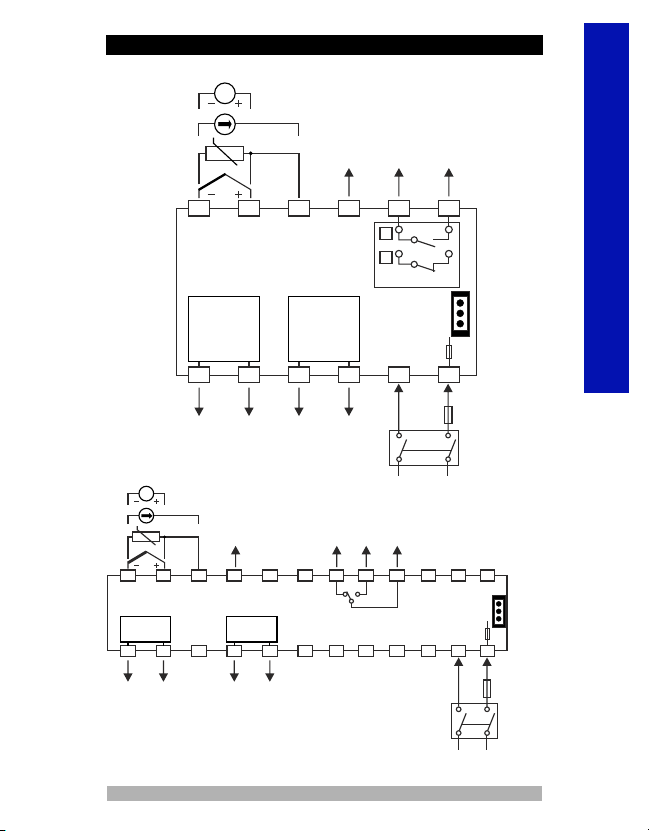

Process Input Type

TC input type selection

RTD input type selection

ZVoltage / Current input type selection.

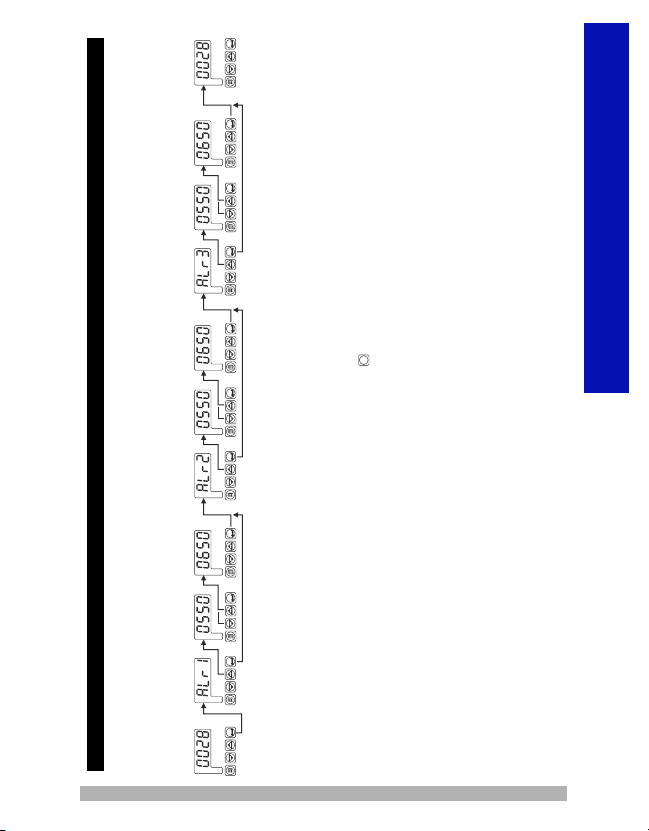

TC Input Selection

This parameter is active if TC input type is selected.

L (-100°C;850°C) or (-148°F;1562°F)

L (-100.0°C;850.0°C) or (-148.0°F;999.9°F)

J (-200°C;900°C) or (-328°F;1652°F)

J (-199.9°C;900.0°C) or (-199.9°F;999.9°F)

K (-200°C;1300°C) or (-328°F;2372°F)

K (-199.9°C;999.9°C) or (-199.9°F;999.9°F)

R (0°C;1700°C) or (32°F;3092°F)

R (0.0°C;999.9°C) or (32.0°F;999.9°F)

S (0°C;1700°C) or (32°F;3092°F)

S (0.0°C;999.9°C) or (32.0°F;999.9°F)

T (-200°C;400°C) or (-328°F;752°F)

T (-199.9°C;400.0°C) or (-199.9°F;752.0°F)

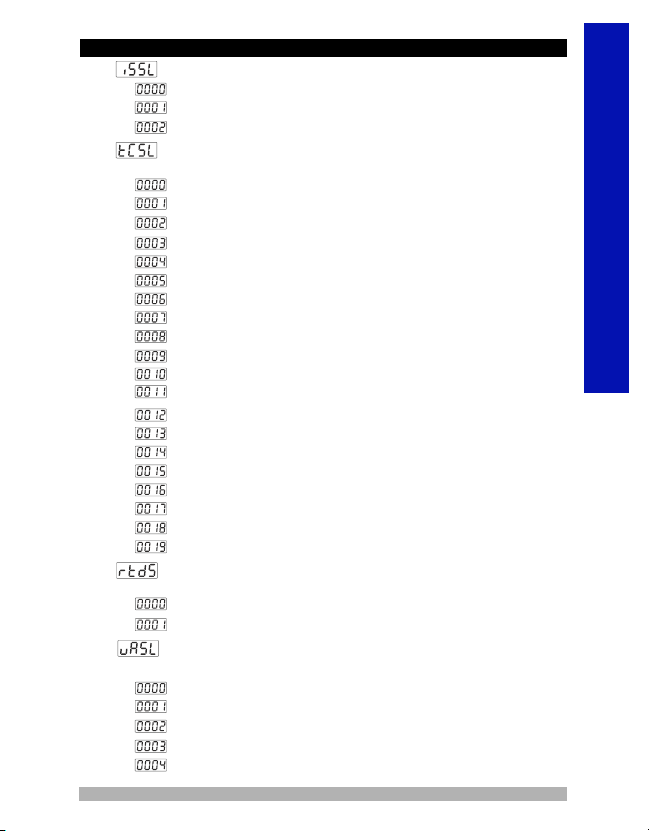

PınP ConF: Process Input Type and Relevant Parameters

B (44°C;1800°C) or (111°F;3272°F)

B (44.0°C;999.9°C) or (111.0°F ; 999.9°F)

E (-150°C;700°C) or (-238°F;1292°F)

E (-150.0°C;700.0°C) or (-199.9°F;999.9°F)

N (-200°C;1300°C) or (-328°F;2372°F)

N (-199.9°C;999.9°C) or (-199.9°F;999.9°F)

C (0°C;2300°C) or (32°F;3261°F)

C (0.0°C;999.9°C) or (32.0°F;999.9°F)

RTD Input Selection

This parameter is active if RTD input is selected.

PT-100 ( -200°C ; 650°C ) or ( -328°F ; 1202°F)

PT-100 ( -199.9°C ; 650.0°C ) or ( -199.9°F ;999.9°F)

Zvoltage / Current Input Selection

This parameter is active if ZVoltage / Current is selected.

0...50mV Z ( -1999 ; 9999 )

0...5V Z ( -1999 ; 9999 )

0...10V Z ( -1999 ; 9999 )

0...20mA Z ( -1999 ; 9999 )

4...20mA Z ( -1999 ; 9999 )

10

ENGLISH