8

GBGB

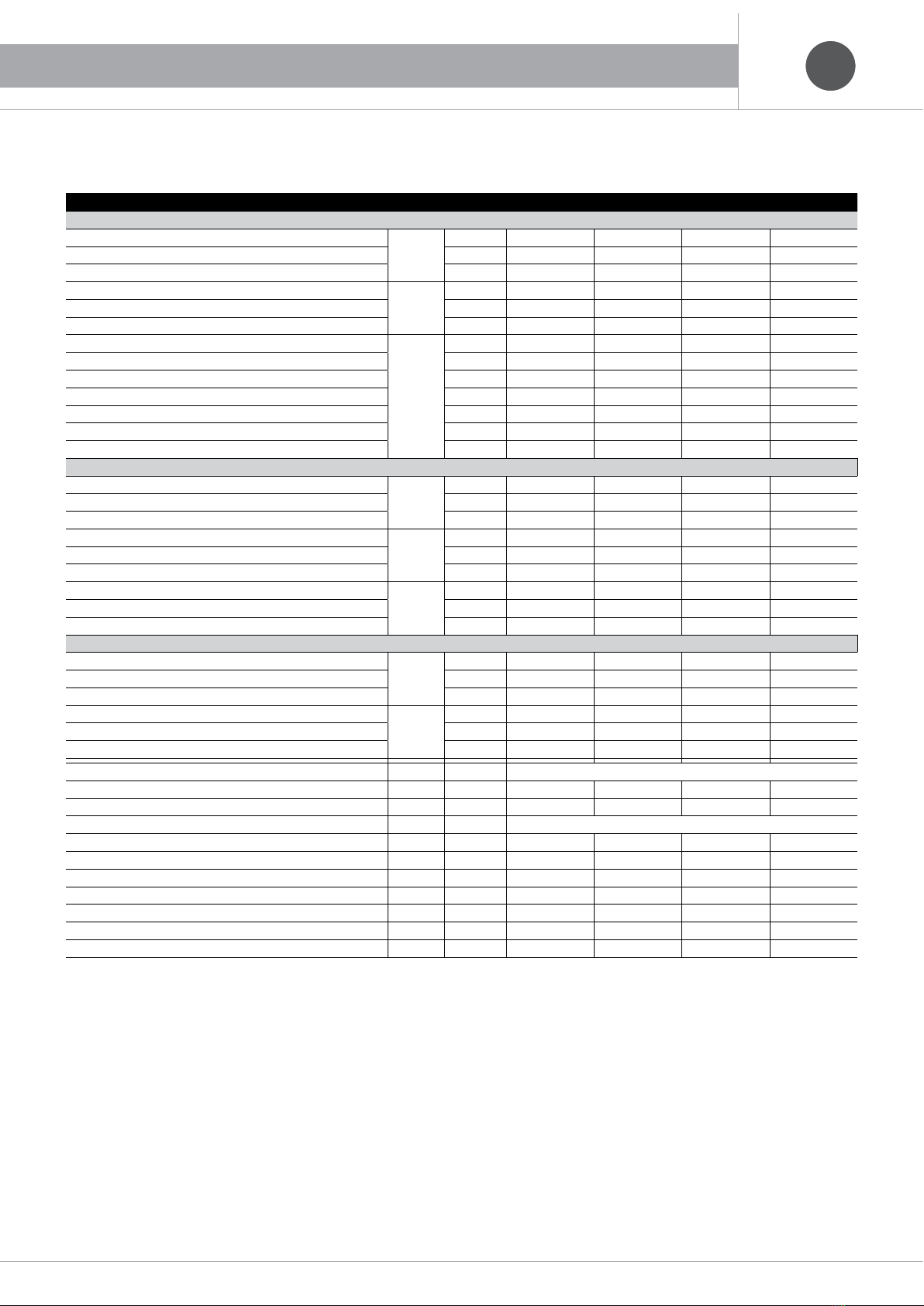

Technical Specifications

Models Ref. u.m.

EH0614DC EH1014DC EH1314DC EH1614DC

APPLICATION USING AIR TERMINAL UNITS

Nominal Thermal Power

A7 W45

kW 6,40 9,75 13,30 16,00

Nominal Absorbed Power kW 1,99 2,83 3,76 4,70

COP 3,22 3,44 3,54 3,40

Nominal Thermal Power

A-7 W45

kW 3,70 5,90 9,10 10,60

Nominal Absorbed Power kW 1,76 2,79 4,08 4,83

COP 2,10 2,12 2,23 2,20

Nominal Cooling Power

A35 W7

kW 3,95 5,53 10,70 12,60

Nominal Absorbed Power kW 1,37 1,90 3,11 4,17

EER 2,88 2,91 3,44 3,02

ESEER 4,69 4,54 5,96 5,88

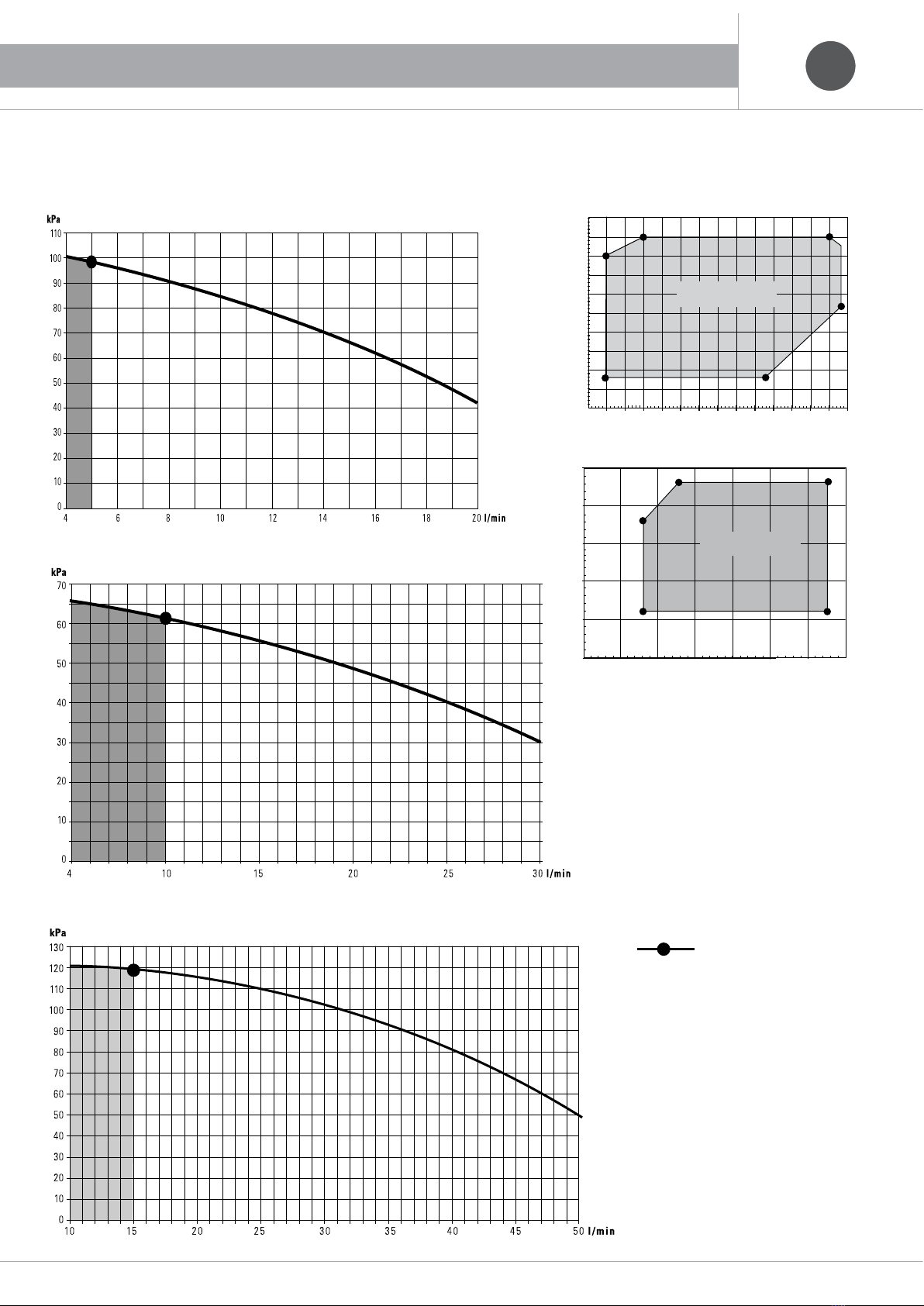

Pump - Available Pressure kPa 100 55 92 90

Noise Level dB(A) 60 62 63 63

Noise Pressure* dB(A) 38 40 41 41

APPLICATION USING HEATING PANELS

Nominal Thermal Power

A7 W35

kW 6,48 9,87 14,10 17,00

Nominal Absorbed Power kW 1,47 2,15 3,14 4,05

COP 4,40 4,58 4,49 4,20

Nominal Thermal Power

A-7 W35

kW 4,00 6,50 9,50 11,00

Nominal Absorbed Power kW 1,47 2,38 3,46 4,06

COP 2,72 2,73 2,74 2,71

Nominal Cooling Power

A35 W18

kW 5,30 7,30 14,20 16,20

Nominal Absorbed Power kW 1,32 2,02 3,05 3,98

EER 4,02 3,61 4,66 4,07

APPLICATION USING LOW-TEMPERATURE RADIATORS

Nominal Thermal Power

A7 W55

kW 5,90 9,30 12,50 14,00

Nominal Absorbed Power kW 2,31 3,26 4,38 5,01

COP 2,55 2,85 2,85 2,80

Nominal Thermal Power

A-7 W55

kW 3,10 5,40 8,70 9,20

Nominal Absorbed Power kW 1,83 3,11 4,75 4,96

COP 1,70 1,73 1,83 1,85

Electricity Supply 230V~ 50Hz

Maximum Power Absorbed kW 2,5 3,5 5,5 5,6

Maximum Current A11,2 18,3 25,3 25,3

Compressor Type Twin Rotary

R410 Refrigerant kg 1,05 1,60 2,99 2,99

Water Connections Ø3/4” 1” 1” 1/4 1” 1/4

Maximum Water Pressure bar 3,0 3,0 3,0 3,0

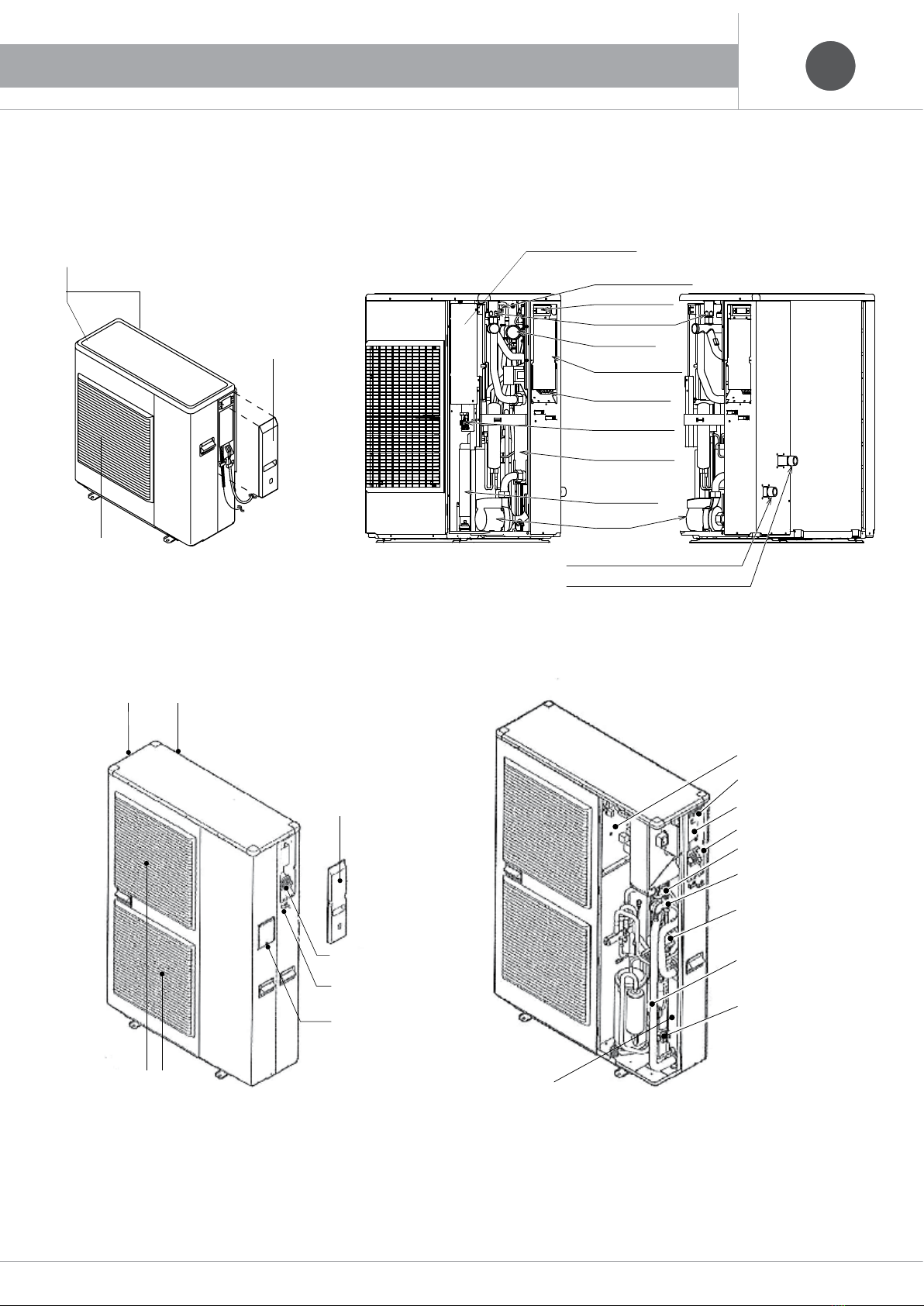

Width mm 850 874 1024 1024

Height mm 675 882 1420 1420

Depth mm 315 345 356 356

Weight kg 52 77 118 118

Data in relation to the following conditions:

A35 W18 Air: 35 °C - Water: 18/23 °C

A35 W7 Air: 35 °C - Water: 7/12 °C

A7 W35 Air: 7(6) °C - Water 30/35 °C

A7 W35 Air: -7(-8) °C - Water G/35 °C. G=water range the same as in condition A7 W35

A7 W35 Air: 7(6) °C - Water 40/45 °C

A7 W35 Air: -7(-8) °C - Water G/45 °C. G=water range the same as in condition A7 W35

A7 W35 Air: 7(6) °C - Water 47/55 °C

A7 W35 Air: 7(-8) °C - Water G/55 °C. G=water range the same as in condition A7 W35

(*) In an open area (Q = 2) 5 metres from the unit.

(European Seasonal Energy Efficiency Rating)

Performance in accordance with EN 14511:2011.

3. TECHNICAL SPECIFICATIONS