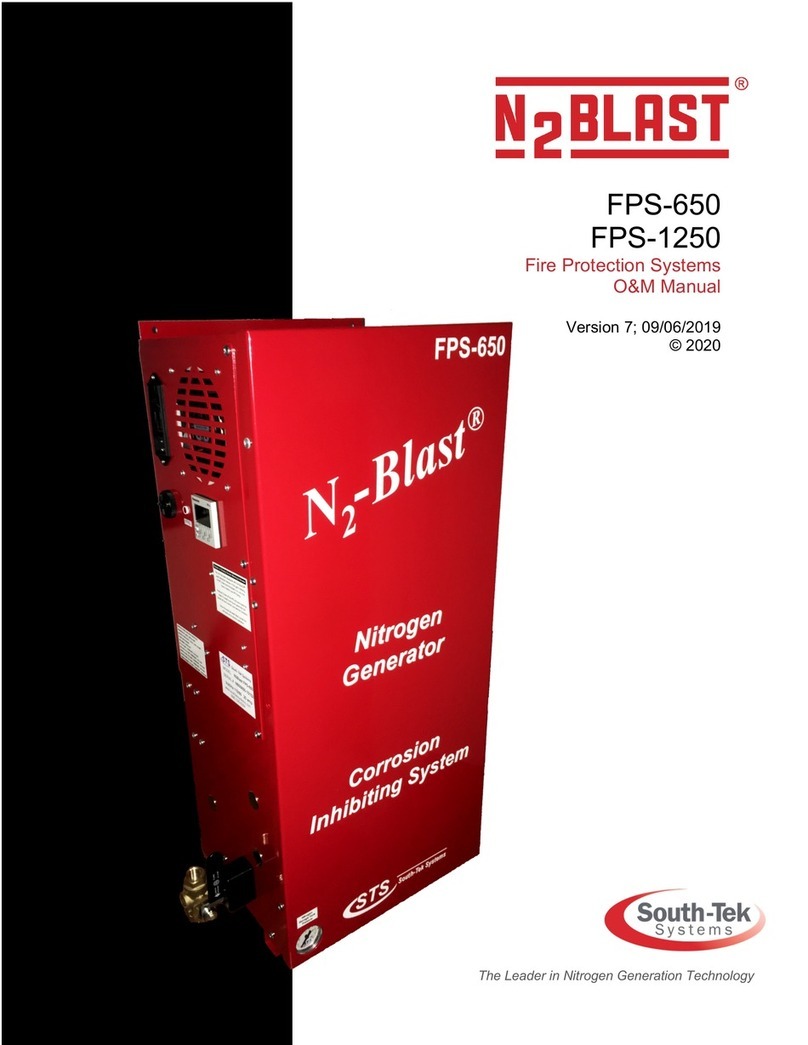

South-Tek Systems N2Blast FPS-1750 User manual

FPS-1750

FPS-3000

FPS-6000

Fire Protection Systems

O&M Manual

Version 7; 05/24/2016

© 2020

The Leader in Nitrogen Generation Technology

N2-BLAST®Nitrogen Generator FPS-1750, FPS-3000, and FPS-6000 South-Tek Systems

Version: 7

Revision Date: 5/24/16 Page 2 of 25

VERSION HISTORY

Revision

#

Implemented

By

Revision

Date

Approved

By

Approval

Date

Reason

1

J. Nguyen

10/13/13

A. Norman

10/13/13

Initial Release

2

J. Nguyen

7/5/14

A. Norman

7/5/14

3

J. Nguyen

8/15/14

A. Norman

8/15/14

4

J. Nguyen

3/6/15

A. Norman

3/6/15

5

J. Nguyen

10/15/15

A. Norman

10/15/15

Bypass Added

6

J. Nguyen

01/12/16

A. Norman

1/12/16

Updated Information

7

J. Nguyen

5/26/16

A. Norman

5/26/16

FM Approval

N2-BLAST®Nitrogen Generator FPS-1750, FPS-3000, and FPS-6000 South-Tek Systems

Version: 7

Revision Date: 5/24/16 Page 3 of 25

TABLE OF CONTENTS

1INTRODUCTION.................................................................................................................... 6

1.1 Purpose...................................................................................................................... 6

1.2 Audience.................................................................................................................... 6

1.3 Important Information............................................................................................... 6

2SAFETY GUIDELINES.......................................................................................................... 7

2.1 General ...................................................................................................................... 7

2.2 Service....................................................................................................................... 7

3SYSTEM DESCRIPTION ...................................................................................................... 8

3.1 Key Features.............................................................................................................. 8

3.2 Specifications ............................................................................................................ 9

4PRODUCT INSTALLATION.............................................................................................. 10

4.1 Unpacking and Preparation ..................................................................................... 10

4.2 Electrical Requirements .......................................................................................... 10

4.3 Mounting (For N2-BLAST®Nitrogen Generator)................................................... 10

4.4 Installation (For N2-BLAST®Nitrogen Generator) ................................................ 12

4.5 Panel Layout and Gas Connection .......................................................................... 13

4.6 Blastoff™ – Air Bypass setup (Optional)............................................................... 13

4.7 Check for Leaks ...................................................................................................... 13

5SYSTEM USAGE .................................................................................................................. 14

5.1 Instructions.............................................................................................................. 14

5.2 Start-Up Procedures ................................................................................................ 14

5.3 Normal Operating Procedures................................................................................. 14

5.4 Alarm Notification .................................................................................................. 14

6SYSTEM MAINTENANCE.................................................................................................. 16

7KEY CONTACTS.................................................................................................................. 18

8FAQS....................................................................................................................................... 18

8.1 Power Issues............................................................................................................ 18

8.2 Pressure Issues......................................................................................................... 18

8.3 Gas Leaks:............................................................................................................... 19

8.4 BlastOff™ - Leak Detection System: ..................................................................... 19

APPENDIX A: WARRANTY.................................................................................................... 20

APPENDIX B: AUTO PURGE SYSTEM (APS)..................................................................... 21

APPENDIX C: WIRING DIAGRAM....................................................................................... 22

N2-BLAST®Nitrogen Generator FPS-1750, FPS-3000, and FPS-6000 South-Tek Systems

Version: 7

Revision Date: 5/24/16 Page 4 of 25

APPENDIX D: INSTALLATION DIAGRAM........................................................................ 23

APPENDIX E: APS INSTALLATION DIAGRAM................................................................ 24

N2-BLAST®Nitrogen Generator FPS-1750, FPS-3000, and FPS-6000 South-Tek Systems

Version: 7

Revision Date: 5/24/16 Page 5 of 25

--------------------------------------------------Notes---------------------------------------------------

N2-BLAST®Nitrogen Generator FPS-1750, FPS-3000, and FPS-6000 South-Tek Systems

Version: 7

Revision Date: 5/24/16 Page 6 of 25

1INTRODUCTION

1.1 PURPOSE

The N2-BLAST®Nitrogen Generator FPS-1750, FPS-3000, and FPS-6000 (Type II

Series), provide an economical, precise means of generating high purity nitrogen.

Since air is comprised of ~79% N2we simply and cost-effectively separate the N2

from the air. Nitrogen is an inert gas (non-combustible) and widely used in

thousands of industries along with Fire Protection Systems. The N2is “generated”

by means of the air compressor pushing air into the simple, safe membrane

element, which in turn mechanically separates N2molecules from other molecules

found within air.

**The installer and the user should read this manual in its entirety.

1.2 AUDIENCE

This manual is intended for Installer/Supervisory Staff and should be read in its

entirety prior to operation.

Please contact your local distributor provider for any operation and maintenance

first prior to contacting the manufacturer.

1.3 IMPORTANT INFORMATION

All personnel (and their supervisors) installing, operating, and maintaining the N2-

BLAST®Nitrogen Generator must read and fully understand this manual prior to

installing, operating or performing maintenance on the system.

The N2-BLAST®Nitrogen Generator produces nitrogen (N2) at a low flow rate,

which quickly dissipates into the air. N2gas is not poisonous but the gas should not

be directly inhaled since in high concentrations it can cause asphyxiation. Ensure

the unit is installed within a well-ventilated room, one that is not sealed off from

normal living space air changes.

All personnel involved with installation, operations, and maintenance of the N2-

BLAST®Nitrogen Generator must follow safe working practices, OHSA, and local

health/safety code regulations during the installation, operation, and maintenance of

the unit.

N2-BLAST®Nitrogen Generator FPS-1750, FPS-3000, and FPS-6000 South-Tek Systems

Version: 7

Revision Date: 5/24/16 Page 7 of 25

2SAFETY GUIDELINES

2.1 GENERAL

Correct use of N2-BLAST®Nitrogen Generator is important for your personal

safety and for trouble-free functioning of the N2-BLAST®Nitrogen Generator.

Incorrect use can cause damage to the N2-BLAST®Nitrogen Generator or can lead

to incorrect gas supply.

N2-BLAST®Nitrogen Generator produces nitrogen (N2) at a low flow rate, which

quickly dissipates into the air. N2gas is not poisonous but it should not be directly

inhaled, since in high concentrations, they can cause asphyxiation. Ensure that

the unit is installed within a well-ventilated room, one that is not sealed off

from normal living space air changes.

All personnel involved with installation, operations, and maintenance of the N2-

BLAST®Nitrogen Generator must follow safe working practices, OSHA, and local

health/safety code regulations during the installation, operation, and maintenance of

the unit.

Warning:

This manual must be read in its entirety to installing and operating

the N2-BLAST®Nitrogen Generator to prevent accidents and damage

to the N2-BLAST®Nitrogen Generator.

Contact your supplier if you detect a problem that you cannot solve

with this manual.

Only use the N2-BLAST®Nitrogen Generator in accordance with its

designed purpose.

Only service-engineers, that are qualified to work on electric and

pneumatic equipment, are allowed to do the installation, maintenance

and repairs. Unqualified people are not allowed to repair the

equipment.

Do not tamper or experiment with the equipment or exceed the

technical specifications

2.2 SERVICE

Before personnel attempt to service the unit, ensure the power switch has been

turned to the off position, and then disconnect the unit’s external power cord from

the building electrical power supply. Always follow specific manuals from STS

when servicing your system.

N2-BLAST®Nitrogen Generator FPS-1750, FPS-3000, and FPS-6000 South-Tek Systems

Version: 7

Revision Date: 5/24/16 Page 8 of 25

3SYSTEM DESCRIPTION

3.1 KEY FEATURES

The N2-BLAST®Nitrogen Generator key features include the following:

-Air Filters and Pressure Regulator

-Membrane

-Pressure Switch for Automatic Start/Stop (per demand)

-Safety Relief Valve

-N2 Storage Tank

-STS Patented Blast-Off (optional)

Air Filters and Pressure Regulator:

The generator has three filters: the particulate, coalescing, and adsorber filters. The

particulate has a 5 micron filter that will catch any of the larger particles. The

coalescing has a 0.1 micron filter that will catch the remaining smaller particles.

Both filters feature and auto drain that will drain the water captured after the air

compressor. The drain is plumbed to the outside of the cabinet where the end-user

can then connect ¼” tubing and drain to a safe location. The adsorber filter captures

0.003 ppm/wt oil content.

Pressure Switch for Automatic Start/Stop (per demand):

The generator comes with a built in pressure switch to indicate when the nitrogen

demand is needed or has been met. When the pressure switch is triggered (nitrogen

storage tank pressure is met), it will pause the production of nitrogen to the tank.

Once the pressure switch is reset (automatically reset when pressure fall 7-10 PSIG

below set pressure), it will resume the production of nitrogen to the storage tank.

Safety Relief Valves:

Safety Relief Valves have been placed throughout the system for maximum safety.

They are designed and put in place to minimize failure of other components. They

all come with an ASME stamp.

N2 Storage Tank:

A N2 Storage Tank is housed inside the cabinet with manual ball valves and gauge.

It is plumbed to an external manual ball valve so that the end-user will not have to

do any plumbing within the cabinet.

Patented Blast-Off Detection (optional):

The Blast-Off Leak Detection will provide the end-user with an alarm when it

detects characteristics of a leak somewhere on the system. It will trigger an audible

alarm, display it on the screen, and the end-user can tie into the dry contact so that

the alarm can be relayed back to the Building Management System (BMS).

N2-BLAST®Nitrogen Generator FPS-1750, FPS-3000, and FPS-6000 South-Tek Systems

Version: 7

Revision Date: 5/24/16 Page 9 of 25

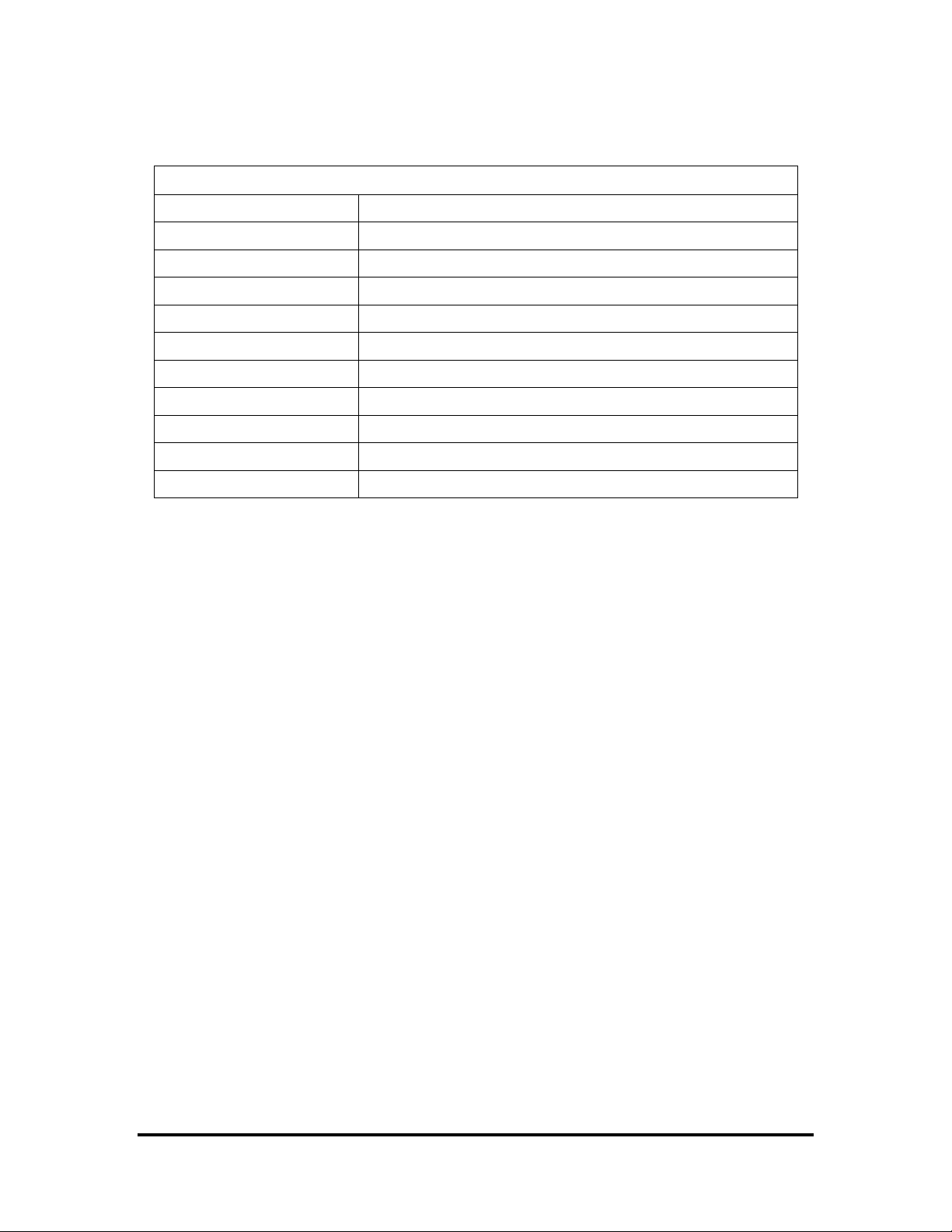

3.2 SPECIFICATIONS

Table 1: Specification Data

N2-BLAST®Nitrogen Generator FPS-1750, FPS-3000 & FPS-6000 Specifications

Nitrogen Purity

98.0+%

Installation

Wall Mounted

Display

Hours / Operating / Standby / BlastOffTM

N₂Storage Pressure

Up to 80 PSIG

Cabinet Port Connections

1/2" NPT Female

Electrical

110V / 60Hz / 1Phase; 20 Amp Breaker

Compressor

External

Ambient Temperature

40° to 90°F

Noise Level (dbA)

< 80 dbA

Size

42.3’’H x 17’’W x 11.8’’D

Weight

Appx: 85 lbs

N2-BLAST®Nitrogen Generator FPS-1750, FPS-3000, and FPS-6000 South-Tek Systems

Version: 7

Revision Date: 5/24/16 Page 10 of 25

4PRODUCT INSTALLATION

4.1 UNPACKING AND PREPARATION

The N2-BLAST®Nitrogen Generator System’s cardboard carton should be

carefully opened and all parts should be inspected for damage upon receipt.

Identify and verify that all parts listed on the packing list are present and

undamaged. South-Tek Systems (STS) is not responsible for damages that have

occurred during the shipping and handling of the N2-BLAST®Nitrogen Generator.

Any visual damages should be immediately documented and reported to the

shipping company responsible. Then, contact STS at (888)526-6284 to assess the

damages only after the shipping company has been notified.

Until Installation:

oStore the N2-BLAST®Nitrogen Generator in a dry and climate controlled

(60-80°F) room.

oAlways keep the N2-BLAST®Nitrogen Generator in an upright position or

in box as shipped.

oDo not connect the AC power cable until this manual has been read

completely and all connections are made as stated within.

oKeep all gas lines dry so you don’t get moisture in the generator upon

hookup.

oNever place/stack objects on top of the N2-BLAST®Nitrogen Generator.

4.2 ELECTRICAL REQUIREMENTS

The N2-BLAST®Nitrogen Generator requires 110V / 60 Hz / 1ph connection rated

at 20 amp service. It has a built in 20A circuit breaker and a standard 3-prong US

power cord is provided for the electrical connection. The system is UL 508A ICP

approved. Electrical schematic available upon request.

4.3 MOUNTING (FOR N2-BLAST®NITROGEN GENERATOR)

It is recommended that the N2-BLAST®Nitrogen Generator be wall mounted using

its supplied wall mounting brackets. The N2-BLAST®Nitrogen Generator should

always be installed indoors in an environment between 40° and 90° F in the

upright and level position where it will not be damaged by water or moving

equipment.

N2-BLAST®Nitrogen Generator FPS-1750, FPS-3000, and FPS-6000 South-Tek Systems

Version: 7

Revision Date: 5/24/16 Page 11 of 25

Figure 1: N2-Blast® Type II Series Wall Mount Diagram

1. Install the lower mounting bracket on the N2-BLAST®Nitrogen Generator by

sliding the bracket through the keyway on the lower mounting flanges. (Item

#3 into Item #4)

a. Looking at the wall bracket, the hole is installed to the top; the key (a

welded bolt to the bracket) goes to the bottom.

b. Put the supplied ¼” x 1¼” bolt through the holes (2) to lock the bracket

in place. (Insert Item #5 thru Item # 8 and secured with Item # 6)

2. Install the upper mounting bracket on a sturdy wall. The brackets have a 16”

center to center hole set for mounting to a standard studded wall.

a. Use ¼” hardware (min) to support system weight. (Item #2 into Item

#1)

b. Always mount the system away from extreme heat/water/steam

sources. These can cause damage to the system or persons.

3. Once upper mounting bracket is installed, hang the cabinet by sliding the key

through the keyway on the top flange of the N2-BLAST®Nitrogen Generator.

The system should hang level and the lower bracket can now be affixed to the

wall with the same wall mounting hardware. Once the lower bracket is

mounted to the wall, the system is locked into place. To remove the unit from

the wall, simply take the locking bolts out and slide the system off the wall

mounts.

N2-BLAST®Nitrogen Generator FPS-1750, FPS-3000, and FPS-6000 South-Tek Systems

Version: 7

Revision Date: 5/24/16 Page 12 of 25

4. An 110VAC power connection should be installed per local code by a qualified

electrician. See the wiring diagram for specifics. Optionally a standard

110VAC power cord can be installed on the system by a qualified electrician.

Warning: Secure the N2-BLAST®Nitrogen Generator to the wall at the top

and bottom flanges. Failure to do so could cause damage or bodily injury.

4.4 INSTALLATION (FOR N2-BLAST®NITROGEN GENERATOR)

The installation layout drawings are provided with your system in the

documentation package of the system. For electronic copies, please contact your

local distributor. Review and make sure the setup installations are followed per the

installation layout drawings. Ensure that you follow the correction installation

drawing per your system’s design. In some cases, a nitrogen bypass system for pre-

filling is required in the installations to meet NFPA (National Fire Protection

Association) code.

If your system requirements are more complex, please consult your sales

representative or equipment

installer for more detailed installation instructions.

1. The N2-BLAST®Nitrogen Generator is designed with ½” inlet/outlet

connections. Use Teflon tape or similar on fittings to prevent leakage.

2. Install the “Supply Line” coming from the air compressor to the N2-

BLAST®Nitrogen Generator Air Inlet.

3. Connect the N2-BLAST®Nitrogen Generator to the storage tank and then

to the systems Air Maintenance Device(s).

4. Once connections are made and the air compressor has been started

up, slowly open the System’s On/Off Valve.

a. Air will start rushing through the nitrogen generator

b. If there is a leak or bad connection, shut valve off, depressurize the

line, and fix the issue.

c. If a leak within the unit, remove top cover and locate the issue.

Only use factory parts supplied from your distributor or South-

Tek

Systems. Consult the factory for any questions.

5. Once the N2-BLAST®Nitrogen Generatorfills the nitrogen storage tank

to the cut-out pressure (~80 PSIG), the system will enter standby -

green light on the control panel will turn off and orange (standby) light

will turn on. This will stop the air flow through the generator and

eventually stop the air compressor once it reaches the cutout pressure.

a. This will save air and time on the compressor’s motor.

b. This also prolongs life of nitrogen generator’s media and filter life.

i. Lesser quality systems have a constant purge flow

through their systems which decreases system life and

increases the need for maintenance.

6. When you draw nitrogen from the system and the tank pressure falls

below cut-in pressure

(approximately 72 PSIG), the pressure switch will

trigger the system back into run mode and refill nitrogen into the storage

tank automatically. The pressure switch is preset at the factory –no field

N2-BLAST®Nitrogen Generator FPS-1750, FPS-3000, and FPS-6000 South-Tek Systems

Version: 7

Revision Date: 5/24/16 Page 13 of 25

adjustment is required.

4.5 PANEL LAYOUT AND GAS CONNECTION

Air Input is located on the left side of the unit. Nitrogen outlet will be located on

the right side of the unit. Double-check all connection locations before turning on

the system or opening any valves.

Note: All N2-BLAST®models are factory equipped with ½”NPT Female

connections. See drawing (DD-TYP2M-FPS and DD-A01-0100-04-04) for detail

generator and tank connections.

4.6 BLASTOFF™ – AIR BYPASS SETUP (OPTIONAL)

The BlastOff™ - Air Bypass Option ensures that nitrogen is the only supervisory

gas entering the FPS. It safeguards your installation all while providing piece of

mind knowing the FPS is being filled with nitrogen vs any other gas. It will alarm if

the N2-BLAST®Generator is being bypassed by the air compressor. It safeguards

against a maintenance technician from inadvertently leaving the “air bypass” open

or the N2-BLAST®being powered in the off position. It will provide a visual alarm

when it is in alarm mode. See wiring diagram and installation drawing included

with this package. For electronic copies, please contact your local distributor.

4.7 CHECK FOR LEAKS

When a leak is suspected, first try to listen for leaks and/or spray with soapy water

around the connection ports. If a leak is found, isolate the area and relieve any

pressure on it prior to working on it. Fix the leaking part and return the system back

to operation. If no leak are heard (or visually seen with the soapy water), turn off

the unit and try isolating sections to see if there’s a pressure loss. If the BlastOff™

option is included with your unit, the system will alarm indicating that there is a

leak in the line. Consult with your installer if you cannot locate the leakage area.

For more information on leak checking go to Check for Leaks.

N2-BLAST®Nitrogen Generator FPS-1750, FPS-3000, and FPS-6000 South-Tek Systems

Version: 7

Revision Date: 5/24/16 Page 14 of 25

5SYSTEM USAGE

5.1 INSTRUCTIONS

The N2-BLAST® Nitrogen Generator is intended to be used to generate nitrogen

and provide nitrogen for the fire protection piping system. Follow the installation

instructions above and only use in an approved environment. The generator

generates enough nitrogen to maintain zone pressure requirements. Please consult

with your local provider for questions not answered in this manual.

The system is design for 24 hour operation, but routine maintenance on the filters

must be performed. See section “System Maintenance” for detail maintenance

instructions.

5.2 START-UP PROCEDURES

The system is shipped ready for power once the equipment line connections are

completed. Connect the pipe or hose to the nitrogen storage tank outlet using

Teflon tape or other pipe connection sealant. All valves should be open and ready

for gas to be distributed. Plug the N2-BLAST®Nitrogen Generator into a 110VAC

power outlet and turn on the rocker switch. The external air compressor will turn on

if the N2storage tank is not already pressurized. If the nitrogen storage pressure is

at or above the system cut-off pressure, the amber “Standby” light will be

illuminated. Once the pressure drops to the cut-in pressure, the nitrogen generator

will start replenishing the nitrogen into the storage tank. The “Operating” green

light will illuminate until the N2storage tank pressure reaches the cut-out pressure

(approximately 80 PSI) and the external air compressor will cut off once it reaches

its cut-off pressure.

Use caution when working with pressurized gas, making sure that all fittings

and gas

lines are installed correctly. Always leak check (see Check for Leaks

section) every line before using the system.

Note: Line leaks will cause the N2-BLAST®Nitrogen Generator to run

excessively, shortening its life and cause excess wear on the compressor.

5.3 NORMAL OPERATING PROCEDURES

Once the generator has been started-up and the nitrogen storage tank has been

filled, the system should be left power on. The system will automatic start/stop as

the pressure in the nitrogen storage tank reaches the preset cut-in/out pressures. To

pause or bypass the nitrogen open/close corresponding valves as necessary.

5.4 ALARM NOTIFICATION

BlastOff™ - Leak Detection System Alarm

An optional feature that can be included with the system is the BlastOff™ - Leak

Detection System. It is a patented system when installed into the N2-BLAST®

Nitrogen Generator, detects line leaks within the downstream gas lines from the

nitrogen generator to the FPS piping. Line leaks could be due to pin-hole leaks in

N2-BLAST®Nitrogen Generator FPS-1750, FPS-3000, and FPS-6000 South-Tek Systems

Version: 7

Revision Date: 5/24/16 Page 15 of 25

Buzzer and Red Light Warning

This unit is equipped with The BlastOffTM Leak Detection System. If the red

light and buzzer are on,

you may have a leak in one of the gas lines. Note:

To reset alarm, turn power off and close the

nitrogen tank valves. Turn the

power back on. If the unit goes into “Stand-By”mode and shows an orange

light, the generator is operating properly and you have a leak downstream.

Correct the leaks and resume operation. Contact your distributor or the mfg.

as necessary. This is a safety feature

designed to provide a safer operating

environment and to prevent equipment damages or failure

the pipe lines, loose fittings, faulty connection, etc. These leaks are potential safety

hazards, they can cause the nitrogen to deplete quickly, and could cause your N2-

BLAST®Nitrogen Generator to run in excess (decreasing the life of the unit).

Once a leak has been detected, the BlastOff™ will sound the buzzer, and the red

light on the lower left side of the cabinet will illuminate. To reset the BlastOff™,

simply turn off the N2-BLAST®Nitrogen Generator, and turn it back on. The N2-

BLAST®Nitrogen Generator, can be ordered with the BlastOff™ System Factory

installed or the system can be retrofitted in the field. Some rewiring is required to

field install.

Never reset repeatedly; if the BlastOff™ goes off daily, there is a real potential

issue. Consult your installer for a solution. The label below and the Logo above

will be on your FPS if factory installed.

BlastOffTM –Leak Detection System Wiring:

The BlastOffTM can be wired to an external alarm if the customer desires. The

internal relay is set to trigger when there’s an alarm indication. The relay’s dry

contact is configured with 11-14 termination normally open, and 11-12 are

normally closed. BlastOffTM Assembly and customer dry contact relay is located in

the upper left hand portion of the N2-BLAST®Nitrogen Generator’ cabinet’s

interior.

BlastOffTM–Air Bypass Option

The BlastOff™ - Air Bypass Option ensures that nitrogen is the only supervisory

gas entering the FPS. It safeguards your installation all while providing piece of

mind knowing the FPS is being filled with nitrogen vs any other gas. It will alarm if

the N2-BLAST®Generator is being bypassed by the air compressor. It safeguards

against a maintenance technician from inadvertently leaving the “air bypass” open

or the N2-BLAST®being powered in the off position. It will provide a visual alarm

when it is in alarm mode. See wiring diagram in APPENDIX c: Wiring Diagram

and installation instruction in Appendix D: Installation Diagram.

N2-BLAST®Nitrogen Generator FPS-1750, FPS-3000, and FPS-6000 South-Tek Systems

Version: 7

Revision Date: 5/24/16 Page 16 of 25

6SYSTEM MAINTENANCE

Servicing the N2-BLAST®Nitrogen Generator:

Before personnel attempt to service the unit, ensure the power switch has been

turned to the off position, and then disconnect the unit’s external power cord from

the building electrical power supply. Always follow specific manuals from STS

when servicing your system.

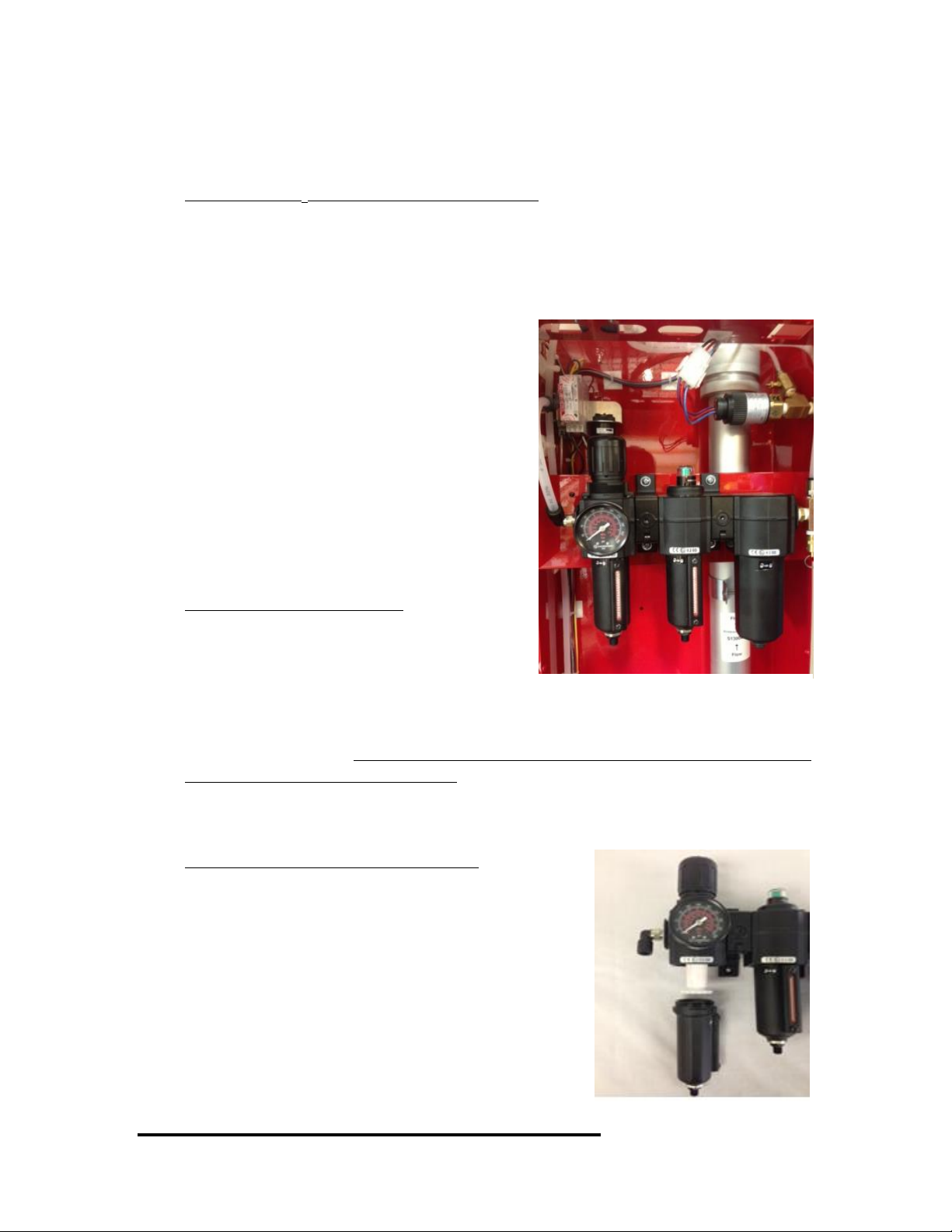

The N2-BLAST®Nitrogen Generator utilize

three different filters, seen in Figure 2 to the

right. The Particulate, Coalescing, and

Absorber filters must be changed out

annually or every 1000 hours (hour meter

located on the outside bottom right corner of

the cabinet) of operating time, whichever

comes first. Filter Replacement Kits can be

purchased from South-Tek Systems that

include the Filter Elements for the specified

unit (STS Part # FRP-002).

Prior to Filter Bowl Removal

Ensure the power has been disconnected

from the source. Air supply to the unit

should also be bypassed, or disconnected

from the unit. You can remove the top cover

to the unit by removing the 4 screws that secure it to the cabinet, however it is not

necessary to do this. The pressure gauge located on the regulator that houses the

Particulate Filter should read 0 psi. If the pressure gauge still shows the system

having pressure, you can relieve the pressure by pulling the safety Relief Valve

ring located after the Absorber Filter.

Particulate Filter Element Replacement

1) Remove Filter Bowl by pressing up slightly

and turning the bowl 1/8 turn to the left,

then pulling down (see Figure 3). After

bowl is removed you will be able to see the

filter element secured in place by a

threaded ring just under the element.

2) Unscrew the thread counter-clockwise, and

the filter element can be removed easily by

pulling down.

3) Install the new Particulate element and

Figure 2: Particulate, Coalescing, and

Absorber, respectively

Figure 3: Particulate Element

Replacement

N2-BLAST®Nitrogen Generator FPS-1750, FPS-3000, and FPS-6000 South-Tek Systems

Version: 7

Revision Date: 5/24/16 Page 17 of 25

secure it in place with the threaded ring.

4) Before reinstallation of the filter bowl, be sure to clean out any debris with

hot water and shake dry the water out.

5) Change the O-ring on the top of the bowl with the new one supplied in the

kit, use some light oil/grease if the O-ring seems to be dry.

6) To reinstall the filter bowl, reverse the procedures used in removing the

filter bowl.

Coalescing Filter Replacement

1) Remove the filter bowl by pushing up slightly and turning the bowl 1/8

turn to the left then pulling down (See Figure 4). After the bowl is

removed, you’ll be able to see the filter element still secured in place.

2) The element can be removed by twisting counter-clockwise until the filter

element comes completely off. 3) Install the new element by

twisting clockwise. HAND TIGHT ONLY!

4) Before reinstallation of the filter

bowl, rinse out the bowl of any debris with hot

water and shake dry the water out.

5) Change the O-ring on the top of

the bowl with the new one supplied in the kit,

use some light oil/grease if the O-ring seems to

be dry. 6) To reinstall the filter bowl,

reverse the procedures used in removing the

bowl.

Absorber Filter Replacement

1) Remove filter bowl by pressing up slightly and

turning the bowl 1/8 turn to the left then pulling

down (See Figure 5). After the bowl is removed,

you’ll be able to see the filter element still secured in

place.

2) The Element can be removed by unscrewing counter-

clockwise.

3) Install the new element with new O-Ring by

screwing clockwise. HAND TIGHT ONLY!

4) Before reinstallation of the filter bowl, be sure to

rinse it out thoroughly with hot water and shake dry.

5) Change the O-ring on the top of the bowl with the new one supplied in the

kit, use some light oil/grease if the O-ring seems to be dry.

Figure 4: Coalescing Filter Element

Replacement

Figure 5:

Absorber Filter

N2-BLAST®Nitrogen Generator FPS-1750, FPS-3000, and FPS-6000 South-Tek Systems

Version: 7

Revision Date: 5/24/16 Page 18 of 25

6) To reinstall the filter bowl, reverse the procedures used in removing the

filter bowl.

Reconnecting Your N2-BLAST®Nitrogen Generator:

1) After all filter elements have been replaced, wipe down all surfaces with a

clean dry towel. Do not use any cleaning agents as they could damage the

finish on the filters.

2) Reconnect to power source and slowly open the incoming air supply ball

valve.

3) After the system has been powered up, listen for any air leaks to ensure

filter bowls have been adequately tightened.

4) If no leaks are present, allow the system to fill up the storage tank.

7KEY CONTACTS

Contact your local provider/installer for any questions with the performance and/or

maintenance of the system. They will be best suited to answer your questions and

your quickest solution on any issues you may have.

8FAQS

8.1 POWER ISSUES

If the N2-BLAST®Nitrogen Generator does not have power, the production and

storage of nitrogen will become apparent once the storage pressure drops.

1. Check the power cord

2. Has building’s circuit breaker or GFCI tripped? Locate the breaker and

reset. If breaker continues to trip, you may have that circuit overloaded.

8.2 PRESSURE ISSUES

The N2-BLAST®Nitrogen Generator will produce and store nitrogen at 70 (+/-3)

psig. Once the storage tank reaches 70 (+/-3) psig, the system will go into Stand-

By Mode. When the pressure drops by about 7-10 psig, the system should go into

Operation Mode and begin to refill the storage. If you are out specifications, we

need to determine where the issue is. Contact the manufacturer or factory trained

technician.

Nitrogen Pressure Check:

Look at the pressure gauge on the top of the cabinet. It should be between 50 and

80 psig. If the pressure is low, a few things need to be checked.

Check the power.

Check leaks throughout system. Refer to section “Checking for Leaks”.

N2-BLAST®Nitrogen Generator FPS-1750, FPS-3000, and FPS-6000 South-Tek Systems

Version: 7

Revision Date: 5/24/16 Page 19 of 25

8.3 GAS LEAKS:

As with any gas system, only use a spray bottle on non-electrical equipment to find

leaks. Fix or replace leaking fittings or old hose. Push-to-connect fittings will show

bubbles and typically have up to a 5ccm acceptable leakage rate. Contact your local

provider/installer for help.

8.4 BLASTOFF™ - LEAK DETECTION SYSTEM:

“There is an alarm sounding in the N2-BLAST®

Nitrogen Generator and the control panel has Blast Off light

illuminated on the side panel of the unit.”

If you hear the alarm and see the red “BlastOff light on, it means that the system is

equipped with “The BlastOff™- Leak Detection” feature. If the BlastOff is

activated, there may be a leak in one of the lines, internal system components, or

fittings may not be properly seated, causing gas leaks. Note: Turn off this unit’s

on/off power switch and check for leaks. If none are found, leave the unit turned

off and contact your local FPS contractor. Once the leak has been fixed, turn the

system back “On” to resume normal operation. By turning the system power off,

then back on, this will reset the BlastOff™ automatically.

N2-BLAST®Nitrogen Generator FPS-1750, FPS-3000, and FPS-6000 South-Tek Systems

Version: 7

Revision Date: 5/24/16 Page 20 of 25

APPENDIX A: WARRANTY

The N2-BLAST®Nitrogen Generator System is warrantied against any defects in

workmanship and materials for 12 months (or 1000 hours) from the date of shipment

from South-Tek Systems, whichever comes first. The purchaser has the liability to ensure

that the system is fully inspected upon delivery and shall contact the appropriate shipping

company to make any claims on damaged goods due to transit within that shipping

company’s policies. If the system is received with defects that are not due to shipping, a

written claim should be submitted to South-Tek Systems within 1 week of receiving the

shipment. South-Tek Systems can deny all other claims at their discretion.

All warranty work shall be done at a South-Tek System facility or at a N2-BLAST®

Nitrogen Generator Authorized Service Center. Only factory trained and authorized

personnel are covered under warranty. Any part that is returned / repaired / replaced

under warranty may be remanufactured or changed to a different specification at the

factory’s option. Any work performed by an unauthorized person/company or usage of

non-factory parts, may void all warranties to the product.

Any item not manufactured by South-Tek may carry its own warranty from its

manufacturer and will be warrantied by that manufacturer. All parts that need to be

returned should be announced. Any item(s) that is returned to South-Tek Systems

without an RMA number (return authorization number) may be denied and returned to

the sender. Contact the factory for RMA #’s, prior to return shipment.

South-Tek Systems is not liable for damages caused by normal wear and tear, water, fire,

erosion, corrosion, explosion, misuse, oil/gas vapors or unauthorized modifications.

South-Tek Systems is also not liable for any losses (including CO2), damages, or cost of

delays, including incidental or consequential damages. There are no warranties or

guarantees, expressed or implied, including the warranties of merchantability or fitness

for a particular purpose or use, other than those warranties expressed herein.

For Claims, contact South-Tek Systems LLC at:

tel (919) 847-3800 fax (919) 847-0255

Email: [email protected]

Or write to:

South-Tek Systems, Warranty Claims, 4724 Sharpstone Lane, Raleigh, NC 27615

This manual suits for next models

2

Table of contents

Other South-Tek Systems Inverter manuals

South-Tek Systems

South-Tek Systems N2Blast FPS-650 User manual

South-Tek Systems

South-Tek Systems N2Blast FPS-900 User manual

South-Tek Systems

South-Tek Systems N2-BLAST FPS-500 User manual

South-Tek Systems

South-Tek Systems N2Blast FPS-15000 User manual

South-Tek Systems

South-Tek Systems BEERBLAST 7 KPH Operating instructions

Popular Inverter manuals by other brands

Zgonc

Zgonc yellow PROFILINE YPL 6000-D Translation of original instruction manual

SMA

SMA SUNNY BOY STORAGE 3.8-US installation manual

Phase Green

Phase Green PhG-P5 K0HT-M Series user manual

Huawei

Huawei SUN2000-33KTL-US user manual

ETQ

ETQ TG1200 owner's manual

SolaX Power

SolaX Power X3-Retro Fit Series Quick installation guide