EMX Industries VMD202 User manual

VMD202

V E H I C L E M O T I O N D E T E C T O R

The VMD202 vehicle motion detector senses moving

ferrous metal within its magnetic field. It has a

detection range up to 3.5 m at a minimum speed of

8 km/hr. An optional sensitivity remote finely tunes

the VMD202 to fit any installation requirement and

then easily detaches to prevent unwanted changes

or tampering. The settings are stored in a non-

volatile memory, saving them in case of power

failure. The VMD202 accepts a wide range of power

inputs from 12-39 VDC or 12-27 VAC and features a

low current consumption (70 uA standby / 25 mA

activated) making it ideal for solar applications.

VMD202

Vehicle Motion Detector

• The probe assembly and cable are water tight and direct burial compatible.

• An optional remote can be connected via screw terminals to select 10 sensitivity settings.

• The detection range is up to 3.5 m at a minimum speed of 8 km/hr.

12-39 VDC or 12-27 VAC

70 uA standby / 25 mA activated

Form C (SPDT) 1A@24 VDC; 1A@120 VAC

o o o o

-30 C to 70 C (-22 to 158 F) 0 to 95% relative humidity

ABS plastic for VMD202-R, PVC for probe

VMD202-R 2.9" (74 mm) x 1.7" (35 mm) x 0.6" (15 mm)

5 wire direct burial PVC

Power

Current

Relay

Operating Temperature

Material

Remote Dimensions

Probe Cable

Technical Data

Ordering Information

VMD202

VMD202-R

VDM202 24" (610 mm) x 1" (25 mm)

Probe Dimensions (L x Dia.)

WARRANTY EMX INC. the product described herein for a period of 2 years under normal use and service from the date of sale to our

customer. The product will be free from defects in material and workmanship. This warranty does not cover ordinary wear and tear,

abuse, misuse, overloading, altered products, or damage caused by the purchaser from incorrect connections, or lightning damage.

There is no warranty of merchantability. There are no warranties expressed, implied, or any affirmation of fact or representation which

extend beyond the description set forth herein. EMX Inc. sole responsibility and liability, and the purchaser’s exclusive remedy shall be

limited to the repair or replacement at EMX’s option of a part or parts not so conforming to the warranty. In no event shall EMX Inc. be

liable for damages of any nature, including incidental or consequential damages, including but, not limited to any damages resulting

from non-conformity defects in material or workmanship. Rev 1.3 01/04/2021

• VMD202-15 Prop with 15m of cable

• VMD202-R Remote for tuning and adjustment control

VMD202™

Single Piece Vehicle Motion Detector

And Sensitivity Remote

Instruction Manual

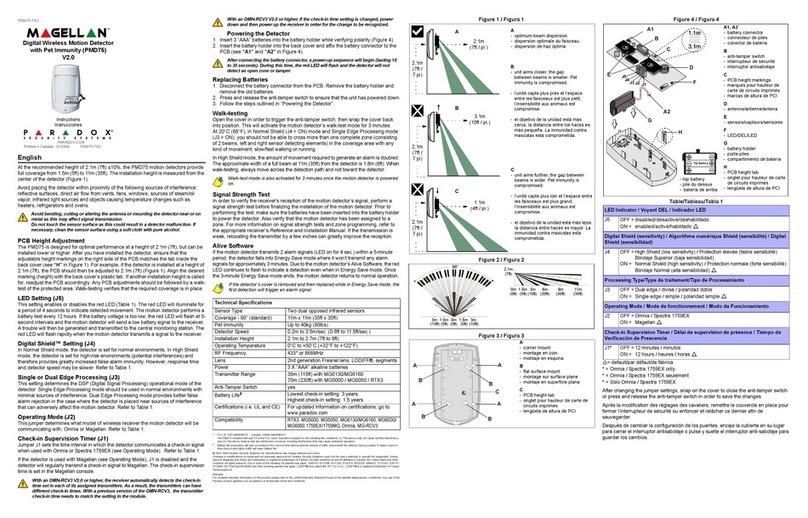

Cautions and Warnings

Specifications

Power 12-39 VDC or 12-27 VAC

Power Indicator Green LED (Sensitivity Remote Only)

Standby Current 70 uA

Detection Current 25 mA

Range Sensitivity 12 ft @ 5 mph min. speed

Sensitivity Adjustment 10 settings

Output Time 5 seconds

Surge Protection Probe input circuitry protected by surge suppressors

Relay Output Configuration Form C (SPDT)

Relay Contact Rating 1 A @ 24 VDC / 1 A @ 120 VAC

Operating Temperature -30˚C to 70˚C (-22˚to 158˚F) 0 to 95% relative humidity

Remote Housing Material ABS plastic

Remote Dimensions (L x W x H) 2.9” (74 mm) x 1.7” (35 mm) x 0.6” (15 mm)

Remote Weight 0.05 lbs (23 g)

Probe Housing Material PVC watertight

Probe Dimensions (L x Dia.) 24” (610 mm) x 1” (25 mm)

Probe Cable 5-wire, direct burial

The VMD202 is a compact, single-piece vehicle motion detector that operates by detecting changes in the

earth’s magnetic field that occur near the probe. It has a detection range of up to 3.5m at a Minimum

Speed of 8 km/h. The VMD202 will only detect a moving vehicle and will not detect a stationary vehicle. It

may be used as a free exit sensor to allow gates to open and guests to exit without the use of a key fob

or passcode. The VMD202 may also be wired to notify a home automation system or security system that

a vehicle is moving down a driveway.

The VMD202 is designed to detect moving vehicles. It is not suitable for use as a vehicle

presence detector such as a reversing loop for a gate or door.

The VMD202 detects ferrous metals. It will not detect aluminum but will detect any

moving ferrous metallic object.

The probe must be stationary to function properly.

Ordering Information

Controls and Indicators

Sensitivity is a function of speed and mass. The smaller a vehicle is and the slower it is

moving, the closer it must pass the probe to trigger the detector.

Wiring Connections

Probe Connections

Wire Color Description

Red Power + (12-39 VDC or 12-27 VAC)

Black Power – (12-39 VDC or 12-27 VAC)

Green Relay – COM (common contact)

White Relay – NC (normally closed contact)

Brown Relay – NO (normally open contact)

Remote Connections

Terminal Description

Probe PWR + Power out to probe (Probe Red Wire)

Probe PWR – Power out to probe (Probe Black Wire)

Earth GND Earth ground connection

Operator PWR + Power in from operator (12-39 VDC or 12-27 VAC)

Operator PWR – Power in from operator (12-39 VDC or 12-27 VAC)

TIP:

VMD202-15 - Advanced Gate Automation Vehicle Motion Detector with 15m Cable

Vehicle Motion Detector VMD202 with 15m Cable and VMD202-R Sensitivity Remote

Suitable for 12-39 VDC / 12-27 VAC and Solar Power Applications

5

Applications

Standard Applications:

Solar Applications:

The remote control is removed to minimize power consumption.

*Values are without remote connected

Number of Vehicle

Activations Per Day

Average Current

(Amps)

720 0.001442

288 0.000619

144 0.000344

72 0.000207

48 0.000161

IMPORTANT: EARTH GROUND CONNECTION

The VMD202 contains protection devices to guard against damage and false triggering due to electrical

transients caused by lightning or other sources. Always provide a good earth-ground connection to the green

wire of the VMD202 remote control in standard applications or the black wire of the VMD202 probe in solar

applications. A 20cm copper rod or metal cold-water pipe provides a sufficient earth-ground connection.

SOLAR NOTE: The probe consumes only 70 uA when no vehicle

motion is detected and draws a higher current for 5 seconds

when detecting vehicle motion. This table provides an average

current draw based on an estimate of how many cars per day

may activate the VMD202. Connect the remote to the probe to

adjust the sensitivity, then remove the remote and power the

probe directly from the operator (the remote draws extra

current). A 12 VDC battery is recommended for solar applications

(a 24 VDC battery can be used as well).

Read the following list of tips prior to beginning the installation process.

This will save significant time in the long run.

•

Size of Moving Vehicle Speed Detection Distance

Average size car or truck 8 km/hr min. Up to 30 cm

Average size car or truck 16-80 km/hr Greater than 30 cm

Large truck or semi-truck Over 80 km/hr Greater than 1 m

Train Any 2.5 m

• The detector is sensitive to minute changes in the magnetic field around the probe.

Power lines, transformers, and other electrical devices located in the vicinity of the probe

that produce transients could cause disturbances in the magnetic field that may result in

triggering the detector. Avoid installation of the probe near these devices.

• Do not install the probe or lead wire near or parallel to:

• Low voltage lighting wires or in-ground power lines

• Telephone lines or intercom systems

• Electric motors or control relays

• Overhead power lines, transformers, or underground power lines

• Cell phone towers, TV towers or communications links

• Moving metal flagpoles, fences, gates, or horses with metal shoes

• Do not mount on any moving surface, such as bridges or walkways that may vibrate under traffic.

The probe must always be installed in such a way that it remains completely motionless.

Any movement will cause the probe to trigger.

• Probes are available in various cable lengths, when possible select the appropriate cable length

for the installation. If it is necessary to extend the cable length (maximum 15 m) use a

high-quality lead-in cable suitable for direct burial and a high quality, watertight cable splice

to prevent moisture from entering the cable causing false triggering. Lead-in wire is available from

EMX.

• When there is a high incidence of damage from burrowing animals or other potential damaging

activities, it is recommended that the cable be placed in plastic conduit (3.8 cm internal diameter).

Damage to the cable jacket may allow moisture to enter the cable causing false triggering. When

placing the probe in plastic conduit, use foam or tape to assure that the probe

does not move or vibrate. It is recommended that the conduit be sealed to prevent water from

collecting in it.

Installation

The detector’s sensitivity is a function of speed and mass. The detection distance for a moving,

average size car or truck is approximately 3.5 m at a speed of 8 km/hr. At higher speeds, the

detection distance can exceed 3.5 m as noted below.

Installation Methods

Adjacent to Roadway (Recommended Method) In a Roadway

1. Temporarily place the probe parallel to the

roadway (driveway) in the desired location.

1. Position the probe in the center of the

roadway, perpendicular to the direction of

traffic. The probe should be located at a

minimum of 5cm deep in concrete or asphalt.

• If installing the probe prior to paving a hot

asphalt roadway, the VMD202 and its lead

cable need to be insulated. A common

method to do this would be to dig a small

trench and bury the probe and lead cable in

10cm of sand prior to paving.

(DO NOT APPLY

HOT ASPHAULT DIRECTLY AGAINST

PROBE AND LEAD CABLE!)

• If installing the probe in concrete, make sure

it is installed above the rebar.

• The probe may be positioned prior to paving

or a cut may be made in the finished

pavement for installation.

2. Connect the power, VMD202 remote control, output relay contact and earth ground to the

intended equipment. (Reference EARTH GROUND CONNECTION in Wiring Connections.)

DO NOT EXCEED 39 VDC or 27 VAC.

3. Apply power and allow 5 minutes of warm-up for system stabilization.

4. Set sensitivity to 0.

5.

Drive a vehicle at a minimum speed of 8 km/hr passed the probe and to the far side of the roadway.

6. Repeat step 5 while gradually increasing the sensitivity until the system detects the vehicle.

•

•

7.

7. Installation in roadway complete.

For instances of high pedestrian traffic, heavy animals or heavy vehicles, bury the probe

60 cm deep to prevent false triggering in either installation method.

TIP:

TIP:

TIP:

15m CABLE

GATE OPENER

JUNCTION BOX “BY OTHERS”

VMD202 PROBE

BURIED 20-30 CM DEEP

SENSING AREA - APPROX. 3.5M

DIAMETER CIRCLE AROUND PROBE

A higher sensitivity setting than required to detect the vehicle makes the system more

vulnerable to triggering from unintended sources such as movement of other objects,

including bicycles, horses, small vehicles, metal in shoes or other electrical disturbances.

When the detector is set to maximum sensitivity (full counterclockwise on the sensitivity

adjustment) detection distance is approximately 3.5m at a speed of 8 km/hr. At higher

speeds, 15-20 km/hr, detection distance can exceed 3.5m.

Bury the probe at this location approximately

20-25 cm deep for typical applications. Repeat

the previous sensitivity check (steps 4-5) to

verify proper operation. Installation is adjacent

to roadway complete.

Symptom Possible Cause Solution

False triggering Electrical disturbances

Damaged probe cable

Moisture in probe cable

Movement in the probe’s

environment

Dirty or noisy power supply

Lightning

Low Input Voltage

1. Verify that the earth ground connection to the

VMD202 is secure. If the connection is not secure,

reconnect both the VMD202 and the

earth ground and retest the system.

2. Disconnect the relay wires (green, white, brown)

and see if the false triggering continues. If the false

triggering stops, check the probe as outlined below

in step 3. If the false triggering continues,

disconnect the power and temporarily connect a

12V battery to the VMD202 and reconnect the

probe. Wait 5 minutes for the system to stabilize. If

the false triggering stops, consider using a separate

power supply for the VMD202 such as a 120 VAC to

12 VDC power converter (min. 100 ma). Reconnect

the probe and retest the system.

3. Inspect the area around the probe to see if any

ferrous metal objects may be subject to any

movement. These may include fences, flagpoles,

signs, etc. Other possible causes are electrical

power lines, electric motors, invisible dog fences,

low voltage lighting and high-power lighting.

No output

Bad wire connection

Failed relay

1. Disconnect the output contacts from the operator.

2. Connect a digital multimeter, set to read ohms, to

the COM and NO contacts. The meter should read

open (infinity, or “OL”).

3. Move a metal tool over the length of the probe.

Verify that the meter reads less than 10 ohms. If the

meter reads more than 10 ohms, the VMD202 is

defective.

No detection Minimum 8 km/hr

Bad wire connection

Faulty power connection

Failed relay

1. Verify that the VMD202 remote control’s

green LED is on. If not, check the supply voltage

using a digital multimeter. Verify the voltage is

12-39 VDC or 12-27 VAC.

2. If voltage is present and there is still no detection,

the VMD202 is defective.

EMX Industries, Inc. products have a warranty against defects in materials and workmanship for a period

of two years from date of sale to our customer.

Troubleshooting

Warranty

VMD202™

Single Piece Vehicle Motion Detector

Sensitivity Remote

Guide: Removing VMD202 Probe Harness for Remote w/ Terminals

Required Tools: Wire strippers, small flat-head screwdriver

Wiring to Remote and Operator

• Wire the Red (Probe PWR +) and Black (Probe PWR -) wires from the probe cable into the

two remote screw terminals labeled “Probe PWR”.

• Wire the probe relay wires (Green=COM, White=NC, Brown=NO) to the operator input terminals.

See the operator’s manual for wiring instructions.

• Wire power (12-39 VDC / 12-27 VAC) from the operator into the remote terminals

labeled “Operator PWR”. Ensure power is wired in with the correct polarity. Incorrect wiring

can cause permanent damage to the remote. The operator power cable is not provided with the

VMD202 system.

• If the remote is going to permanently be part of

the installation, connect an earth ground to the

remote terminal labeled “Earth GND”.

Probe Connections

Wire Color Description

Red Power + (12-39 VDC or 12-27 VAC)

Black Power – (12-39 VDC or 12-27 VAC)

Green Relay – COM (common contact)

White Relay – NC (normally closed contact)

Brown Relay – NO (normally open contact)

• The image to the right shows how the final wiring

should look. If you intend to use the VMD202 without

the remote, use the table below for connections to the

probe cable.

Final Wiring to the VMD202 Remote

Other manuals for VMD202

1

Table of contents

Other EMX Industries Security Sensor manuals

EMX Industries

EMX Industries CarSense202 CS202 User manual

EMX Industries

EMX Industries ULT-V2 User manual

EMX Industries

EMX Industries ULT-MVP User manual

EMX Industries

EMX Industries USVD-4X User manual

EMX Industries

EMX Industries OWL User manual

EMX Industries

EMX Industries Ultra II DTEK User manual

EMX Industries

EMX Industries IRB-MON2 User manual

EMX Industries

EMX Industries CarSense 202 User manual

EMX Industries

EMX Industries MVP D-TEK User manual

EMX Industries

EMX Industries VMD202 User manual