EMX Industries, Inc. ULT-PLG ULTRALOOP User manual

O P E R A T I N G I N S T R U C T I O N S

Operating Instructions

4564 Johnston Parkway, Cleveland, Ohio 44128

P. 800 426 9912 F. 216 518 9884

www.emxinc.com

ULT-PLG

ULTRALOOP

V E H I C L E L O O P D E T E C T O R

ULT-PLG™ Operating Instructions 1

Document no. 10180904

Contents

Cautions and Warnings

2

Product Overview

2

Specifications

3

Operation

4

Controls and Indicators

6

Connections

7

Troubleshooting

8

Loop Installation

9

Ordering Information

10

ULT-PLG™ Operating Instructions 2

Document no. 10180904

Cautions and Warnings

CE REQUIREMENT: Use EMX pre-formed loops with built-in surge

suppression for CE compliance. Connect shield on lead in wire to

earth ground.

CE REQUIREMENT: Use CE rated power supply for CE compliance

providing suppression as specified by EN61000-4-5.

Not to be used in personal safety applications.

When more than one loop detector is used, set each one to a different

frequency.

Refer to DIP switch diagram for frequency settings.

IMPORTANT:

This product is an accessory or part of a system. Always read and follow the manufacturer’s

instructions for the equipment before connecting this product. Comply with all applicable codes and

safety regulations. Failure to do so may result in damage, injury or death.

Product Overview

The ULT-PLG vehicle loop detector is compatible with most gate operators. The ULT-PLG may be used

in Center, Safety and Exit loop positions. The UltraMETER™ display feature makes set-up easy by

displaying the optimum sensitivity setting required to detect a vehicle positioned on the loop. Ten

sensitivity settings allow for fine adjustment of detection level. The Detect On Stop (DOS®) feature

allows detection only when a vehicle has come to a complete stop. Output B switch allows

configuration of output 2 for FAIL, PULSE ON ENTRY, PULSE ON EXIT, or SAME AS OUPUT A. Four

frequency settings provide flexibility in preventing crosstalk in multi-loop applications.

The ULT-PLG is compatible with a wide variety of gate operators including:

Advanced Access Automation/FAAC CSL2000, CSW2000, RSW1000

All-O-Matic SL100-DC

Apollo 4300, 4500

Chamberlain/Elite SL3000,CSW200

Intelligate Systems IQ500, IQ5000

Linear (OSCO) with APeX controller

PowerMaster operators with PowerMaster controllers

Rotary Gate Systems models SL1000C, SL1000I, SL1000R

SECOM Late model operators with 10 pin Molex connectors

TyMetal TYM 1000,TYM 2000

Viking Access Models L-3, F-1, T-21, H-10, B-12, Q-4

ULT-PLG™ Operating Instructions 3

Document no. 10180904

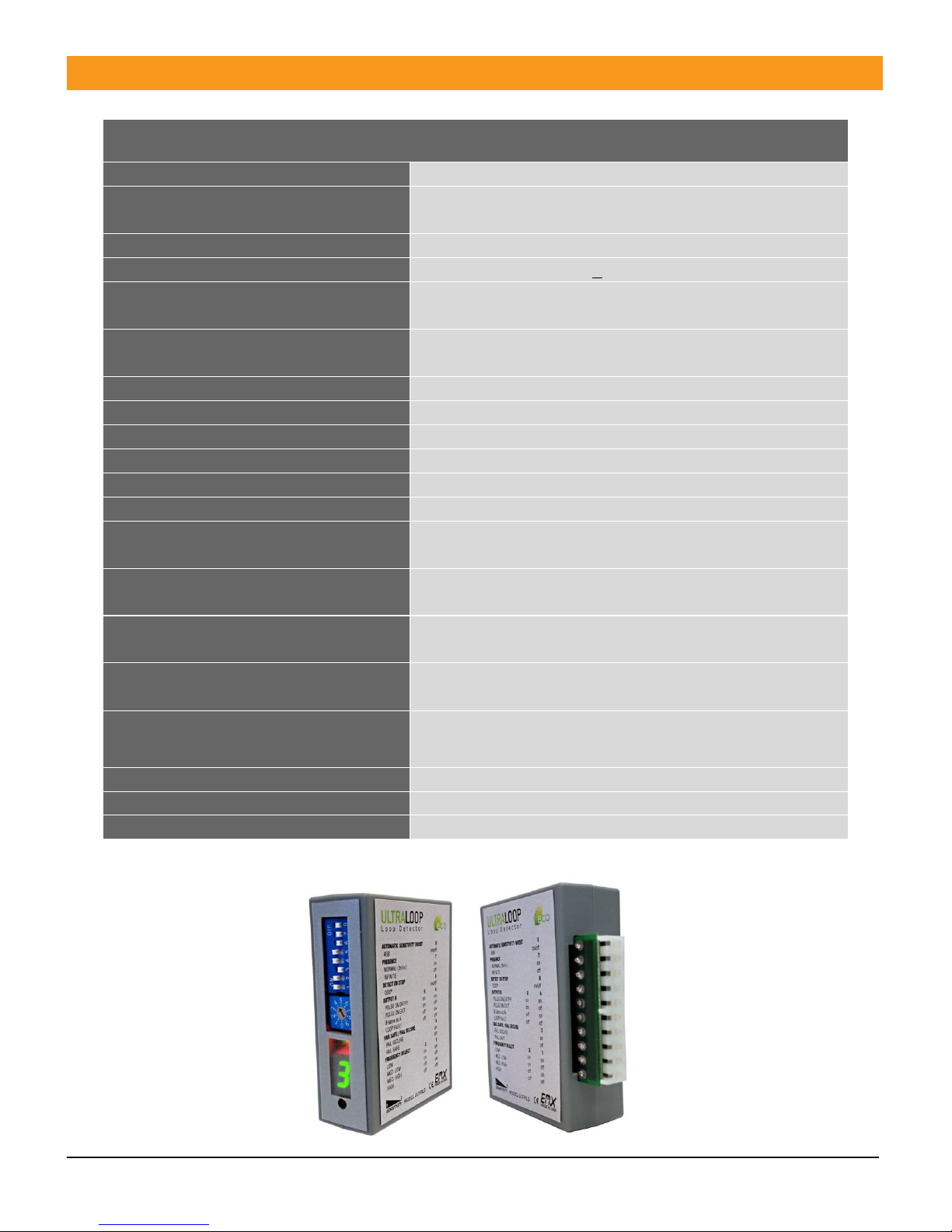

Specifications

Specifications

Sensitivity

10 levels, 0-9

UltraMETER™ Display

Indicates optimum sensitivity level, 0-9

Diagnostic aid

Loop frequency

4 settings (low, med-low, med-hi, high)

Loop inductance

20…2000µH (Q factor > 5)

Grounded loop

Isolation transformer allows operation with poor

quality loops

Automatic tuning

Detector tunes to loop on power-up and following

frequency count function

Environmental tracking

Automatic compensation

Surge protection

Loop circuitry protected by surge suppressors

Detect output

Solid-state

Output B

Solid-state

Output B inverted

Solid-state

Power / loop fault indicator

Green LED

Detect / frequency count

indicator

Red LED

ASB (Automatic Sensitivity Boost)

Increases sensitivity after initial detection to prevent

dropout due to high-bed vehicles

Power (see Cautions and

Warnings)

12VDC…24VDC. (See Cautions and Warnings)

Operating current

(standby/detect)

15mA

Operating temperature

-40˚C…82˚C (-40˚F…180˚F)

0…95% relative humidity

Dimensions (L x W x H)

76mm (3.0”) x 22mm (0.9”) x 70mm (2.75”)

Weight

0.15 lbs. (68g)

Connector

10-pin female

ULT-PLG™ Operating Instructions 4

Document no. 10180904

Operation

Power up

Upon power up the detector initializes by automatically tuning to the loop. The green LED

indicates that the detector is powered and operational.

Frequency setting

The operating frequency of the loop is a function of the specific loop inductance and DIP

switch settings 1 and 2. The primary purpose of the frequency setting is to allow the

installer the ability to set different operating frequencies for multi-loop installations,

recommended to prevent crosstalk/interference from adjacent loops. After changing the

frequency setting, press the Frequency Count switch to re-initialize the detector. To check

the operating frequency of a loop, refer to the Frequency Count section. To determine

whether crosstalk between adjacent loops is occurring, refer to the UltraMETER™Sensitivity

Display section.

UltraMETER™ Sensitivity Display

The UltraMETER™ sensitivity display simplifies the installation process by displaying the

sensitivity setting required to detect a vehicle on the loop. To use this feature, observe the

display while a vehicle is moving into position on the loop, note the number displayed, then

adjust the sensitivity setting (rotary switch) to the displayed position.

During normal operation, when a vehicle is not on the loop, the display is blank. The

effects of crosstalk or other interference can be observed on the display when the loop is

vacant. Interference or crosstalk will cause the display to indicate a level, typically 8 or 9. It

may be necessary to observe the display for a minute or so to see this effect. Change the

frequency setting to prevent crosstalk.

Sensitivity setting

The 10-position rotary switch allows for precise adjustment of detection level. The sensitivity

level increases from position 0 thru 9 with position 0 being the lowest sensitivity. Typical

applications require a setting of 3 or 4. The UltraMETER™sensitivity display simplifies the

installation process by displaying the sensitivity setting required to detect a vehicle on the loop.

To use this feature, observe the display while a vehicle is moving into position on the loop, note

the number displayed, then adjust the sensitivity setting (rotary switch) to the displayed

position.

ULT-PLG™ Operating Instructions 5

Document no. 10180904

Operation (continued)

Frequency Count / Reset

Press the Frequency Count switch and count the number of flashes on the red LED. Each flash

represents 10kHz. To help to prevent crosstalk when multiple detectors are used for adjacent

loops, perform a frequency count on each detector to confirm the operation frequencies are

different. Following a frequency count cycle, the detector re-initializes

Automatic Sensitivity Boost

The Automatic Sensitivity Boost causes the sensitivity to increase following initial detection.

This feature is useful to prevent dropout when detecting high-bed vehicles. The sensitivity

returns to its normal setting after the vehicle exits the loop. Decimal point on the display

indicates ASB on.

Presence output

The Presence settings provides two selections, the output can be set for Infinite Presence

or Normal Presence. Infinite Presence causes the output to remain in detect mode as long

as the vehicle remains on the loop. Normal Presence causes the output to reset after 5

minutes. DO NOT USE THE NORMAL PRESENCE SETTING UNLESS THE OPENING IS

PROTECTED BY A SECONDARY SAFETY DEVICE SUCH AS THE IRB-4X.

Detect-on-stop (DOS™)

The detect-on-stop affects B and /B (inverted B output). This function requires that a

vehicle come to a complete stop on the loop for the output to activate. This feature is

useful in cases where cross-traffic causes the detection.

Output B

Output B settings allow Pulse on Entry, Pulse on Exit, Detect-On-Stop (DOS®) and Loop

Fault. The Detect-On-Stop feature requires that a Vehicle must come to a complete stop

over the loop for a minimum of 1 second (typical 1-2s) before Output B activates.

Fail Safe / Fail Secure

Fail Safe setting causes the ULT-PLG to activate the Presence output in the event a loop

failure. Fail Secure setting will cause the ULT-PLG not to activate the Presence output in the

event a loop failure.

ULT-PLG™ Operating Instructions 6

Document no. 10180904

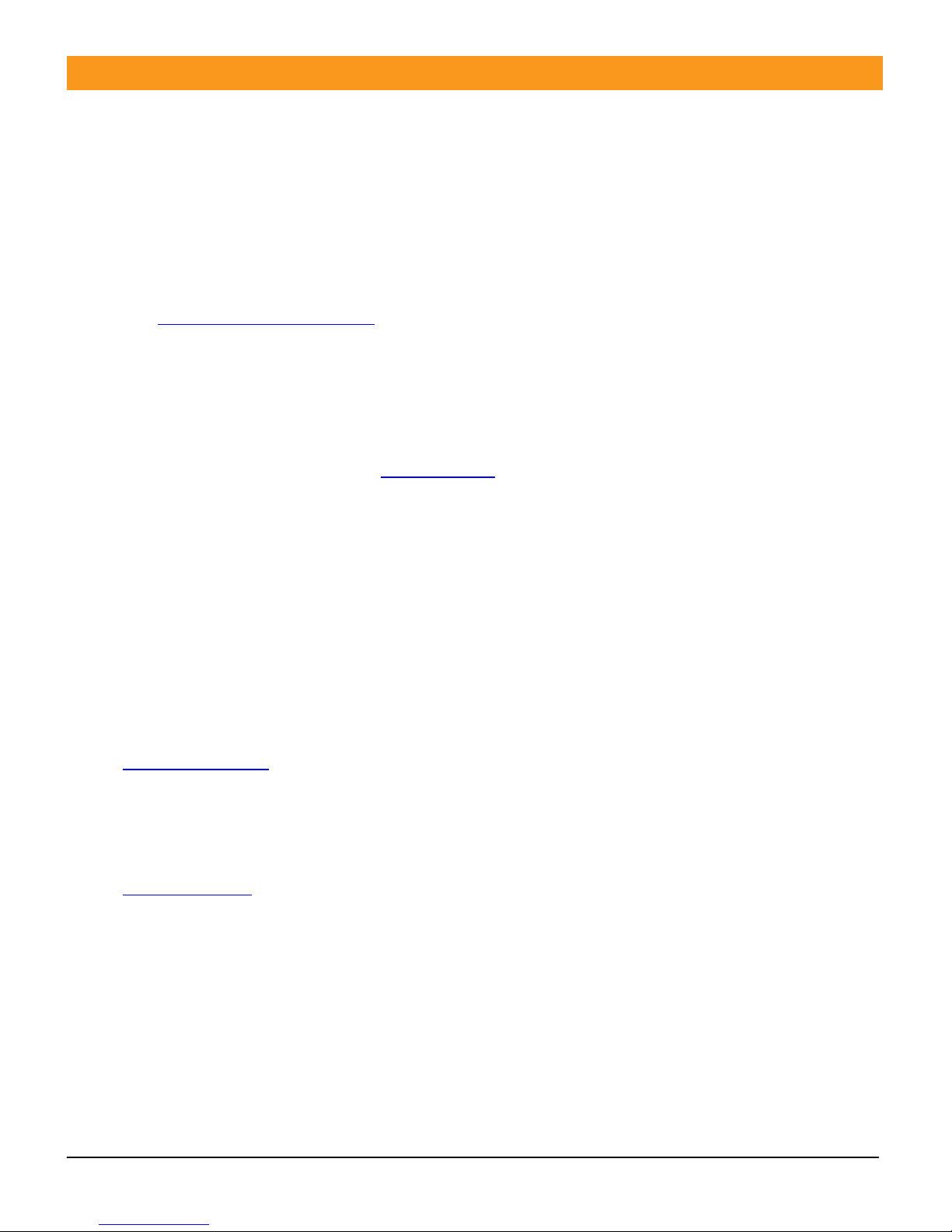

Controls and Indicators

AUTOMATIC SENSITIVITY BOOST

PRESENCE

DETECT-ON-STOP (DOS)

OUTPUT B

(1) Not used when DOS is selected

FAIL SAFE / SECURE

FREQUENCY SETTINGS

SENSITIVITY SETTING

DETECT / FREQUENCY COUNT

ULTRAMETER™ DISPLAY

Indicates sensitivity setting required to detect vehicle

FREQUENCY COUNT / RESET

Press to start frequency count, re-initializes after count

DIP switch position 8

ASB enabled

on

DIP switch position 7

NORMAL (5 min.)

on

INFINITE

off

DIP switch position 6

DOS on

on

DOS off

off

DIP switch position

MODE

4

5

Pulse on Entry

on

on

Pulse on Exit(1)

off

on

B same as A

on

off

Loop Fault

off

off

DIP switch position 3

Fail Secure

on

Fail Safe

off

DIP switch position

FREQUENCY

2

1

Low

on

on

Medium low

on

off

Medium high

off

on

High

off

off

Position 0…….9

Sensitivity

Low……….high

Red LED

Presence detected

on

No presence

off

Frequency count

flashing

ULT-PLG™ Operating Instructions 7

Document no. 10180904

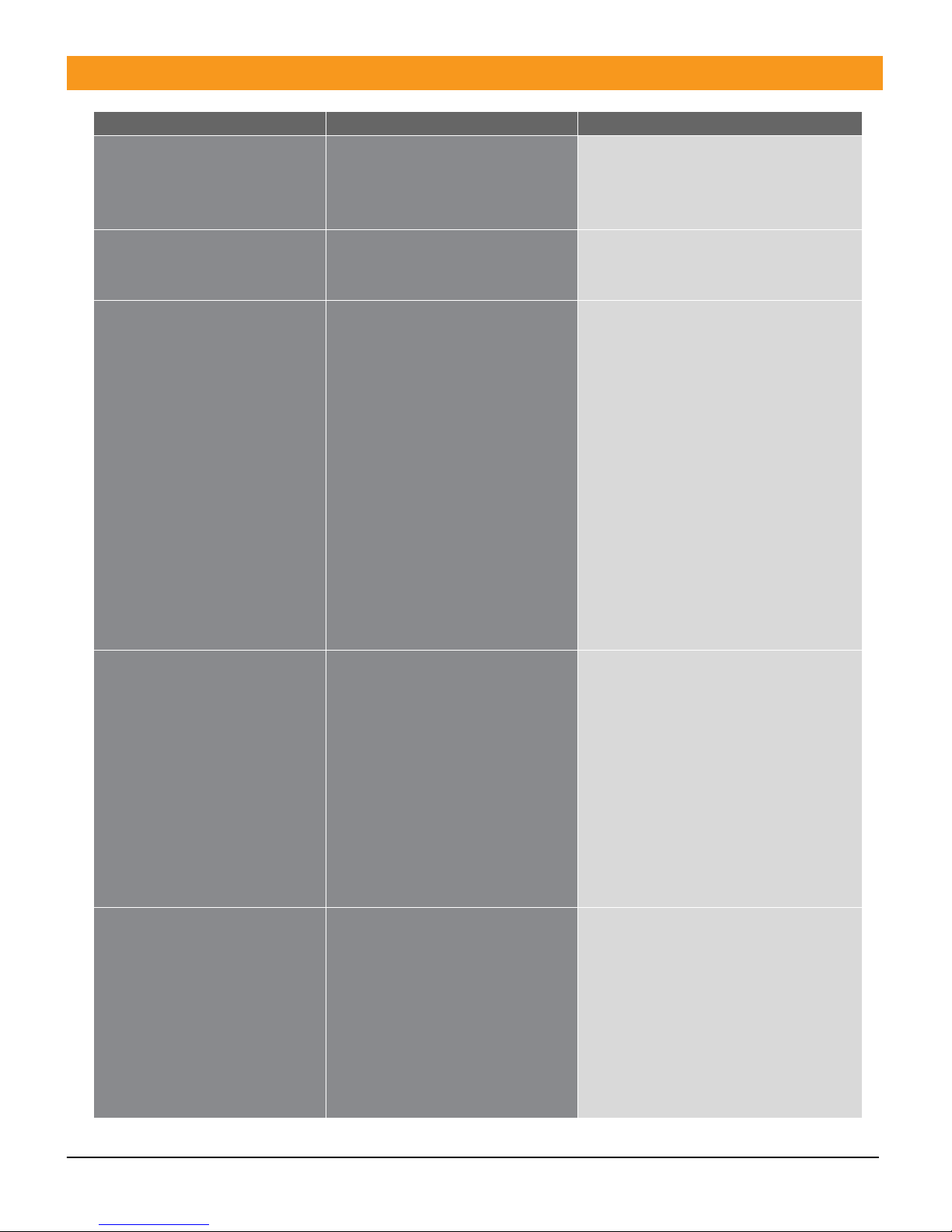

Connections

Connector pin

Description

1

Loop

2

Loop

3

Power + (12VDC…24VDC)

4

No connection

5

No connection

6

Output B

7

Output B inverted

8

Presence output

9

Power + (12VDC…24VDC)

10

Common

ULT-PLG™ Operating Instructions 8

Document no. 10180904

Troubleshooting

Symptom

Possible cause

Solution

Green LED flashes

Loop wire shorted or open

Check loop resistance on the

appropriate loop pins on the

control board connector,

between .5 ohms and 5 ohms.

Green LED flashes, 2 fast

Loop was previously

shorted or open

Check loop resistance on the

appropriate loop pins on the

control board connector.

Detector remains in

detect after vehicle has

left loop

1. Faulty loop

2. Poorly crimped

terminals

3. Loose connections

1. Perform megger test from

loop lead to ground, should

be >100 megaohms

2. Check loop connections to

terminals

3. Check splices are properly

soldered and sealed against

moisture

4. Observe ULTRAMETER

display, level indicated on

display indicates residual

frequency shift from vacant

loop to vehicle presence,

press Frequency Count switch

to re-initialize the detector

Intermittent detection

1. Faulty loop

2. Poorly crimped

terminals

3. Loose connections

4. Cross-talk between

adjacent loops

1. Perform megger test from

loop lead to ground, should

be >100 mega ohms

2. Check loop connections to

terminals

3. Check splices are properly

soldered and sealed against

moisture

4. Set adjacent loops to

different frequencies (see

Frequency Setting)

No detection

1. Loop wire shorted or

open

2. Loop sensitivity set too

low

1. Check loop resistance on the

appropriate loop pins on the

control board connector,

between .5 ohms and 5

ohms.

2. With vehicle on loop, observe

ULTRAMETER display, set

sensitivity to the level

indicated on the display

ULT-PLG™ Operating Instructions 9

Document no. 10180904

Loop Installation

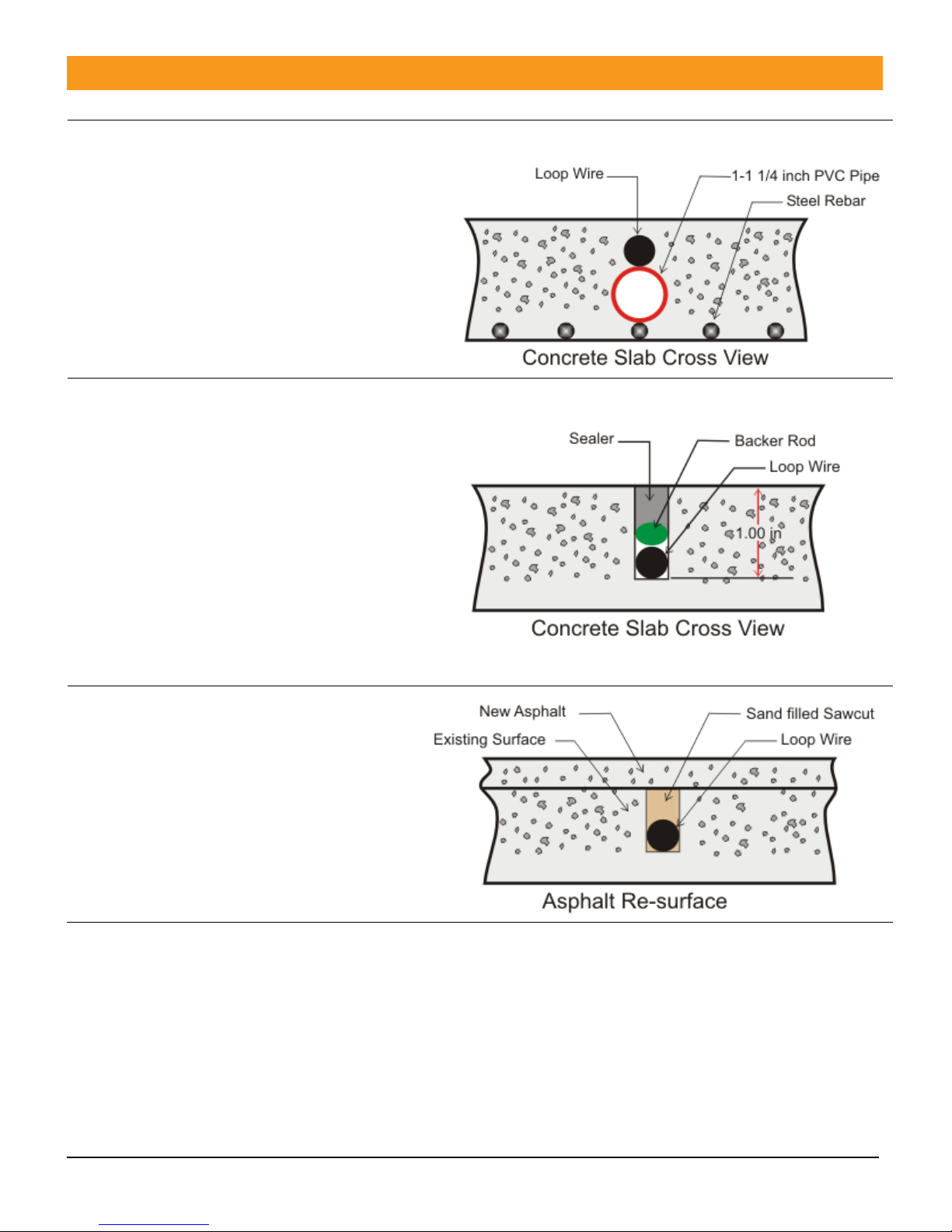

NEW SLAB POUR

Ty-wrap 1-1/4” PVC pipe to the top of the

rebar in the size and configuration of the

loop (ex. 4’ x 8’). Then ty-wrap the loop to

the top of the PVC frame. This stabilizes the

loop during the pour and separates it from

the rebar.

SAW CUT EXISTING SURFACE

Cut 1” deep into the existing surface, place

a 45° cut at the corners to prevent sharp

edges from damaging the loop wire. Notch

out for the “T” connection where the lead

wire connects to the loop. Remove all

debris from the finished cut with

compressed air. Place the loop into the

saw cut. Place backer material into the saw

cut over the loop wire and pack tightly.

Place a high-quality sealer over the saw cut

to seal the surface.

RESURFACE ASPHALT

Saw cut the existing surface ¾” deep and

place a 45° cut at the corners to prevent

sharp edges from damaging the loop wire.

Remove all debris from the finished cut

with compressed air. Place sand over the

loop wire to the surface and pack tightly.

Lay new asphalt.

General Installation Guidelines

Use EMX Lite Preformed loops for quick, reliable installations and for CE compliance.

Lead-in wire (wire from loop to detector) must be must be twisted a minimum of 6 turns/ foot

to avoid the effects of noise or other interference.

Detection height is approximately 70% of the shortest side of the loop. Example: detection

height for an 4’ x 8’ loop = 48” x .7 = 33.6”

ULT-PLG™ Operating Instructions 10

Document no. 10180904

Ordering Information

ULT-PLG Ultra PLG Vehicle Loop Detector with DIN rail mounting

Accessories

PR-XX EMX Lite Preformed Loops™

Warranty

EMX Industries Incorporated warrants all products to be free of defects in

materials and workmanship for a period of two years under normal use and

service from the date of sale to our customer. This warranty does not cover

normal wear and tear, abuse, misuse, overloading, altered products, damage

caused by incorrect connections, lightning damage, or use other than intended

design.

There is no warranty of merchantability. There are no warranties expressed or

implied or any affirmation of fact or representation except as set forth herein.

EMX Industries Inc. sole responsibility and liability, and the purchaser’s

exclusive remedy shall be limited to the repair or replacement at EMX

Industries option of a part or parts found not conforming to the warranty. In

no event shall EMX Industries Inc. be liable for damages, including but not

limited to damages resulting from non-conformity, defect in material or

workmanship.

Effective date: January 1st, 2002

ULT-PLG™ Operating Instructions 11

Document no. 10180904

BLANK PAGE

ULT-PLG™ Operating Instructions 12

Document no. 10180904

BLANK PAGE

ULT-PLG™ Operating Instructions 13

Document no. 10180904

4564 Johnston Parkway

Cleveland, Ohio 44128

United States of America

www.emxinc.com

Technical Support: (216) 834-0761

Sales: (216) 518-9888

Fax: (216) 518-9884

Revision 1.4

3.12.2018

Table of contents

Other EMX Industries, Inc. Security Sensor manuals

Popular Security Sensor manuals by other brands

Memco

Memco 618 Installation sheet

Elko

Elko iNELS Air AirKey quick start guide

LEGRAND

LEGRAND Mosaic 0 489 22 manual

DMP Electronics

DMP Electronics 1128 installation guide

Honeywell

Honeywell 5800COMBO Installation and setup guide

System Sensor

System Sensor AFD Accuflow Installation and maintenance instructions

Sentrol

Sentrol 5150-W - Security Glassbreak Shock Sensor installation instructions

Wenglor

Wenglor IR2D001 operating instructions

Smartenit

Smartenit ZBMS3 quick start guide

Bullard

Bullard H3000 Installation instruction

BST

BST Flamonitec IFR 400 operating manual

Antec Scientific

Antec Scientific DECADE II SDC 174 user manual