Enchlor GASBLASTER User manual

www.enchlor.com

GASBLASTER

OzoneGenerator

UserGuide

Table of Contents

Warranty 1

Safety 2

Ozone Generator Chassis Layout 3

Standard LSX Series Control Panel Layout 4

Standard LSX Control Panel Description 5

Generator Installation 6

Start-up 7

On Board Sensors 8

Shut Down 9

Technical Support 10

Application and Sizing 11-15

Application Overview 16-20

Troubleshooting Guide 21-24

Optional Gas Detection 25-30

Discharge Fan 32

Air Compressor 33

Tubing and Clamps 34

Flow Diagragm 35

Wiring 36

Dimensions 37

General Layout Drawing 38

Enclosure Heater 39

Wall Mounting Brackets 40

Air Filtration System 41

Generator 42

Discharge Check Valve 43

Ozone Gas Sensor 44

Gasblaster LSX O&M Sept 2009.doc 1 Enchlor Inc.

Warranty

All Enchlor products are protected by a one year limited warranty.

This warranty covers all parts and labor for all Enchlor products used under normal operating

conditions and procedures as described in the User Guide supplied with each product. Enchlorʼs

obligation under this warranty is limited to the repair, replacement, or return/refund of the unit or

component determined to be defective.

Any misuse, improper operation or installation of any Enchlor parts or equipment, as determined

by Enchlor, will void any and all warranty claims to the primary component as well as all

supporting components.

Any repair, modifications, or service performed by someone other than a Enchlor authorized

technician will void any and all warranty claims to the primary component as well as all

supporting components.

Warranty of equipment and / or accessories from outside sources, purchased by Enchlor and

incorporated into Enchlor products, is subject to that manufactures standard warranty.

Enchlor shall not be liable to the purchaser or others for loss of use of any product or for other

special, indirect, incidental or consequential damages.

The Enchlor warranty policy does not cover shipping and handling charges incurred during the

warranty claim process.

The warranty will be voided by the following:

•Allowing water to enter the ozone generator.

•Supplying feed gas that is not clean and free of oil or other contaminates.

•Supplying feed gas that is not dry to -60°F minimum dew point (excluding generators that

have onboard oxygen concentrators). Ref. ISO 8573-1 Quality Class 1.

•Connecting an improper power source to the unit that does not match the incoming power

requirements as outlined in the User Guide.

•Locating any product in an environment that is not well ventilated and protected.

Limits of Liability

Enchlor shall not be liable for any special, indirect, incidental or consequential damages that

result from the use or malfunction of any system, ozone generator and/or any of its components.

Enchlor equipment and components are sold for use in industrial and commercial applications

only.

Gasblaster LSX O&M Sept 2009.doc 2 Enchlor Inc.

Safety

Carefully review and familiarize yourself with the following important safety information statements

concerning Enchlor generators.

WARNING: Oxygen is a fire hazard. It is very dangerous and vigorously accelerates the

burning of combustible materials. To avoid fire and/or explosion, never use oil,

grease, cotton fibers or any other combustible material on or near the ozone or

oxygen generators. Smoking, heat, and open flame should be kept at a distance

of no less than 5 feet from any part of the system. It is STRONGLY

recommended that only individuals experienced in the safe handling of oxygen be

allowed to operate this equipment.

WARNING: OSHA exposure limit to ozone is 0.1 ppm for a period of 8 hours.

(Ref. OSHA Air Contaminants Standard, 29 CFR 1910.1000)

(EU Directives - 96/62/EC, 92/72/EC, 99/30/EC.)

WARNING: Ozone is a highly toxic oxidizer. Ozone has a distinctive odor, which is easily

recognized at very low concentrations. If this odor presents itself at any level,

disconnect the generator and contact your installer.

WARNING: High voltage and high capacitance is present in ozone generators. Only qualified

electricians should work on this equipment.

Gasblaster LSX O&M Sept 2009.doc 3 Enchlor Inc.

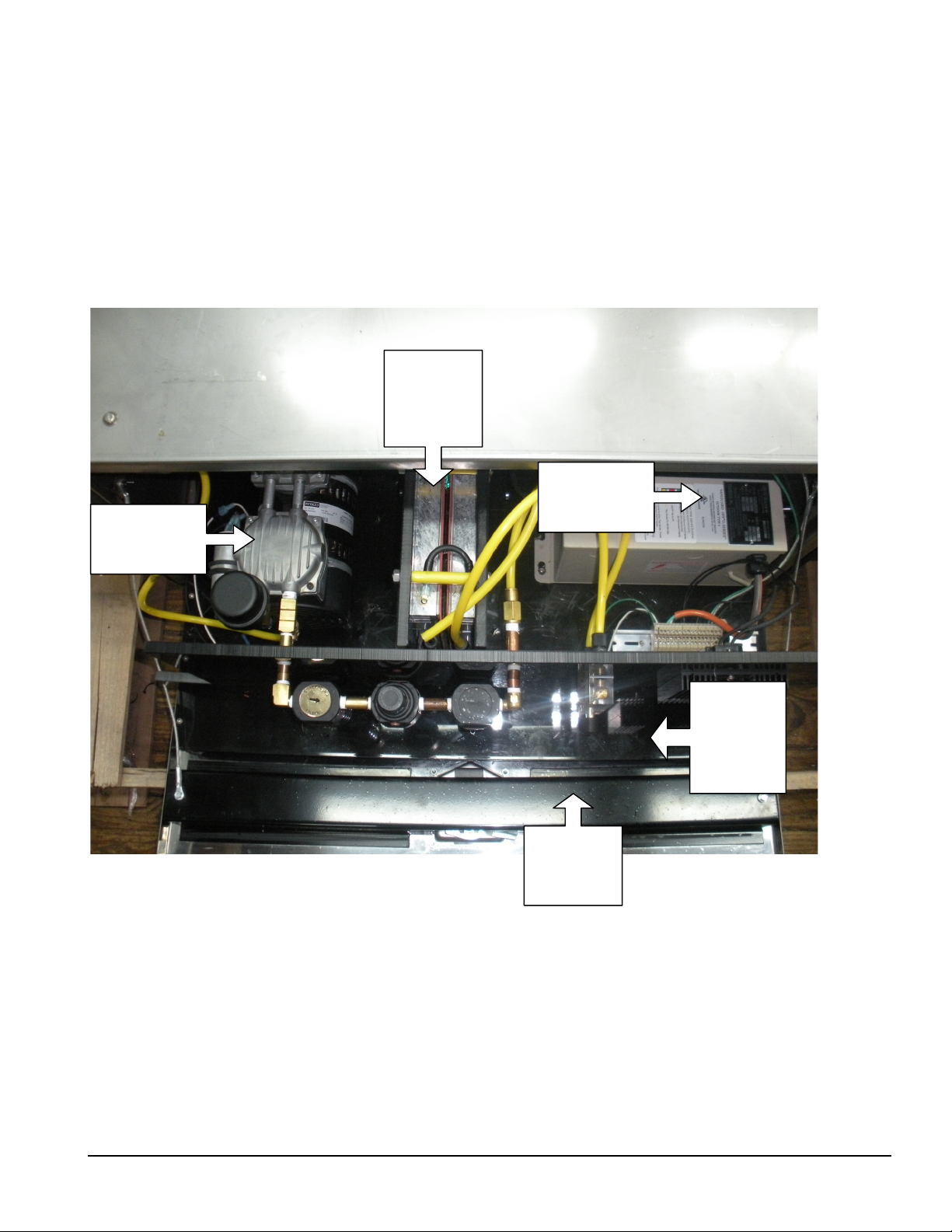

OzoneGeneratorChassisLayout

Reactor

Cell

High Output

Transformer

Air

Compressor

0-10 vdc or

4-20mA

control

(optional)

LSX

System

Rack

Gasblaster LSX O&M Sept 2009.doc 4 Enchlor Inc.

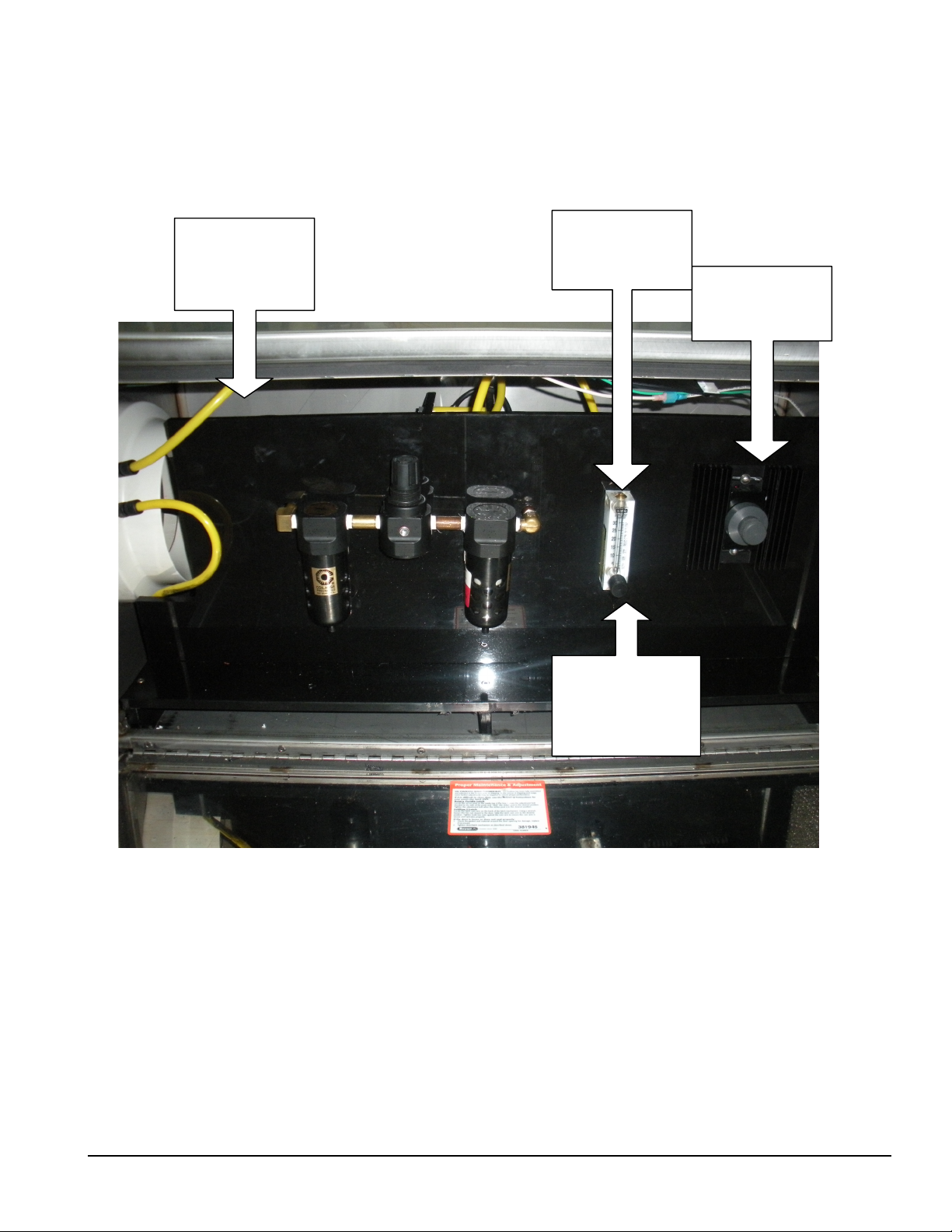

StandardLSXSeriesControlPanelLayout

Ozone Output

Adjustment

Knob

Feed Gas

Flowmeter

(SCFH)

High Voltage

and Ozone

Gas Caution

Notice

Gas Flow

Adjustment

Knob

Gasblaster LSX O&M Sept 2009.doc 5 Enchlor Inc.

StandardOEMControlPanelDescription

GasFlowMeterKnob: Controls the amount of oxygen or dry air feed gas that is fed through the ozone

production cells.

Ozone Output Indicator (GREEN Light): Verifies that the ozone modules are working and producing

ozone. (LOCATED ON SIDE OF TRANSFORMER)

Ozone Output Adjustment Knob: Controls ozone produced by the machine from 0% through 100% of

the certified maximum ozone production shown on the serial number and certification plaque.

On/Off Main Power Breaker Switch: Controls ALL incoming power to the ozone generator. Located on

outside of LSX enclosure

Gasblaster LSX O&M Sept 2009.doc 6 Enchlor Inc.

GeneratorInstallation

LocationRequirements

•Clean and dry-protected from direct rain and snow

•Well ventilated

•A 12” minimum free air space maintained on all sides of the ozone generator

•Stable cabinet or frame mount or similar placement

•Ambient temperature 32º F (0º C) to 100 ºF (43º C)

•A degree of protection from airborne water and dirt

ElectricalRequirements

•Dedicated 115/240 VAC - 15-amp outlet on a circuit with disconnect a maximum 50 feet away

and in the line of sight of the ozone generatorʼs operator panel.

Note: Incoming power must be free of any power surges or spikes.

•Do not add or remove length to the incoming power cord.

•The generator must be grounded to an external ground source supplied with the incoming

power wiring.

WARNING: No liquid water should be allowed to enter the ozone generator. The compressed

air inlet water load saturated at 120ºF at 30 PSIG is acceptable (.0216 lb

water/lb dry air).

WARNING: No oil in vapor or aerosol form greater then 0.008 ppm should be allowed to

enter the ozone generator. Air quality should be equivalent to the output of an

oil-less compressor (no hydrocarbons).

•The feed gas connection is via the 3/8” polyethylene tube leading to the lower port of the

Feed Gas Flowmeter

•Ozone out is from the 3/8” tube coming from the outlet of the ozone reactor cell.

•It is recommended that an anti-siphon loop or other back flow protection be used to prevent

water from backing up into the ozone production cells. Damage incurred from water is not

covered by the manufacturerʼs warranty.

Gasblaster LSX O&M Sept 2009.doc 7

StartUp

1. Make sure the amber On/Off Main Power Breaker Switch is in the OFF position.

2. Power down or close off the external incoming oxygen or dry air gas source (if equipped).

WARNING: No liquid water should be allowed to enter the ozone generator.

WARNING: No oil in vapor or aerosol form greater then 0.008 ppm should be allowed to

enter the ozone generator (no hydrocarbons).

3. Completely open any back pressure control valves that may be installed in the ozone

output line.

4. Set the Ozone Output Adjustment Knob to 0%.

5. Turn the On/Off Main Power Breaker Switch to the ON position.

6. Set the Gas Flow Adjustment Knob so that the Gas Flowmeter indicates a minimum of (15

SCFH – LSX-100) (20 SCFH – LSX-200) .

7. To control the amount of ozone production, rotate the Ozone Output Adjustment Knob

clockwise. The signal demand can be seen on the Reference Meter and the activation of

the ozone generator cells will be indicated by the Ozone Output Indicator Light located on

the transformer.

Supply Air Specifications: The quality of the air supplied to the ozone generator is critical to its proper

operation. Damage incurred from improper feed gas quality is not covered by the manufacturerʼs

warranty. Outside air enters the system through the air intake hood. A filter is installed in the hood

to prevent most contaminents from entering. It is critical that this filter remain inplace and be

cleaned on a regular basis. Water MUST be prevented from entering the air intake hood. The

system must be located so that during rain or snow conditions, the air intake hood is not subject to

rainfall, standing water, snow etc.

Gasblaster LSX O&M Sept 2009.doc 8

OnBoardSensors

High temperature sensor: If the temperature of the transformer exceeds 160°F, the transformer will

shut down in order to protect the electronic components from excessive heat. After the

temperature of the cell drops below the set point, the unit will re-engage.

Gasblaster LSX O&M Sept 2009.doc 9 Enchlor Inc.

ShutDown

1. Rotate the Ozone Output Adjustment Knob counterclockwise to 0%, wait until the

Reference Meter shows less then 2 Volts DC, and the red Ozone Output Indicator Light is

off.

2. Allow two minutes to purge ozone out of system.

3. Turn the amber On/Off Main Power Breaker Switch to the OFF position.

Note: In a shut down mode, air or oxygen in a receiver tank may expand and contract in the

tank. This will cause water to be pulled over the anti-siphon loop. During shut down,

open the receiver tank to atmosphere or disconnect the ozone generator from the air

or oxygen line.

Enchlor Inc., Box 99, 130 West Main Street, Silverdale, PA 18962

Phone: 215-453-4533 Fax: 215-453-1101 www.enchlor.com

TechnicalSupport

Technical Support and Parts

Technical support is available by telephone directly from Enchlor at

(215) 453-2533. When calling, please have the following information available:

•Model number

•Serial number

•Brief description of installation

•Confirm line voltage

•Confirm inlet air conditions

•Confirm output connections

Online Support

Technical Online Support is available through the Enchlor web site at www.enchlor.com and

includes topics such as:

•Troubleshooting guides

•Product specifications

Field Services

Complete field services are also available. Please contact Enchlor Services for prices and

scheduling. Enchlor will confirm all field service requests in writing prior to scheduling.

Enchlor Inc., Box 99, 130 West Main Street, Silverdale, PA 18962

Phone: 215-453-4533 Fax: 215-453-1101 www.enchlor.com

GASBLASTER APPLICATION WORKSHEET

This sheet is designed to help gather the information required to assist in the selection of the correct odor control device to neutralize the

odor challenge.

NOTE: Wastewater odors can be composed of numerous gases and concentrations. For the purpose of sizing, H2S (hydrogen sulfide)

concentration will be used as the indicator gas to determine odor level. If another gas and concentration are known, and desired to be

used for sizing, please consult the factory.

Date: ______________ Job Reference: ______________________________

Salesperson: ___________________Organization:______________________

Customer: ______________________________________________________

Contact: ________________________________________________________

Customer Address: _______________________________________________

City: __________________________ State: __________ Zip: _____________

Phone: ________________________,

Fax:_____________________________

Customer E-mail: _________________________________________________

Application type: __________________________________________________

Site Address: _____________________________________________________

City: __________________________ State: __________ Zip: ______________

Enchlor Inc., Box 99, 130 West Main Street, Silverdale, PA 18962

Phone: 215-453-4533 Fax: 215-453-1101 www.enchlor.com

GASBLASTER SIZING

Sizing formula is an estimating guide only. Many factors will affect the actual sizing required. These factors include: volume of lift station

chamber, contents of wastewater, cycle timing of station, outside peak temperature etc.

Hydrogen Sulfide concentration in vent stream: _______ ppm

Average inflow of sewage at above concentration: _______ gpm

FLOW: average station flow rate generating normal H2S levels (GPM)

H2S: peak VENT level of H2S monitored in normal operating conditions and temperatures (PPM)

Flow (gpm) x H2S (in ppm) = EOR (Estimated Oxidizer Required)

_________ (gpm) x _________ (ppm) x 0.13 = ____________ (EOR)

Select GasBlaster model corresponding to GBR number. It is recommended that the units GBR (Gas Blaster Rating) should always

exceed the EOR value. If a unit cannot be found, please consult the factory for specialized unit configuration.

EXAMPLE 1:

A small lift station with a flow rate of 250,000gpd has a vent reading that peaks at 40ppm of H2S. First, convert the GPD to GPM = 173.6

173.6gpm X 40ppm X 0.13 = 902.72 EOR

A selection of a model LSX-100 or LSX-3001 would be suggested as the GBR rating for each of these models is 3000 GBR

EXAMPLE 2:

A large lift station has a flow rate of 5mgd and has a peak vent H2S reading of 40ppm

First, convert the flow to GPM = 6944gpm

3472gpm X 40ppm X 0.13 = 18,054 GBR

A selection of a single LSX-3006 model with a GBR rating of 19,200 would be acceptable –OR – a selection of two model LSX-3003 with

a GBR rating of 9600 each.

Gasblaster LSX O&M Sept 2009.doc 13 Enchlor Inc.

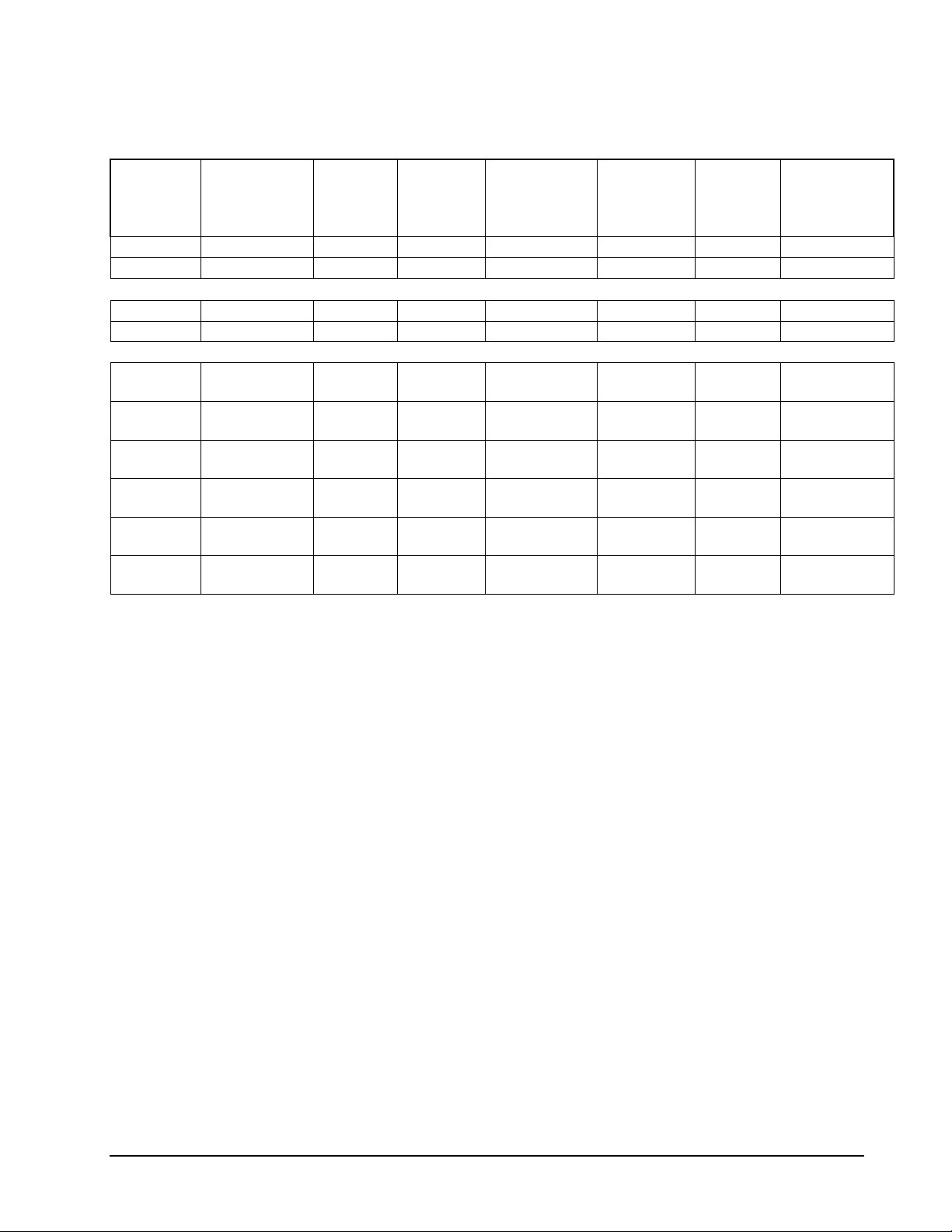

MODEL

#

# of

gm/h

PPD

OZONE

PPM

OZONE**

PPM

OZONE

Supply

Gas

GAS

BLASTER

generators

ozone

air feed

200CFM

fan

400CFM

fan

Feed

SCFH

RATING*

(GBR)

EPRO-4

4 plates

4

0.22

N/A

N/A

N/A

N/A

EPRO-8

8 plates

8

0.44

N/A

N/A

N/A

N/A

LSX-100

1

10

0.55

16

7.5

10

3200

LSX-200

2

20

1.10

32

15.0

20

6400

LSX-

3001

1

10

0.55

16

7.5

10

3200

LSX-

3002

2

20

1.10

32

15.0

20

6400

LSX-

3003

3

30

1.66

48

22.5

30

9600

LSX-

3004

4

40

2.21

64

30.0

40

12800

LSX-

3005

5

50

2.76

80

37.5

50

16000

LSX-

3006

6

60

3.31

96

45.0

60

19200

*all ratings calculated with 200cfm discharge fan rating and dry air supply

(standard)

**all PPM Ozone ratings are calculated with a 20% effeciency reduction

Enchlor Inc., Box 99, 130 West Main Street, Silverdale, PA 18962

Phone: 215-453-4533 Fax: 215-453-1101 www.enchlor.com

CONVERSION - GPM TO CFM TO MGPD

0

500

1000

1500

2000

2500

3000

3500

0 23 46 70 93 116 139 162 186 209 232 255 279 302 325 348 371 395 418

CUBIC FEET PER MINUTE

GALLONS PER MINUTE

0

0.5

1

1.5

2

2.5

3

3.5

4

4.5

5

MILLION GALLONS PER DAY

Enchlor Inc., Box 99, 130 West Main Street, Silverdale, PA 18962

Phone: 215-453-4533 Fax: 215-453-1101 www.enchlor.com

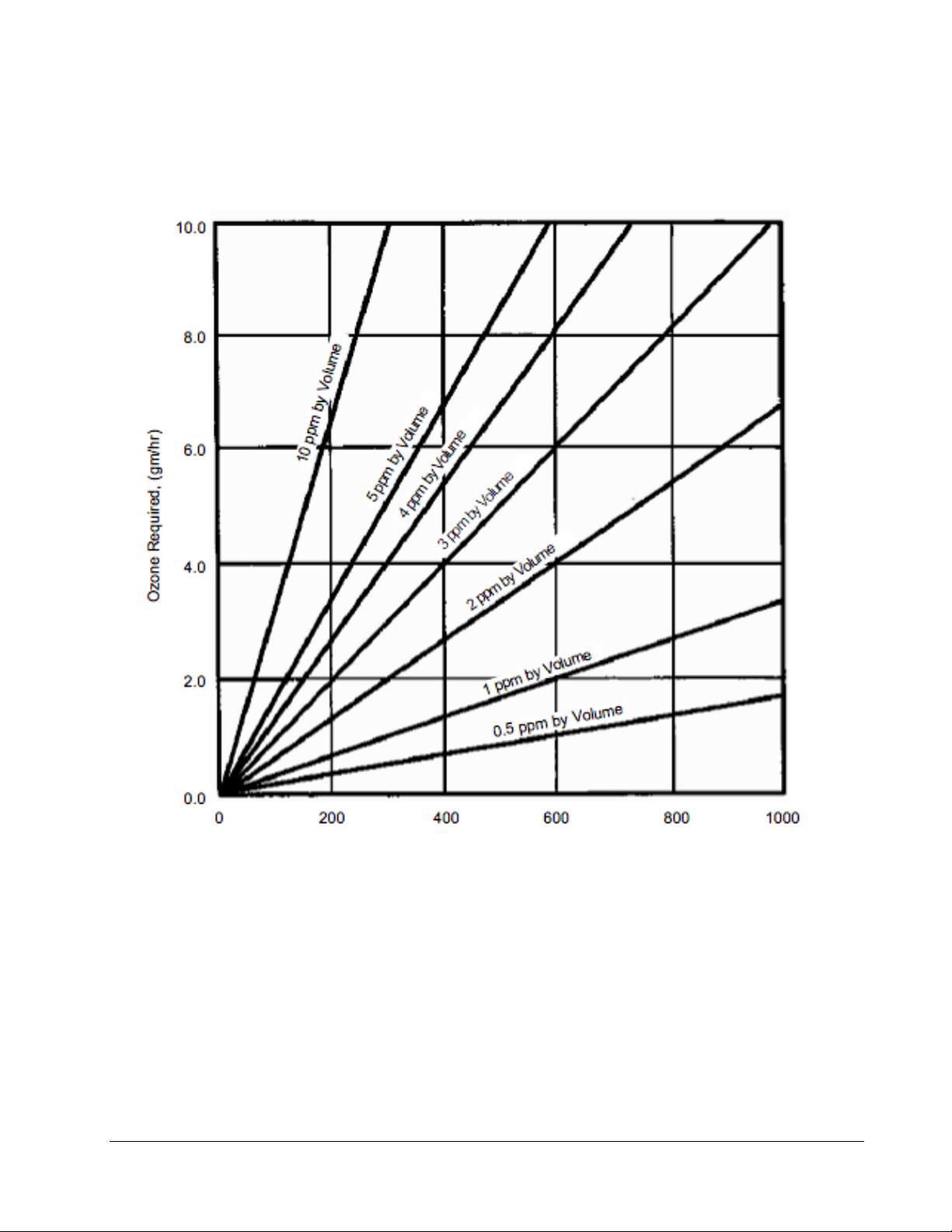

REFERENCE

OZONE REQUIRED (gm/h) for PRESCRIBED DOSAGE in PPM/Volume

AIR FLOW CFM

APPLICATION / INSTALLATION OVERVIEW

The treatment and transfer of wastewater produces odor emissions what are sometimes

disturbing for the population living nearby a waste treatment facility or pumping station. The

main sources of bad odors are sludge and its treatment as well as the collecting and primary

treatment stages. The measurement of odors and the tolerance threshold of bad smells are

subjective and no legislation about it has been made. The two main sources of nauseous

odors are H2S and NH3.

To aid in the removal of these odors, Enchlor Inc. has developed the Gasblaster Series of

Ozone generators specifically designed to remove these odors. The Gasblaster prevents

these odors from escaping the treatment or transfer chamber by injecting high concentrations

of ozone into the air above the wastewater providing destruction of the offending gaseous

odors and reducing them to simple compounds that simply returns to the wastewater for

disinfection.

Direct Ozonation

Two methods are available to control the odors related to wastewater facilities and treatment,

the simplest one is the direct ozonation. This method is suitable for small plants and can be

relatively inexpensive. The alternative is washing the air with ozonized water. The method of

elimination of odors by direct ozonation consists in putting in contact ozone molecules (O3)

and nauseous molecules (H2S, NH3 and CH4). Those last compounds are mainly reducers

whereas ozone is a strong oxidant, consequently they react so that the ozone molecule looses

an oxygen atom and an oxygen molecule (O2) is released. At the same time the addition of an

oxygen atom to the odorous compound provokes it to break up into smaller compounds or to

transform into a stable compound. Those new molecules are not odorous.

Concerning hydrogen sulphide two ways of reaction are possible:

H2S + O3 = H2O + S + O2 (principal reaction)

H2S + O3 = H2O + SO2 (secondary reaction)

Obviously the principal reaction is environmentally more interesting since the secondary

reaction releases sulphur dioxide (SO2) that belongs to the family of sulphur oxide gases

(SOx). SO2 dissolves in water vapor to form acid, and interacts with other gases and particles

in the air to form sulphates and other products that can be harmful to people and their

environment.

Ammonia and methane also react with ozone and gives stable products (carbon dioxide and

nitrogen gas):

CH4 +4O3 = CO2 + 4H2O + O2

4NH3 + 3O3 = N2 + 3H2O + 3O2

Enchlor Inc., Box 99, 130 West Main Street, Silverdale, PA 18962

Phone: 215-453-4533 Fax: 215-453-1101 www.enchlor.com

These reactions gives water (H2O), oxygen (O2), carbon dioxide (CO2) and nitrogen (N2).

There are all stable molecules and do not have harmful or nauseous effects.

Five parameters have to be taken into account in order to design a proper ozonation process:

1. Concentration of the nauseous molecules

2. Temperature and moisture

3. Type of contact between the gas and the ozone

4. Contact time between the gas and the ozone

5. Volume to be treated and flow of air

Ozonation can as well remove totally the odors as reduce them at a suitable level. Generally if

the ratio ozone molecule by hydrogen sulphide molecule (O3: H2S) is comprised between 1.5

and 2, it is enough to obtain a sufficient result. Nevertheless a ratio of 2 permits to prevent

from peaks.

Higher quantity of ozone can be used in case of difficult conditions (such as high temperature

and high moisture content). It can also be required for highly concentrated odorous

compounds, especially when treating the sludge.

The installation of the ozone generator is also important. The ozone reacts better when

injected into a warm and wet medium, but its production by the generator is the best when it

occurs in a dry and fresh place. Then the generator uses to be installed outside or a least not

at the same place where the reaction happens.

As mentioned before the contact surface between the ozone and the nauseous gas is critical

for the process. This is reinforced by the fact that the concentrations of hydrogen sulphide are

only around a few ppm.

Safety Issues of high Hydrogen Sulfide Levels

Hydrogen sulfide levels are an indication of the aggressiveness of the atmosphere. This

situation greatly increases the rate at which corrosion occurs inside the wet well. Severe

corrosion damage can be expected at stations with high Hydrogen sulfide levels and without

effective protection these stations can quickly be considered to be structurally compromised to

the point where repairs are required or operator safety is compromised. This corrosion

produces conditions, which are considered unsafe for manned entry into a wet well. These

conditions included failed access ladders, corroded/disintegrated handrails, access platforms

with missing sections of grating etc.

The Gasblaster series of control units provides valuable benefits in both odor control and a

reduction in corrosion to facility equipment from the reduction and removal of H2S. For

additional information and system details, please contact your local Enchlor Inc.

representative.

Enchlor Inc., Box 99, 130 West Main Street, Silverdale, PA 18962

Phone: 215-453-4533 Fax: 215-453-1101 www.enchlor.com

General Ozone Information

Ozone (O3) is a colorless gas with a distinct, pungent odor. It is a molecule made up of 3

atoms of oxygen. Interestingly ozone occurs quite readily in nature, most often as a result of

lightning strikes that occur during thunderstorms.

In fact that "fresh, clean, spring rain " smell that we notice after a storm most often results

from natures creation of ozone. Ozone generators create ozone in your home or business

ensuring the same clean air as found in nature.

Ozone is one of the most powerful disinfectants in the world, second only to Fluorine. It is

three thousand times more potent than chlorine in destroying germs, bacteria, and viruses.

Benefits of Ozone Cleaning

It doesn't have as strong, or over–powering odor like Fluorine or Chlorine, yet it is so powerful,

it actually kills those odors. Once generated, ozone is quite unstable, one of the three oxygen

atoms eagerly splits off the molecule and attaches itself to any particle or pollutant with which

it comes in contact. That single oxygen atom from the ozone air purifier proceeds to "oxidize"

that particle. As a result, the particle will no longer be toxic, and will no longer be able to

reproduce, if it is biological.

In other words, the toxic particle becomes completely harmless once ozone does its job.

When the single oxygen (O1) molecule oxidizes the particle, it too is destroyed.

Ozone cleaning leaves behind the O2, from which it split away, or pure and clean oxygen.

EPA / OSHA Information

The National Institute of Occupational Safety and Health (NIOSH) recommends an upper limit

of 0.10 ppm for occupied spaces not to be exceeded at any time.

EPAʼs National Ambient Air Quality Standard for ozone is a maximum 8-hour average outdoor

concentration of 0.08 ppm.

If an ozone air purifier is going to be running while people are present, the EPA recommends

the proper settings should be selected so that the ozone level is less than 0.08 ppm.

NOTE: The Gasblaster systems are designed for use in NON-OCCUPIED spaces

only. If access to the lift station/wet-well chamber in required, the system

must be turned-off and the chamber ventilated prior to entering.

Table of contents

Popular Inverter manuals by other brands

Cobra

Cobra High Gear HG-PI1000 operating instructions

South-Tek Systems

South-Tek Systems N2Blast FPS-1750 manual

CHISAGE

CHISAGE CE-3P12K1G-LE-EU user manual

TECO

TECO E510s Series Quick Setting-up Manual

Pyramid

Pyramid 5 KW 3 Phase User & installation manual

Agilent Technologies

Agilent Technologies E4412A Operating and service guide