EN-KO Electronics AMF 4.0 User manual

EN-KO Electronic Control Systems AMF 4.0/ENG/K.K./02

1

AMF 4.0 AUTOMATIC MAINS FAILURE UNIT

USER MANUAL

V1.36

(AMF 4.0 versi n 25)

GEN

I

T

Battery

Temp

I

S

I

R

Oil press

TEMPERATURE LEVEL

OIL LEVEL

Critical

Level

Max.

Level

00

0

C50

0

C

AUX.

AMF 4.0

Automatic Mains Failure

22

0

F 2 2

0

F

Engine

hour

Freq

V

R

V

S

V

T

MAINS

G

START

A

TEST

V

V

RS

V

S T

V

T R

Esc

EscEsc

Esc

MENU

OFF

STOP

I / 0 I / 0

DESCRIPTION

AMF 4.0 genset control unit provides t e functions, required in automatic mains failure

applications of gensets. It can be operated in automatic, test and manual modes. It contains

digital displays providing functions of all analog displays needed in generator panels. Device

digital displays s ow 3 p ase mains and generator voltages, 3 p ase generator currents, mains

and generator frequencies, battery voltage, oil pressure (bar), engine temperature and engine

our. Generator is monitored constantly and w en generator or mains values exceed t e limits

adjusted in t e parameter menu, necessary actions are taken and alarm is activated. Last ten

alarms are recorded in t e device memory. All operating modes and timings can be adjusted

in t e parameter menu. T is flexibility is provided for different kinds of generator

applications.

FUNCTIONS

• Manual engine starting and stopping

• Mains monitoring, automatic start, stop and transfer switc functions

• True RMS voltage and current measurements

• Failures monitoring

• Pre eating

• Manuel, automatic and test modes

• Cost effective digital measurement displays

• Recording of last 10 failure

• Engine our measurement and periodic service time warning

• Manuel and automatic control of mains and generator contactors

• Analog engine temperature and oil pressure measurement capability

• Adjustable operating modes and timings via parameter menu

• Analog bar grap , engine temperature and oil pressure displays

• Adjustable measurement calibrations

• Remote Start

EN-KO Electronic Control Systems AMF 4.0/ENG/K.K./02

2

INPUT / OUTPUTS

• 3 p ase mains and generator voltage inputs

• 3 p ase generator current inputs

• 12 or 24 V battery supply input

• Oil pressure and temperature analog inputs

• C arge alternator input

• Cranking relay output

• Pre eat relay output

• Fuel solenoid relay output

• Mains contactor relay output

• Generator contactor relay output

• Alarm relay output

• 2 programmable auxiliary relay output

• 2 programmable auxiliary input

ALARMS

• Engine start/stop failure

• Under/over speed failure

• Under/over voltage failure

• Over current failure

• Hig temperature failure

• C arge fail warning

• Low oil pressure failure

• Periodic service time warning

• Auxiliary failure

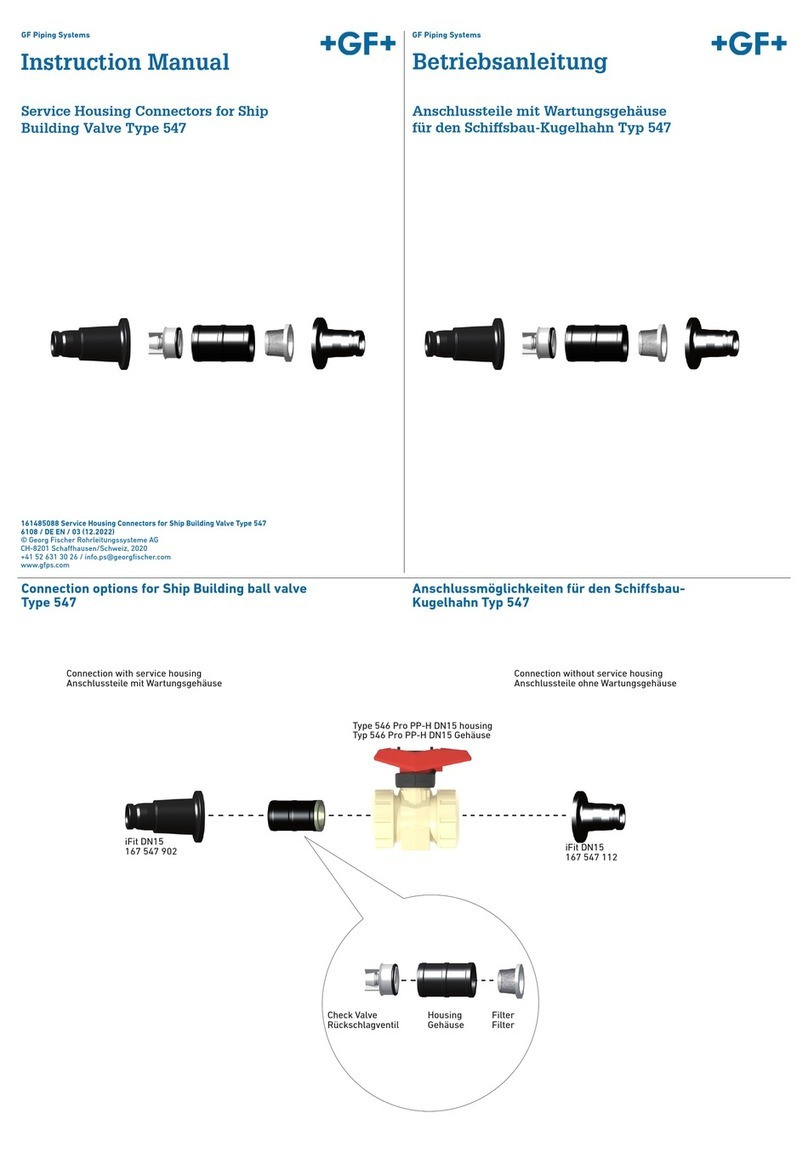

AMF 4.0 CONNECTION DIAGRAM

AMF 4.0

Generator Contactor

Relay

Mains Contactor Relay

G

R

S

T

N

U

V

W

N

LOAD

R S T N GENERATORMAINS

2

23

9

8

7

22

4 353433

32

3

30

2928

27

26

25

24

Configurable Input

(Default Oil Pressure Switch)

Configurable Input 3

Battery

2

Oil Pressure sender

Temperature Sender

Crank Charge

Fuel Selenoid

Preheating Ralay

35 2200

98

7

5

6

4

Configurable output

(Default Horn)

D+WL

Power Supply

Crank Relay

3

Emergency

Stop

Com 2

6

Configurable Input 4

Generator Current

Inputs

Configurable output 2

Configurable output 3

Configurable Input 2

(Default Temperature Switch)

NEGATIVE TERMINAL OF BATTERY

SHOULD BE GROUNDED

EN-KO Electronic Control Systems AMF 4.0/ENG/K.K./02

3

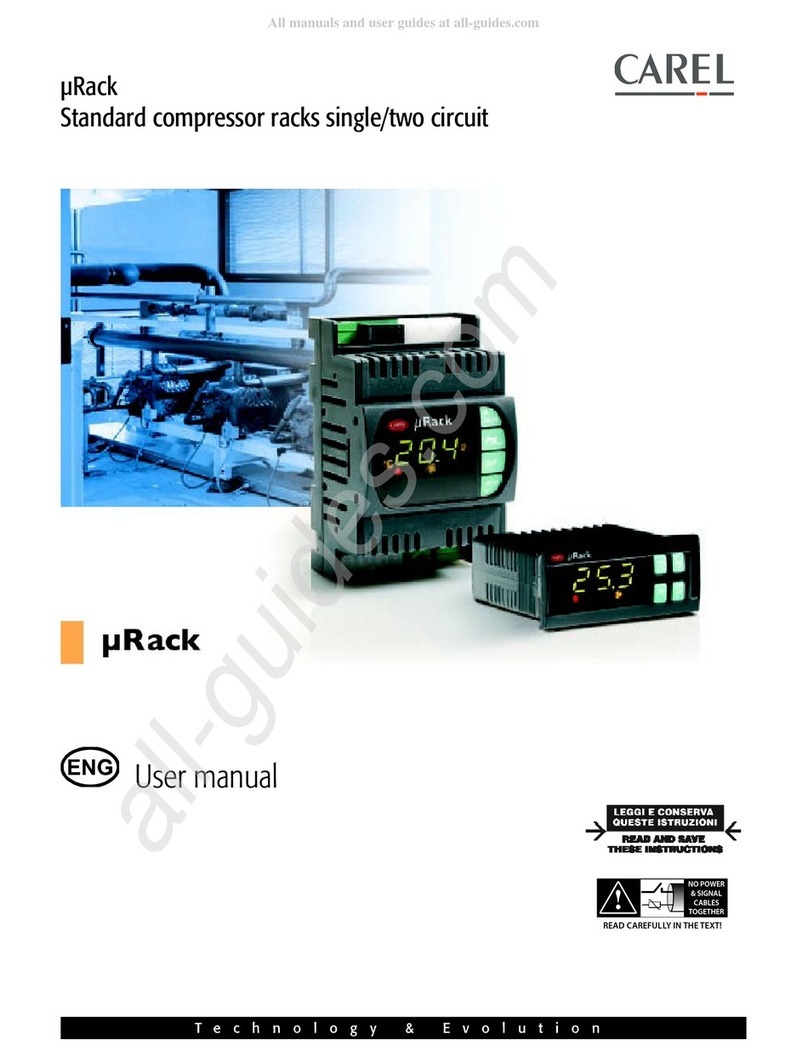

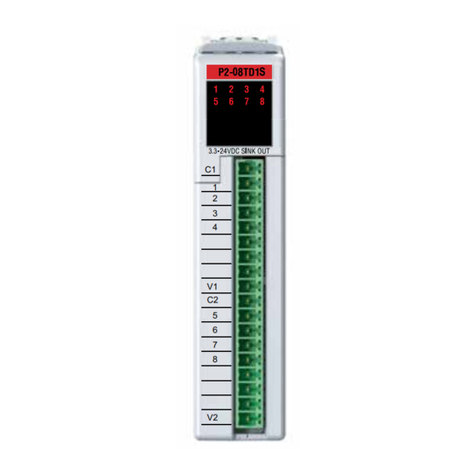

FRONT PANEL

GEN

I

T

Battery

Temp

I

S

I

R

Oil press

TEMPERATURE LEVEL

OIL LEVEL

Critical

Level

Max.

Level

00

0

C50

0

C

AUX.

AMF 4.0

Automatic Mains Failure

22

0

F 2 2

0

F

Engine

hour

Freq

V

R

V

S

V

T

MAINS

G

START

A

TEST

V

V

RS

V

S T

V

T R

Esc

EscEsc

Esc

MENU

OFF

STOP

I / 0 I / 0

PreHeat Butt n (1): W en genset doesn’t start in cold weat ers, engine can be pre eated

wit t is button. Button function can be set as “button must be eld down to pre eat” or

“preset pre eat time w en you press button”. Pre eat button can be used in manual mode and

w en engine is not running.

Start Butt n: T is button is used to start genset . Panel will stop cranking w en it detects

engine running signals. Button function can be set as “button must be eld down to crank” or

“preset cranking time w en you press button”. Start button can be used in manual mode and

w en engine is not running. Panel will display “Str” message during cranking.

St p Butt n: T is button is used to stop t e genset. W en you pressed t is button first time

panel switc ed to manual mode and if generator contactor is used before, genset is switc ed

to cooling mode. If you pressed second time genset stops immediately. Second function of

t is button w en you press more t an 3 seconds panel will switc to off mode.

Generat r C ntact r (2): T is button is used to transfer load to genset. W en genset is

running t is button can be used. Led lamp above t e button s ows contactor status. W en t e

led lamp is lit, contactor is closed. Generator contactor cannot be closed w en t e mains

contactor is closed. To close generator contactor, you must open t e mains contactor first. In

engine running condition, w en you press stop button, generator contactor will open

immediately.

9

7

6

8

1

2 3

4

5

EN-KO Electronic Control Systems AMF 4.0/ENG/K.K./02

4

Mains C ntact r (3): T is button is used to control mains contactor. It cannot be closed if

generator contactor is closed.

Generat r Status Led Lamp (4):

• It is off, if engine isn’t running.

• It is on, if engine is running

• It is blinking, if genset is in engine stabilization, cooling or stopping. T ese topics will

be explained later

Mains Status Led Lamp (5):

• It is off, if mains voltage is outside t e limits of preset values.

• It is on, if mains voltage is inside t e limits of preset values.

• It is blinking in transition times (mains failure delay and mains return delay) if mains

c ange t e state from normal to failure or failure to normal state

Alarm Led Lamps (6): From t e upper left corner, ig and low generator speed, ig and

low generator voltage, ig coolant temperature, over current and service alarms. From lower

left corner start and stop failure, low oil pressure, c arge failure, battery voltage failure and

auxiliary alarms. Detailed description will be given in t e following c apters.

Oil Pressure and C lant Temperature bar graphs (7): Analog oil pressure and coolant

temperatures can be seen in bar grap s. In temperature bar grap temperature can be seen

from 50° C/ 112 °F to 100 °C/212 °F. In oil press bar grap , oil press can be seen from oil

pressure failure level to maximum oil press sender level.

Display Leds: T ese leds are in t e rig t side of numerical displays. Leds indicates meaning

of t e value in t e displays. Values in t e displays can be c anged by up, down and menu

buttons.

Measuring M de Butt n (8): T e button selects t e displayed values at lower 2 numerical

display. T ese displays can s ow generator voltage and frequency or mains voltage and

frequency.

Esc Butt n: T is button as multiple tasks. T ese are listed below,

• In alarm condition, first press stops t e orn and second press clears t e alarm.

• It is used to exit parameter menu. For t is process button must be eld down 3

seconds.

• In t e process of c anging parameter w en you enter invalid values you can cancel by

t is button.

Menu Butt n (Enter): T is button as multiple tasks. T ese are listed below

• It is used to select t e values in t e numerical displays. W en you press first time led

will be lit on t e rig t of t e display t at is in selection mode. If you press up and

down buttons before stop blinking you can c ange t e value s own in display. If t e

display t at is wanted to c ange mode is different you can press menu button and

c ange t e display in selection mode.

• If you press t is button 3 seconds, you will enter t e parameter menu. In parameter

menu you can use menu button to c ange selected parameter. You can c ange t e

active digit. After all active digits are set last press will write value to parameter

memory. Detailed information will be given in parameters section.

EN-KO Electronic Control Systems AMF 4.0/ENG/K.K./02

5

Up, D wn Butt ns (+, -): T is button as two tasks. T ese are listed below.

• It is used to select t e values in t e numerical displays. W en you press first time led

will be lit on t e rig t of t e display t at is in selection mode. If you press second time

you can c ange t e value of display t at is in selection mode.

• In parameter menu you can press menu button to c ange selected parameter. You can

c ange t e number of active digit.

Running M de Butt ns (9): T ese are manual ( and mark), automatic (A letter) and test

buttons. T ese buttons set running mode of genset. T ere is mode indication leds near eac of

t ese buttons. W en panel is in off mode you can press t ese buttons to wake up panel and

genset will run in selected mode.

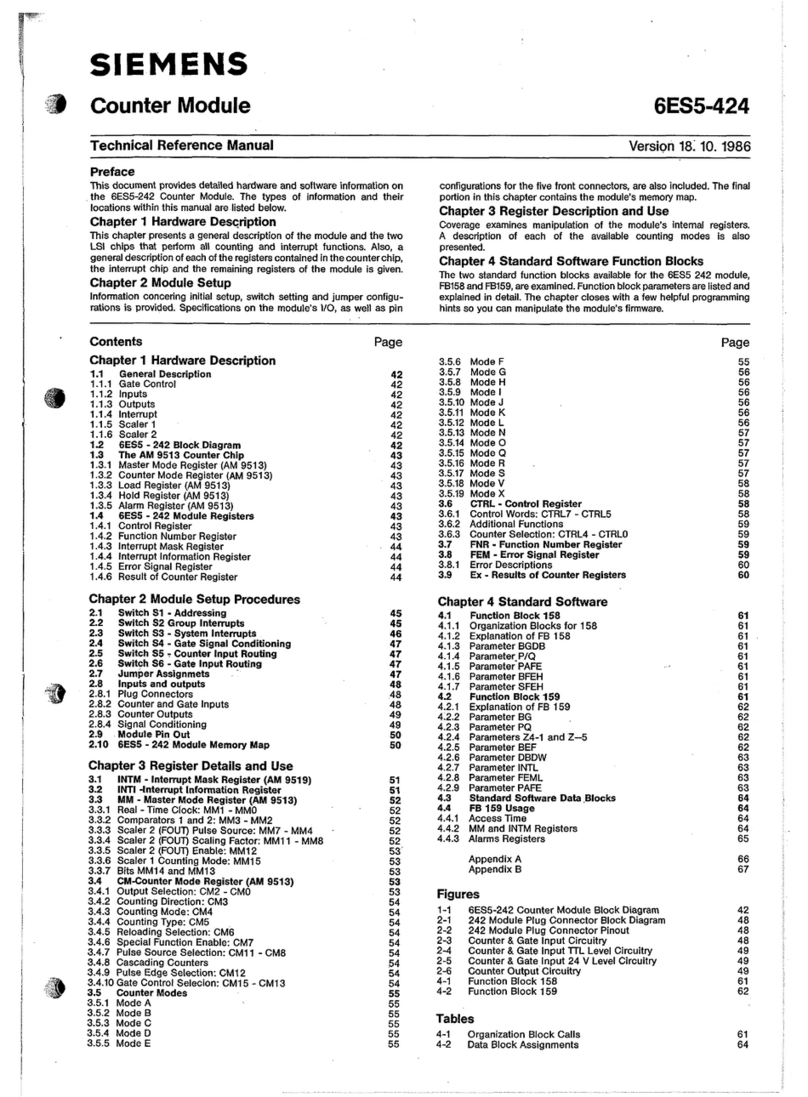

REAR CONNECTIONS

I

T

+

I

S

+

I

R

+

I

R

-

I

T

-

I

S

-

30 31 32 33 34 35

22 23 24 25 26 2 28 29

G

11 12 13 14 15 16 1 18 19 20 21

CRANKING

COM 1

BATT (+)

COM 2

BATT (-)

AUX. OUTPUT 2

FUEL SELENOID

AUX. OUTPUT 1

AUX. OUTPUT 3

PREHEAT

1 2 3 4 5 6 8 9 10

MAINS CONT. COM.

AUX. INPUT 3

OIL PRESSURE

AUX. INPUT 2

AUX. INPUT 4

TEMPERATURE

MAINS CONT. NC

GEN CONT. COM.

GEN. CONT. NO

CHARGE FAIL-EXCIT.

AUX. INPUT 1

N

W

V

U

N

T

S

R

CURRENT

TRANSFORMER

INPUTS

EN-KO Electronic Control Systems AMF 4.0/ENG/K.K./02

6

CONNECTIONS

Terminal N

Terminal Name Descripti n

1 Bat (+) Battery positive. Voltage must be between 9- 30 V

2 Bat (-) Battery negative. Battery negative must be connected

to eart .

3 Com 1 Common terminal of pre eat, fuel solenoid and

cranking relays.

4 Pre eat Pre eat relay

5 Cranking Cranking relay

6 Fuel Solenoid Fuel or stop solenoid relay. Operating mode must be

selected from parameter menu.

7 Com 2 Common terminal of auxiliary relay 1, 2, 3

8,9,10 Aux. Output 1, 2, 3

Multiple function auxiliary relay outputs. Auxiliary

output 1 is default orn output.

11

HIGH

VOLTAGE

Mains Cont. Com.

Input terminal of mains contactor relay. Line R of

mains can be connected to t is terminal

12

HIGH

VOLTAGE

Mains Cont. NC Output terminal of mains contactor relay. T is output

is connected to mains contactor.

13

HIGH

VOLTAGE

Gen Cont. Com. Input terminal of generator contactor relay. Line U of

generator can be connected to t is terminal

14

HIGH

VOLTAGE

Gen Cont. NO

Output terminal of generator contactor relay. T is

output is connected to generator contactor.

15 C arge Fail Excit.

Warning lamp output of c arge alternator must be

connected ere. In t e cranking excitation current is

supplied to c arge alternator over 150 o m resistor.

16 Aux. Input 1

Multiple function auxiliary input. T ese inputs are

activated if it is connected to battery negative. If oil

sender t at ave bot sender and switc function is

used, switc terminal must be connected to t is

terminal. Suitable configuration must be set for t is

input to use it as oil pressure switc input. If t is

input is used for auxiliary input. Alarm will be s own

as A1 in t e display at t e same time wit auxiliary

led indication.

17 Aux. Input 2

Multiple function auxiliary input. T ese inputs are

activated if it is connected to battery negative. If

temperature sender t at ave bot sender and switc

function is used, switc terminal must be connected to

t is terminal. Suitable configuration must be set for

t is input to use it as temperature switc input. If t is

input is used for auxiliary input. Alarm will be s own

as A2 in t e display at t e same time wit auxiliary

led indication.

EN-KO Electronic Control Systems AMF 4.0/ENG/K.K./02

7

18 Aux. Input 3

Multiple function auxiliary input. T ese inputs are

activated if it is connected to battery negative. If t is

input is used for auxiliary input. Alarm will be s own

as A3 in t e display at t e same time wit auxiliary

led indication.

19 Aux. Input 4

Multiple function auxiliary input. T ese inputs are

activated if it is connected to battery negative. If t is

input is used for auxiliary input. Alarm will be s own

as A4 in t e display at t e same time wit auxiliary

led indication.

20 Oil Pressure If oil sender t at ave bot sender and switc function

is used, sender terminal must be connected to t is

terminal. If oil sender t at as single oil pressure

switc output, switc output must be connected to t is

input. Suitable configuration must be set for t is input

to use it as oil pressure switc or sender input.

21 Temperature If temperature sender t at ave bot sender and

switc function is used, sender terminal must be

connected to t is terminal. If temperature sender t at

as single temperature switc output, switc output

must be connected to t is input. Suitable

configuration must be set for t is input to use it as

temperature switc or sender input.

22,23,24,25

HIGH

VOLTAGE

Mains Line and

Neutral Inputs

Mains line and neutral are connected to t ese

terminals.

26,27,28,29

HIGH

VOLTAGE

Generator Line and

Neutral Inputs

Generator line and neutral are connected to t ese

terminals.

30,31,32,33

34, 35

Current Transformer

Inputs

Secondary side of current transformer must be

connected ere. Eac transformer must be connected

separately.

N te: Battery negative must be c nnected t earth

RUNNING MODES

Aut matic M de: If you press automatic button marked “A” genset will switc to automatic

mode. In t is mode panel controls mains voltages and if mains is outside t e limits t at you

programmed, Panel will open t e mains contactor and starts t e genset. After “engine

stabilization time” and “generator contactor delay” load transferred to t e generator. Panel

controls all t e engine values to detect possible failures after engine stabilization time. If

mains come to normal condition, mains is controlled during “mains return delay” for

stabilization. If mains is normal “after mains return delay”, generator contactor opens and

mains contactor closes. Genset is stopped after cooling period. In automatic mode, if panel is

in engine off state and detects an engine running signal. Panel will stop t e engine.

Test M de: If you press test button at t e rig t side of front panel. Genset will be switc ed to

test mode. In test mode engine starts immediately. After “engine stabilization time” if

parameter”test mode” is test off load genset wait for mains failure in running condition. W en

mains failure occur mains contactor opens and generator contactor closes. In same way w en

mains returns, panel waits”mains return delay” and switc back to mains. If parameter “test

mode” is test on load. After engine starting, generator contactor closes and genset supply t e

EN-KO Electronic Control Systems AMF 4.0/ENG/K.K./02

8

load. If operator wants to stop t e engine in test mode panel must be returned to automatic or

manual mode. In manual mode you can stop t e engine by stop button.

Manual M de: If you press t e manual button genset will be switc ed to manual mode. In

manual mode all start stop and pre eat operations, contactor control fulfilled by panel buttons.

PANEL RUNNING PHASES

1. Generat r is still: In t is condition engine running signals must be absent. T ese are oil

pressure, c arging alternator warning lamp signal, generator voltage and frequency. In

manual mode panel doesn’t react to t is signal but in automatic mode panel will try to

stop engine. If electricity panel of genset as manual control and t ese are wanted to be

used. Electronic panel must be switc ed to manual mode.

2. Preheating: In cold weat ers pre eating of engine can be necessary. Engine must be still

during pre eating. If parameter “pre eating time” is not zero, pre eating is accomplis ed

before starting process by panel.

3. Cranking: In t is stage engine is cranking. All engine signals must be absent and engine

must be still before cranking. If one of t e engine signal is detected before cranking, panel

switc to start and stop alarm. Panel will s ow w ic signal is detected wit engine start

stop alarm. If oil pressure signal is detected before cranking panel will wait for it to

decrease to zero. If “before cranking oil pressure delay” is elapsed and oil pressure is not

zero panel will switc to start and stop alarm. In cranking stage all engine signals,

alternator frequency, alternator voltage, c arge alternator voltage and oil pressure is

controlled. If one of t e signals is detected, Panel detects engine is running, crank

disconnects and switc to engine stabilization time. Generator status led starts to blink.

During cranking, “Str” message is s own in t e display. Oil pressure can rise before

engine running so w en oil pressure is detected, crank disconnected after “crank

disconnect oil pressure delay”.

4. Stabilizati n: After generator running signals detected panel waits for engine signals to

stabilize. After engine stabilization time, all alarms are activated.

5. Running: After stabilization time genset is in running condition. If genset in manual and

test modes, alternator contactor time is waited and alternator contactor is closed. In

manual mode operator can close t e generator contactor by generator contactor button. In

running mode generator status led is lit.

6. C ling: If a stop condition occurs by operator or mains status. Generator is switc ed to

cooling period and engine is cooled during “cooling time”. During t is time engine status

led is blinking. If alternator contactor asn’t been closed since last start cooling period is

bypassed. If mains failure occurs during cooling process generator is switc ed back to

running mode and alternator contactor is closed. After cooling process generator is

switc ed to stopping condition.

7. St pping: After cooling stage, generator switc es to stopping stage. If fueling system is

operating solenoid, operating solenoid is de-energized. If fueling system is stop solenoid

solenoid energizes until engine stops. If one of t e engine running signals is detected

stopping period doesn’t ends. Alternator frequency and voltage, c arge alternator warning

lamp signal and oil pressure must be absent. If panel detects engine signals after “fail to

stop delay” panel will switc to start stop alarm.

8. Generat r shutd wn: Generator is stopped because of a red alarm. Generator cannot be

started if alarm is not cleared.

EN-KO Electronic Control Systems AMF 4.0/ENG/K.K./02

9

ALARMS

Alarms are divided to red and yellow alarms. Yellow alarms are for warning purposes and

don’t stop t e generator. Red alarms are serious and if occur generator contactor is opened

and generator is stopped immediately.

High and l w speed (RED ALARM): If alternator frequency is ig er t an

“generator over frequency failure” or is lower t an “generator under frequency

failure” “panel switc es to t is alarm. Alarm is activated after “generator

frequency failure delay”.

High and l w alternat r v ltage (RED ALARM): If alternator voltage is ig er

t an “generator over voltage failure” or is lower t an “generator under voltage

failure” “panel switc es to t is alarm. Alarm is activated after “generator voltage

failure delay”

High c lant temperature (RED ALARM): If temperature t at is read from

temperature sender is ig er t an “ ig coolant temperature level” or if

temperature switc sends alarm to panel. Panel switc es to ig coolant

temperature alarm.

Over current failure (RED ALARM): If currents values read from current

transformers is ig er t an “over current level”. Generator contactor is opened and

generator switc es to cooling. After cooling stage generator stops. Alarm is

activated if condition continues for “over current alarm delay”

Peri dic service:

W en periodic service time elapsed after last periodic service.

Alarm is displayed. Only service personnel can reset alarm.

Fail t start st p: If t is alarm occurs t at means panel couldn’t start or stop

engine. All engine signals must be absent and engine must be still before cranking.

If one of t e engine signals is detected, before cranking, panel switc to start and

stop alarm. Panel will s ow w ic signal is detected wit engine start stop alarm.

If oil pressure signal is detected before cranking panel will wait for it to decrease

to zero. If “before cranking oil pressure delay” is elapsed and oil pressure is not

zero panel will switc to start and stop alarm. In automatic and test modes if

generator couldn’t be started after user defined crank attempts, panel switc es to

fail to start stop alarm. In engine stopping stage if panel still detects engine signals

after “fail to stop delay”. Panel switc es to fail to start stop alarm. Alarm led lamps

indicates w ic engine signal is still present and causes fail to start stop alarm.

L w il pressure (RED ALARM): If oil pressure t at is read from oil pressure

sender is lower t an “low oil pressure level” or if oil pressure switc sends alarm

to panel. Panel switc es to low oil pressure alarm.

Charge Failure (YELLOW ALARM): If c arge voltage read from c arge

alternator warning lamb terminal decreases, panel switc es to t is alarm. T is

alarm doesn’t stop generator.

V

Battery high and l w v ltage (YELLOW ALARM): If battery voltage is ig er

t an “battery ig alarm level” or is lower t an “battery low alarm level” panel

switc es to t is alarm. T is alarm doesn’t stops engine.

AUX.

Auxiliary input (YELLOW r RED ALARM): W en an auxiliary input alarm

occur. T is led is lit and A1, A2, A3 or A4 message is written to display. A1

means auxiliary input1 alarm.

EN-KO Electronic Control Systems AMF 4.0/ENG/K.K./02

10

Mains failure: If mains voltage is lower t an “mains under voltage failure” or is

ig er t an “mains over voltage failure” mains failure occur and in automatic

mode generator is started. If mains comes to normal condition ( ig er t an “under

voltage return” and lower t an “over voltage return”) generator is stopped in

automatic condition.

Emergency st p: If auxiliary input is adjusted for emergency stop and user

presses emergency stop button. “StP” message is s own in t e display, generator

contactor opens and engine stops immediately. To clear t is alarm user must pull

emergency stop button and clear t e alarm.

Sens r failure: If cable connected to sender terminal of oil pressure and

temperature senders breaks. Sensor failure alarm is given. For oil pressure sender

“oSn” message and for coolant temperature sender “tSn” message is s own in t e

display. Alarm is activated if condition continues for 4 seconds. If “analog oil

pressure sender usage” and “analog coolant temperature sender usage” parameters

are set to 0, sender will be used for display purposes and no alarm is given in

sensor failure condition.

EEPr m Failure: W en t is alarm occurs “EEP” message is written to display

and you must call service. Genset mustn’t be started.

PARAMETER MENU

To enter parameter menu, menu button must eld down for 3 seconds. Password screen is

displayed. Parameter menu contains 3 separate sections. T ese are operator, tec nician and

calibration parameters sections. You can give separate password to t ese sections and enter to

t ese sections by its passwords. In parameter section leftmost digit starts to blink. If you press

up and down buttons you can increase and decrease t e value s own in t e blinking digit. If

you want to proceed to digit at one-step rig t menu button must be pressed. You can adjust

t is digit up and down buttons and t en you press menu button again. If you are in t e

rig tmost digit and you ave adjusted t is digit, you can complete password entering by

pressing menu button. You can exit menu by olding esc button for 3 second. W en you enter

t e parameter menu at t e first row of display “P0” (first parameter number) is s own. At t e

second row of display value of parameters is s own. If you want to proceed to ot er

parameters you can use up and down buttons (P0, P1, P2…). Maximum parameter number is

depends on your entered password (operator, tec nician or calibration). If you want to c ange

parameter, menu button must be pressed at t e selected parameter. At t e t ird row parameter

value is displayed and first digit of value blinks. C anging process is same as password

entering process. By pressing menu button at last blinking digit new value is recorded. If you

want cancel entering process you can press esc key. In return to factory defaults parameters

w en you press menu button NO message displayed if you press up and down buttons

message will switc to YES and NO messages if you press menu button, w en selection is

YES, parameters will be returned to factory defaults. If you press NO process is cancelled.

Eac return to factory defaults, return its own section to factory defaults (operator, tec nician,

calibration). If you want exit menu you can press down esc button for 3 second.

EN-KO Electronic Control Systems AMF 4.0/ENG/K.K./02

11

AMF 4.0 PARAMETERS

Initial parameter settings are for genset model 10. T ese are as following table. For c osen

genset model, parameter table can be loaded by means of parameter 69. Parameters t at is

c anged according to genset models are specified in t e next sections.

N Parameter Setting Range Default Value

Operat r Parameters

P0 Operator menu password 0-999 050

P1 Temperature unit 0: Celsius

1: Fa ren eit

0

P2 Crank attempts 1 – 9 3

P3 Cranking time 1-60 sec 10 sec

P4 Cranking pause time 3-60 sec 10 sec

P5 Manuel cranking type 0: Start button must be eld down to crank

1: Automatic start

0

P6 Pre eating type 0:Pre eat button must be old down to pre eat

1: Automatic pre eat

0

P7 Auxiliary input 1 function 0: Input disabled

1: Yellow alarm (always active)

2: Yellow alarm (active from starting)

3: Yellow alarm (active form engine stabilization time)

4: Red alarm (always active)

5: Red alarm (active from starting)

6: Red alarm (active from engine stabilization time)

7: Remote start

8: Remote main failure disable

9: Mains available

10: Emergency stop

11: Cabinet t ermostat alarm

6

P8 Auxiliary input 2 function Same as auxiliary input 1 0

P9 Auxiliary input 3 function Same as auxiliary input 1 10

P10 Auxiliary input 4 function Same as auxiliary input 1 4

P11 Auxiliary input 1 activation met od 0: Close to activate

1: Open to activate

0

P12 Auxiliary input 2 activation met od Same as auxiliary input 1 0

P13 Auxiliary input 3 activation met od Same as auxiliary input 1 0

P14 Auxiliary input 4 activation met od Same as auxiliary input 1 0

P15 Auxiliary output 1 function 0: Output disabled

1: Engine running

2: Panel is in auto or test mode

3: Yellow alarm

4: Red alarm

5: Common alarm

6: Horn

7: Panel is in manual, auto or test mode

8: Panel is in auto mode

9: 6 sec stop output during engine stop

10: Fuel solenoid output

11: Auxiliary services

0

P16 Auxiliary output 2 function Same as auxiliary output 1 0

P17 Auxiliary output 3 function Same as auxiliary output 1 0

P18 Auxiliary output 1 activation met od 0: De-Energize

1: Energize

1

P19 Auxiliary output 2 activation met od Same as auxiliary output 1 1

P20 Auxiliary output 3 activation met od Same as auxiliary output 1 1

P21 Test Mode 0: Test off load

1: Test on load

0

P22 Max. Stop solenoid working time 1-180 sec 6 sec

EN-KO Electronic Control Systems AMF 4.0/ENG/K.K./02

12

P23 Mains failure delay 0-120 sec 3 sec

P24 Transfer delay 1-60 sec 1 sec

P25 Alternator contactor delay 0-90 sec 2 sec

P26 Mains return delay 2-900 sec 5 sec

P27 Pre eat time 0-300 sec 0 sec

P28 Generator voltage failure delay 2-20 sec 3 sec

P29 Generator frequency failure delay 2-20 sec 3 sec

P30 Horn time 0-900 sec 30 sec

P31 Current failure mode 0: Disabled

1: Enabled

1

P32 Crank disconnect on c arge signal 0: Disabled

1: Enabled

0

P33 Crank disconnect on generator

voltage

20V-500V 165V

P34 Mains under voltage failure 46V-500V 184 V

P35 Mains under voltage return 46V-500V 194 V

P36 Mains over voltage return 46V-500V 244 V

P37 Mains over voltage failure 46V-500V 254 V

P38 Generator under voltage failure 46V-500V 184 V

P39 Generator over voltage failure 46V-500V 254 V

P40 Generator under frequency failure 10-75 Hz 42.5 Hz

P41 Generator over frequency failure 10-75 Hz 57.5 Hz

P42 Last 10 failure

P43 Return to operator factory defaults Yes / No

Technician Parameters

P44 Tec nician menu password 0-999 060

P45 Analog Oil sender type 0: Analog oil sender disabled

1: Analog Endiksan type

2: Analog Olcusan (VDO 7 Bar) type

3: Analog Olcusan (VDO 10 Bar) type

4: Analog Olcusan (VDO 80 PSI) type

5: Analog VDO 5 Bar

6: Analog AKSA type

6

P46 Oil switc type 0: Oil switc disabled

1: Normally closed for low pressure

2: Normally open for low pressure

0

P47 Low oil pressure level 0.1 – 9.5 bar 1.2 bar

P48 Analog temperature sender type 0: Not used

1: Analog Endiksan type

2: Analog Olcusan (VDO 120 C) type

3: Analog Volvo type

4: Analog AKSA type

5: Analog AKSA type 2

4

P49 Digital temperature switc type 0: Not used

1: Digital open for ig temperature

2: Digital closed for ig temperature

2

P50 Analog oil pressure sender usage 0: Only for indication

1: For indication and control

1

P51 Analog coolant temperature sender

usage

0: Only for indication

1: For indication and control

1

P52 Fueling system 0: Operating solenoid

1: Stop solenoid

2: ECU type

0

P53 C arging alternator 0: C arging alternator isn’t present

1: C arging alternator is present

1

P54 Crank disconnect alternator

frequency

10-30 Hz 21 Hz

P55 Crank disconnect oil pressure 0.5 – 9.5 bar 4.0 bar

P56 Crank disconnect oil pressure delay 1-30 sec 3 sec

P57 Before cranking oil pressure delay 1-10 sec 3 sec

EN-KO Electronic Control Systems AMF 4.0/ENG/K.K./02

13

P58 Cooling Time 0-600 sec 180 sec

P59 Fail to stop delay 4-120 sec 30 sec

P60 Engine stabilization time 2-60 sec 10 sec

P61 Engine protection delay after

stopping

1-60 sec 3 sec

P62 Current transformer primary 5-900 200

P63 Parameter menu current multiplier 0: x1 mode

1: x10 mode

0

P64 Over current level 1-990 A 159 A

P65 Over current alarm delay 2-250 sec 30 sec

P66 Hig coolant temperature level 80 C – 140 C (176 – 284 F) 105 C (221 F)

P67 Battery low alarm level 0-40 V 24.0

P68 Battery ig alarm level 0-40 V 30.0

P69 Automatic parameter load 0-41 10

P70 Periodic service time 10-5000 50

P71 Engine our adjustment 0.0 - 99999.0 our 0

P72 Clear last ten alarm Yes/ No

P73 Clear periodic service alarm Yes/ No

P74 Return to tec nician factory defaults Yes/ No

Calibrati n Parameters

P75 Calibration menu password 0-999 070

P76 Mains Vr gain 0.01-9.99 0.87

P77 Mains Vs gain 0.01-9.99 0.87

P78 Mains Vt gain 0.01-9.99 0.87

P79 Generator Vr gain 0.01-9.99 0.87

P80 Generator Vs gain 0.01-9.99 0.87

P81 Generator Vt gain 0.01-9.99 0.87

P82 Generator Ir gain 0.01-9.99 3.53

P83 Generator Is gain 0.01-9.99 3.53

P84 Generator It gain 0.01-9.99 3.53

P85 Battery Voltage gain 0.01-9.99 0.54

P86 Mains Vr offset -29,+29 V 0

P87 Mains Vs offset -29,+29 V 0

P88 Mains Vt offset -29,+29 V 0

P89 Generator Vr offset -29,+29 V 0

P90 Generator Vs offset -29,+29 V 0

P91 Generator Vt offset -29,+29 V 0

P92 Battery voltage offset -9.9,+9.9 0.8

P93 Oil pressure offset -9.9,+9.9 0.0

P94 Temperature offset -9,+9 0

P95 Generator Ir offset -0.99, +0.99 (for 5 A ) 0.00

P96 Generator Is offset -0.99, +0.99 (for 5 A ) 0.00

P97 Generator It offset -0.99, +0.99 (for 5 A ) 0.00

P98 Return to calibration factory defaults Yes / No

P99 Mains contactor control in off mode 0: No

1: Yes

1

CHANGED PARAMETERS FOR GENSET MODELS

Initial parameter settings are for genset model 10. Parameter settings are different for ot er

genset models. Parameters t at are different from model 10 parameters are as following table.

Model number is used to select genset model in parameter 69

M dels

Number

Changed

Parameters

0 P15 → 1

P62 →100

P45 → 3

P64 → 29

P52 → 1

P67 → 9

P53 → 0

P68 → 15

1 P15 → 1

P62 →100

P45 → 3

P64 → 36

P52 → 1

P67 → 9

P53 → 0

P68 → 15

EN-KO Electronic Control Systems AMF 4.0/ENG/K.K./02

14

2 P15 → 1

P62 →100

P45 → 3

P64 → 48

P52 → 1

P67 → 9

P53 → 0

P68 → 15

3 P62 →100 P64 → 43

4 P15 → 1

P62 →100

P45 → 3

P64 → 54

P52 → 1

P53 → 0

5 P62 →100 P64 → 62

6 P15 → 1 P52 → 1 P62 →100 P64 → 64

7 P15 → 1 P52 → 1 P62 →100 P64 → 87

8 P62 →100 P64 → 87

9 P15 → 1 P52 → 1 P64 → 149

10 Default

parameters

11 P62 →300 P64 → 210

12 P15 → 1 P52 → 1 P62 →300 P64 → 269

13 P62 →300 P64 → 289

14 P15 →1 P48 → 2

P64 → 26

P52 → 1 P62 → 50

15 P48 → 2 P62 → 150 P64 → 130

16 P48 → 2 P62 → 250 P64 → 217

17 P48 → 2 P62 → 300 P64 → 289

18 P48 → 2 P62 → 500 P64 → 433

19 P48 → 2 P62 → 400 P64 → 360

20 P48 → 2 P62 → 500 P64 → 437

21 P48 → 2 P62 → 400 P64 → 383

22 P48 → 2 P62 → 600 P64 → 506

23 P48 → 2 P62 → 600 P64 → 542

24 P48 → 2 P62 → 100 P63 → 1 P64 → 98

25 P48 → 2 P62 → 100 P63 → 1 P64 → 99

26 P48 → 2 P62 → 125 P63 → 1 P64 → 103

27 P48 → 2 P62 →150 P63 → 1 P64 → 144

28 P15→1

P62→100

P53→0

P45→3

P64→17

P48→2

P67→9

P52→1

P68→15

29 P15→1

P62→100

P53→0

P45→3

P64→23

P48→2

P67→9

P52→1

P68→15

30 P15→1

P62→100

P53→0

P45→3

P64→48

P9→10

P48→2

P67→9

P52→1

P68→15

31 P15→1

P62→100

P45→6

P64→51

P48→2

P68→15

P52→1

P67→9

32 P15→1

P62→100

P45→6

P64→65

P48→2

P68→15

P52→1

P67→9

33 P15→1

P62→100

P45→6

P64→72

P48→2

P68→15

P52→1

P67→9

34 P15→1

P62→100

P45→6

P64→95

P48→2

P68→15

P52→1

P67→9

35 P15→0

P62→100

P45→6

P64→95

P48→4 P52→0

36 P15→1

P62→150

P45→6

P64→101

P48→2

P68→15

P52→1

P67→9

37 P15→0

P62→300

P45→6

P64→253

P48→4 P52→0

38 P15→0

P62→400

P45→6

P64→310

P48→2 P52→0

39 P15→0

P62→400

P45→6

P64→318

P48→2 P52→0

40 P15→0

P62→400

P45→6

P64→397

P48→2 P52→0

41 P15→0

P62→500

P45→6

P64→476

P48→2 P52→0

EN-KO Electronic Control Systems AMF 4.0/ENG/K.K./02

15

PARAMETER DESCRIPTIONS

N Parameters Descripti n

Operat r Parameters

P0 Operator menu password Operator password can be c anged by t is parameter

P1 Temperature unit T is parameter selects coolant temperature unit s own in t e

display. According to selected unit “ ig coolant

temperature level“ is adjusted.

P2 Crank attempts Number of cranking during starting in automatic, test and

manual modes.

P3 Cranking time Cranking time during automatic cranking

P4 Cranking pause time Interval between two cranking period in automatic and test

modes.

P5 Manuel cranking type If t is parameter selected”0”, operator must old down start

button pressed during cranking period. If t is parameter

selected “1” panel will perform cranking for “cranking

time”. Crank is disconnected automatically w en panel

detects engine-running signals.

P6 Pre eating type If t is parameter selected”0”, operator must old down

pre eat button pressed during pre eating period. If t is

parameter selected “1” panel will perform pre eating for

“Pre eat time”.

P7 Auxiliary input 1 function It selects function of auxiliary input

• Auxiliary input can be adjusted as red r yell w

alarm. Activation time can be “always active, active

from engine starting or active from engine

stabilization time”. W en input activates auxiliary

input led lit and A1.A2, A3 or A4 message is s own

according to activated auxiliary input number.

• W en rem te start input is activated generator starts

and generator contactor closes. If input deactivated

generator contactor opens, engine enters cooling

period and t en generator stops. Remote start is

active only in automatic mode.

• W en mains failure disable input is activated if

mains failure occur generator doesn’t start. Generator

opens mains contactor.

• If mains available input is activated panel assume

mains is available. If t is input deactivated genset

return to its normal mode.

• If emergency st p button is pressed, generator opens

generator contactor and stops immediately. Panel

s ow “StP” message in t e display. To clear

emergency stop alarm, emergency stop button must

be pulled back and alarm clear button must be

pressed.

• Cabin therm stat function is used in cabinet type

EN-KO Electronic Control Systems AMF 4.0/ENG/K.K./02

16

generators. Panel doesn’t control t is input for 2

minute after engine start. After 2 minute if input is

still active panel gives alarm, open generator

contactor, cools engine t en stop generator.

If il pressure sender that has b th sender and switch is

used, switch terminal must be c nnected t this input and

this parameter is disabled.

P8 Auxiliary input 2 function Functions are same as auxiliary input 1

If c lant temperature sender that has b th sender and

switch is used, switch terminal must be c nnected t this

input and this parameter is disabled.

P9 Auxiliary input 3 function Functions are same as auxiliary input 1

P10

Auxiliary input 4 function Functions are same as auxiliary input 1

P11

Auxiliary input 1 activation

met od

If t is parameter is 0, input will be activated w en it is

connected to battery negative. If t is input is 1, input will be

activated, w en input is disconnected from battery negative.

P12

Auxiliary input 2 activation

met od

Same as auxiliary input 1

P13

Auxiliary input 3 activation

met od

Same as auxiliary input 1

P14

Auxiliary input 4 activation

met od

Same as auxiliary input 1

P15

Auxiliary output 1 function T is parameter select t e functions of auxiliary output 1

• Engine running: If engine running signal generator

voltage, frequency or c arge alternator warning lamb

voltage is detected t is output will be activated.

• Panel is in aut r test m de: If panel is in

automatic or test mode t is output is activated.

• Yell w alarm: If yellow alarm occurs, t is output is

activated.

• Red alarm: If red alarm occurs, t is output is

activated.

• C mm n Alarm: If yellow or red alarm occurs, t is

output is activated.

• H rn: If orn is activated. T is output will close and

open by intervals of 1 second.

• Panel is in manual, aut r test m de: If panel is in

manual, automatic or test mode, t is output will be

activated.

• Panel is in aut m de: If panel is in automatic

mode, t is output will be activated.

• 6 sec st p utput during engine st p: T is output is

activated for 6 second during engine stopping

• Fuel s len id utput: T is output can be used as

auxiliary fuel solenoid output

P16

Auxiliary output 2 function Same as auxiliary output 1

P17

Auxiliary output 3 function Same as auxiliary output 1

P18

Auxiliary output 1 activation If t is parameter is selected as 0, w en output is activated

EN-KO Electronic Control Systems AMF 4.0/ENG/K.K./02

17

met od output relay de-energizes. At startup w en you supply

battery to panel t is relay energizes and w en output is

activated relay energizes. If t is parameter is selected as 1,

w en output activates, output relay energizes.

P19

Auxiliary output 2 activation

met od

Same as auxiliary output 1

P20

Auxiliary output 3 activation

met od

Same as auxiliary output 1

P21

Test Mode If t is parameter is selected as “0”. In test mode, w en

engine is started, load isn’t transferred to generator if mains

is available. If mains isn’t available generator contactor

closes. If t is parameter is selected as “1” generator

contactor is closed, in test mode, wit out controlling mains

P22

Max stop solenoid working

time

T is parameter is used to limit maximum working time of

stop solenoid.

P23

Mains failure delay If mains is out of limits specified in t e parameter menu,

Mains failure occur and generator starts.

P24

Transfer delay If generator contactor opens and mains contactor closes or

vice versa. Transfer time is waited between t em. It is used

in test and automatic modes.

P25

Alternator contactor delay In automatic and test modes after engine stabilization time

alternator contactor delay is waited and alternator contactor

closes.

P26

Mains return delay If mains return from a mains failure condition. Mains return

delay is waited before mains accepted as normal. After t is

delay in auto mode load transferred to mains.

P27

Pre eat time T is parameter defines, in automatic pre eating, ow long

pre eating continues.

P28

Generator voltage failure delay W en generator voltages are out of voltage limits, a voltage

alarm is given after “generator voltage failure delay”.

P29

Generator frequency failure

delay

W en generator frequency is out of frequency limits, ig

low speed alarm is given after “generator frequency failure

delay”.

P30

Horn time If orn output is activated. After “ orn time” orn is

deactivated. If parameter is “0”, orn isn’t deactivated until

pressing alarm reset button.

P31

Current failure mode T is parameter defines t at alternator current alarms is

enabled or disabled.

P32

Crank disconnect on c arge

signal

If t is parameter is enabled. Crank is disconnected w en

c arge alternator voltage rises. (approx. 7 V)

P33

Crank disconnect on generator

voltage

If alternator voltage rises to t e voltage level defined in t is

parameter, Crank is disconnected.

P34

Mains under voltage failure If mains fall bellow t is limit mains failure occur and

generator started in auto mode. Mains failure delay is waited

before mains failure.

P35

Mains under voltage return If mains exceeds t is limit after a mains failure. Mains is

accepted normal after “mains return delay” and in auto mode

generator contactor is opened and generator is stopped.

P36

Mains over voltage return If mains fall below t is limit after a mains failure. Mains is

accepted normal after “mains return delay” and in auto mode

generator contactor is opened and generator is stopped.

P37

Mains over voltage failure If mains exceeds t is limit mains failure occur and generator

EN-KO Electronic Control Systems AMF 4.0/ENG/K.K./02

18

started in auto mode. Mains failure delay is waited before

mains failure.

P38

Generator under voltage failure

If generator voltage fall below t is limit under over voltage

alarm occur. Failure occurred after generator voltage failure

delay

P39

Generator over voltage failure If generator voltage exceeds t is limit under over voltage

alarm occur. Failure occurred after generator voltage failure

delay

P40

Generator under frequency

failure

If generator frequency fall below t is limit under over speed

alarm occur. Failure occurred after generator frequency

failure delay

P41

Generator over frequency

failure

If generator frequency exceeds t is limit under over speed

alarm occur. Failure occurred after generator frequency

failure delay

P42

Last 10 failure Last ten alarm is recorded in t e panel memory. T ere alarm

can be controlled by t is parameter.

P43

Return to operator factory

defaults

W en you select “YES” and press menu key operator

parameters is returned to factory defaults

Technician Parameters

P44

Tec nician menu password Tec nician password can be c anged by t is parameter

P45

Analog oil sender type Analog oil pressure sender type can be selected from t is

parameter. If genset as only digital oil switc , and t is

parameter is adjusted to “0” oil switc input is transferred to

analog oil pressure sender input.

P46

Oil switc type Oil pressure switc type can be selected from t is parameter.

P47

Low oil pressure failure If oil pressure fall below t is limit. Oil pressure failure alarm

is activated.

P48

Analog temperature sender

type

Analog coolant temperature sender can be selected from t is

parameter. If genset as only digital coolant temperature

switc , and t is parameter is adjusted to “0” coolant

temperature switc input is transferred to analog temperature

sender input.

P49

Digital temperature switc type

Analog coolant temperature sender can be selected from t is

parameter.

P50

Analog Oil pressure usage If analog sender is used for display purposes only. Generator

doesn’t control t is analog value. Value read from sender is

used only for display purposes. No sensor alarm is given if

sensor cable breaks.

P51

Analog temperature sensor

usage

If analog sender is used for display purposes only. Generator

doesn’t control t is analog value. Value read from sender is

used only for display purposes. No sensor alarm is given if

sensor cable breaks.

P52

Fueling system Fueling system is can be adjusted as operating or stop

solenoid. W en t is parameter is selected as ECU type.

Cranking output be aves like start output and fuel solenoid

output be aves like stop output. T is configuration is

necessary in some type of ECU managed engines. In engine

starting condition, start output is activated for 3 second and

cranking is stopped by means of activating stop output for 2

EN-KO Electronic Control Systems AMF 4.0/ENG/K.K./02

19

second. In engine stopping condition stop output is activated

as 2 second cycling pulses.

P53

C arging alternator If parameter is adjusted as “0”. C arge alternator failure

doesn’t occur and crank doesn’t disconnected by c arge

alternator.

P54

Crank disconnect alternator

frequency

In cranking if alternator frequency exceeds t is limit crank

disconnected.

P55

Crank disconnect oil pressure In cranking if oil pressure exceed t is limit and stay ig ,

after “crank disconnect oil pressure delay” crank

disconnected.

P56

Crank disconnect oil pressure

delay

In cranking if oil pressure rise, after “crank disconnect oil

pressure delay” crank disconnected.

P57

Before cranking oil pressure

delay

If oil pressure is ig before cranking t is delay is waited. If

oil pressure is fall down cranking begins. If oil pressure

doesn’t fall panel give fail to start stop alarm.

P58

Cooling Time Parameter contains ow long cooling period continue

P59

Fail to stop delay In stopping period, parameter defines ow long panel will

wait for engine to stop before giving fail to start stop alarm.

P60

Engine stabilization time W en generator starts all engine alarms will be delayed for

engine stabilization time. During t is time all values read

from sensors stabilize (Alternator voltage, frequency, c arge

alternator warning lamp voltage and oil pressure).

P61

Engine protection delay after

stopping

In stopping period after panel detected all engine running

signals absent, panel will wait an additional protection delay

T is is necessary for engine to stop completely before next

engine start. D n t decrease this value if n t necessary.

P62

Current transformer primary T is parameter contains current transformer primary value.

If Current transformer primary is more t an 999 you must

c ange parameter menu current multiplier to x10 mode.

P63

Parameter menu current

multiplier

If t is parameter is made x10, Parameter “P62: current

transformer primary” and”P64: over current level” are

multiplied by 10. You must use t is parameter if values are

bigger t an 999. For example for 2500:5 current transformer

and 2000 Amp over current level. After setting parameter

menu current multiplier x10, you must set current

transformer primary as 250 and over current level 200.

P64

Over current level If measured alternator current exceeds value t at parameter

contains. Over current alarm will be given.

P65

Over current alarm delay If over current condition occur more t an over current alarm

delay. Panel will give over current alarm.

P66

Hig coolant temperature level If engine coolant temperature exceeds t e value t at t is

parameter contain. Panel will give ig coolant temperature

alarm. T is parameter must be entered according to

parameter temperature unit.

P67

Battery low alarm level If battery voltage falls below voltage level t at parameter

contains battery ig low alarm will be given.

P68

Battery ig alarm level If battery voltage exceeds voltage level t at parameter

contains battery ig low alarm will be given.

P69

Automatic parameter load Parameter tables according to genset models can be loaded.

EN-KO Electronic Control Systems AMF 4.0/ENG/K.K./02

20

Enter model number to load parameter table of selected

genset model.

P70

Periodic service time T is parameters selects After ow many running our

periodic service alarm will be given

P71

Engine our adjustment Engine our is adjusted by t is parameter.

P72

Clear last ten alarm W en you select “YES” and press menu key last ten failure

is cleared.

P73

Clear periodic service alarm W en you select “YES” and press menu key, periodic

service alarm is cleared and service time is reset

P74

Return to tec nician factory

defaults

W en you select “YES” and press menu key tec nician

parameters is returned to factory defaults

Calibrati n Parameters

P75

Calibration menu password Calibration menu password adjustment

P76

Mains Vr gain Mains line R voltage gain calibration.

P77

Mains Vs gain Mains line S voltage gain calibration.

P78

Mains Vt gain Mains line T voltage gain calibration.

P79

Generator Vr gain Generator line R voltage gain calibration.

P80

Generator Vs gain Generator line S voltage gain calibration.

P81

Generator Vt gain Generator line T voltage gain calibration.

P82

Generator Ir gain Generator line R current gain calibration.

P83

Generator Is gain Generator line S current gain calibration.

P84

Generator It gain Generator line T current gain calibration.

P85

Battery Voltage gain Battery voltage gain calibration.

P86

Mains Vr offset Mains line R voltage offset calibration.

P87

Mains Vs offset Mains line S voltage offset calibration.

P88

Mains Vt offset Mains line T voltage offset calibration.

P89

Generator Vr offset Generator line R voltage offset calibration.

P90

Generator Vs offset Generator line S voltage offset calibration.

P91

Generator Vt offset Generator line T voltage offset calibration.

P92

Battery voltage offset Battery voltage offset calibration.

P93

Oil pressure offset Oil pressure offset calibration.

P94

Temperature offset Coolant temperature offset calibration.

P95

Generator Ir offset Generator line R current offset calibration.

P96

Generator Is offset Generator line S current offset calibration.

P97

Generator It offset Generator line T current offset calibration.

P98

Return to calibration factory

defaults

W en you select “YES” and press menu key calibration

parameters is returned to factory defaults

P99

Mains contactor control in off

mode

If t is parameter is selected as “YES”, Unit will control

mains voltages in off mode and w en mains exceed t e

limits defined in parameter menu, mains contactor opens and

protect t e load and w en mains returns to normal condition

mains contactor closes. If t is parameter is selected as “NO”,

mains isn’t controlled and mains contactor is always closed.

Table of contents