1. PREFACE...........................................................................................................................................

2. INSTALLATION...................................................................................................................................

3. ELECTRICAL WIRING.......................................................................................................................

1.1 GENERAL SPECIFICATIONS

1.2 ORDERING INFORMATION

2.1 GENERAL DESCRIPTION

2.4 PANEL CUT-OUT

2.5 ENVIRONMENTAL RATINGS

2.6 PANEL MOUNTING

2.7 INSTALLATION FIXING CLAMP

2.8 REMOVING FROM THE PANEL

3.1 TERMINAL LAYOUT AND CONNECTION INSTRUCTIONS

3.4 SUPPLY VOLTAGE INPUT CONNECTION OF THE DEVICE

3.7 ALARM OUTPUT CONNECTIONS

3.7.1 RELAY OUTPUT CONNECTION

1.3 WARRANTY

1.4 MAINTENANCE

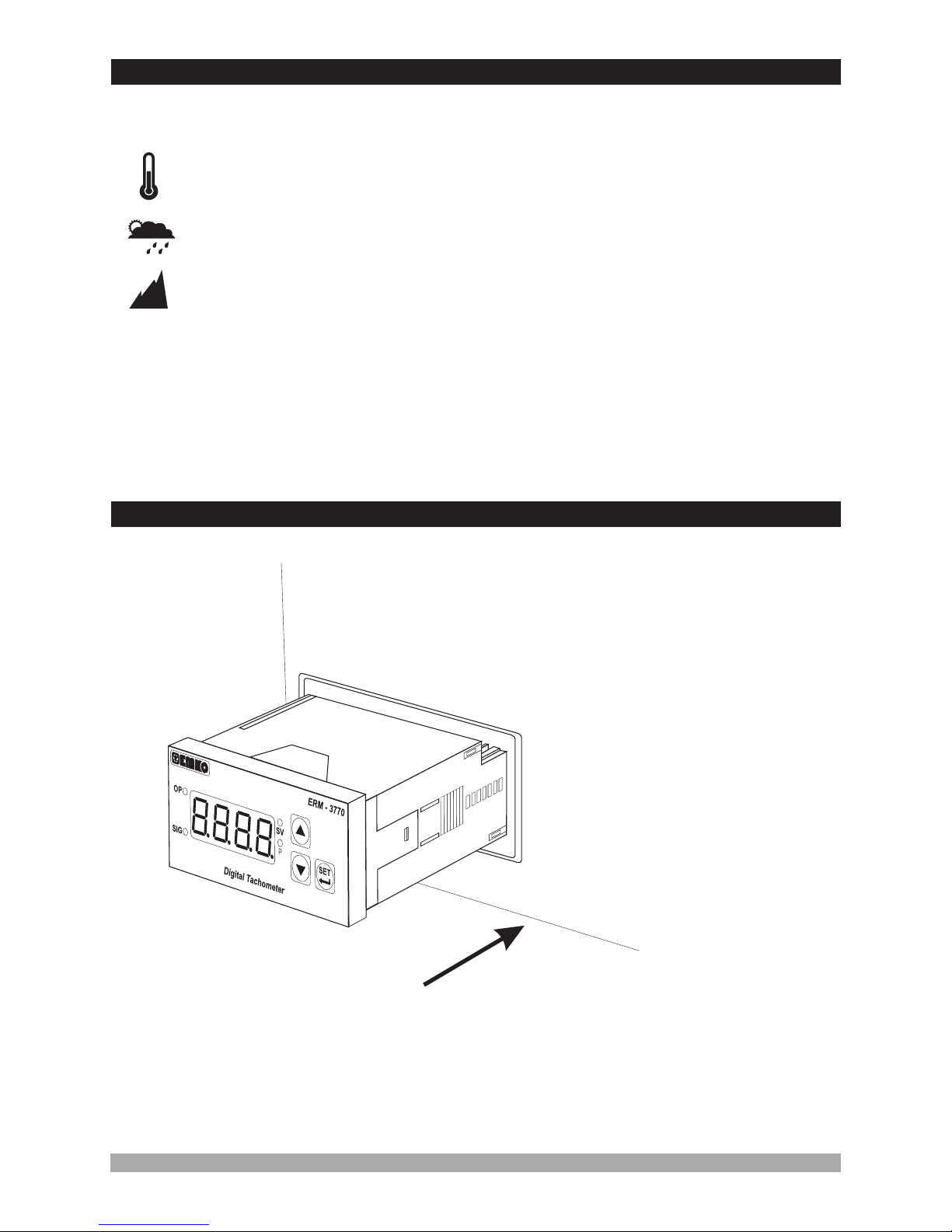

2.2 FRONT VIEW AND DIMENSIONS OF ERM-3770 DIGITAL TACHOMETER WITH ALARM

OUTPUT

2.3 FRONT VIEW AND DIMENSIONS OF ERM-3770 DIGITAL TACHOMETER WITHOUT

ALARM OUTPUT

3.2 ELECTRICAL WIRING DIAGRAM

3.3 VIEW OF THE DEVICE LABEL

3.5 PROCESS INPUT CONNECTION

3.5.1 PROXIMITY CONNECTION

3.5.2 SWITCH CONNECTION

3.6 GALVANIC ISOLATION TEST VALUES OF ERM-3770 DIGITAL TACHOMETER

3.7.2 SSR DRIVER OUTPUT CONNECTION

4.1 FRONT PANEL DEFINITION OF ERM-3770 DIGITAL TACHOMETER WITH ALARM

OUTPUT

4.2 FRONT PANEL DEFINITION OF ERM-3770 DIGITAL TACHOMETER WITHOUT ALARM

OUTPUT

4.3 OBSERVATION OF THE SOFTWARE REVISION ON THE DISPLAY

4.4 CHANGING AND SAVING PROCESS SET VALUE

4.5 PROGRAMMING MODE PARAMETER LIST

4.6 OPERATION GRAPHICS OF ALARM OUTPUT AND ALARM TYPES

4.7 EASY ACCESSING DIAGRAM OF PROGRAMMING MODE PARAMETERS

4.7.1 DEVICE WITH ALARM OUTPUT

4.7.2 DEVICE WITHOUT ALARM OUTPUT

4.8 ENTERING TO THE PROGRAMMING MODE, CHANGING AND SAVING PARAMETERS

4. FRONT PANEL DEFINITION AND ACCESSING TO THE MENUS...................................................

5. FAILURE MESSAGES IN ERM 3770 DIGITAL TACHOMETER........................................................

6. SPECIFICATIONS...............................................................................................................................

6.OTHER INFORMATIONS....................................................................................................................

Contents

Page 5

Page 19

Page 12

Page 7

Page 30

3

Page 29

Page 30