END ARMATUREN TA Series Technical document

Butterfly Valves

Mounting and Operating Manual

END-Armaturen GmbH & Co. KG

Postfach (PLZ 32503) 100 341 · Oberbecksener Str. 78 · D-32547 Bad Oeynhausen · Telefon (05731) 7900-0 · Telefax (05731) 7900-199 · http://www.end.de

2 http://www.end.de 11/02

© by END-Armaturen GmbH & Co. KG

All rights reserved. END-Armaturen GmbH & Co. KG claims copyright over this documentation.

This documentation may neither be altered, expanded, reproduced nor passed to third parties without the written

aggreement of END-Armaturen GmbH & Co. KG. This restriction also applies to the corresponding drawings.

END-Armaturen GmbH & Co. KG has the right to change parts of the butterfly valves at any time without prior

or direct notice to the client. The contents of this publication are subject to change without notice.

This publication has been written with great care. However, END-Armaturen GmbH & Co.KG cannot be held

responsible, either for any errors occuring in this publication or for their consequences.

The products are specified by the statements in this documentation; no assurance of the properties is given.

END-Armaturen GmbH & Co. KG

Oberbecksener Straße 78

D-32547 Bad Oeynhausen

Telefon: 05731 / 7900 - 0

Telefax: 05731 / 7900 - 199

Internet: http://www.end.de

E-Mail: [email protected]

Edition: 11/02

Impressum

11/02 http://www.end.de 3

Contents

Contents

1 Foreword 4

2 General Advice 5

2.1 Validity 5

2.2 Inward monitoring 5

2.3 Complaints 5

2.4 Guarantee 5

2.5 Symbols and their signification 6

3 Safety advice 7

3.1 Personal safety 7

3.1.1 Safety advices for mounting 7

3.1.3 Safety advice for adjustment / starting 8

3.1.4 Safety advice for maintaining / repairing 9

3.2 Device safety 10

4 Name-plate 11

5 Butterfly Valve 12

5.1 General 12

5.2 Corresponding use 12

5.3 Operation 12

5.4 Mounting/Disassemble 12

5.4.1 Mounting of the snap-in disc and the handle 13

5.4.2 Mounting of a wafer type butterfly valve 15

5.4.3 Mounting of a LUG type butterfly valve 16

6 Maintenance 17

4 http://www.end.de 11/02

1 Foreword

Dear customer,

Dear assembler / user,

these operation and installation manuals are intended to give you the knowledge, which is

necessary for you to be able to carry out the mounting and adjustment of the butterfly valves rapa-

idly and correctly.

Please read these instructions carefully and pay particular attention to the advice and warning

notes.

Only instructed and qualified mechanician should mount, adjust or maintain the butterfly valves.

If you have any questions in relation to the butterfly valves we shall be pleased to answer them.

The telephone number will be found on the inside cover of these operation and installation

manual.

Yours

END-Armaturen GmbH & Co. KG

Foreword

11/02 http://www.end.de 5

2 General Advice

2.1 Validity

This mounting and installation manual is valid for the standard versions of the butterfly valves

TA, WA, WM and their variants

2.2 Inward monitoring

Please check directly after delivery the butterfly valves for any transport damages and deficiencies

and with reference to the accompanying delivery note the number of parts.

Do not leave any parts in the package.

2.3 Complaints

Claims for replacement or goods which relate to transport damage can only be considered valid if

the delivery company is notified without delay.

In case of returns (because of transport damage / repairs), please make a damage protocol and

send the parts back to the manufacturer, if possible in the original packaging.

In case of a return, please mention the following:

• Name and address of the consignee

• Stock-/ ordering-/ article-number

• Description of the defect

2.4 Guarantee

For our butterfly valves we give a guarantee period in accordance with the sales contract.

The end of the normal duration of life of the wearing parts represents no defect.

The warrenty and guarantee rules of END-Armaturen GmbH & Co. KG are applicable.

General Advice

6 http://www.end.de 11/02

2.5 Symbols and their signification

Paragraphs which are identified with this symbol contain very important advices; this also includes

advices for averting health risks. Observe these paragraphs without fail!

Paragraphs which are identified with this symbol contain very important advices, this also includes

how to avoid damage to property. Observe these papgraphs without fail!

This symbol indicates paragraphs which contain comments / advices or tips.

This spanner identifies the description of actions which you should carry out.

Symbols and their Signification

11/02 http://www.end.de 7

3 Safety advice

Depending on the technical circumstances and the time under and at which the butterfly valves

are mounted, adjusted and commissioned, you must take into account particular safety aspects in

each case!

If, for example, a butterfly valve works a slide in an operational chemical plant, the potential

hazards of commissioning have another dimension from that when this is only being carried out for

test purposes an a „dry“ part of the plant in the assembly room!

Since we do not know the circumstances at the time of the mounting/adjustment/commissioning,

you may find advices on hazards in the following descriptions which are not relevant to you.

Please observe (only) the advices which applies to your situation!

3.1 Personal safety

3.1.1 Safety advices for mounting

We wish to point out expressly that the mounting, adjusting and at accessories the pneumatical

and eletrical installation of the butterfly valves must be carried out by trained specialist person-

nel having mechanical, pneumatical and electrical knowledge!

Secure that the machine / plant come up to the Machinery Directice after the mounting and instal-

ling of the butterfly valves.

Switch off all the devices / machines / plant affected by mounting or repair.

If appropriate, isolate the devices / machines / plant from the mains.

Check (for example in chemical plants) whether the switching off of devices / machines / plant

will cause potential danger.

If appropriate, in the event of a fault in the butterfly valve (in a plant which is in operation) inform

the shift forman / safety engineer or the works manager without delay about the fault, in order,

for example, to avoid an outflow / overflow of chemicals or the discharge of gases in good time

by means of suitable measures!

Before mounting or repairing, remove the pressure from pneumatic / hydraulic devices / machi-

nes / plant.

If necessary, set up warning signs in order to prevent the inadvertent starting up of the devices /

machines / plant.

Observe the respective relevant professional safety and accident prevention regulations when

carrying out the mounting / repair work.

Check the correct functioning of the safety equipment (for example the emergency push off but-

tons/ safety valves, etc)!

Safety Advice

8 http://www.end.de 11/02

3.1.3 Safety advice for adjustment / starting

As a result of the starting (pneumactic, electric or by hand) of the butterfly valves the flow of

gases, steam, liquids, etc. may be enabled or interrupted! Satisfy yourself that, as a result of the

starting or the test adjustment no potential hazards will be produced for the personnel or the

environment!

If necessary, set up warning signs in order to prevent the inadvertent starting up or shutting down

of the device / machine / plant.!

By ending the adjustment check the correct function and should the occasion arise the position

of the butterfly valve.

Check the function of the limit switches (option)!

Check, whether the butterfly valve will be closed totally, if the control signals the appropriate

limit stop!

Through suitable measures, prevent links being trapped by moving actuating elements!

Check the right function of all safety devices (for example emergency push off buttons / safety

valves)!

Carry out the starting and the adjustments only in accordance with the instructions discribed in

this documentation!

Adjusting switchs on butterfly valves with options (e.g. actuators, solenoid valves, limit swit-

ches) there is the risk that live parts (230 V AC~) can be touched!

Therefore the adjustments must be carried out only by the electrican or a person having adequate

training, who is aware of the potential hazard!

Safety Advice

11/02 http://www.end.de 9

3.1.4 Safety advice for maintaining / repairing

Do not carry out any maintenances / repairs if the butterfly valve will be under pressure.

Before disassembling the butterfly valve some essential points should be clarified!

• Will the butterfly valve to be disassembled be replaced by another immediately?

• If appropriate, does the production process of the plant needed to be stopped?

• Is it necessary to inform specific personnel about the disassmbly?

If necessary, inform the shift foreman/ safety engineer or the manager about the maintenance

or repair without delay in order, for example, to avoid an outflow/ overflow of chemicals or a

discharge of gases in good time by means of suitable measures!

You have to relieve the pressure in the pipes in which the butterfly valve is mounted.

Switch off pilot pressure and the power supply and relieve the pressure in the pipes.

If necessary set up warning signs in order to prevent

• the inadvertent starting up of the devices/machines/plants in which the butterfl

valve is mounted

• the switching on of pilot medium supply, pilot power supply and/or the power supply

of actuators and accessories.

In case of defect in the butterfly vavle make contact to the supplier. The telephone number will be

found on the back cover of these mounting and installation manual.

If you ascertain a damage of the butterfly valve, isolate the device from the mains. Please observe

the safefy advices.

Do not mount, start or adjust the butterfly valve if itself, the pipes or a mounted actuator will be

damaged.

After the maintenance or repair check the right function of the butterfly valve and the tightness

of the pipe connections.

Also check the function of the accessories e.g. actuators, limit switches, etc.

Safety Advice

10 http://www.end.de 11/02

3.2 Device safety

The butterfly valves

• are quality products which are produced in accordance to the recognized industrial

regulations.

• left the manufacturer`s work in a perfect safety condition.

In order to maintain this condition, as installer / user you must carry out your task in accordance

with the description in these instructions, technically correctly and with the greatest possible

precision .

We assume, as a trained specialist you are having mechanical and electrical knowledge!

Satisfy yourself that the butterfly vales will only be used within their admissible limiting value

(see the technical data) .

The butterfly valves must be used only for a purpose corresponding to their construction!

The butterfly valves must be used within the values specified in the technical data!

The operating of the butterfly valve outside the nominal temperature range could destroy the

sealings and the bearings.

The operating of the butterfly valves outside the nominal pressure range could destroy the inner

parts and the body.

Do not mount, start or adjust the butterfly valve if itself, the pipes or a mounted actuator will be

damaged.

After the maintenance or repair check the right function of the butterfly valve and the tightness

of the pipe connections.

Also check the function of the accessories e.g. actuators, limit switches, etc.

The assign accessories for the butterfly valves, e.g. actuator, solenoid valve, limit switch, etc.

will be estimate at their potenial ignition sources speparatly.

If the accessories are electrical parts we will enclose the declaration of conformity of our sup-

pliers. The declaration contains the number of the EC-Type Examination Certificate und the name

and the number of the notified body who make out the certificate.

Safety Advice

11/02 http://www.end.de 11

Name-plate

4 Name-plate

The butterfly valves will be provided with a name-plate, which permitts a definite identification of the butterfly

valve and shows the most important technical data to you. The name-plate should not displaced or changed.

Art.Nr. article number of the butterfly valve

Serie serial or production number

Betriebsdruck (PS) max. pressure range of the butterfly valve [bar]

Temperatur (TS) max. temperature range of the butterfly valve

Größe (DN) connection size

Prüfdruck (PT) testing pressure of the butterfly valve

Fluidgruppe allowed fluid group of the butterfly valve

Herstellung manufacturing date of the butterfly valve

Fig. 4.1 - Name-plate

END-Armaturen GmbH & Co. KG

D-32547 Bad Oeynhausen

+49 (0)5731 - 7900-0 www.end.de

Art.Nr.: TA534010

Serie: 313857

Betriebsdruck (PS): 16 bar

Temperatur (TS): -20°C ... +65°C

Größe (DN): 100

Prüfdruck (PT): 24 bar

Fluidgruppe: 1

Herstellung: 05.2003

0062

12 http://www.end.de 11/02

5 Butterfly Valve

5.1 General

Before you are mount, adjust, start, operate or disassemble a butterfly valve you have to read

the

Safety advices

If you have nor read the safety advices until now, read this important advices now and turn back

to this point.

5.2 Corresponding use

Butterfly valves will be used to control and to cut off media flow.

It should only be used clean liquids and gases, on which the material of the butterfly valve will be

resistant. It should also be used for pulverised and pasterised media and pouring goods if it suited

to the butterfly valve. Pollution or using outside the nominal pressure range and/or the nominal

temperature range should causes damages on the butterfly valve especially on the seals.

5.3 Operation

The butterfly valve will be opened or closed by using a handle or actuator (option). The snap-in

handle of a hand actuated butterfly valve have to been snaped out during the operation. The disc

has 9 resp. 10 snap-in positions in which the lever could click in, to prevent an inadvertent mis-

place.

During the closing operation take care that there won`t be insert any objects or limbs into the

armature. Heavy injuries or damages will be the consequence. If it`s necessary you have to

install a protective device.

5.4 Mounting/Disassemble

The mechanical installation of the butterfly valves differs by the variants of the body. The wafer

type butterfly valve will be squeezed between to flanges and the lug type is able to be mounted

directly on flanges.

Butterfly Valves

11/02 http://www.end.de 13

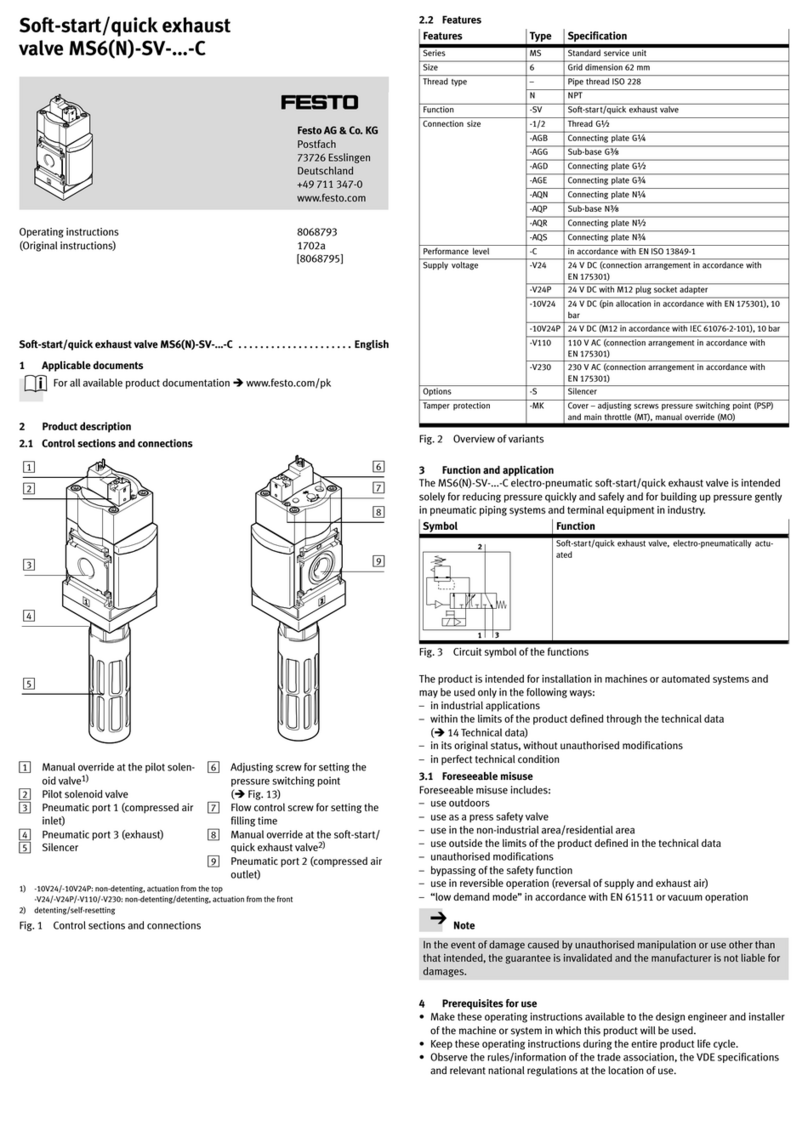

5.4.1 Mounting of the snap-in disc and the handle

At butterfly valves which will be actuated by hand the snap-in disc and the handle will be enclosed

the package. Before installing the butterfly valve you have to mount the handle and the snap-in

disc.

Observe the flow direction: the handle should point at the flow direction.

Remove the package and the protective devices (eg. caps and plugs). Take care that there will be

no parts of the package or other parts in the armature.

Clean up the pipes in which the butterfly valve will be mounted. Pollution could affect the safety in

operation and the duration of life of the butterfly valve.

Avoid stress in case of non align pipes.

The flanges have to be align parallel and centircally and must have carefully worked surfaces.

Butterfly Valves

Fig. 5.1 - Butterfly valves, mounting of the snap-in disc and the handle (Fig.: Art. TA534010)

operation position

o.k.

o.k.

14 http://www.end.de 11/02

The butterfly valve will be squeezed between two flanges. The sealing takes places by the sleeve

of the butterfly valve other sealing compounds are not allowed. Take care that there won`t be

insert any rests of sealing compounds or other pollution into the armature.

The flanges would not been welded into the pipes if the armature is mounted. The increasing

temperatures will destroy the sleeve of the butterfly valve.

At polluted media we recommend to install the butterfly valve horizontally. In this case the lower

disc half have to close in the flow direction.

Fig. 5.2 - Butterfly valves, mounting at pollute media (Fig.: Art. TA534010)

o.k.

Butterfly Valves

sectional drawing

11/02 http://www.end.de 15

5.4.2 Mounting of a wafer type butterfly valve

In the following description we assume that you have welded the flanges at the end of the pipes

and they are cooled down.

Adjust the disc in a not totally closed position so that the disc won`t be stand out off the body.

Put the butterfly valve between the flanges. The butterfly have to been insert between the flanges

easily so that the sleeve won`t be destroyed.

Align the butterfly valve and put fit screws through the borings of the flanges.

Screw nuts onto the screws and tighten them equaly slightly and crosswise.

Check wheather the disc of the butterfly valve will be open and close easily. Let the disc a little

bit open.

Tighten all the screws crosswise and check the function of the butterfly valve again. Observe the

max. torque of the screws.

Check the tightness of all the connections.

Butterfly Valves

Fig. 5.3 - Butterfly valves, mounting of a wafer type butterfly valve (Fig.: Art. TA534010)

disc not

disc not

totally

totally

closed

closed

!

!

sectional drawing

don´t use

don´t use

flange sealings

flange sealings

16 http://www.end.de 11/02

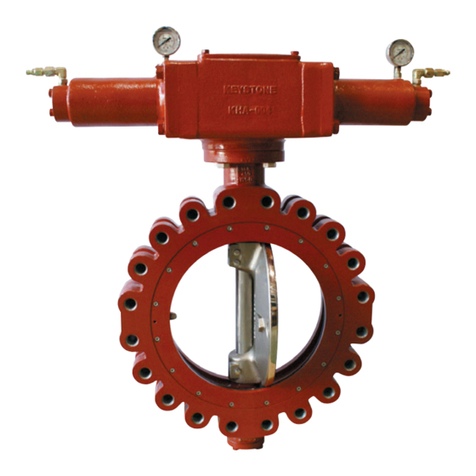

5.4.3 Mounting of a LUG type butterfly valve

In the following description we assume that you have welded the flanges at the end of the pipes

and they are cooled down.

Adjust the disc in a not totally closed position so that the disc won`t be stand out off the body.

Put the butterfly valve in front of the flange and tighten the screws slightly and crosswise.

Check wheather the disc of the butterfly valve will be open and close easily. Let the disc a little

bit open.

Tighten all the screws crosswise and and check the function of the butterfly valve again. Observe

the max. torque moment of the screws.

Check the tightness of all the connections.

You have to install a protective device, to prevent the insertion of any objects or limbs into the

butterfly valve.

Install protectivedevices, to prevent a uncontrolled outflow of the media.

Attention: When using the butterfly valve as end piping the nominal working pressure will be

decreased.

Fig. 5.4 - Butterfly valves, mounting of a LUG - type butterfly valve (Fig.: Art. TA534010/M)

disc

disc

not

not

t

t

ot

ot

ally c

ally c

losed

losed

!

!

sectional drawing

don`t use

don`t use

flange sealing

flange sealing

Butterfly valves

11/02 http://www.end.de 17

6 Maintenance

Before you maintain or shut down the butterfly valve you have to read the

Safety advice

If you have nor read the safety advices until now, read this important advices now and turn back

to this point.

On normal accounts the butterfly valve is maintenance free.In periodical turns the controlling of

the function and the tightness should happen:

• Check the tightness of stem seals

• Check the tightness of the sleeve

• Check the wear of the sleeve

At a leaky stem seal or sleeve you have to disassemble the butterfly valve and sent it back to the

manufacturer.

Don`t try to disassemble the sleeve of the butterfly vale by yourself. Heavy injuries or damages

could be the consequence.

In case of a defect of the valve make a contact to the supplier. The telephone number will be

found on the back or these operation and installation manual.

If you determinate that there is a demage to the valve switch off the device/ machine/ plant!

However before doing this, it is essential to refer to the

Safety advice.

Butterfly Valves

END-Armaturen GmbH & Co. KG

Postfach (PLZ 32503) 100 341 · Oberbecksener Str. 78 · D-32547 Bad Oeynhausen (Germany) · Telefon +49 - 5731 - 7900-0 · Telefax +49 - 5731 - 7900-80 · http://www.end.de

Declaration in conformity

as defined by Pressure-Equipment-Directive 97/23/EG

Herewith we declare that the supplied articles:

AA, AB, AC, AD, AG, AK, AR, BE, BF, BG, BH, BK, CA, CB, CD, CK, CU, CV, CW, DK, EA, EA, EB, EK, FG,

HK, IC, IG, IK, IL, KA, KU, MA, MB, MD, MR, NG, NK, PB, PD, RG, RK, RM, SD, SK, SV, TA, TB, TC, TD,

TE, TF, TH, TR, UV, VA, VC, VD, VH, VK, VL, VM, VN, VO, VS, VT, VU, WG, ZA, ZD, ZE, ZF, ZG, ZK, ZP,

ZR, SONV, and all variations of these articles

of the company END-Armaturen GmbH & Co. KG

D-32547 Bad Oeynhausen

Germany

are in conformity with the regulations of the directive 97/23/EG.

Applied conformity assessment PED: Modul H.

Notified body for conformity assessment PED an Quality-Management-System:

Bureau Veritas S.A.

Paris / Frankreich

Kennzeichen 0062

Applied harmonized standards, in particular:

DIN 3840:1982 Armaturengehäuse

Festigkeitsberechnung gegen Innendruck

On behalf Bad Oeynhausen, 20. Juli 2004

Friedhelm König Michael End

Technical Manager Quality Manager

(1)

(2)

(3)

(4)

(5)

(6)

(8)

(9)

(7)

20 http://www.end.de 11/02

We are developing and producing sophisticated industrial fittings proving every day in the field.

This is supported by our fullfilling the requirements of Quality Standards DIN EN ISO 9001.

Satisfied partners and success are proving the investment for quality and protection of the

environments is worthwhile.

END-ARMATUREN GMBH & CO. KG END-AUTOMATION GMBH & CO. KG

OBERBECKSENER STR.78 OBERBECKSENER STR.78

D-32547 BAD OEYNHAUSEN D-32547 BAD OEYNHAUSEN

POSTFACH (PLZ 32503) 100 341 POSTFACH (PLZ 32503) 100 342

TELEFON +49 (0) 5731 / 7900-0 TELEFON +49 (0) 5731 / 7901-0

TELEFAX +49 (0) 5731 / 7900-199 TELEFAX +49 (0) 5731 / 7901-999

INTERNET http://www.end.de INTERNET http://www.end.de

PRODUCTS

This manual suits for next models

2

Table of contents

Other END ARMATUREN Control Unit manuals

Popular Control Unit manuals by other brands

Grundfos

Grundfos PM 1 Installation and operating instructions

FMS

FMS CMGZ411 operating manual

ICP DAS USA

ICP DAS USA M-7033D quick start guide

Cabletron Systems

Cabletron Systems SmartSwitch 9500 Hardware and installation guide

Festo

Festo MS6(N)-SV-...-C operating instructions

Dungs

Dungs SV-DLE 1005/604 Installation instructions manual

ADTRAN

ADTRAN ATLAS 800 Series Module QUAD E1 user manual

Emerson

Emerson KEYSTONE V30 Series Installation & operation manual

Sunshine Solar

Sunshine Solar ETFE user manual

IDEC

IDEC HR6S Series Original instructions

Inbal Valves

Inbal Valves 700D Series Technical data

IFM Electronic

IFM Electronic AC2380 operating instructions