8

EVALUATING EARLIER APPROACHES

Not surprisingly, each of the approaches described above has its own unique set of pros and

cons. The electrostatic, because its diaphragm is so thin and light, offers exceptionally good transient

response and reproduction of subtle, low-level musical detail. And, because it is a true push-pull

device (i.e., its diaphragm is, by design, driven from both the front and the rear), the ESL operates in a

linear fashion. Typically, gross distortion results only when the driving amplifier clips into the

speaker, or when, in an attempt to play the speaker louder than its design allows, its step-up

transformer reaches a point of saturation.

On the negative side of the ledger, the ESL does require passing the amplified musical signal

through a transformer, which can introduce its own colorations and non-linearities. Also, some ESLs

are prone to a condition known as arcing: Under the conditions of stress induced by playing an ESL

loudly, it is not uncommon for an electrical spark to jump between one stator and the diaphragm (a

phenomenon exactly analogous to lightning), burning a minute hole in the diaphragm and, over time,

causing failure.

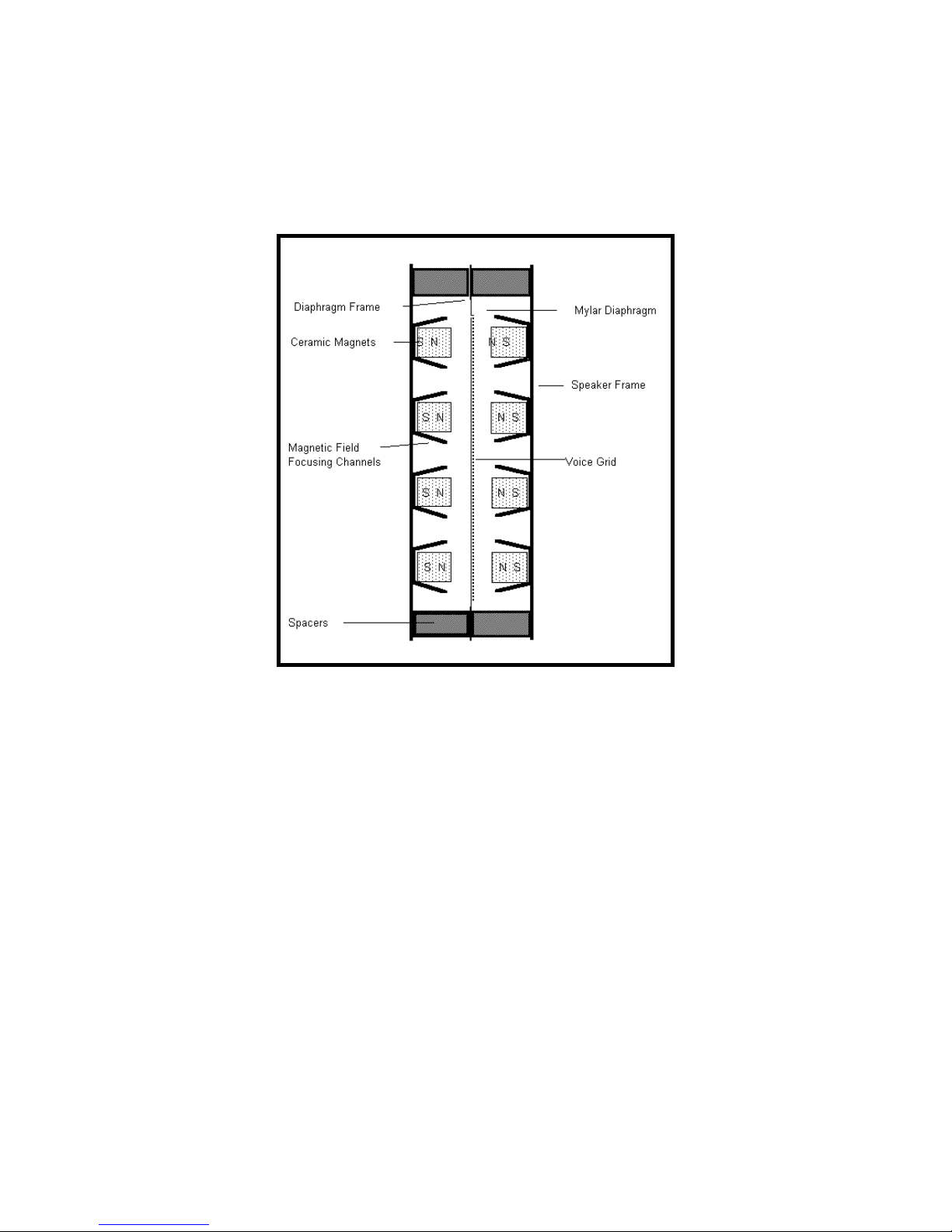

As for the planar magnetic, its strengths are similar to those of the ESL--although the addition

of several feet of wire and an adhesive coat make for a somewhat more massive diaphragm, limiting

this design’s transient capabilities by comparison. However, the planar magnetic requires no step-up

transformer or bias voltage supply, and it has the added benefit of being an extremely manageable

load for most amplifiers. However, the most specific drawback of the traditional planar magnetic is

that it is a single-ended (as opposed to push-pull) device: As the diaphragm’s physical excursion

increases, the voice grid moves further away from its optimal location within the permanent magnetic

field (at least in one direction). Thus, at the very instant when this speaker is called upon to reproduce

large-amplitude waveforms, it is least able to do so without distortion.

In many ways, a ribbon driver can be an excellent performer: the moving element (the

“ribbon” itself) is extremely light, allowing good “speed” and transient performance as well as

freedom from coloration. There is no significant physical structure on either side of the ribbon’s

radiating pattern. The ribbon’s main problem is not one of performance but of application: it cannot

be used to reproduce low frequencies. To create a moving element large enough to generate

frequencies lower than a few hundred Hz would mean moving opposing magnetic poles so far apart

that they would no longer exert a sufficient magnetic field over the entire area of the ribbon.

Also, when a ribbon is operated at frequencies approaching the element’s own resonant

frequency (which is naturally quite low, due to its high compliance), the ribbon element stretches and

“bows” to a point where it is no longer within the magnetic gap. To get around either of these

problems means to move the permanent magnet structure from the edges of the element to one entire

side of the element, and/or to bond the element to a “host” diaphragm, such as a sheet of Mylar, and to

clamp that diaphragm around its perimeter. In either case the driver is no longer a ribbon; it is, in fact,

a planar magnetic. To date, no one has succeeded in creating a full range ribbon loudspeaker.