5

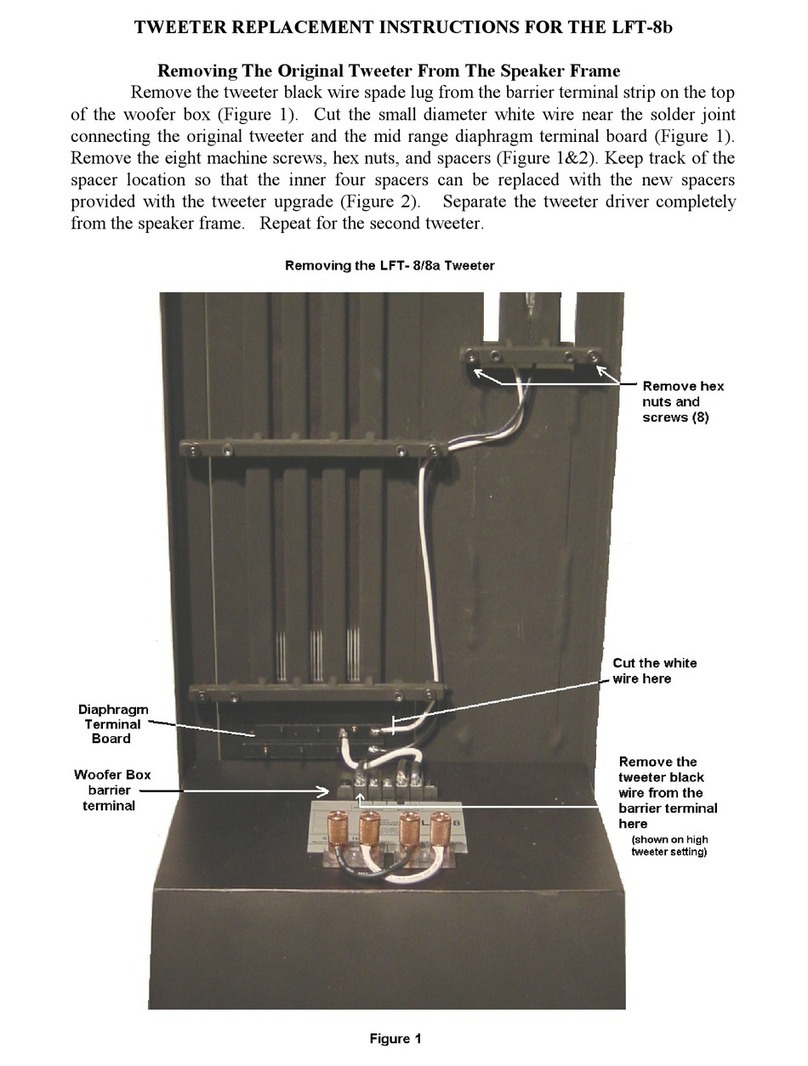

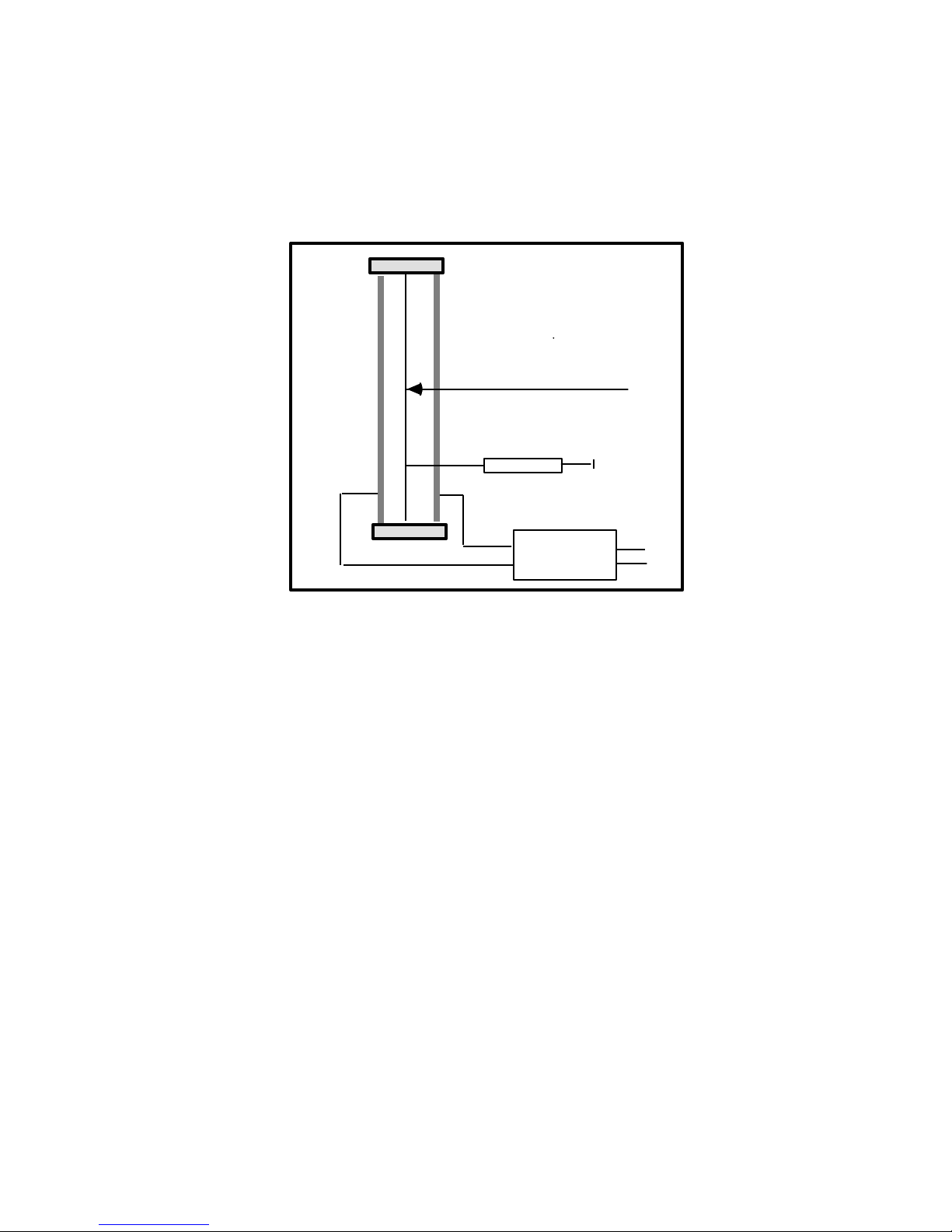

The high frequency performance of the LFTs can be tailored with the

tweeter lever control. A jumper is mounted under the crossover cover.

There are three tweeter level positions. If the jumper is disconnected, the

treble energy is rolled off slightly and this is the lowest setting. When the

jumper is connected to the third terminal up from the bottom of the right

hand row of six terminal points, the tweeter output at its middle position.

The highest tweeter level setting is achieved when the jumper is moved up

one terminal to the fourth one. It is best to start with the tweeter level

jumper disconnected, position the speakers for the best overall frequency

balance, and the decide if more high frequency energy is needed.

Overall imaging depends primarily on the distance separating the two

speakers relative to their distance from the preferred listening position; it is

also affected by the degree of toe-in. We cannot accurately predict what

will work best in your listening room, and can suggest only that you begin

with the drawing on the previous page as a starting point or general

guideline. Keep in mind that the parameters that affect frequency balance

also tend to affect imaging properties, and vice versa, so it is best to adjust

speaker placement in small increments and to note carefully all of the

changes effected by each shift in position before proceeding further.

The LFT-6 is wired for 6-Ohm operation, and is appropriate for use with

most higher-powered tube and solid-state amplifiers. The efficiency is

83dB with a 2.83 volt drive (1 “8” Ohm watt). This efficiency rating is

lower than average. However, the LFT radiates a planar wavefront, and as

such its apparent efficiency at the listening position is higher than the

numerical rating implies. The LFT-6 has a minimum requirement of 100

watts per side, whether tube or solid-state. It can handle “music power”

levels (short-term bursts) of 500 watts or more without difficulty. In

general, the limit of the speaker is only reached when the diaphragm

actually “bottoms out” against the magnets.

The above minimum requirements are really only estimates and depend on

listening taste and the listening environment. More power will be required

if the listening room is large, or if average sound pressure levels higher than

90 dB are desired.

The Tweeter Level

Imaging

Amplifier

Requirements