EMX IRB-RET2 UL325 User manual

EMX Industries, Inc. Tech support: 216-518-9889 1/13

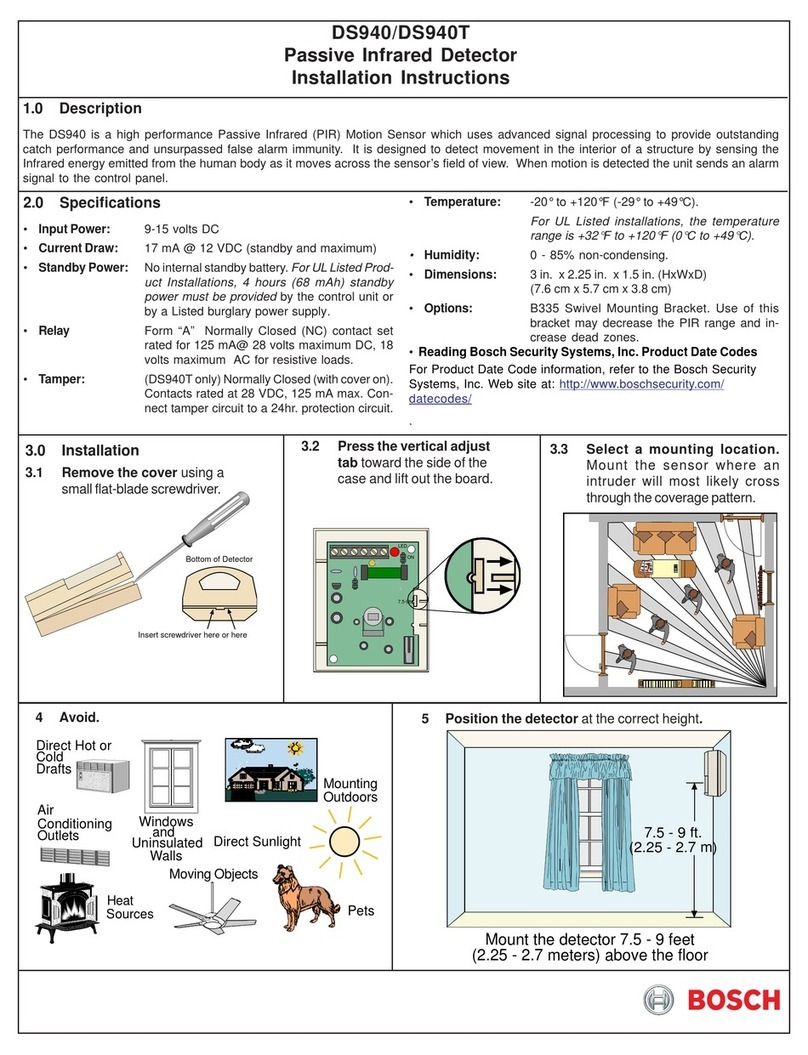

IRB-RET2™

Universal UL325 Retroreflective Photoeye

Instruction Manual

The IRB-RET2 retroreflective, infrared photoeye is an external entrapment protection device type B1, non-

contact sensor for use with automatic gates and doors. The reflector directs the beam back to the

photoeye, therefore wiring to the other side of the roadway is not needed. The IRB-RET2 is compatible

with most operators that accommodate monitored external entrapment devices per UL325. (six

monitoring methods are available) The IRB-RET2 operates up to 60 feet over a wide range of voltages (6-

40 VDC and 12-24 VAC). A red alignment indicator on the receiver provides easy set-up and alignment.

Cautions and Warnings

This product is an accessory or part of a system. Install the IRB-RET2 according to

instructions from the gate or door operator manufacturer. Comply with all applicable codes

and safety regulations.

Specifications

Ordering Information

• IRB-RET2 KIT Retroreflective photoeye kit, includes photoeye, reflector with hood and

mounting bracket.

Operating Range

5 ft (1.5 m) to 60 ft (18.3 m)

Power

6-40 VDC, 12-24 VAC

ononly)

Current (NC and 10K Monitoring Methods)

50 mA DC (relay activated)

Current (Pulse Monitoring Methods)

15 mA DC

Resistive Termination

10K ohm across NO contact (switch selectable)

Surge Protection

Thermal fuse, MOV

Relay Output Operation

Light ON/Dark ON

Response Time

250ms

Operating Temperature

-30° to 140°F (-34° to 60°C)

Dimensions (L x W x H)

5.1” (130 mm) x 3.15” (80 mm) x 5.5” (140 mm)

Ball Joint Mount Conduit Thread

½Inch NPT

EMX Industries, Inc. Tech support: 216-518-9889 2/13

Monitoring Methods

UL325 requires continuous monitoring of all safety devices connected to gate and door operators.

Consult the gate or door operator manufacturer’s instruction manual for the necessary monitoring

method.

•

Normally Closed: Cycles power to the transmitter while monitoring the receiver contacts for proper

operation

•

10K Resistive Termination: Provides a measurable 10K ohm resistance across the normally open

(NO) contact when unobstructed

•

Two-wire Pulse (2 Frequency): Provides 300Hz “heartbeat” unobstructed, 0Hz obstructed over

power supply lines

•

Two-wire Pulse (3 Frequency): Provides 300Hz “heartbeat” unobstructed, 2Hz obstructed, and

0Hz failure over power supply lines

•

Four-wire Pulse (2 Frequency): Provides 300Hz “heartbeat” unobstructed, 0Hz obstructed over

separate connection

•

Four-wire Pulse (3 Frequency): Provides 300Hz “heartbeat” unobstructed, 2Hz obstructed, and

0Hz failure over separate connection

EMX Industries, Inc. Tech support: 216-518-9889 3/13

Installation

•

Determine the mounting location of the IRB-RET2 photoeye according to UL325 guidelines.

•

Deactivate the gate or door prior to and during photoeye installation.

•

The IRB-RET2 cannot be used for a detection range of less than 5 feet.

1. Check the instruction manual of the gate

or door operator to determine which

monitoring method is required for that

specific operator.

2. Unscrew the four back cover screws,

then remove back cover. Feed wiring

through ball joint opening.

The wiring to the enclosure must enter

via a UL listed watertight fitting such as a

strain relief or ½inch NPT thread

watertight conduit connector.

3. Review the configuration table and

wiring diagram on PAGE 10 that

corresponds with the monitoring

method required for the gate or door

operator. Wire the IRB-RET2 accordingly.

MUST USE 6-40 VDC FOR PULSE

MONITORING.

EMX Industries, Inc. Tech support: 216-518-9889 4/13

The IRB-RET2 has detachable screw terminals for

easier wiring. Remove them while connecting

wires, then plug them back in properly and secure

them.

The 4-terminal connector on the right is for power,

while the 5-terminal connector on the left is for

control signals.

Be careful not to install the connectors upside

down.

4. To mount the photoeye, first secure the bracket clamp base (ITEM C) to the mounting surface.

The mounting for a flat surface, such as a square tube or wall is shown below.

EMX Industries, Inc. Tech support: 216-518-9889 5/13

The mounting for a curved surface, such as a pole, is shown below:

Note the different screw locations for a flat vs. curved surface. The mounting patterns for flat and

curved surface are shown below.

Mounting Position for Gates

Mounting Position for Overhead Doors

EMX Industries, Inc. Tech support: 216-518-9889 7/13

5. After mounting the bracket base, attach the photoeye and bracket clamp. Tighten the two bracket

clamp screws (ITEM B) to secure the photoeye, but leave them loose enough for the photoeye to

swivel using the ball joint during the alignment process.

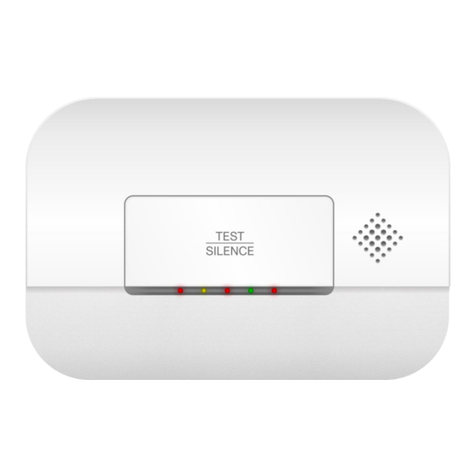

LED Indicators

Indication

State

Safety State

Green LED & Red LED On

Aligned with reflector, no

obstruction

Safe

Green LED On & Red LED

Flashing

Partial Alignment

Safe

Green LED On & Red LED Off

Beam obstructed or not aligned

Not Safe

Green LED Off

No power

Not Safe

6. Sensitivity Adjustment - Adjust sensitivity using potentiometer R1

(shown to the right) at the top left of the circuit board. Use the

markings as a guide based on the distance between the sensor and

reflector:

• 5-20 ft: Point the dial at the 5-20 ft marking

• 20-30 ft: Point the dial at the 20-30 ft marking

• 30-60 ft: Point the dial at the 30-60 ft marking

If you have trouble aligning the sensor or if you are concerned

about rain, snow, or fog obstructing the IR beam, you can increase the sensitivity by adjusting the

potentiometer clockwise.

Configuration - After setting sensitivity, check DIP switches SW1 and SW2, and jumper JP1 to ensure

proper setup (refer to Configuration Table on PAGE 9 and Wiring Diagrams on PAGES 10-12).

Adjusting sensitivity and configurations might be harder once the photoeye is aligned, as the back

cover may not be easily accessible.

Stealth Mode – Enable Stealth Mode by turning ON Position 2 on DIP switch SW2. In Stealth Mode,

LEDs turn off after 30 seconds if the sensor is aligned and unblocked, but turn on when obstructed,

turning off again after 30 seconds. This mode is helpful for hiding the sensor from passers-by and

vandals, especially at night. It can be used in any setup and doesn't affect other functions.

After final adjustments are made, replace the back cover ensuring the gasket is present, and tighten

the screws.

EMX Industries, Inc. Tech support: 216-518-9889 8/13

7. Alignment: Apply Power to the photoeye and aim it at the reflector's planned location. Go to the

reflector's mounting spot. Move the reflector left, right, up, and down to find the center of the

detection pattern (a typical installation will have a 2-foot diameter). The reflector should be placed

in the center of the detection pattern for best performance.

During this, watch the Red LED on the photoeye during alignment. A solid RED LED means the best

alignment. If the alignment isn't optimal, the Red LED will flash. Slow flashing means poor alignment,

while fast flashing indicates better alignment.

If you cannot get the photo eye to align near your intended mounting

location, adjust the aim of the photoeye and repeat this Alignment process.

Note: If Stealth Mode is on (STEP 6), LEDs turn off after 30 seconds when the

photoeye is powered and aligned. To turn LEDs back on, briefly block the light

beam with an object in front of the reflector. LEDs will turn on for 30 seconds

before turning off again.

8. To ensure the integrity of the enclosure, make sure the gasket is present, the cover is properly

seated, and the cover screws are tight. The wiring to the enclosure must enter via a UL listed

watertight fitting such as a strain relief or ½inch NPT thread watertight conduit connector.

RED LED is

located on the

RIGHT

EMX Industries, Inc. Tech support: 216-518-9889 9/13

9. Tighten the two bracket clamp screws (ITEM B) and the set screw (ITEM A). (3/32" allen wrench is

required)

10. Verify that the photoeye and reflector are aligned.

11. Place an obstruction (ex. hand) between the photoeye and reflector. The red LED will turn off.

Remove the obstruction and the red LED will turn on.

12. Check the operator control board and verify that the safety input is recognized by the operator.

Test the beam with an obstruction between transmitter and reflector at multiple distances to

confirm proper operation.

13. Follow the gate or door operator manufacturer’s installation instructions and safety checks to

verify that the photoeye is operating properly.

Configuration Settings and Wiring Diagrams

Terminals

Description

VTX

Transmitter power input

VRX

Receiver power input

Pulse C

Isolated pulse output collector

Pulse E

Isolated pulse output emitter

Energized NO

Normally open contact, relay output shown in energized state (power on, and no

obstruction) when properly aligned to the reflector

Energized COM

Relay common

Energized NC

Normally closed contact, relay output shown in energized state (power on, and no

obstruction) when properly aligned to the reflector.

EMX Industries, Inc. Tech support: 216-518-9889 10/13

Configuration Table

Monitoring

Method

Diagram

DIP Switch 1 Settings

DIP Switch 2 Settings

Output

Connections

Power

Connection

JP1

1

2

3

4

1

2

3

4

Normally

Closed

A

OFF

OFF

OFF

ON

OFF

OFF

ON

ON

NC, COM

VRX

4W

10K

Resistive

Termination

B

OFF

OFF

OFF

ON

ON

OFF

ON

ON

NO, COM

VRX

4W

Normally

Closed:

Power Cycle

Transmitter

Only

C

OFF

OFF

OFF

ON

OFF

OFF

OFF

OFF

NC, COM

VRX, VTX

4W

Two-Wire

Pulse (2

Frequency:

300Hz, 0Hz)

D

ON

OFF

OFF

ON

OFF

OFF

ON

ON

VRX

VRX (DC

Only)

2W

Two-Wire

Pulse (3

Frequency;

300Hz, 2Hz,

0Hz)

E

OFF

ON

OFF

ON

OFF

OFF

ON

ON

VRX

VRX (DC

Only)

2W

Four-Wire

Pulse (2

Frequency:

300Hz, 0Hz)

F

ON

OFF

OFF

ON

OFF

OFF

ON

ON

E,C

VRX

4W

Four-Wire

Pulse (3

Frequency:

300Hz, 2Hz,

0Hz)

G

OFF

ON

OFF

ON

OFF

OFF

ON

ON

E,C

VRX

4W

Table 1: PCB Configurations

• For two-wire pulse monitoring, use 6-40VDC. 2-wire pulse will not work with any AC input

voltage.

• The relay contacts labeled on the terminals and the references to them in these instructions are

shown in the energized state, and no obstruction. (Dark ON setting –normally open (NO) contact

closes when the beam is unobstructed.)

• 2-Wire Pulse configurations require current limiting in the operator.

• 4-Wire Pulse output provides an emitter (Terminal “E”) and collector (Terminal “C”) connection to the

operator. The emitter is generally connected to the circuit common (ground) and the collector is

typically an open-collector output using a pull-up resistor to low-voltage DC power.

EMX Industries, Inc. Tech support: 216-518-9889 11/13

EMX Industries, Inc. Tech support: 216-518-9889 12/13

EMX Industries, Inc. Tech support: 216-518-9889 13/13

Symptom

Possible Cause

Solution

Does not detect obstruction

Signal is reflecting off another

surface

Check area for highly reflective

surfaces such as a shiny vehicle.

Possible solutions are to move

the photoeye farther away from

the roadway or adjust the

sensitivity counter-clockwise.

Red LED flashes continuously.

Sensitivity is too low

Photoeye is not aligned with

reflector

Adjust the sensitivity clockwise

according to STEP 6.

Realign the reflector according

to STEP 7 under installation.

Photoeye activates but does not

transmit signal to operator

Faulty connection between

photoeye and operator control

input

Verify all wires and terminal

connections to operator.

Green LED not on when

powered

DIP switch SW2 positions 3 and 4,

not in the correct position

Switch DIP switch SW2 positions

3 and 4 to “ON”.

Verify input power is between

6-40 VDC / 12-24 VAC and

wire per the wiring diagram.

Device will not align,

No Red LED

No transmitter power

Turn DIP switch SW2 position 3

and 4 to ON

OR

Wire power to VTX

Warranty

EMX Industries, Inc. products have a warranty against defects in materials and workmanship for a period

of two years from date of sale to our customer.

Troubleshooting

Table of contents

Other EMX Security Sensor manuals