Duct RH-Temperature BACnet MSTP Modbus RTU Sensor

Installation and

#N2-BN2110-D-4-PB-C – 8/31/23

Specifications subject to change without notice.

Catalog No. 11-808-994-01 Page 6of 10

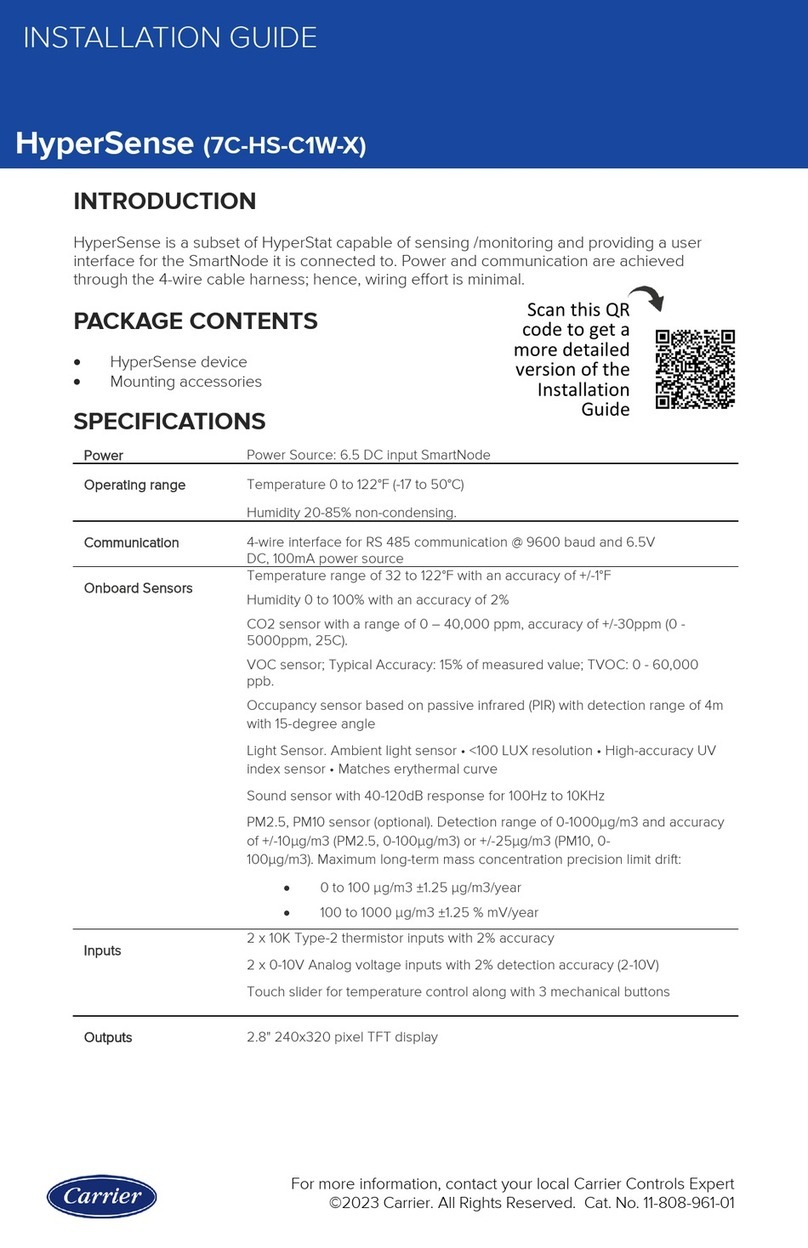

BAUD RATE SELECTION

By default, BACnet Protocol and Auto-Baud is factory set. If

the sensor is field adjusted for Modbus RTU, the baud rate

should be selected at this time to match the Master

configuration. If Modbus RTU protocol is selected it is

recommended the sensor unique address is selected at this

time. Switches 8-10 are used to set the BACnet and Modbus

baud rate. Refer to switch settings. Where (0) is OFF and (1) is

ON. If the system’s baud rate is known, it is recommended to

set the specific baud rate to match the system. If the device is

powered when a change is made, the device must be power

cycled or reset for changes in baud rate to be made.

EOL TERMINATION RESISTANCE SELECTION

RS-485 requires that the last device in a chain have a termination

resistor. This is controlled using a jumper in the EN (enabled) position

marked on FIGURE 5. When the jumper is set to EN (enabled), a 1200

resistance is added in parallel to the data line. When the jumper is set

to DIS (disable), the resistance is not added. By default, the jumper is

placed in the DIS (disabled) position.

RESET

The reset button can be used to reset the device without disconnecting power. The location of this button is shown in

Figure 3.

LED INFORMATION

One LED indicates four statuses. Solid green shows that power is good, but no data is transmitting. A solid Amber

indicates that auto-baud is set and no data has been received to set a baud rate. Green/Amber flashing indicates data is

being transmitted or received. Solid Red LED status indicates an error state, usually loss of communication on the

network. If BACnet is the selected protocol, and this status remains for 10 times the APDU timeout, the device will

automatically reset. If this state remains longer than that, reset the device.

ADDRESS SELECTION

Switches 1-7 are used to set the BACnet and Modbus addressing.

Refer to switch settings. Each device in a network branch must

have a unique address. The value of each position is printed on the

board. By default, the address is

(0). Note: (0) cannot be used if Modbus RTU protocol is selected

and will require a unique address. If the device is powered when a

change is made, the device must be power cycled or reset for

changes in address to be made.

Figure 5: EOL Termination Jumpers