INTRUSION • FIRE • ACCESS • NETWORKS

2500 North Partnership Boulevard

Springfield, Missouri 65803-8877

866.266.2826 | DMP.com

© 2021 Digital Monitoring Products, Inc.

LT-1825 21203

Specifications

Battery

Life Expectancy 3 Years (normal operation)

Type 3 V lithium CR123A

Frequency Range 905-924 MHz

Transmit Condition Alarm, Low Battery, Tamper

Detection Method Omni-directional

Range 20 ft (6 m)

Operating Temperature -10°C to +55°C

Color White (passes VW1)

Housing Material Flame retardant ABS

Dimensions 3.3"L x 2.1"W x 0.9"D

Weight 4.2 oz.

Compatibility

• All DMP 1100 Series Wireless receivers and

transmitters v106 and higher

Note: If the 3rd digit of the transmitter's serial

number is greater than 0, it will be v106 or

higher. If the 3rd digit is equal to zero, that

transmitter must be removed or replaced with

a newer transmitter for the 1128 to function

properly.

• All DMP Burglary Panels with built-in 1100

Series Wireless

• Test Mode requires XT/XR Series Version

191 firmware

Certifications

FCC Part 15 Registration ID CCK1128

IC Registration ID 5251A-1128

Accessories

FG-701 Glassbreak Simulator

FCC INFORMATION

This device complies with Part 15 of the FCC Rules. Operation is subject to the following two conditions:

1. This device may not cause harmful interference, and

2. This device must accept any interference received, including interference that may cause undesired operation.

The antenna used for this transmitter must be installed to provide a separation distance of at least 20 cm (7.874 in.) from all

persons. It must not be located or operated in conjunction with any other antenna or transmitter.

Changes or modifications made by the user and not expressly approved by the party responsible for compliance could void the

user’s authority to operate the equipment.

Note: This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to

part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful interference in a

residential installation. This equipment generates, uses and can radiate radio frequency energy and, if not installed and

used in accordance with the instructions, may cause harmful interference to radio communications. However, there is no

guarantee that interference will not occur in a particular installation. If this equipment does cause harmful interference to

radio or television reception, which can be determined by turning the equipment o and on, the user is encouraged to try

to correct the interference by one or more of the following measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and receiver.

• Connect the equipment into an outlet on a circuit dierent from that to which the receiver is connected.

• Consult the dealer or an experienced radio/TV technician for help.

INDUSTRY CANADA INFORMATION

This device complies with Industry Canada Licence-exempt RSS standard(s). Operation is subject to the following two conditions:

1. This device may not cause interference, and

2. this device must accept any interference, including interference that may cause undesired operation of the device.

Le présent appareil est conforme aux CNR d’Industrie Canada applicables aux appareils radio exempts de licence. L’exploitation

est autorisée aux deux conditions suivantes:

1. l’appareil ne doit pas produire de brouillage, et

2. l’utilisateur de l’appareil doit accepter tout brouillage radioélectrique subi, même si le brouillage est susceptible d’en

compromettre le fonctionnement.

This system has been evaluated for RF Exposure per RSS-102 and is in compliance with the limits specified by Health Canada

Safety Code 6. The system must be installed at a minimum separation distance from the antenna to a general bystander of 7.87

inches (20 cm) to maintain compliance with the General Population limits.

L’exposition aux radiofréquences de ce système a été évaluée selon la norme RSS-102 et est jugée conforme aux limites établies

par le Code de sécurité 6 de Santé Canada. Le système doit être installé à une distance minimale de 7.87 pouces (20 cm) séparant

l’antenne d’une personne présente en conformité avec les limites permises d’exposition du grand public.

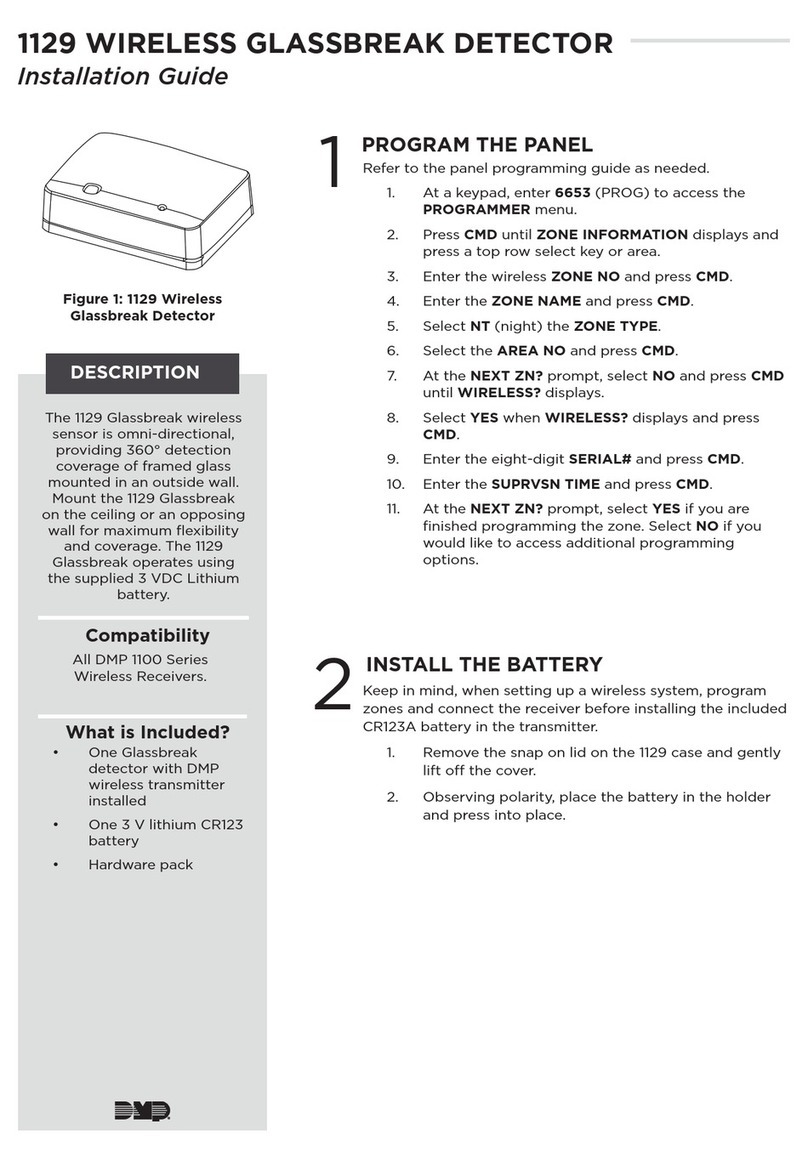

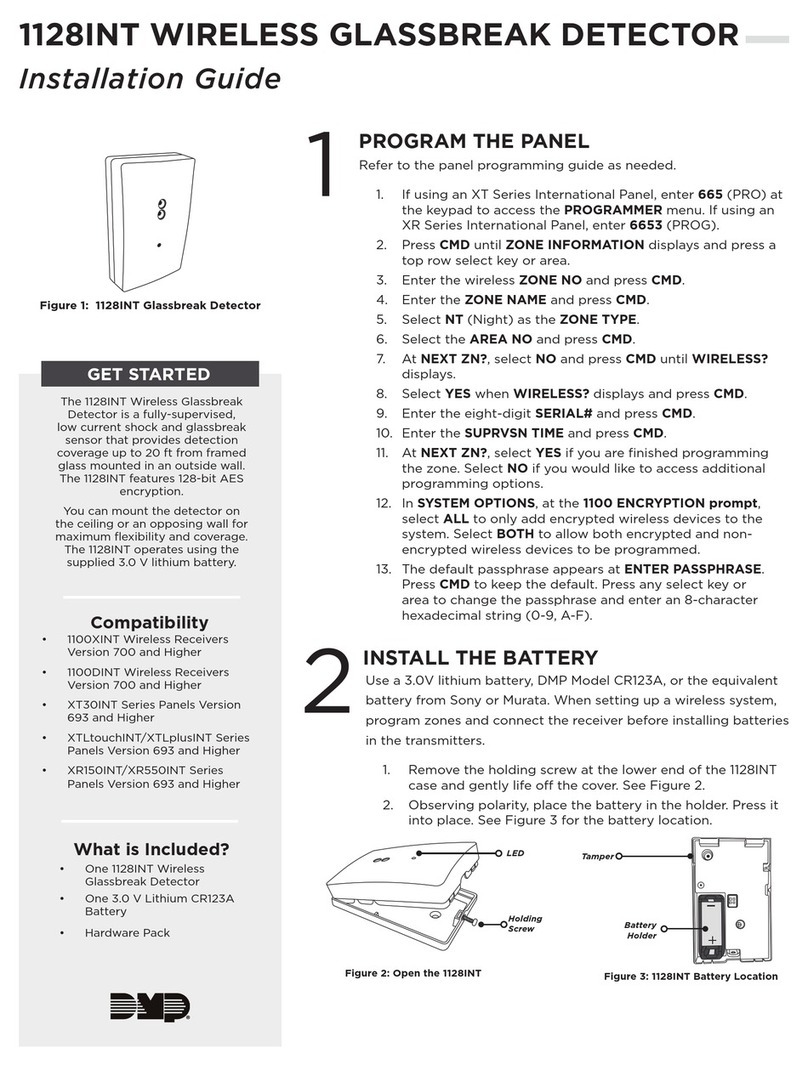

1128 WIRELESS GLASSBREAK

DETECTOR