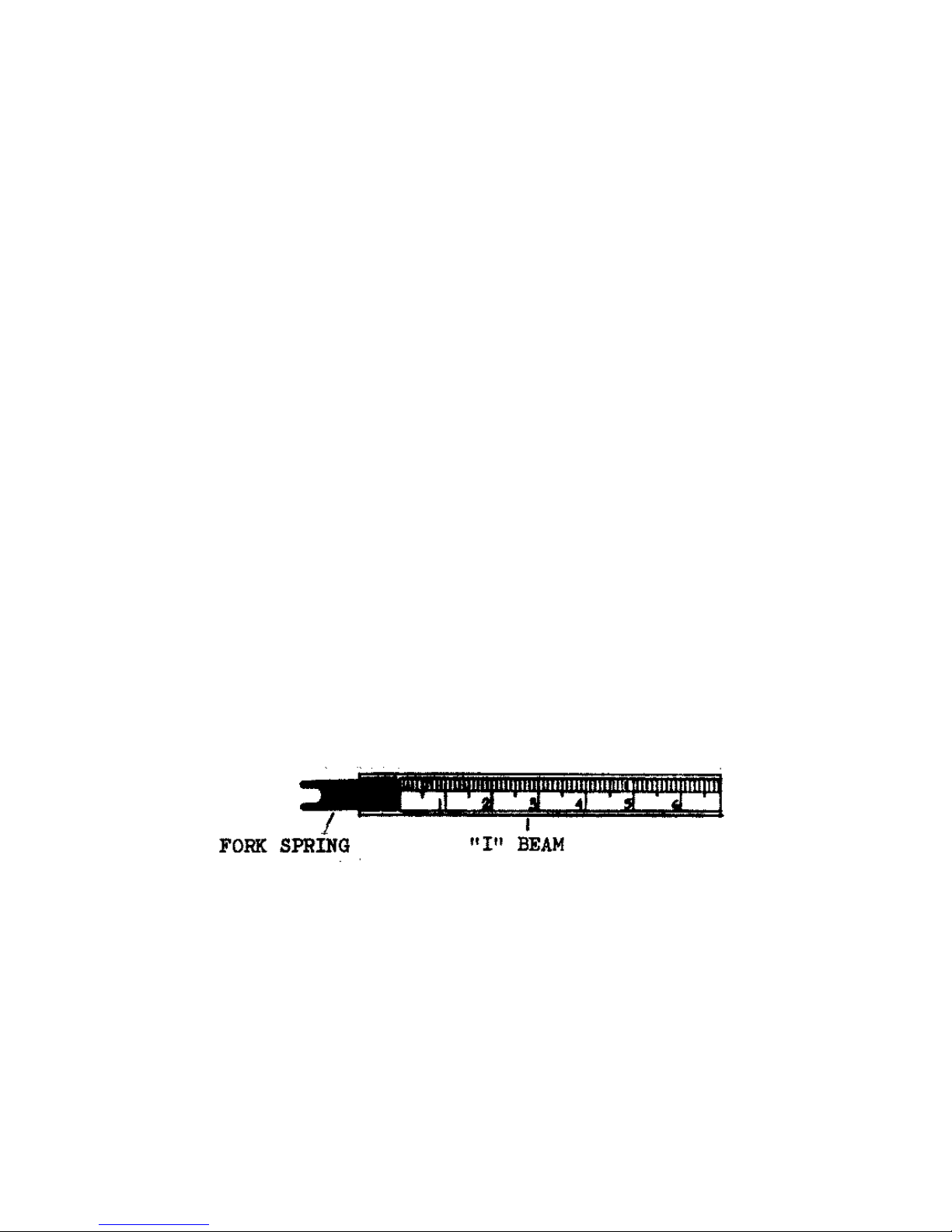

If the fork spring breaks off the I-beam during the above process it can be glued back into

place using ordinary “super glue” (cyanoacrolate) and then re-assembled.

The counterweight I-beam should be positioned by rotating the counterweight clamp on

the spindle until the I-beam is parallel to the tonearm tube. It can be positioned up or down

slightly with respect to the tonearm tube, but generally parallel is the best position.

A very aggressive adhesive has been applied to the trough along the side, which is to be

attached to the underside of the manifold housing. When the wax paper is removed exposing the

adhesive on the trough it is ready to be put in place.