Cloud LM-2 Series Instruction Manual

Clearly better sound

Technical Note

Connecting an LM-2 to a Line Input on a Z4MK4/Z8MK4

Preamble:

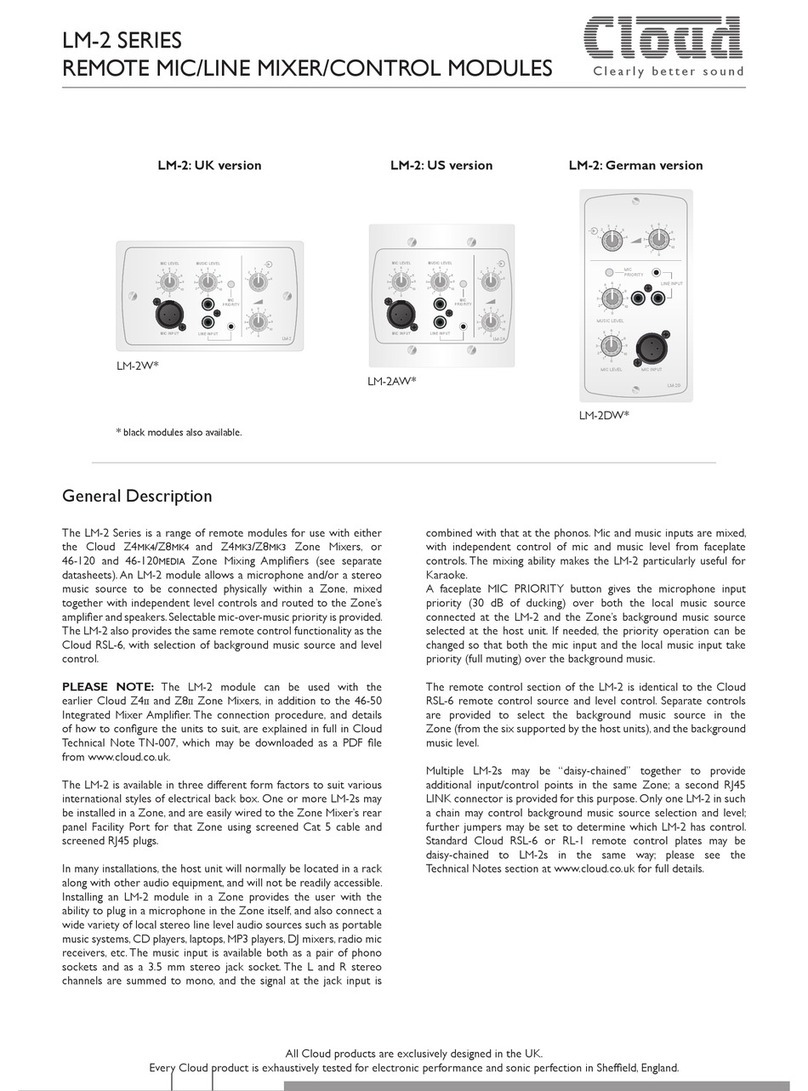

The LM-2* is a remote module for use with Cloud host units tted with an RJ45 Facility Port. It combines

the functions of a remote input connection plate, local audio mixer and a remote control for the host unit’s

background music.

Microphone and stereo line inputs are provided, with individual level controls. The stereo input is summed

to mono, and then mixed with the mic input. The LM-2 is designed to be connected to a Facility Port on

the host unit using screened Cat 5 cable and shielded RJ45 connectors. An audio source connected at the

LM-2 module is then routed into the Zone to whose Facility Port it has been connected (normally the one

where the LM-2 is installed).

It is sometimes useful to be able to make the remote audio source available to every Zone supported by

the host unit, rather than just the one local to the LM-2. To achieve this, the balanced audio signal from the

LM-2 needs to be connected to one of the host unit’s balanced line inputs instead of a Facility Port; it can

then be selected as the music source for each Zone where it is required, from the host unit’s front panel

(or from further LM-2 or RSL-6 Series remote control plates, if they are installed).

This Technical Note describes how to connect an LM-2 module to a balanced line input instead of a Facility Port.

Note that the LM-2 Installation Guide (supplied with each module) should also be referred to while making this

connection.

* The LM-2 is currently available in six style/nish variants: LM-2B, LM-2W, LM-2AB, LM-2AW, LM-2DB and LM-2DW. This Technical Note is

applicable to all variants; the wording “LM-2” is used throughout for brevity.

Applicable products:

Cloud Z4MK4 and Z8MK4 Zone Mixers are tted with

both an RJ45 Facility Port and balanced line inputs

and are thus suitable for the connection described in

this Technical Note.

Parts required:

•2 x screened RJ45 plugs

•Screened Cat 5 cable of the appropriate length

(host to module location)

•Short length 25 cm (12”) of twin-and-screen

audio cable

•9-way nylon terminal block (“choc-strip”) suitable

for 1.5 mm2 (6 A) cable

•Crimp ferrules (white)

•H15 silicone sleeves, 2 mm bore silicone sleeving

•Plastic enclosure to house terminal block with

two cable grommets (recommended but not

essential)

(Note that as the cable carries analogue audio, only screened

Cat 5 cable and shielded RJ45 connectors should be used.)

LM-2 front panel

MIC LEVEL

1

2

34

5

6

MUSIC LEVEL

LINE INPUT

MIC INPUT

LM-2

MIC

PRIORITY

1

4

5

2

3

67

9

10

8

0

1

4

5

2

3

67

9

10

8

0

1

4

5

2

3

67

9

10

8

0

TN-012

Clearly better sound

Required Skill Level: Low.

Ability to strip wire neatly, crimp RJ45 connectors,

and use of crimp ferrules.

Tools required:

RJ45 crimp tool, small wire cutters, wire stripper,

small screwdriver, ferrule crimp tool. A drill will also

be required if an enclosure is being used.

Procedure - wiring:

The procedure essentially consists of “breaking-out”

three cores of Cat 5 cable and wiring them to one

of the Z4/8MK4’s four balanced line inputs. A terminal

block housed in a plastic enclosure is used to make a

neat and mechanically robust set of connections.

Follow the wiring instructions in the LM-2 Installation

Guide, and install screened Cat 5 cable between the

host unit and the LM-2. Crimp a shielded RJ45 onto

each end of the cable according to the normal wiring

standard, which is included here for completeness:

At the LM-2 end, plug the RJ45 into the LM-2’s

OUTPUT connector.

Turn the host unit off, plug the RJ45 into the Facility

Port for the Zone in use, then cut the Cat 5 cable

approximately 15 cm (6”) back from the connector.

Strip the jacket back on both ends by about 5 cm

(2”), t H15 sleeves, and fan the cores out, including

the drain wire for the cable screen.

If the terminal block is to be housed in a plastic

container (recommended for neatness), pass

the cables through holes in the enclosure, tting

grommets in the holes rst. (The holes may need to

be drilled.)

FROM LM-2 IN

REMOTE LOCATION

TO FACILITY PORT

ON HOST UNIT

Screened Cat 5 cable

Plastic enclosure with

grommetted entry holes

As Cat 5 cores are invariably solid wires, it is strongly

recommended that crimp ferrules are tted to all

cores to make a mechanically robust connection.

White ferrules should be satisfactory for all the

connections.

Connect the cores into the terminal block as shown:

WT/OR

OR

WT/GN

GN

BL

WT/BL

WT/BN

BN

SCN

WT/OR

OR

WT/GN

GN

BL

WT/BL

WT/BN

BN

SCN

hot (‘+’)

cold (‘-’)

Cat 5 to Facility Port

Cat 5 from LM-2

1 32

Z4/Z8 Balanced Line Input

hot (‘+’)cold (‘-’) Note: Do not connect RJ45

Pins 1, 2 or 3 (Wt/Gn, Or & Wt/Or)

Twin-and-Screen

Audio Cable

9-way Terminal Block

Note that the White+Green core (RJ45 pin 3) should

not be connected in this particular application. This

core carries the VCA priority control voltage from

PIN USE CAT 5 CORE

1 Audio ‘cold’ phase (-) White + Orange

2Audio ‘hot’ phase (+) Orange

3 Priority VCA control White + Green

4 +V Blue

50 V White + Blue

6-V Green

7Music level control (0 to 10 V) White + Brown

8Music source select control (0 to 10 V) Brown

SCN GND for system music controls Connector shell

1

8

1

8

1

8

Clearly better sound

the LM-2 and use of the PRIORITY button on the

LM-2 will interfere with correct operation in this

case. Disconnecting Pin 3 disables the PRIORITY

switch.

Connect a suitable length of twin-and-screen audio

cable to the terminals carrying the orange pair from

the incoming Cat 5 cable. Do not connect the screen

at the terminal block end. Wire the other end to the

screw-terminal connector for any of Line Inputs 3, 4,

5 and 6 as shown:

PIN CONNECTION

1 Screen

2Signal ‘-’ (cold)

3 Signal ‘+’ (hot)

Note that Line Inputs 1 and 2 are unbalanced, and use

phono connectors on the Z4MK4 and Z8MK4. Only

make the connections as shown to Line Inputs 3 to 6.

When all connections are made, ret the lid on the

enclosure (if used).

Procedure – host conguration:

In order for the LM-2’s remote control section

(background music source and level controls) to

operate correctly, the host unit must be set for

remote control operation. Please refer to the

Z4/Z8MK4 Installation Guide for full details of how

to do this.

Operation

Once the connections have been made as described,

the audio source(s) connected at the LM-2 will be

available in any Zone by selecting the Line Input to

which the connection has been made as the Music

Source for the Zone.

In the Zone where the new “global” audio source is

connected to the LM-2, this selection will be made

using the MUSIC LEVEL control on the LM-2 itself,

and the volume in the Zone will be set by the adjacent

MUSIC LEVEL control.*

In all other Zones, the source can be selected either

by a remote control module or plate (e.g., LM-2 or

RSL-6) installed in the Zone, or - if remote controls

are not installed - by the Music Source controls on

the front panel.

In the same way, audio level can be adjusted by either

by a remote control module or plate, or the front

panel Music Level controls, as appropriate.

Note however, that the MIC LEVEL and MUSIC

LEVEL controls on the LM-2 module where the

source is connected now act as “Master” controls

and will alter the levels of the audio source in all

Zones.

In the example diagram shown on the following page,

the global source is connected to an LM-2 in Zone1;

the Cat 5 cable from the LM-2 is “broken out” to Line

In 3 on the Z4MK4 using the modication described

in this Technical Note. Zones 2 and 3 also have LM-2s

installed, but Zone 4 does not. To route the laptop

audio to all zones, Line In 3 must be selected as the

music source: in Zones 1, 2 and 3 this is done on

the LM-2 modules in each zone, but for Zone 4,

the selection must be made on the front panel of

the Z4MK4. The MUSIC CONTROL switches for

Zones 1, 2 and 3 must be set to REMOTE to enable

their remote control sections, while that for Zone

4 is left at LOCAL, so that the Zone 4 front panel

music controls remain operative.

From the above it will be seen that a practical

method of setting levels might be to rst turn the

Zone Music control on the LM-2 to which the

source is connected to maximum, and then increase

the MUSIC LEVEL until the volume in the Zone

is as high as is ever likely to be required. This will

provide a sensible setting for input gain, and the levels

in other Zones can then be adjusted individually.

* This assumes that the LM-2’s remote controls are in use and have thus

been enabled at the host. If they are not, the front panel Music Source

and Music Level controls should be set in a similar way.

Clearly better sound

E&OE

www.cloud.co.uk www.cloudusa.pro

Issue_1.0

MIC LEVEL

1

2

34

5

6

MUSIC LEVEL

LINE INPUT

MIC INPUT

LM-2

MIC

PRIORITY

1

4

5

2

3

67

9

10

8

0

1

4

5

2

3

67

9

10

8

0

1

4

5

2

3

67

9

10

8

0

MIC LEVEL

1

2

34

5

6

MUSIC LEVEL

LINE INPUT

MIC INPUT

LM-2

MIC

PRIORITY

1

4

5

2

3

67

9

10

8

0

1

4

5

2

3

67

9

10

8

0

1

4

5

2

3

67

9

10

8

0

MIC LEVEL

1

2

34

5

6

MUSIC LEVEL

LINE INPUT

MIC INPUT

LM-2

MIC

PRIORITY

1

4

5

2

3

67

9

10

8

0

1

4

5

2

3

67

9

10

8

0

1

4

5

2

3

67

9

10

8

0

Select Line In 3 for Zone 4

Adjust the laptop audio in

Zone 4 here

MUSIC CONTROL switches are set to

REMOTE for Zones 1, 2 & 3

MUSIC LEVEL control is “master” level

for laptop audio throughout system

Cat 5 from LM-2 in Zone 1 is “broken

out” to e.g., Line in 3

Adjust the laptop audio level in

Zone 3 here

Select Line in 3 for Zone 1

Source (laptop) connected to LM-2 in Zone 1

ZONE 3

ZONE 2

Cat 5

Cat 5

Cat 5

Select Line in 3 for Zone 2

Select Line in 3 for Zone 3

Adjust the laptop audio level in

Zone 1 here

Adjust the laptop audio level in

Zone 2 here

ZONE 1

Other manuals for LM-2 Series

1

Other Cloud Control Unit manuals