EMOVE EM303A User manual

34 3 Cable number markers (1,2,3,4)

16 1 Positive (+) red battery cable 1.8m including fuse holder & 100A fuse

EM303A 1

TABLE OF CONTENTS

Package contents (Parts list) Page 1

Introduction Page 2

Intended use Page 2

Specifications Page 2

Installation - safety guidelines Page 2

Installation - mechanical components Page 3

Installation - electrical/electronic components Page 4

Installation - tips for tandem axle Page 6

Operation - safety guidelines Page 7

Operation - motor units Page 8

Operation - remote control handset Page 8

Operation - electronic control unit Page 9

Operation - getting started Page 10

Operation - hitching and unhitching Page 11

Maintenance Page11

Trouble-shooting Page 12

PACKAGE CONTENTS

Ref Qte Description

1 1 Motor unit (A)

2 1 Motor unit (B)

3 1 Main cross bar

4 1 Electronic control unit

5 1 Remote control handset with lanyard

6 1 Emergency key

17 1 Negative (-) black battery cable 1.6m

41 20 Screw - M4x15

32 10 Cable trunking P-clip 19.2mm

33 10 Cable P-clip 10.4mm

29 4 Battery terminal connector 8mmØ

28 2 Battery terminal connector 6mmØ

30 4 Spade fork connector big

35 3 Cable polarity markers (+,-)

37 10 Cable tie 2x70

39 1 Battery isolation switch, cover & key

40 2 Roller distance spacers 20x20

38 2 Rubber isolation shell for battery isolation switch

43 1 Remote control handset wall holder

42 2 Screw – M5x40

31 4 Spade fork connector small

7 2 Chassis stop blocks

8 4 Chassis hanging bracket

9 2 Carrier plate

10 8 5mm shim for narrow chassis

11 2 Cross member support bracket ( Chassis U plate)

12 2 Bar support hanging bracket

13 1 Convoluted cable trunking

18 4 Bolts M12x30

19 4 Bolts M12x40

20 4 Bolts M12x50

21 12 Nuts M12

22 12 Spring washers M12

23 24 Plain washers M12

24 8 Bolts M10x40

25 8 Nuts M10

26 16 Plain washers M10

27 8 Spring washers M10

44 1 User manual

INTRODUCTION

INTENDED USE

SPECIFICATIONS

Designation EM303A

Operational voltage 12 Volt DC

Average current consumption 20 Ampere

Maximum current consumption 100 Ampere

Transmitting frequency remote control 868MHz

Speed approx.13

Weight (2 motor set) approx. 46kg (exclusive battery)

Permissible overall Weight single axle (2 motors) 3960lbs (3300lbs on 18% gradient)

Permissible overall Weight tandem axle (2 motors) 3960lbs (3300lbs on 18% gradient)

Permissible overall Weight tandem axle (4 motors) 5500lbs (3960lbs on 18% gradient)

Minimum width (trailer) 1800mm

Maximum width (trailer) 2500mm

Maximum tyre width 205mm

INSTALLATION - SAFETY GUIDELINES

Read this user manual carefully before installation and use. Failure to comply with these

rules could result in serious injury or damage to property.

These symbols identify important safety precautions. They mean CAUTION! WARNING!

SAFETY FIRST! IMPORTANT INFORMATION!

EM303A 2

cm per sec

according to very high standards and has undergone careful quality control procedures.

Simply by using the remote control handset you can move your trailer effortlessly into any position required

within operating guidelines. Soft start and soft stop technology allows you to manoeuvre your trailer even

more accurately without any shocks.

The trailer manoeuvring system consists of two 12V motor-power rollers, a 12V electronic control unit and a

remote control handset. To function, the motor-powered rollers must be engaged against the tyres of your

trailer. The EM303A trailer manoeuvring system is provided with an automatic engaging system. By

pushing two buttons on the remote control, both motor-powered rollers will be simply pressed on the tyre.

Once this is done the manoeuvring system is ready for operation. The remote control will allow you to move

your trailer in any direction. You can even rotate the trailer on it’s own axis without moving forwards or

backwards (this function just can work under the “single-axle function”).

Congratulations on choosing the EM303A trailer manoeuvring system. This has been produced

Before proceeding with installation and starting to use the manoeuvring system, please read

this manual very carefully and be aware of all the safety instructions! The owner of the

trailer will always be responsible for correct use. Keep this manual inside your trailer for

future reference.

The EM303A trailer manoeuvring system is suitable for single axle and tandem axle trailers.

Depending on the weight of the trailer, the manoeuvring system cannot overcome obstructions that are more

than about 2cm in height without assistance (please use wedges as a ramp).

The standard installation kit only provides parts for installing the trailer manoeuvring system within the

measurements given in Fig. 13.

Power source (deep cycle battery) 4: 12V, 20Ah

Lead acid: 12V, 85Ah (min.)

LiFePO

Before starting installation under the trailer:

Check the towing load of your vehicle and the gross weight of your trailer in order to establish whether they

are designed for the additional weight. The manoeuvring system itself has a weight of about 46kg.

Only use adapters and accessories that are supplied or recommended by the manufacturer.

Check that the trailer is disconnected from the battery supply and the mains electrical supply.

Check that the tyres are not over worn and do have the same size and design.

Check the minimal installation dimensions of the manoeuvring system based on figure 13.

Make sure that the tyre-pressures are correct to the manufacturer’s recommendation.

Make sure the chassis is in good condition without any damage and is free from rust, dirt etc.

Stop work immediately if you are in doubt about the assembly or any procedures and consult one of our

engineers.

Do not remove, change or alter any parts of the chassis, axle, suspension or brake mechanism. Any drilling of

holes in the chassis is not allowed.

Do not install the unit if you are under the influence of drugs, alcohol or medication that could impair your

ability to use the equipment safely.

INSTALLATION - MECHANICAL COMPONENTS

FOR PROFESSIONAL INSTALLATION ONLY! These instructions are for general guidance.

Working under a vehicle without appropriate support is extremely dangerous!

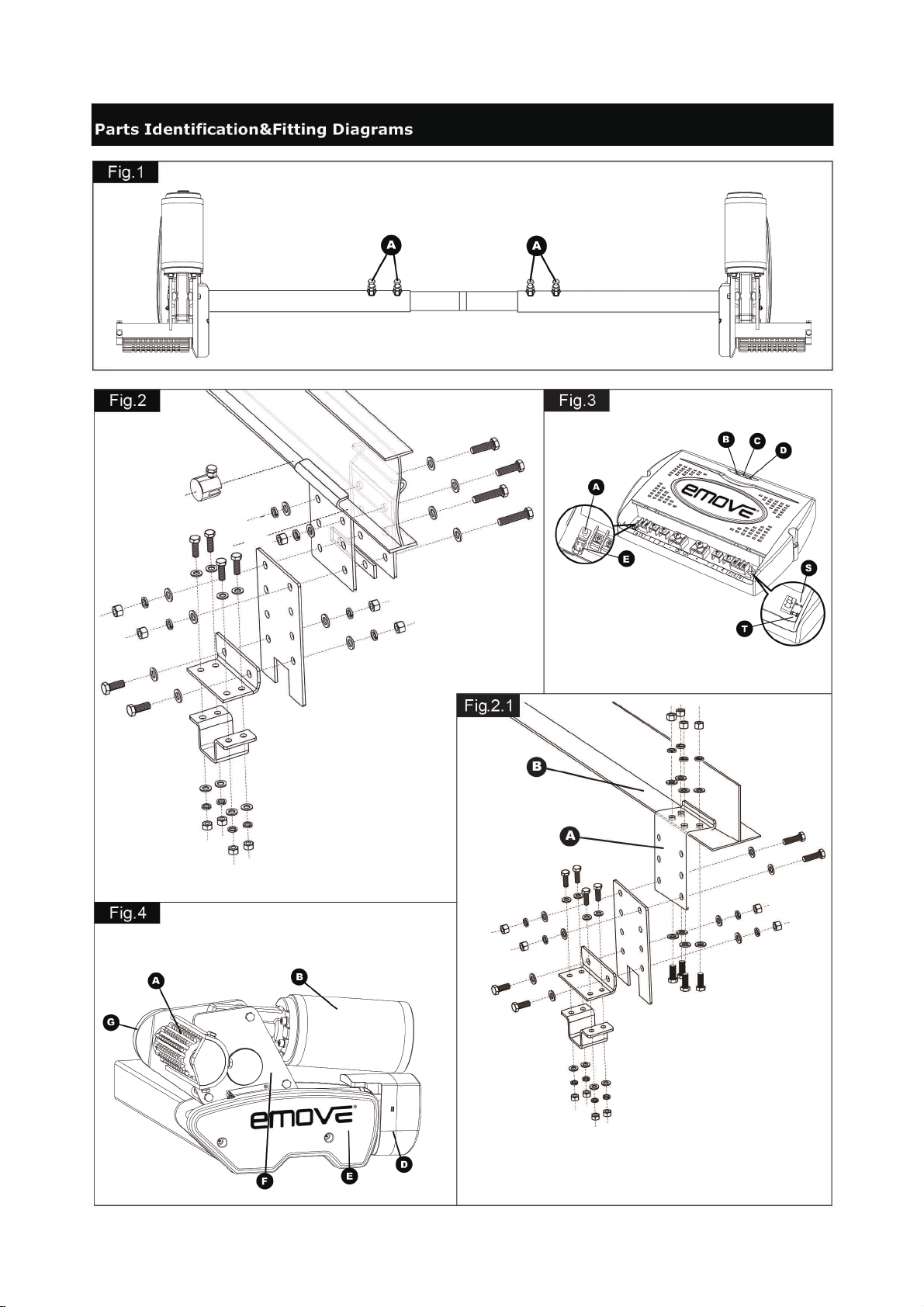

Please refer to figure 5 for an overview of the whole assembly fully fitted.

Assemble the pre-mounted manoeuvring system to the steel chassis clamp plates (Fig.2 & Fig.5) by using the

cross member support bracket (11), bolts M10x40 (24), nuts M10 (25), spring washers (27) and plain washers

(26).Nutsmustbenomorethanfinger-tight.

Part A in Fig2.1 is an optional part that you can order from your supplier to substitute two chassis hanging brackets

(8), fitting by drilling holes on chassis first and then fixing with existing two bolts M12x40 (19) ,nuts M12 (21) , washers

EM303A 3

M12 (22 & 23) and another 2 bolts M12x40, nuts M12 and washers M12 supplied with part A.

Locate the battery isolation switch to be accessible at all times when parking and moving the trailer.

Installation procedures may vary depending on trailer type.

Place the trailer on a hard, level surface. The use of a lifting ramp or an assembly pit is ideal for access and

personal safety.

Unpack all the components and check for the presence of all parts (see package contents list). Write down

the serial number (this is located on an aluminium plate on the side of one of the motor units) for our after sales

Clean the area of your chassis where you need to mount all components to ensure a good fitting.

Make sure the trailer is prepared for installation. Check before installation that important areas, such as

drains/spare tyre etc. do not cause any obstruction to the function of the trailer manoeuvring system.

Ensure both rollers are in the DISENGAGED position (Fig. 10), as the unit will not fit correctly otherwise (Note:

when fully disengaged, the pointer is positioned in the beginning of the yellow area).

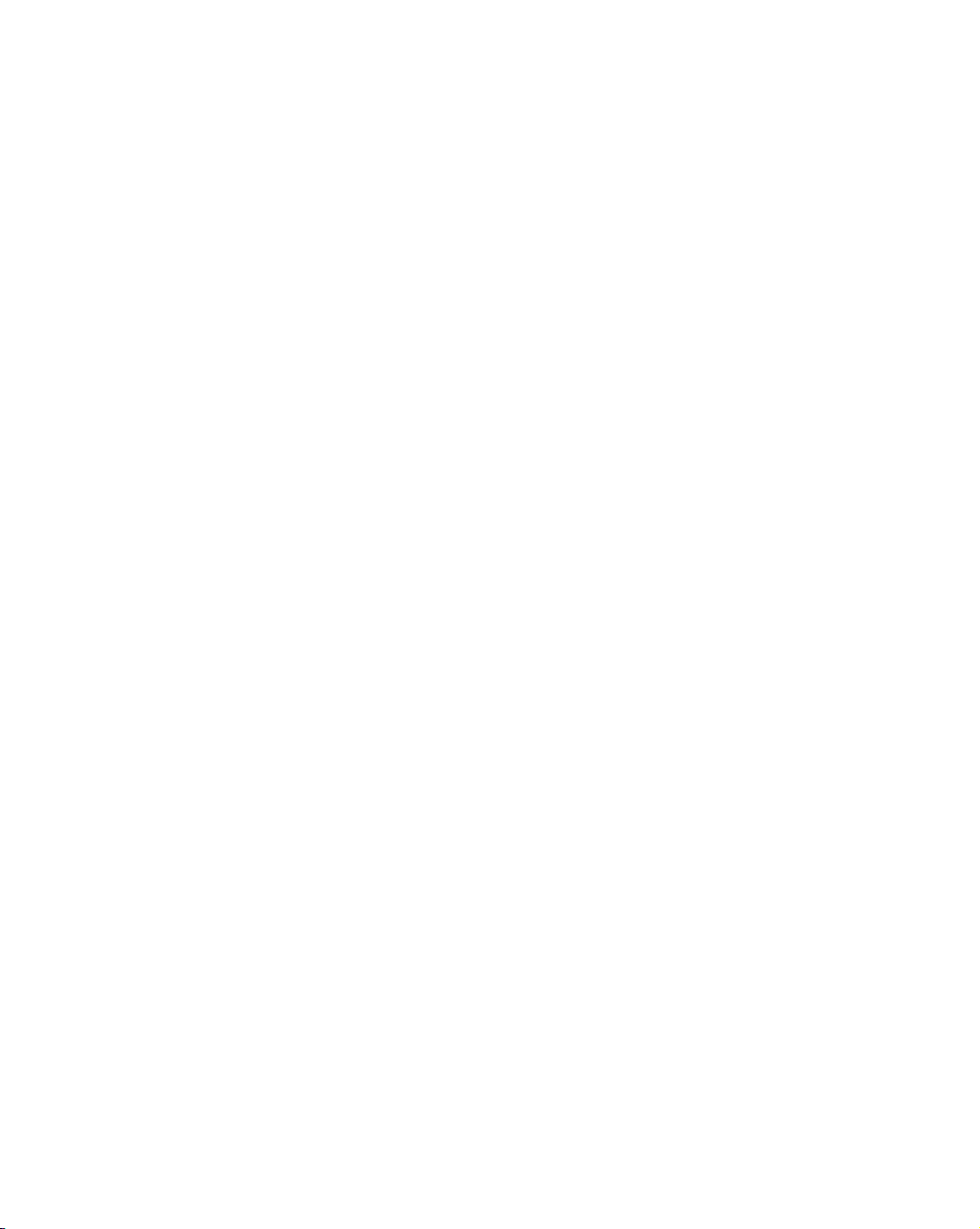

Loosely assemble the left hand motor unit (1), right hand motor unit (2) and main cross bar (3) (Fig. 1). The

nuts (Fig. 1A), on the cross bar (3) to secure both motor units, must be no more than finger-tight at this stage.

service.

Note: In principle, the unit should be fitted in front of the trailer road wheels, but if fitting in this position is

not possible because of obstacles or a too high hitch ball weight, it is permissible to fit it to the rear of the

wheels by rotating the whole assembly (Fig. 1) by 180° degrees.

Loosely fit the two chassis hanging brackets (8)to the chassis (Fig.2 & Fig.5) by using bolts M12 x 40 (19),

nuts M12 (21), spring washers(22) and plain washers (23). Place suitable quantity of 5mm shims (10) between

the two chassis hanging brackets (8), and then loosely fit the carrier plate (9) to the chassis hanging brackets(8)

and 5mm shims (10)by using bolts M12 x 50 (20), nuts M12 (21), spring washers (22) and plain washers (23),

choosing suitable holes in the chassis hanging brackets (8) to fix the carrier plate(9)to make sure the aluminum

drive roller of the pre-mounted manoeuvring system approximately on the same altitude as the center(axle) of

the trailer wheel. Loosely fit the bar support hanging bracket (12) to the carrier plate by using bolts M12 x 30

(18), nuts M12 (21) , spring washers (22) and plain washers (23). Nuts must be no more than finger-tight.

If you are NOT using the clamp bracket option and are bolting the bracket to the chassis you will need to

assemble the bracket with the mover attached for positioning. Ensure the mover is fully disengaged and

position the mover 20mm (3/4”) away from the surface of the centre each tire (Fig.10). Two 20mm spacers (40)

are provided. Mark the chassis where you need to drill the holes and drill the holes. Remove the mover from

the bracket and bolt the bracket to the chassis.

With the main assembly is loosely fitted onto the chassis, slide the whole assembly along the chassis until the

rollers are 20mm away from the surface of the centre each tyre (Fig. 10). Two 20mm spacers (40) are provided.

It is vitally important that each roller is at exactly the same distance away from the tyre.

Slide the motor units in or out of the cross bar (3) accordingly to ensure the roller will have

the maximum possible contact with the tread of the tyre. Ensure that the position of each

motor unit does not obstruct shock absorbers (if fitted) and that the gear cover (Fig. 8) is

not too close to the surface of the tyre/shock absorber. The minimum clearance when the

drive units swivelled in is 10mm.

Fully tighten the four bolts (Fig. 1A) on the main cross bar (3) and lock them by the additional nuts.

Re-check that all bolts/nuts have been tightened to the correct torque!

The main mechanical components have now been installed.

INSTALLATION - ELECTRICAL/ELECTRONIC COMPONENTS

Make sure the 12V supply from the battery and any 230V electricity supply are disconnected.

Remove battery cable terminals and disconnect any external electrical power before starting work.

Find a suitable place for the electronic control unit (4), such as a storage area, under a seat or a bed. Make

sure this place is dry and close to the battery (40cm to 60cm). The electronic control unit can be mounted

vertically on a side wall or be mounted flat. When mounted vertically, the connections must point downwards to

avoid any short-circuits by objects falling into.

Fix the electronic control unit securely into position with two screws M5x40 (42). Note: if the provided screws

are not of suitable length or type for the desired location/material please substitute these as appropriate.

Caution! Take extra care to avoid any chassis members, gas pipes and electrical wires!

Route and connect the motor-cables in accordance with wiring diagram (Fig. 12) (red = positive, black =

negative).

The wiring diagram (Fig. 12 + Table. A (see below)) depicts the wiring route when installing the motor units in

front

of the wheels/axle towards the ‘A’ frame. Please refer to table B (below) for fitment of the motor units to

the rear

of the axle.

Fix the Chassis Stop Blocks(7) next to the mounting brackets

torque,and at the rear of the tyre, see Fig5. Fix the bolts with

then fix the nut with a 40Nm torque to keep the bolts on position.

a 40Nm

EM303A 4

Adequate ground clearance: Please notice that the min. distance between the lowest line of

motors and ground is 110mm( 4½ " ), no matter what kind of chassis or install situation.

Make sure that aluminium drive rollers of the motors are approximately on the same altitude as the centre

(axle) of the trailer wheel (0mm~40mm, see Fig. 10). As well make sure that between the top of the motor

housing and the floor of the trailer is minimal 20mm(3/4") space to make sure the motors can move freely (see

Fig. 10 & 14). To compensate a possible unevenness (and lower the motors),

available from your supplier. One set can compensate 15mm (3/5"). In total three sets can be used so that an altitude

of 45mm can be compensated.

a set of distance plates are

Make sure that the main cross bar (3) is positioned in the middle of the trailer (the centre of the bar is

marked).

The whole assembly must be parallel to the trailer axle.

Re-check that there is sufficient space available (minimal 20mm (3/4" )) between the top of the

motor housing and the floor of the trailer so the motors can move freely (Fig. 14).

Fully tighten all the nylon nuts on both clamping assemblies (Fig.2 and Fig.5). Tighten the M10x40 (24) bolts

to a 40Nm torque.

Re-check the distance of 20mm(3/4") from the rollers to the tires, the position of the aluminium rollers in addition

to the surface of the tire and finally the distance between the gear cover (Fig. 8) and the tires & shock absorbers

(>10mm). The weight of the trailer must be on the wheels when doing this. If necessary, loosen the bolts and

re-adjust the position of the assembly.

Drill a 25mm(1") hole through the floor of the trailer approximately 150mm(6") centrally in front of the control

unit (4) terminals.

Table. A

FRONT OF AXLE FITTING

(4,6mm2cables)

Motor unit A Positive (+) cable to terminal 4

Motor unit A Negative (-) cable to terminal 3

Motor unit B Positive (+) cable to terminal 2

Motor unit B Negative (-) cable to terminal 1

Automatic engaging system (1,5mm2cables):

Motor unit A: Positive (+) cable to terminal d

Motor unit A: Negative (-) cable to terminal c

Motor unit B: Positive (+) cable to terminal b

Motor unit B: Negative (-) cable to terminal a

Table. B

REAR OF AXLE FITTING

(4,6mm2cables)

Motor A Positive (+) cable to terminal 1

Motor A Negative (-) cable to terminal 2

Motor B Positive (+) cable to terminal 3

Motor B Negative (-) cable to terminal 4

Automatic engaging system (1,5mm2cables):

Motor unit A: Positive (+) cable to terminal b

Motor unit A: Negative (-) cable to terminal a

Motor unit B: Positive (+) cable to terminal d

Motor unit B: Negative (-) cable to terminal c

Mark the motor cables (14 & 15) for both motor units using the cable markers (34). The cables for the left and

the right motor should have the same length. Avoid any loops.

Connect the spade connectors to the motors. Please note that the red cable is connected to the terminal under

the moulded ‘+’ symbol on the weatherproof terminal cover.

Use the large cable ties (36) to secure the motor cables to the motor. This ensures that there is no force and

movement on the spade connectors or movement of the cables during transit.

Remember to leave a small amount of slack cable near the motors to allow for their movement when the drive

rollers are engaged.

Once the all cables are through the drilled hole next to the control unit (4), cut the cables, ensuring that they

are the same length. Remove approx. 5mm of the insulation from the ends. Fix the big spade fork connectors

(30) to the motor cables and the small spade fork connectors (31) to the automatic-engaging-cables by using

crimping pliers. A secure and good quality connection on each cable is essential.

Attach the spade fork connectors to the terminals on the control unit (see wiring diagram Fig. 12) and fix them

tightly by the screws. A safe and good quality connection on each cable is again essential.

Use the cardboard template to position the hole positions and the drill holes. Mount the switch and the housing

Route the positive (+) power cable (including fuse) from the battery to the battery power isolation switch (39)

and than further to the control unit (4).

The electronic connections of the battery power isolation switch (29) must be covered by the supplied rubber

isolation shells (38).

Route the negative (-) power cable directly to the control unit (4).

No cables may be routed over the control unit!

Again it is recommended to use the supplied trunking (13) to protect the cables against sharp edges. Attach the

trunking with P-clips (32) and P-clip screws (41).

Cut the cables to an appropriate length and remove approx. 5mm of the insulation from the ends. Fix the

battery terminal connectors by using crimping pliers. Two types of battery terminal connector (29 & 28) are

provided for use as appropriate. A secure and good quality connection on each cable is essential.

Connect the battery cables (16 & 17) to the control unit (4): Attach the spade fork connectors to the positive

(+) and negative (-) terminal of the control box and fix them tightly by the screws.

Connect the battery cables to the existing battery terminals (red = positive, black = negative).

EM303A 5

Route all the cables along the underside of the trailer floor, inside the supplied convoluted trunking (13) (this

will protect the electrical cables against sharp edges and dirt) and through the drilled hole.

Secure the cable trunking (13) to the chassis or under body of the trailer by using the P-Clips (32) and screws

(41).

Find a suitable place for the battery power isolation switch (39) which includes an external holder with hinged

cover. Important: The switch must be mounted onto the exterior body of the trailer and be easily

accessible from the outside of the trailer in case of any emergency. The switch must be mounted close

to the location of the battery in order to keep the length of the battery cables to a minimum.

with the bolts, washers and nuts, and finally mount it on the trailer with stainless steel screws (41).

Caution! Make sure that you do not reverse the Positive (+) and Negative (-) connections.

Incorrect connection (reverse polarity) will result in damage to the control unit.

Finally find a suitable place for the remote control handset wall holder (43) and fix this by the supplied screws

(out of reach of children or other unauthorised people).

This manual describes the general installation and use of the manoeuvring system for single axle caravans.

When you use the manoeuvring system for a twin axle caravan, please check the following:

2 motors:

4 motors:

Finally both electronic control units (4) must be prepared for the use of only one remote handset (43). The

remote handset need to be synchronised with both electronic control units using the following procedure:

Check the installation in accordance with the installation instructions and ensure that the drive rollers are

not applied. Check that the battery is properly connected, check the condition of the battery and that a

voltage of 12V is present at the control unit.

Please ensure that both battery isolation switches are on.

Activate the remote control handset by sliding the slide switch to “On”-I (Fig. 7A). The green LED on the

remote control handset (Fig. 7H) starts to flash slowly.

Press the reset button (Fig. 3A) on the control unit. All three LED’s on the control unit (Fig. 3B, 3C & 3D)

will flash slowly.

Press both forwards (Fig. 5B) and reverse (Fig. 7C) button on the remote control handset for about 3

seconds. Then the handset buzzer will give a short beep to confirm that the synchronisation is complete.

After successful synchronisation, the green LED on the control unit (Fig. 3B) and on the remote control

handset (Fig. 7H) will illuminate continuously.

Repeat this procedure 3,4,5,6 with the second electronic control unit.

Turn the remote handset “Off” and then “On” again so both control units will be activated.

EM303A 6

1.

2.

3.

4.

5.

6.

7.

8.

Seal the 25mm (1") hole in vehicle under body using plastic body sealant.

Installation of the trailer manoeuvring system is now complete.

INSTALLATION – TIPS FOR TANDEM AXLE TRAILER

Permissible overall Weight tandem axle (2 motors) 3960lbs (3300lbs on 18% gradient)

Permissible overall Weight tandem axle (4 motors) 5500lbs (3960lbs on 18% gradient)

The procedure for installing a 2 motors manoeuvring system on a tandem axle trailer is the same as for a single

axle trailer. The electronic control unit (4) only must be prepared for tandem axle use:

Turn off the battery power isolation switch and move the single/tandem axle function switch (Fig 3S/T) on the

control unit to the tandem axle position (Fig. 3T), so that the manoeuvring system can be used for a tandem axle

trailer. In the tandem axle function when making curves, all wheels will drive but at a different speed.

The procedure for installing a 4 motors manoeuvring system on a tandem axle trailer is similar than for a single

axle trailer but then with two sets of manoeuvring system.

Follow the procedure for installing the mechanical components twice: one time for the manoeuvring set

mounted in front of the tandem axle and one time for the manoeuvring set mounted behind the tandem axle.

Follow the procedure for installing the electrical/electronic components twice: one time for the

manoeuvring set mounted in front of the tandem axle and one time for the manoeuvring set mounted behind the

tandem axle.

Note: When installing the four motors it will be necessary to use one higher capacity battery to supply both

sets of manoeuvring system (including two electronic control units and two of battery power isolation switches).

Do not use two separate batteries for a 4 motors manoeuvring system on a tandem axle trailer.

Now both electronic control units (4) must be prepared for tandem axle use:

Turn off the battery power isolation switch and move the single/tandem axle function switch (Fig 3S/T) on the

control unit to the tandem axle position (Fig. 3T), so that the manoeuvring system can be used for a tandem axle

trailer. In the tandem axle function when making curves, all wheels will drive but at a different speed.

The installation of the trailer manoeuvring system for tandem axle use is now complete. For details of the

operation, use and all the LED and button functions, please refer to the standard chapters of this manual.

OPERATION - SAFETY GUIDELINES

Practice operating the manoeuvring system in an open area before using for the first time. This is to fully

familiarise yourself with the handset / manoeuvring system operation.

Always ensure that children and pets are kept well out of the way during operation.

When operating the system, ensure that no hairs, fingers or other body parts, clothing or any other

objects carried on the body can become trapped by moving or rotating parts (e.g. drive rollers).

In the event of malfunctions, pull on the handbrake immediately and turn off the main isolation power

switch.

To maintain signal strength, always make sure that, during manoeuvring, the distance between the

Due to the nature of a radio signal, it can get corrupted by external terrain or objects. So there may be

may stop momentarily.

Always make sure that the rollers are fully disengaged from the tyres when the manoeuvring system is

not in use. This is better for the tyres and for the system.

Always make sure that the rollers are fully disengag

manpower. This can damage the tyres, manoeuvring system and the towing vehicle.

Always make sure that after you have finished using the manoeuvring system, the battery power

isolation switch (39) is switched off and the key is removed and stored in a safe place (out of reach of

children or other unauthorised people). If you don’t switch off, the battery will be discharged by the

small ”standby” current.

Always make sure that the remote control handset is switched off and stored (in the wall holder) in a

safe place (out of reach of children or other unauthorised people). If you don’t switch off, the battery

will be discharged by the small ”standby” current.

Do not rely on the manoeuvring system to act as a brake.

Always apply the handbrake after manoeuvring, before disengaging the drive rollers from the tyres.

Depending on the weight of the caravan, the manoeuvring system cannot overcome all obstructions

without assistance. Please use wedges as a ramp.

EM303A 7

Before use, always check the trailer manoeuvring system for any damage.

When towing or moving the trailer please be aware, at all times, that ground clearance is reduced

when the manoeuvring system has been fitted.

remote control and the trailer does not exceed 5 metres (16').

small areas around the trailer where the quality of reception reduces, hence the manoeuvring system

Always be aware that the manoeuvring system increases the weight of your trailer. So this

reduces the payload of the trailer.

Do not exceed the total permissible working load in specification page.

ed before towing/moving the trailer by vehicle or

Do not use the manoeuvring system as a support when jacking up the trailer, since this can damage

the drive unit.

All wheels and tyres on the trailer must be of the same size and design. If tyres are worn or new

tyres are fitted, the distance between the drive rollers and the tyres may need readjusting (see

“Installation - Mechanical Components”).

Sensitive objects such as cameras, DVD-Players etc, must not be kept in the stowage box near the

control unit or the motor cable. They can be damaged by the electromagnetic fields.

Do not make any modifications on the trailer manoeuvring system (mechanical or electronically).

This can be very dangerous! No warranty claim will be accepted and we cannot guarantee the function

of the system if any modifications are made. We will not be liable for any damage whatsoever caused

as a result of incorrect installation, operation or modification.

OPERATION - MOTOR UNITS

Fig. 4

A. Aluminium drive roller

B. 12V Motor

C. Motor connection terminals (+ and -)

D. Motor for automatic engaging system

E. Base unit

F. Drive unit

G. Gear

Traction indicator label:

The yellow-green-red traction indicator label (Fig. 11A), on the side of each motor unit indicates if the roller is

depressing the tyre sufficiently to provide adequate traction.

If the pointer is in the yellow area – Rollers are not touching or depressing the tyre sufficiently.

If the pointer is in the green area – Rollers should be connecting correctly to the tyre (margin of 15mm).

If the pointer is in the red area – Rollers are connected to the tyre but in an extreme position. It could be

and a visit to a workshop is required to reposition the assembly.

Disconnect the motor powered rollers in case of emergency:

discharged to far to automatically take of the motor powered rollers of

the tyre, or there is a defect, you can also do this manually. See figures 9 & 9.1.

Take the plastic cap (Fig. 9B) at the rear side of the housing of the motor for the automatic engaging system.

If necessary use a screwdriver. Place the emergency key (6) on the emergency socket in the motor unit (Fig.

9A & 9.1C) and turn it until the motor unit including motor powered rollers are in the beginning position. Repeat

this also on the motor unit on the other side.

Put the plastic caps back on the motor housing.

As soon as the battery is charged again, or the problem is solved, the motor powered rollers automatically work

again.

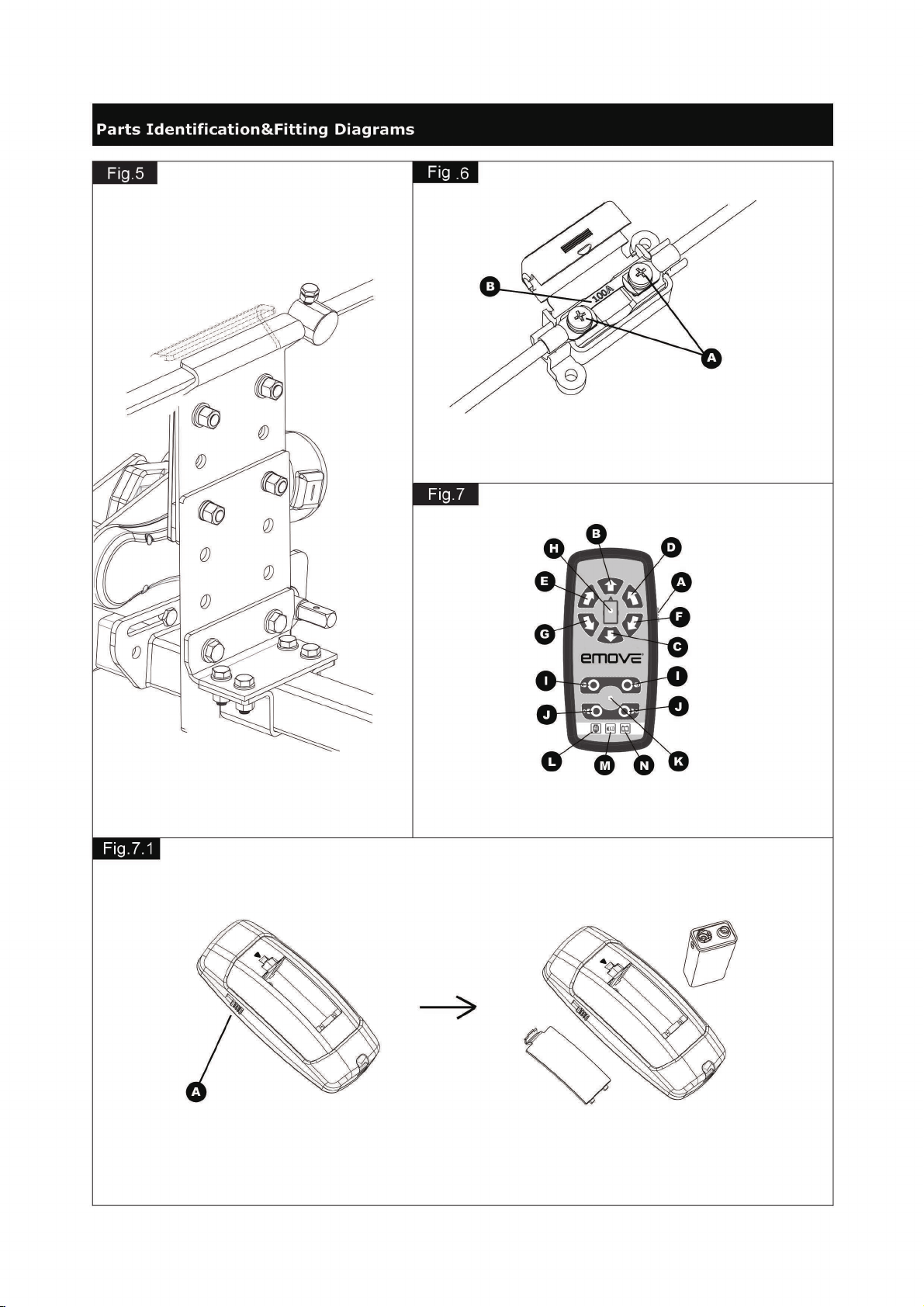

OPERATION - REMOTE CONTROL HANDSET

The remote control handset (5) is powered by one PP3 9Volt battery, and is activated by moving the slide

switch to “On”-I (Fig. 7A). Once activated the green LED (Fig. 7H) will illuminate and the directional controls

can now be used.

Fig. 7

A.

B.

C.

D.

E.

F.

G.

H.

I. Two handed service for automatic engaging of the motor powered rollers to the tyre

J. Two handed service for automatic disengaging of the motor powered rollers from the tyre

K. Blue LED: reflects status of the automatic engaging system

L. Red overload LED: Amp overload protection is activated. Wait about 60 seconds and try again.

M. Blue 9V battery LED: The internal 9V battery of handset is near empty and needs to be replaced.

N.

When you drive straight forwards or reverse (press button B or C), it is also possible to adjust the direction by

additional pressing button D or E (when driving forwards) or button F or G (when driving reverse).

When you switch within 2 seconds from forward driving to reverse driving (and the other way around), a small

delay of 1 second will appear to protect the electronics and the motors.

EM303A 8

The manoeuvring system has two motor units (1 & 2). In general they are mounted in front of the axle of the

trailer. Both units are identical but cannot be switched.

that the tyre of the trailer has insufficient air pressure or the drive unit has been knocked out of position

In the case that the trailer battery is

Slide switch (“Off” –O and “On”-I)

Trailer forwards (both wheels rotate in forwards direction)

Trailer reverse (both wheels rotate in reverse direction)

Trailer left forwards (right wheel rotates in forwards direction)

Trailer right forwards (left wheel rotates in forwards direction)

Trailer left reverse (right wheel rotates in reverse direction)

Trailer right reverse (left wheel rotates in reverse direction)

Green LED: reflects status of the remote control and trailer manoeuvring system

Blue battery voltage LED: Trailer battery voltage too low or too high.

In addition, the ‘right forward’ (E) and ‘left reverse’ (F) buttons or ‘left forward’ (D) and ‘right reverse’ (G)

buttons may be pressed at the same time to turn the trailer around on its own axis without moving forward or

backward (this function just can work under the “single-axle function”).

The slide switch (Fig. 7 A) also acts as an “Emergency stop”.

The automatic engaging system:

To activate the automatic engaging system of the motor powered rollers on the tyre, press the two buttons for

engaging (Fig. 7I) or disengaging (Fig. 7J) for at least three seconds. The blue LED (Fig. 7K) will blink fast

during these three seconds and every second there will be a beep. This warns you that the system will be

activated!

Engaging: After these three seconds the motor powered rollers will be pressed against the tyre, and the blue

LED will illuminate constant. Now you can release the two buttons. When the motor powered rollers are pressed

on the tyre strongly enough you hear a short beep, the blue LED will switch off and the system is ready to use.

Disengaging: after these three seconds the motor powered rollers will be released from the tyre, and the blue

LED will illuminate constant. Now you can release the two buttons. When the motor powered rollers are

completely disengaged you hear a short beep, the blue LED will switch off and is the system ready for transport.

The remote hand set switches off:

After 3 minutes, if no button is pressed: After 2 minutes the buzzer will beep for 5 times with a repetition

After 6 minutes, if one of the movement buttons is permanently held down: After 5 minutes the buzzer will

beep for 5 times with a repetition after 6 minutes. Than the system switches in the “stand-by” modes.

The green LED goes off and the remote control handset is in the “stand-by” modes which means that there

always will be used some current which causes the battery to go down. So always make sure the remote

control handset is turned off by the slide switch.

To reactivate the remote control, move slide switch to “Off” –O and then back to “On”-I after approximately 1

second.

Error messages via the remote control handset:

Error messages of the EM303A will be communicated via the remote control handset by the green LED

(Fig. 7H), the error message LED’s (Fig. 7L, 7M & 7N) and a buzzer signal:

Green LED (Fig. 7H) off, no buzzer: remote control handset is turned off and also system is not activated

Green LED (Fig. 7H) continue on, no buzzer: remote control handset is turned on and system is activated

and ready to use.

Green LED (Fig. 7H) is blinking, no buzzer: no communication between handset and control unit. This could

be because of too much distance between remote control handset and control unit, or the battery isolation

switch for manoeuvring system is not turned on or that there is a distortion signal disturbing the

communication. As soon as connection is good again the green LED will be continue on and the system is

ready to use.

Blue battery voltage LED (Fig. 7N) is blinking in combination with buzzer (2 times blinking, break, 2 times

blinking, break etc.): Battery voltage too low (<10V). Battery needs to be recharged.

Blue battery voltage LED (Fig. 7N) is blinking in combination with buzzer (4 times blinking, break, 4 times

blinking, break etc.): Battery Voltage too high (over charged). Try to discharge the battery by turning on a

user (for example a lamp or water-pump).

Red overload LED (Fig. 7L) is blinking in combination with buzzer (6 times blinking, break, 6 times blinking,

break etc.): Amp overload protection is activated. Wait about 60 seconds and try again.

Blue 9V battery LED (Fig. 7M) is blinking, no buzzer: The internal 9V battery is near empty and needs to be

replaced.

Changing batteries in the remote control:

When the battery is empty (blue 9V battery LED (Fig. 7M) is blinking), it needs to be replaced.

Open the rear cover of the handset (Fig. 7.1A).

Take out the dead/old battery and dispose in the appropriate way.

Install a new replacement battery (Fig. 7.1). Make sure to use a leak proof PP3 (9Volt) battery (No claims

under guarantee can be considered for damage caused by leaking batteries).

Close the rear cover again.

Dead and used batteries may leak and damage the remote control handset! Remove the batteries if the

handset is not going to be used for an extended period.

OPERATION - ELECTRONIC CONTROL UNIT

The control unit has three LED’s, one pushbutton and one slide switch (Fig. 3):

Green LED (Fig. 3B): Power LED continuously illuminated when system is activated (by moving slide switch to

“On”-I). If the handset far away from the control unit, beyond the availably distance, this LED will go out.

Blue LED (Fig. 3C): Error message LED

EM303A 9

after 3 minutes. Then the system switches in the “stand-by” modes.

The electronic control unit (4), which is mounted inside your trailer, is responsible for controlling the

manoeuvring system.

concerning trailer battery:

Blue LED is blinking (2 times blinking, break, 2 times blinking, break etc.): Battery voltage too low (<10V).

Battery needs to be recharged.

Blue LED is blinking (4 times blinking, break, 4 times blinking, break etc.): Battery Voltage too high (over

charged). Try to discharge the battery by turning on a user (for example a lamp or water-pump).

Red LED (Fig. 3D) is blinking (6 times blinking, break, 6 times blinking, break etc.): Amp overload protection is

activated. Wait about 60 seconds and try again.

In general all error messages will reset automatically after one minute. If this is not the case, reset the

electronics of the manoeuvring system by switching off the system via the isolation switch and the remote

control handset for at least 15 seconds and then turning it on again.

The Reset Button (Fig. 3A): The remote control handset and the control unit are synchronised with each other

in the factory. If the control unit or the remote control handset is replaced, they must be re-synchronised as

described below:

Check the installation in accordance with the installation instructions and ensure that the drive rollers are

not applied. Check that the battery is properly connected, check the condition of the battery and that a

voltage of 12 V is present at the control unit.

Please ensure that the battery isolation switch is on.

Activate the remote control handset by sliding the slide switch to “On”-I (Fig. 7A). The green LED on the

remote control handset (Fig. 7H) starts to flash slowly.

Press the reset button (Fig. 3A) on the control unit. All three LED’s on the control unit (Fig. 3B, 3C & 3D)

will flash slowly.

Press both forwards (Fig. 7B) and reverse (Fig. 7C) button on the remote control handset for about 3

seconds. Then the handset buzzer will give a short beep to confirm that the synchronisation is complete.

After successful synchronisation, the green LED on the control unit (Fig. 3B) and on the remote control

handset (Fig. 7H) will illuminate continuously.

OPERATION - GETTING STARTED

Please make sure you read the safety instructions very carefully and make sure that you

follow these guidelines!

Make sure that the battery that supplies the system is fully charged and in good condition.

that the corner steady feet are fully raised.

Turn on the battery power isolation switch (39).

Activate the manoeuvring system by move slide switch to “On”-I on the remote control (Fig. 7A). The green

LED (Fig. 7H) on the remote control handset will illuminate and you will hear a short beep. The remote control

is ready for use.

Press at the same time, during at least three seconds, the two buttons for engaging the motor powered rollers

(Fig. 7I). The blue LED (Fig. 7H) will blink fast during these three seconds and every second there will be a

beep. This warns you that the system will be activated!

After these three seconds the motor powered rollers will be pressed against the tyre and the blue LED will

illuminate constant. Now you can release the two buttons. When the motor powered rollers are pressed on the

tyre strongly enough, the blue LED will switch off and is the system ready to manoeuvre. The colour of the

traction indicator label (Fig. 11A) should be into the green area.

Before operating the manoeuvring system, release the handbrake.

Now you can choose the movements according the symbols shown on the remote control. Straight forward (Fig.

7B), straight reverse (Fig. 7C), left forward (Fig. 7D), left reverse (Fig. 7F), right forward (Fig. 7E), right

reverse (Fig. 7G).

EM303A 10

The single-tandem axle function switch (Fig. 3S/T): The EM405+ trailer manoeuvring system is

suitable for both single axle and tandem axle trailer. Youjust need to pull the single-tandem axle function switch

(Fig 3S/T) on the control unit, so that the manoeuvring system can be used for a single-axle trailer or a tandem-

axle trailer (for 2 motor use but also for 4 motor use). In the tandem axle function the all wheels will drive but at

a different speed.

The switch standard pre-selected for single axle use (Fig 3S). For tandem axle use, just move the switch to the

tandem axle position (Fig. 3T). When move the single-tandem axle function switch, the battery power isolation switch

(39) must be turned off.

Make sure that the trailer is free from the vehicle and the handbrake is on. Also make sure

Press at the same time, during at least three seconds, the two buttons for disengaging the motor powered

rollers (Fig. 7J). The blue LED (Fig. 7H) will blink fast during these three seconds and every second there will be

a beep. This warns you that the system will be activated!

After these three seconds the motor powered rollers will be released from the tyre and the blue LED will

illuminate constant, now you can release the two buttons. When the motor powered rollers are completely

disengaged the blue LED will switch off and the system is ready for transport.

After manoeuvring, deactivate the manoeuvring system by moving the slide switch to “Off”-O on the remote

control handset (Fig. 7A). The green LED (Fig. 7H) on the remote control handset will turn off. Store remote

control in a safe place (out of reach of children or other unauthorised people).

Turn off the battery power isolation switch.

Before you start driving always make sure that the both drive units are fully disengaged!

OPERATION - HITCHING AND UNHITCHING

technology allows you to locate the tow-ball of the car by centimetre. It is better reach the tow ball with several

short “trips” rather than trying to do it in one “trip”.

slowly stop after 0.5 second and continue to move about 6cm (depending on final speed).

When the buttons of the remote control handset are released when the system is still in the

When the hitch is right above the tow ball of the vehicle, lower the hitch to the ball and engage in the normal

way using the jockey wheel.

MAINTENANCE

To prevent the battery from becoming totally discharged during long periods of inactivity it must be

disconnected, fully charged and frost-proof stored.

Please check regularly that the rollers of the drive units are free of any dirt, or debris that may have been

picked up from the road.

EM303A 11

In addition, the left forward (Fig. 7D) and right reverse (Fig. 7G) buttons or right forward (Fig. 7E) and left

reverse (Fig. 7F) buttons may be pressed at the same time to turn the trailer around on its own axis without

moving forward or backward (this function just can work under the “single-axle function”).

When you drive straight forwards or reverse (press button 7B or 7C), it is also possible to adjust the direction

by additional pressing button 7D or 7E (when driving forwards) or button 7F or 7G (when driving reverse).

Because of the “soft start” technology, the trailer will slowly speed up. Because of the “soft stop” technology,

the trailer will stop slowly. This allows you to manoeuvre your trailer even more accurately without any shocks.

WARNING: When the buttons on the remote control handset are released, the trailer will

slowly stop after 0.5 second and continue to move about 6cm(2½ " ) (depending on final speed).

When the buttons of the remote control handset are released when the system is still in the

“soft start” stage (slowly speed up), the trailer will stop immediately.

After the “soft start” stage the trailer moves accordingone fixed speed. The speed can increase a little when

going downhill and decrease a little when going uphill. TIP: The manoeuvring system is more efficient when

reversing the trailer up an incline.

When you finish manoeuvring you need to secure the handbrake and chock all wheels first.

It is possible to position the trailer’s hitch exactly over a stationery car’s tow ball using the manoeuvring

system. But please be very careful!

Use the button controls on the remote control to bring the hitch of the trailer to the car. The soft start

WARNING: When the buttons on the remote control handset are released, the trailer will

“soft start” stage (slowly speed up), the trailer will stop immediately.

Release the rollers from the trailer’s tyres. You cannot tow the trailer with the drive

units are engaged! Before you start driving always make sure that the both drive units are

fully disengaged!

Trying to drive away with the drive units still engaged, will damage the manoeuvring system,

your trailer tyres and strain your tow vehicle!

fuse of the same value (100A). Never “bri

Check the fuse (100A) in the red positive battery cable (Fig.

Regularly clean the drive units with a water hose to dissolve mud etc.

In case of any failure or problem, please contact your

supplier.

TROUBLE SHOOTING

Should your manoeuvring system fail to operate, please check the following:

Unit fails to operate, does not function at all:

Make sure that the battery power isolation switch (39) is turned on.

6). If the fuse is blown, it must be replaced with a

dge” the fuse (if needed contact your supplier). To replace the

fuse, first disconnect the positive (+) power cable from the battery. Then release the mounting screws that hold

the fuse (Fig. 6A), replace the fuse (Fig. 6B), and finally tighten the screws securely. Close the housing of the

fuse and connect the positive (+) power cable again to the battery. The system is ready again for use.

Check the battery of the remote control handset. If empty, renew the 9V battery.

Check if there is any distortion signal (other transmitter, high power cables, Wifi etc.) that disturbs a good

communication between remote control handset and control unit. If there is no good communication between

the control unit and remote control handset, the manoeuvring system will not function and the green LED on

remote control handset is blinking.

In general, all error messages will reset automatically after one minute. If this is not the case, reset the

electronics of the manoeuvring system by switching off the manoeuvring system via the isolation switch and the

remote control handset for at least 15 seconds and then turn them on again.

Unit fails to operate or moves intermittently:

Check the battery of the remote control. If empty, renew the 9V battery.

EM303A 12

Please check regularly the distance between the rollers and the tyres. In the neutral (fully disengaged) position

this must be about 20mm (3/4").

Once a year have your trailer manoeuvring system maintained and visually inspected. This inspection must

include all the bolt/nut connections, the cables and electrical connections and lubrication of movable

parts/joints.

Check the cable-connection between the trailer battery and the control unit.

Trailer battery could be empty. If empty, recharge completely or renew trailer battery before taking any

further action.

Trailer battery could be overloaded. Check your charging equipment and try to discharge the battery by

connecting/using a light or any other load. If this does not give any result, renew trailer battery before taking

any further action.

Check the distance between the remote control and the trailer is not more than 5 metres (16'). If there is no signal

between the remote control handset and the control unit, the manoeuvring system will not function at all and

the green LED on handset is blinking.

Trailer battery could be empty. If empty, recharge completely or renew trailer battery before taking any

further action.

Trailer battery could be low - with the rollers engaged. Check the voltage drop on the trailer battery, if this

drops well below 10 volts, charge or renew trailer battery

Trailer battery could be overloaded. Check your charging equipment and try to discharge the battery by

connecting/using a light or other load. If this does not give any result, renew trailer battery before taking any

further action.

Check the cable-connection between the trailer battery and the control unit.

Badly connected or corroded battery terminals can cause intermittent problems, check battery terminals, clean

and connect again.

Check the distance between the remote control and the trailer is not more than 5metres (16'). If there is no signal

between the remote control handset and the control unit, the manoeuvring system will not function at all and

the green LED on handset is blinking.

Table of contents

Other EMOVE Automobile Accessories manuals

Popular Automobile Accessories manuals by other brands

ULTIMATE SPEED

ULTIMATE SPEED 279746 Assembly and Safety Advice

SSV Works

SSV Works DF-F65 manual

ULTIMATE SPEED

ULTIMATE SPEED CARBON Assembly and Safety Advice

Witter

Witter F174 Fitting instructions

WeatherTech

WeatherTech No-Drill installation instructions

TAUBENREUTHER

TAUBENREUTHER 1-336050 Installation instruction