3

TABLE OF CONTENTS

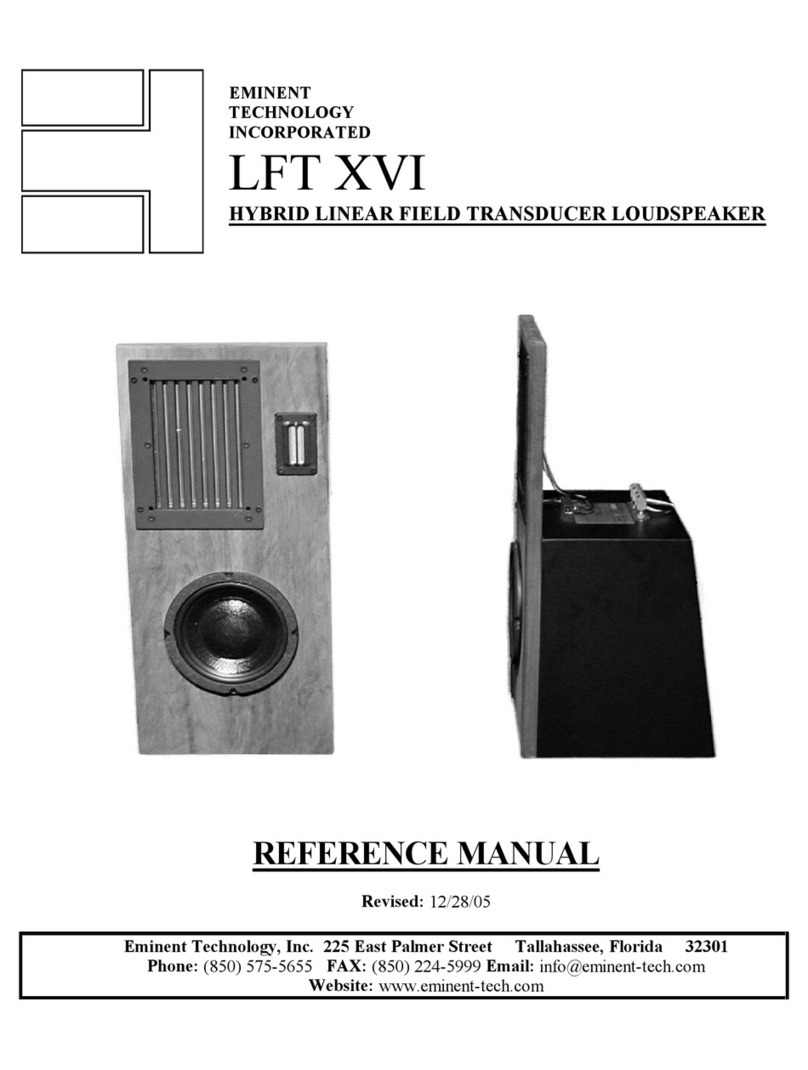

Installation of the LFT-VIII........................................................5

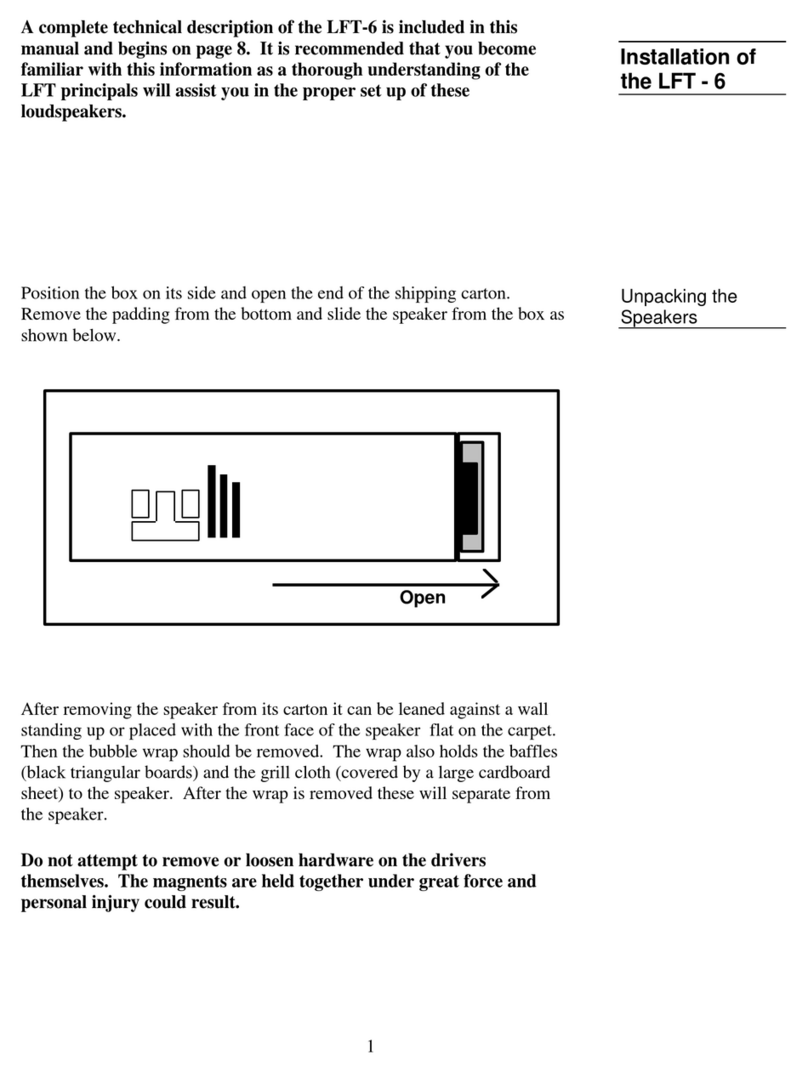

Unpacking the Speakers.............................................................5

Speaker Assembly......................................................................6

Positioning the Speakers in the Listening Room.......................7

Imaging ......................................................................................7

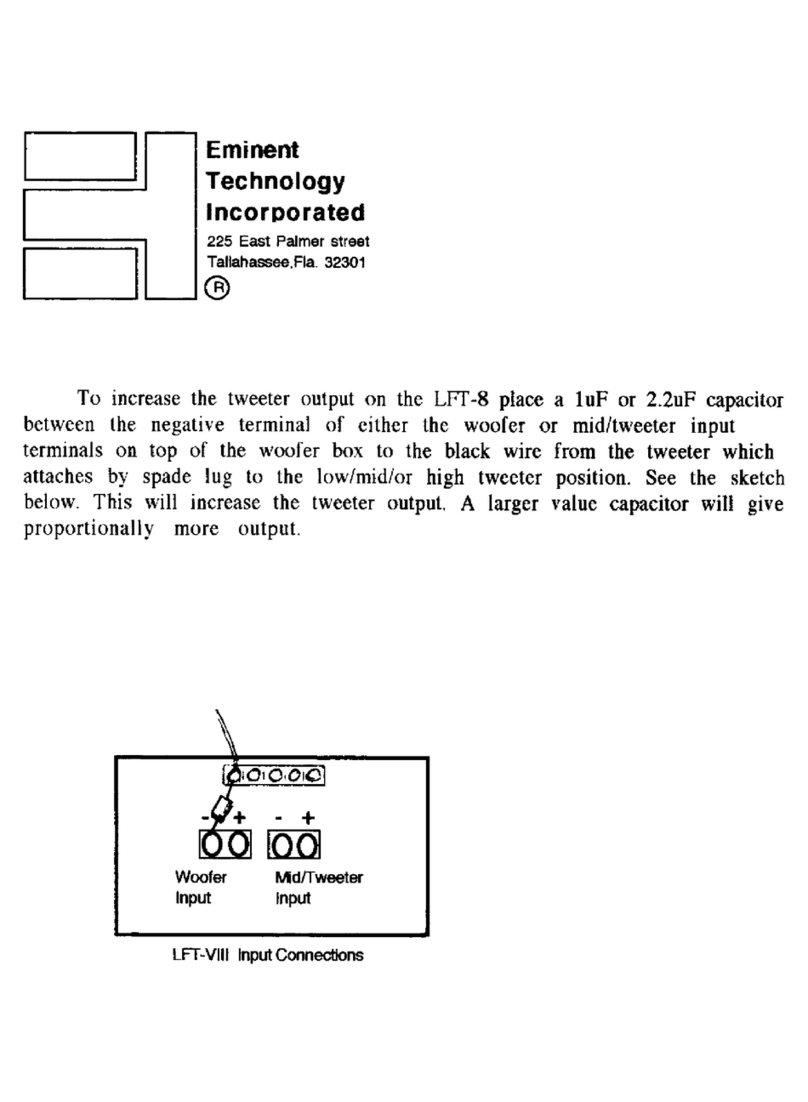

The Tweeter Level Control........................................................8

Amplifier Requirements.............................................................8

Bi-Wiring and Bi-Amping.........................................................9

Bi-Amping .................................................................................9

Technical Description................................................................10

Electrostatic Loudspeakers ......................................................11

Planar Magnetic Loudspeakers................................................12

Ribbon Loudspeakers...............................................................13

Evaluating Earlier Approaches................................................14

Electrostatics............................................................................14

Planar Magnetics......................................................................14

Ribbons ....................................................................................14

The Linear Field Transducer....................................................16

Diaphragm Construction..........................................................16

The Magnet/Frame Structure...................................................16

Panel Frequencies ....................................................................18

General Specifications...............................................................19

LFT-VIII Impedance Curve.....................................................20

LFT-VIII Impedance Data........................................................21

Crossover Information..............................................................22

Square Wave Performance ......................................................23

Frequency Response Curve.......................................................24

LFT-VIII Panel Specifications..................................................25

Mid Range Panel Design...........................................................26

LFT-VIII Woofer Specifications..............................................27

Additional Woofer Specifications.............................................28