Encision AEM ENDSHIELD 2 EM200 User manual

Device Description

The AEM EndoShield® 2 Burn Protection System uses AEM®Monitoring in conjunction with

AEM instruments and an electrosurgical generator to continuously monitor and dynamically

manage stray energy (insulation failure and capacitive coupling) during monopolar

laparoscopic electrosurgery.

The EndoShield 2 is for use only by qualied medical professionals trained in the particular

technique and surgical procedure to be performed. These instructions are intended as

a guide for the setup and operation of the EndoShield 2. They are not intended to be

a general reference about the use of electrosurgery either in general application, or in

laparoscopic procedures.

EM200

Foot-Control Plug

Return Electrode Receptacle

Return Electrode Plug

AEM Cord Connector

2 of 44

WARNING: These devices have been specically designed for use in electrosurgery. Do not

use for other procedures.

Caution: The EndoShield 2 is designed to safely deliver electrosurgical energy and to

prevent injury caused by insulation failure and capacitive coupling. The EndoShield 2 is not

intended to test for insulation damage on laparoscopic instruments. Do not attempt to use

this system as an instrument inspection tool.

Prior to using the EndoShield 2, read and review these instructions, the

instructions for use for the electrosurgical generator, and the instructions

foruse for all instruments and accessories to be used.

Warnings and Cautions start on page 13

EndoShield 2 3 of 44

Table of Contents

How AEM ® Monitoring Works. . . . . . . . . . . . . . . . . . . 4

System Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

At End of Life . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Removing the Battery . . . . . . . . . . . . . . . . . . . . 8

End of Life Indicators . . . . . . . . . . . . . . . . . . . . . 9

Reprocessing . . . . . . . . . . . . . . . . . . . . . . . . . 9

Compatible Products . . . . . . . . . . . . . . . . . . . . . . . 9

Electrosurgical Generator . . . . . . . . . . . . . . . . . . 9

Return Electrode . . . . . . . . . . . . . . . . . . . . . . . 9

Active Electrode . . . . . . . . . . . . . . . . . . . . . . . 9

Instrument Cord . . . . . . . . . . . . . . . . . . . . . . . 9

Encision Adapter . . . . . . . . . . . . . . . . . . . . . . . 9

Troubleshooting and System Maintenance . . . . . . . . . . . . 10

Mechanical Inspection . . . . . . . . . . . . . . . . . . . . 10

Correcting Setup Faults. . . . . . . . . . . . . . . . . . . . 10

Responding to the EndoShield 2 Alarms . . . . . . . . . . . 11

Cleaning the EndoShield 2 . . . . . . . . . . . . . . . . . . 12

Storing the EndoShield 2 . . . . . . . . . . . . . . . . . . . 12

Warnings and Cautions . . . . . . . . . . . . . . . . . . . . . . 13

Technical Specications . . . . . . . . . . . . . . . . . . . . . . 15

Limited Warranty . . . . . . . . . . . . . . . . . . . . . . . . . 20

Symbol Denitions . . . . . . . . . . . . . . . . . . . . . . . . 22

Indications for Use

The EndoShield 2 is an accessory for use with electrosurgical generators and AEM

instruments that is designed to safely deliver electrosurgical energy and to prevent

injury caused by insulation failure and capacitive coupling.

Active electrode monitoring is intended to control stray monopolar energy caused by

insulation failure and capacitive coupling in surgical instruments on the shaft of the

instrument.

Contraindications

There are no known contraindications for the use of the EndoShield 2.

4 of 44

How AEM®Monitoring Works

Non-AEM Laparoscopic Instruments

Monopolar laparoscopic instruments have an inherent problem with their design;

they are prone to insulation failure and capacitive coupling, causing patient

burns. These stray energy burns occur in the surgeon’s blind spot. As a result, they

typically go undiagnosed and further manifest into severe complications.

The EndoShield 2 Burn Protection System

Encision’s AEM technology eliminates stray energy burns to patients during

laparoscopy by electrically shielding and monitoring our instruments.

Every AEM instrument has a protective shield that is actively monitored by the

EndoShield 2 throughout a procedure. This protective shield eliminates the

risk of capacitive coupling to the patient by draining the energy away from the

patient to the electrosurgical generator. If an insulation failure occurs, the AEM

system actively drains the electrosurgical energy away from the patient through

the protective shield. In addition, the EndoShield 2 immediately shuts down the

instrument power, similar to a circuit breaker (GFCI) in the electrical wiring of

ahouse.

Patient Return Electrode

Electrosurgical Generator

EndoShield 2

AEM Foot-Control

Instrument

AEM Cord

EndoShield 2 5 of 44

How AEM®Monitoring Works (continued)

AEM Instruments

In every AEM instrument, the active electrode is surrounded by the primary

insulation layer. The primary insulation layer withstands the high voltages of

electrosurgery, ensuring eective use of the active electrode. The protective

shield is a conductive tube that surrounds the primary insulation layer and active

electrode. The shield conducts stray energy back to the electrosurgical generator,

ensuring there is no chance of a stray energy burn to the patient. The outer

insulation provides an additional layer of insulation for all AEMinstruments.

Hospitals, Physicians, and Nurses can condently use AEM monopolar energy

knowing that stray energy burns to the patient have been eliminated.

WARNING: AEM shielding does not cover zone 1, the active tip of the instrument,

which the surgeon should keep in view during instrument activation.

System Setup

Prior to using the EndoShield 2, read and review these instructions, the

instructions for use for the electrosurgical generator, and the instructions for

use for all instruments and accessories to be used.

The EndoShield 2 is supplied non-sterile.

WARNING: The electrosurgical generators (ESUs) referenced here have been

tested for use with the EndoShield 2. Use of an untested ESU may result in an

inoperative active electrode monitoring system.

Caution: AEM Monitoring will not function without the use of a dual-area patient

return electrode and an electrosurgical generator equipped with contact quality

monitoring patient safety technology.

6 of 44

System Setup (continued)

Caution: Limit electrosurgical generator power settings as noted. Higher settings may

result in spurious insulation failure alarms and/or insulation breakdown.

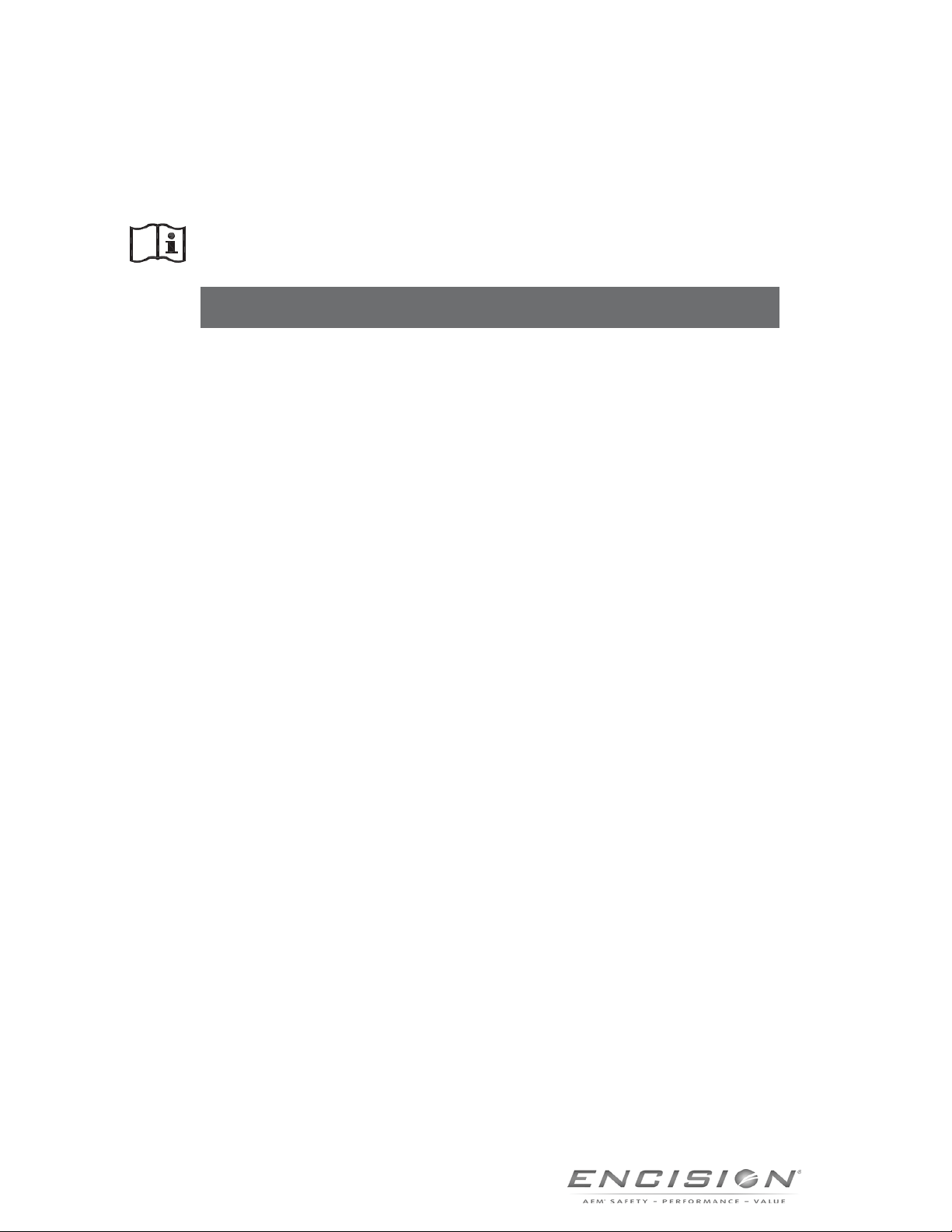

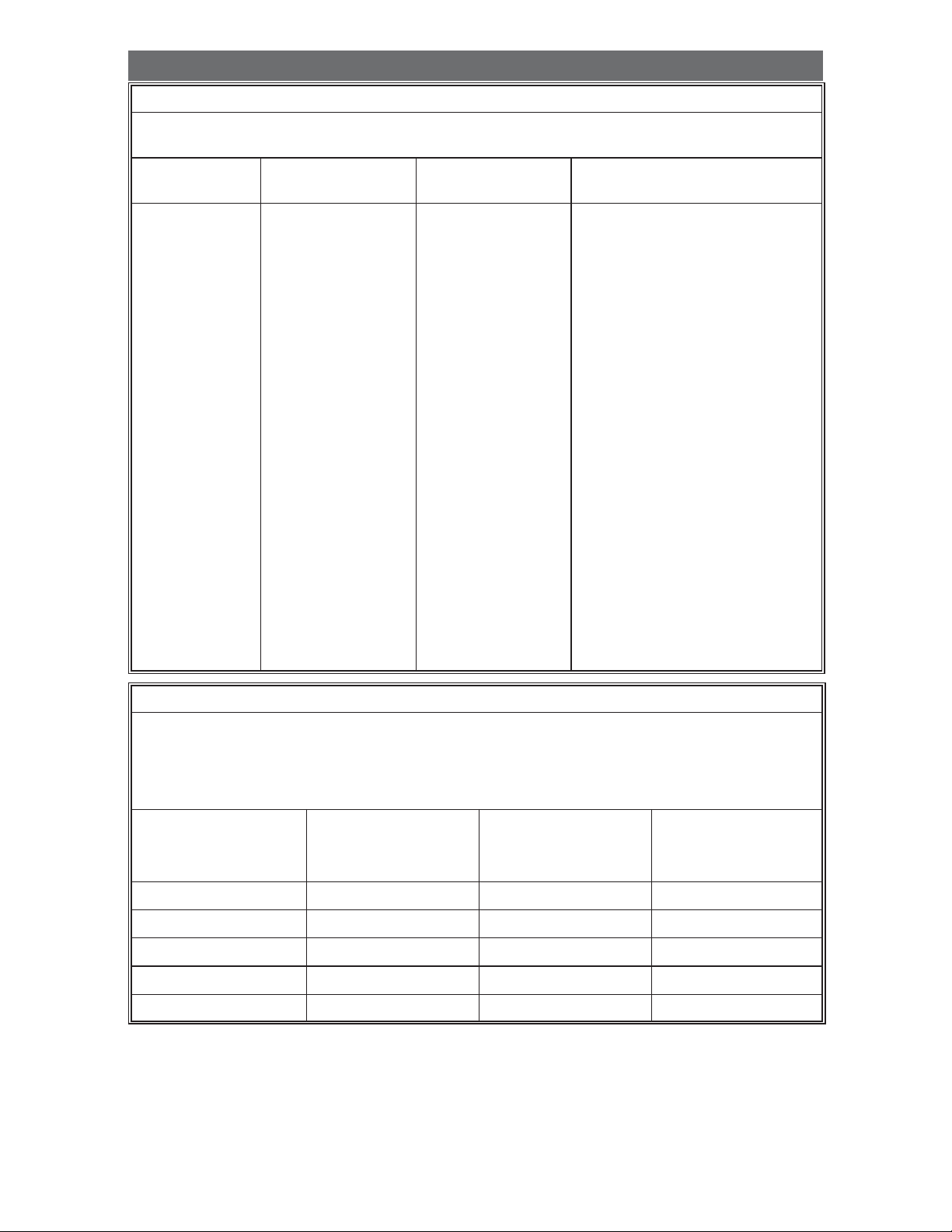

ESU Mode and Power Limitation (Watts)

Conmed SystemSystem 5000™ Use Lap-Specialty Mode Only: Max Power = 80

Covidien Force Triad™ All Modes: Max Power = 80

Covidien Force FX™ or FX-C™

Med COAG: Max Power = 75

High COAG: Max Power = 60

All Other Modes: Max Power = 80

Covidien FT10™ All Modes: Max Power = 80

Erbe VIO 300 D™

Dry Cut: Max Eect = 7, Max Power = 50

COAG Spray Eect 2: Max Power = 25

All Other Modes: Max Power = 50

Megadyne MegaPower™ COAG 1: Max Power = 50

All Other Modes: Max Power = 80

Whenever the patient return electrode is connected to the EndoShield 2, the device

operates continuously.System Setup (continued)

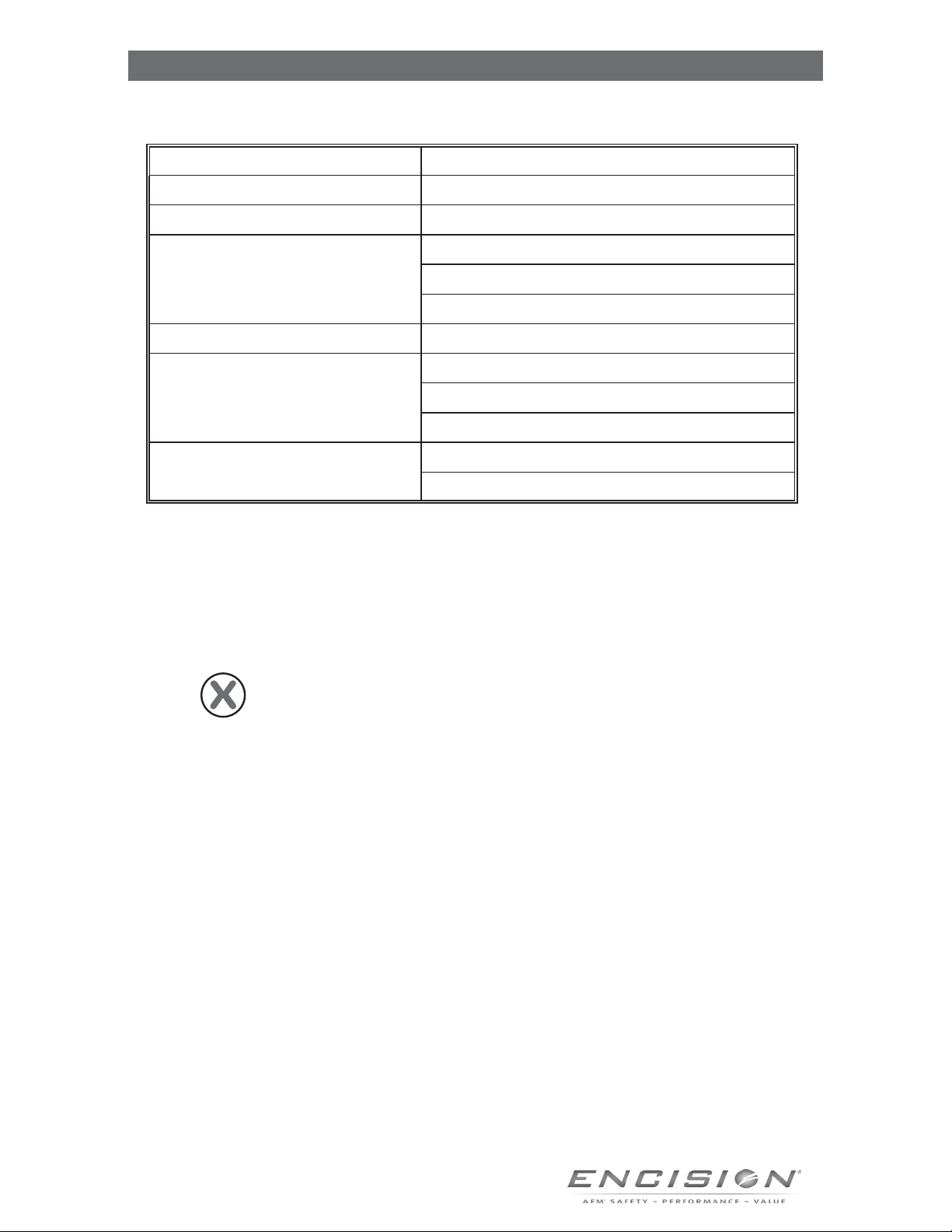

1. Connect the EndoShield 2 to the electrosurgical generator.

2. Connect the patient return electrode to the EndoShield 2.

illuminates RED until an AEM instrument is connected.

If no symbols illuminate, see the Troubleshooting and System Maintenance section.

EndoShield 2 7 of 44

System Setup (continued)

Conmed System 5000™ Covidien Force Triad™

Covidien Force FX™ or FX -C™ Covidien FT10™

Erbe VIO 300 D™ Megadyne MegaPower™

*Reusable Encision Adapter ES9007 required to complete setup.

2

B

I

P

OLAR

C

OA

G

C

UT

MEG

A

D

Y

N

E

®

M

E

G

A

P

O

W

E

R

®

1

1

0

1

2

Note: Install monitor

upside down.

BIPOLAR

MONOPOLAR

MONOPOLAR

NEUTRAL

2

1

*

1

2

1

2

2

1

M

o

n

o

p

olar 1

Bipo

lar

Li

gaSure/

B

ip

ola

r

Mo

n

opol

ar 2

[

]COVIDIEN

Valleylab FT10

8 of 44

System Setup (continued)

3. Connect an AEM cord to the EndoShield 2.

4. Connect an AEM Foot Control Instrument to the AEM Cord.

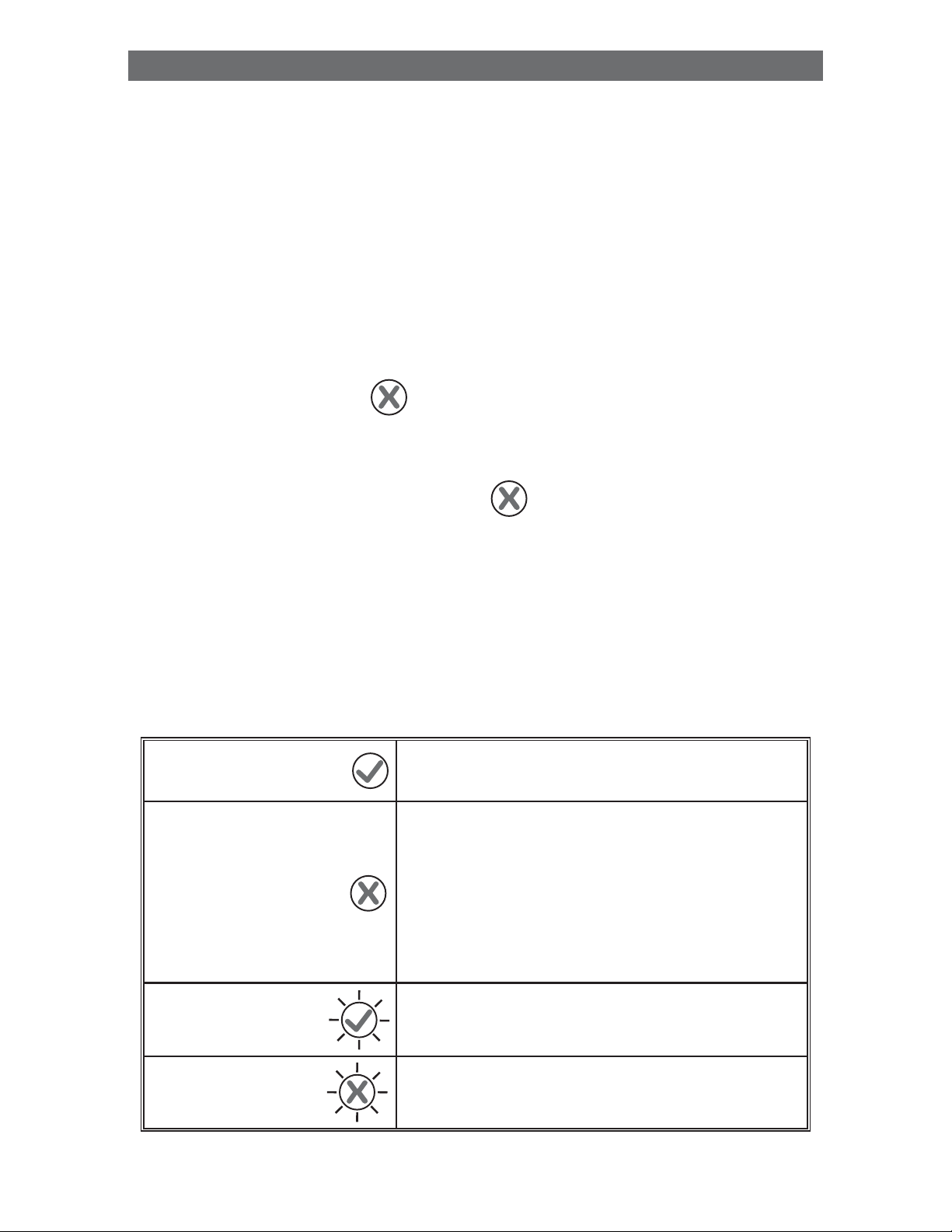

If illuminates GREEN then the EndoShield 2 is fully operational.

If illuminates RED, see the Troubleshooting and System Maintenance section.

If either or are ashing see the Troubleshooting section.

5. Turn on the electrosurgical generator, enabling its contact quality

monitoring system. It should be in its normal operating state.

At End of Life

Removing the Battery

Open the door on the

back of the EndoShield 2 Remove the battery.

The EndoShield 2 contains a 3V CR2 lithium battery. The lithium battery will provide

approximately ten (10) hours of operating time.

WARNING: Dispose of the lithium battery in accordance with local regulations.

Incineration of the device with battery may result in explosion.

Caution: The lithium battery is single use only. Do not reuse or replace the lithium

battery.

4

3

EndoShield 2 9 of 44

At End of Life (continued)

End of Life Indicators

Discontinue use if any of the following are evident:

Intermittent electrical performance.

The device indicates a low or dead battery condition. See the Troubleshooting and

System Maintenance section for indications of low or dead battery.

Reprocessing

WARNING: This product shall not be reprocessed.

Compatible Products

For successful operation, the EndoShield 2 must be used with the following compatible

products.

Caution: Use of other accessories or cables may result in increased EMC emissions or

decreased immunity.

Electrosurgical Generator

Electrosurgical Generator (ESU) Encision Adapter Required

Manufacturer Model

Conmed System 5000 ES9007

Covidien

Force Triad N/A

Force FX N/A

Force FX-C N/A

FT10 N/A

Erbe VIO 300 D N/A

Megadyne MegaPower N/A

WARNING: The electrosurgical generators referenced here have been tested for use

with the EndoShield 2. Use of an untested ESU may result in an inoperative active

electrode monitoring system.

Caution: All electrosurgical generators must have a contact quality monitoring circuit

for return electrodes.

Return Electrode

The EndoShield 2 requires a dual-area patient return electrode.

Active Electrode

The foot-control instrument must have patented AEM technology and be

manufactured by/for Encision Inc., or licensed by Encision Inc.

Hand-control AEM instruments are not compatible with the EndoShield 2.

Instrument Cord

The cord connecting the foot-controlled instrument to the EndoShield 2 must have

patented AEM technology and be manufactured by/for Encision Inc., or licensed by

Encision Inc.

Encision Adapter

Some electrosurgical generators require an adapter for setup of the EndoShield 2

(see the Electrosurgical Generator table above). Refer to the System Setup section for

proper connections.

10 of 44

Troubleshooting and System Maintenance

Mechanical Inspection

Before use, visually inspect the following items of EndoShield 2. Donot use if any of these

items appear damaged:

Insulation of wiring and cables.

Instrument receptacles and connectors.

Correcting Setup Faults

Verify that the setup of the EndoShield 2 is complete.

Situation Recommended Action

No symbols illuminate on the front

of AEM EndoShield 2.

Verify that a dual-area patient return electrode is

connected properly and fully seated in the return

electrode receptacle of the EndoShield 2.

If the fault persists, replace the patient return

electrode.

illuminates continuous RED

on the EndoShield 2.

Verify that the AEM Cord is properly connected to

the EndoShield 2.

Verify that the AEM instrument is properly

connected to the AEM Cord.

If the fault persists, replace the AEM instrument

and/or AEM Cord.

No power to instrument,

but the illuminates GREEN on

the EndoShield 2.

Verify that both EndoShield 2 connectors to the

electrosurgical generator (ESU) are properly and

securely connected.

Ensure that the power settings on the ESU are

sucient.

Verify that the foot pedal is properly connected to

the ESU.

Reset the ESU's pad monitoring system (applies to

some ESU models).

Check the return electrode application to the

patient. Follow the return electrode manufacturer’s

instructions for proper placement.

If the fault persists after performing all the previous

steps, replace the AEM instrument or instrument

cord.

If the fault continues to persist, replace the

EndoShield 2.

Low battery condition.

illuminates ashing

GREEN on the EndoShield

2.

The battery is nearing end of life. Finish existing

procedure and replace the EndoShield 2.

Dead battery condition.

illuminates ashing RED

on the EndoShield 2.

Replace the EndoShield 2 immediately.

EndoShield 2 11 of 44

Troubleshooting and System Maintenance (continued)

Responding to the EndoShield 2 Alarms

When using AEM Monitoring, successful electrosurgery depends on an absence of critical

fault conditions. Should one occur, the EndoShield 2 interrupts the power delivery from

the electrosurgical generator to the AEM instrument for 10seconds.

If for any reason a fault condition persists from the EndoShield 2 after following the steps

described below, use a backup EndoShield 2 to complete the surgical procedure.

CAUTION: Always have a backup EndoShield 2 available in the event of a low or dead

battery situation.

Situation Recommended Action

illuminates RED on the

EndoShield 2 for 10seconds.

EndoShield 2 interrupts the power

delivery from the electrosurgical

generator for 10 seconds.

Replace the instrument.

If the continues to illuminate

RED for 10 seconds after replacing

the instrument, replace the AEM

Cord.

If the continues to illuminate

RED for 10 seconds after replacing

the instrument and cord, replace the

EndoShield 2.

Low battery condition.

illuminates ashing

GREEN on the EndoShield

2.

The battery is nearing end of life.

Finish existing procedure and replace

the EndoShield 2.

Dead battery condition.

illuminates ashing RED

on the EndoShield 2.

Replace the EndoShield 2

immediately.

WARNING: An EndoShield 2 alarm may indicate an unsafe condition. Electrosurgical

energy to the AEM instrument is disabled during the alarm condition.

If other alarm conditions occur during the surgical procedure, see Correcting Setup Faults on

previous page.

12 of 44

Troubleshooting and System Maintenance (continued)

Cleaning the EndoShield 2

WARNING: Electric Shock Hazard. Always unplug the EndoShield 2 before cleaning.

The EndoShield 2 may be cleaned in accordance with your facility's procedures.

1. Disconnect all accessories.

2. Follow the procedures approved by your institution, or use a validated infection

control procedure.

3. Dampen a cloth with a mild cleaning solution (100:1 water to mild detergent, by mass)

or disinfectant and thoroughly wipe all outside surfaces including cords.

4. Ensure unit is dry before use.

Caution:

Do not allow uids to enter the EndoShield 2 housing.

Do not clean the EndoShield 2 with abrasive cleaning or disinfectant compounds,

solvents, or other materials that could damage the unit.

Do not steam sterilize the EndoShield 2.

Do not spray the EndoShield 2 directly with cleaning solution.

Storing the EndoShield 2

The EndoShield 2 should be stored within these parameters:

Temperature -13° to 140° F (-25° to 60° C).

Humidity: 5% to 95% relative, non-condensing.

If you store the EndoShield 2 at a temperature that is outside its normal operating range of

59° to 104° F (15° to 40° C), allow one hour for the EndoShield 2 to reach room temperature

before use.

EndoShield 2 13 of 44

Warnings and Cautions

Prior to using the EndoShield 2, read and review these instructions, the

instructions for use for the electrosurgical generator, and the instructions for

use for all instruments and accessories to be used.

Fire and Shock Hazards

WARNING:

Explosion Hazard. Do not use electrosurgery in the presence of ammable

liquids or in an oxygen enriched environment.

Fire Hazard. Electrosurgical accessories that are activated or hot from use can

cause a re. Do not place them near or touching ammable materials (such as

gauze or surgical drapes).

Electric Shock Hazard. Ensure that all accessories, cords, and adapters are

correctly connected.

Electric Shock Hazard. Do not attempt to connect or disconnect any cable

during power activation.

General

WARNING:

Conrm proper electrosurgical power setting before proceeding with surgery.

Use the lowest power setting that achieves the desired surgical eect.

Keep electrical connections dry while in use to prevent potential conduction of

High Frequency (HF) current to the user.

Only an AEM instrument provides active electrode monitoring. Other

conductive objects at or near the surgical site are not protected. Do not touch

those objects with the active instrument.

No modication of this equipment is allowed.

Caution:

Limit electrosurgical generator power settings as noted in the ESU Mode and

Power Limitation table in the System Setup section. Higher settings may result

in spurious insulation failure alarms and/or insulation breakdown.

Active Accessories and the EndoShield 2 Burn Protection System

WARNING:

Do not wrap accessory cords around metal objects. Wrapping cords around

metal objects may induce currents that could lead to shocks, res, or injury.

The electrode tip may remain hot enough to cause burns after the

electrosurgical current is deactivated.

When not in use, place accessories in a clean, dry, nonconductive, and highly

visible area not touching the patient. Inadvertent contact with the patient

may result in burns.

Ensure that the insulation of conventional, nonshielded disposable and

reusable laparoscopic instrumentation is intact. Compromised insulation of

nonshielded instruments may lead to shocks or burns to the patient or surgical

personnel.

14 of 44

Warnings and Cautions (continued)

When using laparoscopic instrumentation with metal cannulas, the potential

exists for abdominal wall burns to occur in the event of direct electrode tip

contact to the cannula.

Inspect cords for breaks, cracks, and/or nicks. If any are present, do not use.

Failure to observe this precaution may result in injury or electrical shock to the

patient or operating personnel.

Damaged external insulation on instruments AND incorrect setup of the

EndoShield 2 may result in a risk of unintended patient burn. Do not use

product having damaged insulation.

When an alarm is presented by the EndoShield 2, discontinue use of

electrosurgery immediately. Find the cause of the alarm and correct it before

continuing use.

Damaged internal insulation of the instrument, or loss of shield continuity, may

activate the EndoShield 2 alarms. For maximum patient safety, discontinue use

of the instrument if this occurs.

A single AEM instrument must be the sole conductor of energy to tissue. Do

not conduct energy by touching an AEM instrument to a second instrument

contacting tissue. The second device will not be protected from capacitive

coupling and insulation failure.

Caution:

Read the instructions, warnings, and cautions provided with the EndoShield

2 accessories before using. Their specic instructions are not included in this

manual.

AEM Monitoring will not function without the use of a dual-area patient return

electrode and an electrosurgical generator equipped with contact quality

monitoring patient safety technology.

No attempt should be made to reprocess this device.

Electromagnetic Compatibility (EMC) Hazards

For EMC specication tables, refer to the Technical Specications section.

Caution:

Use of accessories, transducers, and cables other than those specied, with

the exception of transducers and cables sold by the manufacturer of the

Equipment or System as replacement parts for internal components, may

result in increased Emissions, or decreased Immunity of the Equipment

orSystem.

EndoShield 2 15 of 44

Technical Specications

Monopolar Operating Mode

The EndoShield 2 detects improper setup conditions and detects operative faults

by providing a monitored pathway for the current which is owing from the shield

to the patient return electrode. The fault condition is indicated on the front of the

EndoShield 2 and the ow of energy is interrupted from the electrosurgical generator

to the AEM instrument.

Functional Characteristics

Monopolar Setup Fault Detection

If the return electrode is disconnected, or the wrong type of return electrode is

connected, no symbols illuminate on the front of the EndoShield 2.

If an AEM foot-control instrument is not connected to the EndoShield 2, or not

connected properly, the illuminates RED to identify the setup fault.

Monopolar Operative Fault Detection

If there is excessive shield current or arcing between the shield and the active

electrode causing an operative fault, the illuminates CONTINUOUS RED for 10

seconds to identify an insulation fault, and the EndoShield 2 interrupts the ow of

energy from the electrosurgical generator to the AEM instrument for 10 seconds.

Radio Frequency Current Sensing

Current-sensing and spark detection are provided. Minimum electrosurgical

generator output for reliable insulation fault detection: 20 Watts.

Shield Cable and Return Electrode Switch Threshold

50 ohms ± 40%.

Indicators and Alarm Functions

CONTINUOUS GREEN Indicates that the EndoShield 2 Burn Protection

System is fully operational.

CONTINUOUS RED

During setup, indicates that the AEM instrument is

not properly connected.

During use, indicates that the instrument in use has

an unsafe operating condition. Indicates that there

is excessive current or arcing between the active

electrode and the shield. Once triggered in this

condition, illuminates RED for 10 seconds.

FLASHING GREEN Indicates a low battery condition.

FLASHING RED Indicates a dead battery condition.

16 of 44

Technical Specications (continued)

Connectors and Cables

Return Electrode Receptacle:

A dual pin receptacle on the front of the EndoShield 2. The Return Electrode

Receptacle connects a dual-area patient return electrode to the EndoShield 2.

Return Electrode Plug:

A single pin plug on the rear of the EndoShield 2. The Return Electrode Plug connects

to the electrosurgical generator's patient return electrode receptacle.

AEM Cord Connector:

The AEM Cord Connector connects the EndoShield 2 to an AEM instrument cord.

Foot-Control Plug:

A single active pin that connects the EndoShield 2 to the electrosurgical generator’s

footswitch accessory receptacle.

Maximum Electrosurgical Generator Voltage

4.1 kV peak.

Electrical Characteristics

Power Source

Lithium Battery, 3V CR2.

Patient Leakage Current

Source or sink leakage current is 10 μA maximum.

Dimensions and Weight

External Dimensions

4” tall x 2” wide x 2.5” deep, excluding integrated cords.

AEM Instrument Connector: 7 inch cord length.

Foot-Control Plug: 6 inch cord length.

Weight

140 g (5 oz).

Environmental Characteristics

Operating Temperature

59° to 104° F (15° to 40° C).

Storage and Transport Temperature

-13° to 140° F (-25° to 60° C).

Operating, Storage and Transport Humidity

5% to 95% relative, non-condensing.

Atmospheric Pressure (Operating)

70 - 110 kPa.

EndoShield 2 17 of 44

Technical Specications (continued)

Standards and IEC Classications

Internally Powered Equipment per IEC 60601-1/EN 60601-1

Equipment operates from an internal electrical power source.

Debrillator Protected Equipment

The electrosurgical generator provides debrillator protection. The Endoshield 2

does not compromise this protection.

Caution: Ordinary equipment is not protected against the ingress of water.

Caution: Medical Electrical Equipment needs special precautions regarding

electromagnetic compatibility (EMC) and needs to be installed and put into service

according to the EMC information provided herein.

Caution: Portable and mobile RF communications equipment can aect Medical

Electrical Equipment.

Electromagnetic emissions and immunity per IEC 60601-1-2/EN 60601-1-2

Guidance and Manufacturer’s Declaration –Emissions

The EndoShield 2 is intended for use in the electromagnetic environment specied below. The

customer or user of the EndoShield 2 should ensure that it is used in such an environment.

Emissions Test Compliance Electromagnetic Environment –Guidance

RF emissions

CISPR 11

Group 1 The EndoShield 2 uses RF energy only for its

internal function. Therefore, its RF emissions

are very low and are not likely to cause any

interference in nearby electronic equipment.

RF emissions

CISPR 11

Class B

The EndoShield 2 is suitable for use in all

establishments, including domestic, and those

directly connected to the public low-voltage

power supply network that supplies buildings

used for domestic purposes.

Harmonics

IEC 61000-3-2

N/A

Flicker

IEC 61000-3-3

N/A

18 of 44

Technical Specications (continued)

Guidance and Manufacturer’s Declaration –Immunity

The EndoShield 2 is intended for use in the electromagnetic environment specied below. The

customer or user of the EndoShield 2 should ensure that it is used in such an environment.

Immunity Test IEC 60601 Test Level Compliance Level Electromagnetic Environment –

Guidance

Electrostatic

Discharge (ESD)

IEC 61000-4-2

±6kV Contact

±8kV Air

±6kV Contact

±8kV Air

Floors should be wood, concrete

or ceramic tile. If oors are

synthetic, the r/h should be at

least 30%.

Electrical Fast

Transient (EFT)

IEC 61000-4-4

±2kV Mains

±1kV Input/Output

(I/Os)

N/A Mains power quality should be

that of a typical commercial or

hospital environment.

Surge

IEC 61000-4-5

±1kV Dierential

±2kV Common

N/A Mains power quality should be

that of a typical commercial or

hospital environment.

Voltage Dips/

Dropout

IEC 61000-4-11

>95% Dip for

0.5 Cycle

60% Dip for

5 Cycles

30% Dip for

25 Cycles

>95% Dip for

5 Seconds

N/A Mains power quality should be

that of a typical commercial or

hospital environment. If the user

of the EndoShield 2 requires

continued operation during

power mains interruptions,

it is recommended that the

EndoShield 2 be powered from

an uninterruptible power supply

or a battery.

Power

Frequency

50/60Hz

Magnetic Field

IEC 61000-4-8

3A/m 3A/m Power frequency magnetic

elds should be that of a

typical commercial or hospital

environment.

EndoShield 2 19 of 44

Technical Specications (continued)

Guidance and Manufacturer’s Declaration –Immunity

The EndoShield 2 is intended for use in the electromagnetic environment specied below. The

customer or user of the EndoShield 2 should ensure that it is used in such an environment.

Immunity Test IEC 60601 Test Level Compliance Level Electromagnetic Environment –

Guidance

Portable and mobile

communications equipment

should be separated from the

EndoShield 2 by no less than the

distances calculated/listed below:

Conducted RF

IEC 61000-4-6

3 Vrms

150 kHz to 80 MHz

N/A D=(3.5/V1)(Sqrt P)

150kHz to 80MHz

Radiated RF

IEC 61000-4-3

3 V/m

80 MHz to 2.5 GHz

(E1)=3V/m D=(3.5/E1)(Sqrt P)

80 to 800 MHz

D=(7/E1)(Sqrt P)

800 MHz to 2.5 GHz

where P is the max power in

watts and D is the recommended

separation distance in meters.

Field strengths from xed

transmitters, as determined by

an electromagnetic site survey,

should be less than the compliance

levels (V1 and E1).

Interference may occur in the

vicinity of equipment containing a

transmitter.

Recommended Separation Distances for the EndoShield 2 Burn Protection System

The EndoShield 2 is intended for use in the electromagnetic environment in which radiated

disturbances are controlled. The customer or user of the EndoShield 2 can help prevent

electromagnetic interference by maintaining a minimum distance between portable and mobile

RF Communications Equipment and the EndoShield 2 as recommended below, according to the

maximum output power of the communications equipment.

Max Output Power

(Watts)

Separation (m)

150kHz to 80MHz

D=(3.5/V1)(Sqrt P)

Separation (m)

80 to 800 MHz

D=(3.5/E1)(Sqrt P)

Separation (m)

800 MHz to 2.5 GHz

D=(7/E1)(Sqrt P)

0.01 0.11667 0.11667 0.23333

0.1 0.36894 0.36894 0.73785

1 1.1667 1.1667 2.3333

10 3.6894 3.6894 7.3785

100 11.667 11.667 23.333

20 of 44

Limited Warranty

Express Warranty: ENCISION hereby warrants to Buyer that products purchased

hereunder shall be free from defects in material and workmanship under normal

use and service, as specied in ENCISION’s Instructions for Use provided with

product, or until the labeled use by date.

Disclaimer: The express warranties set forth in this agreement are in lieu of,

and buyer hereby expressly waives, all other guarantees and warranties of

any kind, whether express, implied or statutory including, without limitation,

merchantability, tness for particular purpose, non-infringement or by sample, and

all such other warranties are hereby disclaimed and excluded by ENCISION. The

sole and exclusive remedy for breach of ENCISION’s warranty of the products shall

be as stated herein.

Exclusions: The express warranty set forth above specically excludes and does

not apply to defects (i) caused through no fault of ENCISION during shipment to

or from Buyer, (ii) caused by modications or alterations made to the products

by Buyer or any third party (iii) caused by unauthorized repair or maintenance

performed on the products by Buyer or any third party, (iv) caused by the failure of

Buyer to comply with any of the return procedures specied below, or (v) damaged

by excessive current, temperature, physical stress or other deviation from the

applicable environmental specications.

Limitation of Remedies: ENCISION’s sole obligation and Buyer’s exclusive remedy

for any breach of warranty is limited to the repair or replacement, at Encision’s

option, of any warranted product that is returned to ENCISION in its standard

shipping container or properly packed in accordance with ENCISION’s packing

procedures, freight prepaid, where ENCISION’s examination shows the product

to have failed under normal use. If ENCISION’s examination discloses that the

returned product is not defective within the terms of this warranty, Buyer shall

be subject to a $200.00 charge per individual product for testing expenses

incurred by ENCISION and the product will be returned to Buyer, freight collect.

Such repair or replacement and reshipment at ENCISION’s expense will be

Buyer’s sole and exclusive remedy for such defect. ENCISION will pay shipping

charges for the repaired or replaced from ENCISION’s factory to Buyer’s location.

If,notwithstanding the foregoing, Buyer ships any product to ENCISION’s factory

freight collect, then ENCISION shall ship the repaired or replaced product freight

collect.

Warranty Procedures: Buyer shall request authorization from ENCISION prior to

the return of each defective product for repair or replacement by ENCISION. Upon

such request, ENCISION shall provide the address of the facility to which such

product must be returned, together with Return Material Authorization (RMA)

tracer number. ENCISION may, at its sole option, employ new or used parts for

products to make such repair or replacement.

Stored Data: ENCISION shall not be liable for any loss or damage to any data

stored in any product, including, without limitation, any data loss or damage

resulting from any malfunction or defect or any loss or damage resulting from

any inspection, repair, refurbishment, reconditioning or testing of the product

or incurred in connection with transportation of the product to ENCISION or

ENCISION’s authorized repair center.

Table of contents

Languages: