TWEETER DIAPHRAGM REPLACEMENT FOR THE LFT-8b

Revised 10/26/2007

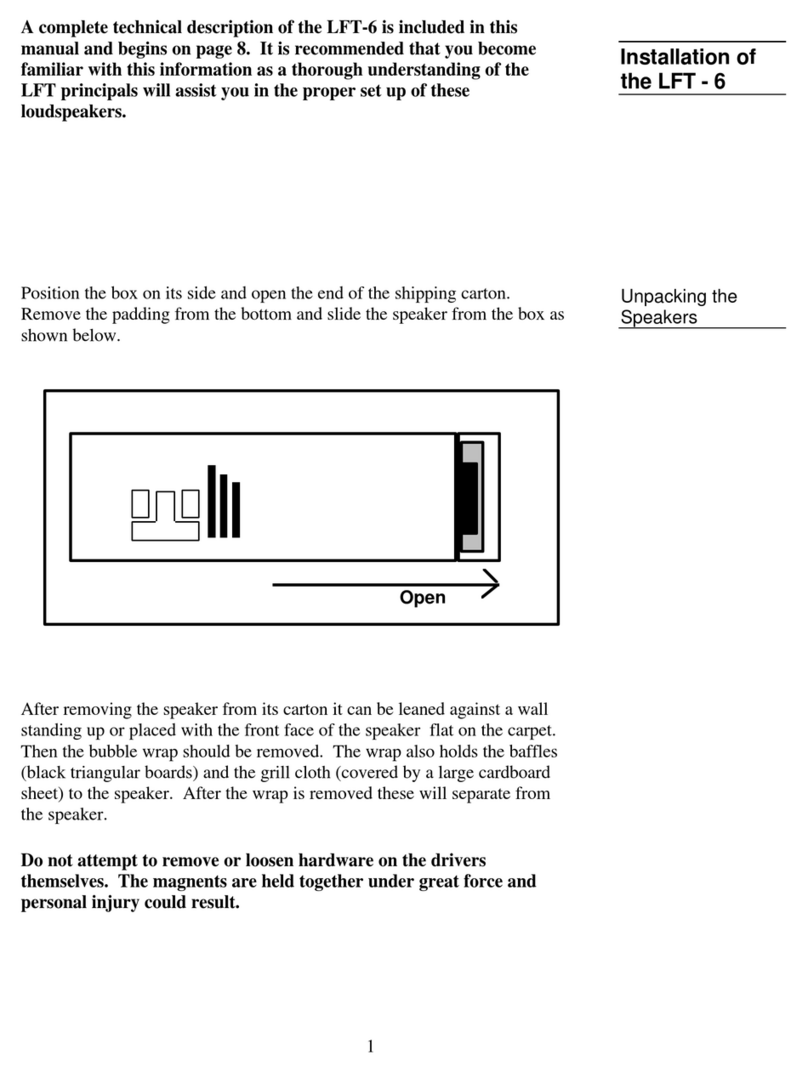

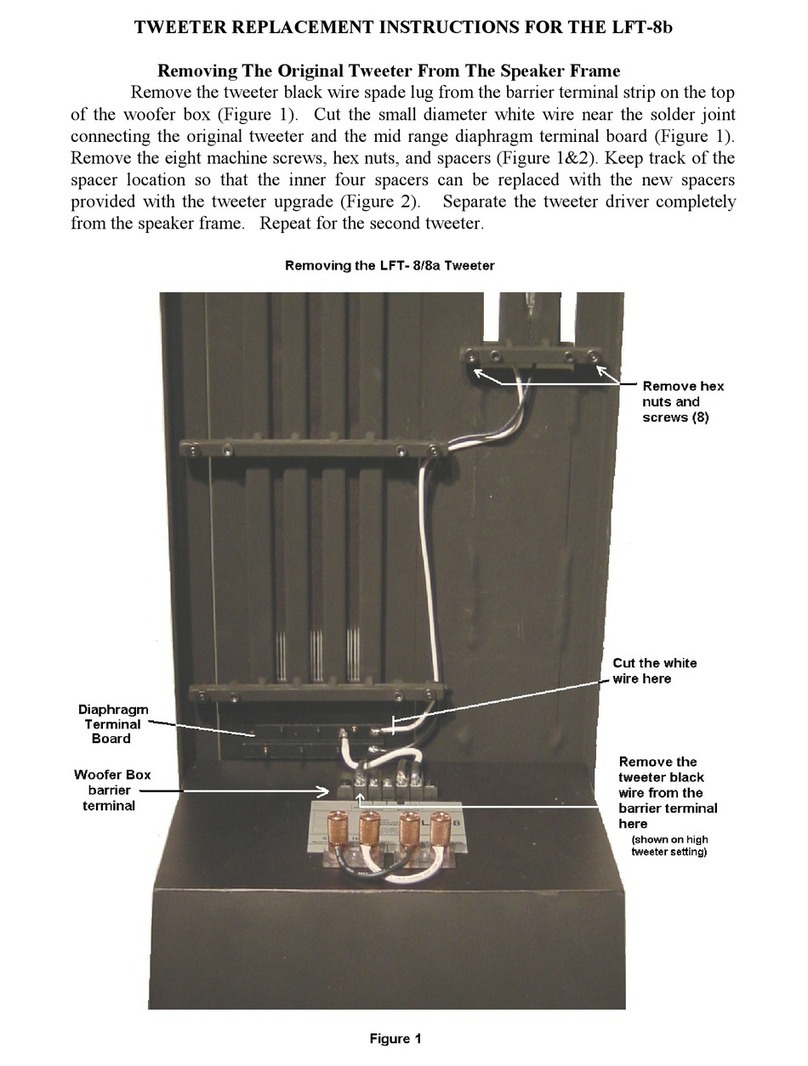

Remove the tweeter driver completely from the speaker frame. Disconnect the

black tweeter wire spade lu from the barrier terminal block and detach the white tweeter

wire from the mid-ran e terminal board usin a solderin iron. Remove the ei ht

machine screws, nuts and spacers. Keep track of each spacer location so that it can be

returned to that same position upon re-assembly. Place the tweeter driver on a smooth,

clean surface with its front assembly, facin down. Remove four 10-32 machine screws

from one end of the tweeter driver assembly. Pull apart the back ma net assembly from

the front (approx. 1”) at this end. Continue pullin apart the channels while removin the

next three pairs of screws, takin care not to allow the front and back channels to slap

to ether. Loosen the remainin screw at the end and pivot the top channel clear of the

bottom channel at ri ht an les from each other. Remove the screw and separate the two

halves.

Replacing The Tweete Diaph agm

Remove the old diaphra m alon with the underlyin double-sided tape on both

rows of ma nets from “front” channel makin sure the rubber insulator squares stay

intact. Please note placement and location of the diaph agm befo e emoval, as to

efe ence the location fo the eplacement diaph agm. Check for and remove any

ma net fra ments from the front and back channels. Place the new tweeter diaphra m on

a hard top table with the terminal board facin down and aluminum conductor facin up.

Tape the non-terminal end of the diaphra m to the table usin ½” wide invisible (office)

tape. Tension and tape the other end of the diaphra m just above the terminal board

usin a 3” piece of invisible tape. Make sure the diaphra m is flush with the table with

no wrinkles or creases above the terminal board. Place an 18 ¾” piece of ½” wide

double-sided tape on the outer three conductor ribbons of the diaphra m, startin at the

non-terminal end and endin around 4 ½” from the terminal board. Cover the final 3” of

conductor ribbons, includin the terminated leads, with invisible tape. Carefully remove

the diaphra m for the table and place the diaphra m by first attachin the non-terminal

end flush with either end of the front channel assembly. Next, tension the diaphra m and

ali n the conductors with the channel while pushin the diaphra m onto the ma nets

makin sure the diaphra m is flat between the ma net channels as you o. The

diaphra m should resemble Diag am (A). Fold and tape the over-han in terminal end

of the diaphra m as illustrated in Diag am (B).