ENDEVCO 727 User manual

IM727 Rev A, Page 1 of 9

®

INSTRUCTION

MANUAL

For Model 727

PIEZORESISTIVE DROP TEST ACCELEROMETERS

IM727, Revision A

(07-10-13)

IM727 Rev A, Page 2 of 9

®

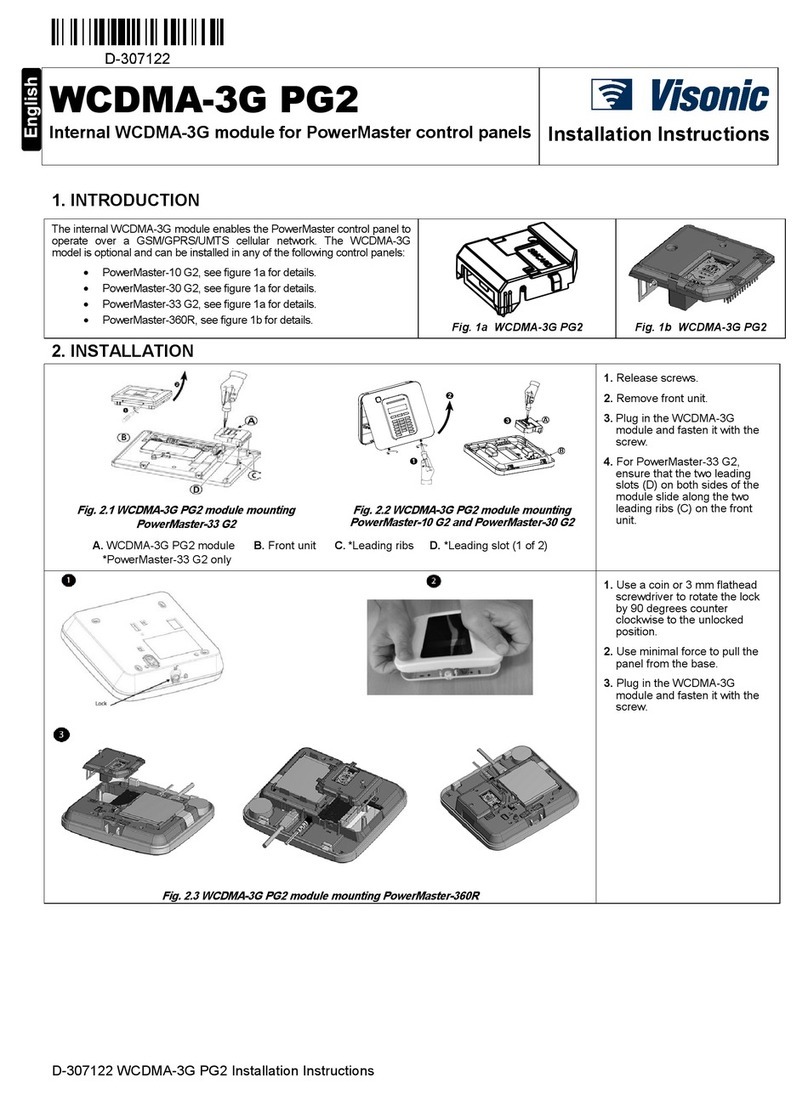

Wax mount,

single axis

undamped

727-60K

undamped

727-20K

undamped

727-6K

undamped

727-2K

Figure 1(a):

Model 727

Top View

Figure 1(b):

Model 727 Side

View

The Endevco® Model 727 is a family of rugged undamped piezoresistive accelerometers, offered in

a variety of ranges. It is designed for shock measurements in mobile

consumer electronic devices. Table 1 shows a summary of the current

Endevco offering of drop-test accelerometers. This instruction manual will supply technical detail

for the single- axis accelerometers in wax mount configuration.

Table 1: Endevco® Drop-Test Accelerometers.

In addition to being undamped, the 727 series has no mechanical stops, maximizing both bandwidth and

amplitude linearity. Its undamped characteristic allows it to be used in applications where the peak

acceleration is known and there is not a significant amount of out-of-band energy that could cause

enough resonance excitation to exceed the overrange limit of the accelerometer.

Due to the severe environment in which these accelerometers are tested, the user should carefully

read this instruction manual in its entirety.

A Calibration Certificate is included in the shipment of your Endevco® drop-test accelerometer.

Additionally, a product specification data sheet, if not already included in your shipment, can be

requested by contacting Endevco’s Application Engineering at +1 (866) ENDEVCO [+1 (866) 363-

3826] in North America, or your local sales representative.

(photos not to scale)

IM727 Rev A, Page 3 of 9

®

HANDLING PRECAUTIONS

Although undamped accelerometers are more susceptible to damage by handling, the follow

precautions should be taken when handling any accelerometer, whether it is damped or undamped.

The amplification factor (or Q) of the undamped accelerometer at the resonant frequency of its

seismic element can approach 100 (10 for the damped accelerometers). This means that if an

unmounted unit were dropped on a metal surface (such as a table or bench top) causing it to

experience a shock input of 2,000 g, the high-frequency content of the metal-to-metal impact could

excite the resonance frequency, resulting in an accelerometer response of 200,000 g (20,000 g for

the damped accelerometers). It has been shown that the accelerometers are more vulnerable to

damage in the unmounted state, as opposed to being mounted to a test subject of large mass. For this

reason the unmounted unit must be handled very carefully to avoid such fast rise time impacts.

Endevco® drop-test accelerometers are shipped in electrostatic discharge (ESD) safe packaging.

When handling any accelerometer it is always best practice to handle with ESD in mind. The

accelerometer should only be handled by properly grounded technicians (via wrist straps or heel

straps) at ESD safe work stations. If ESD damage does occur it will typically result in a large shift in

the zero measurand output (ZMO). If ESD damage is sufficiently high, complete accelerometer

failure is likely, showing up as an extremely large ZMO or an open leg of the Wheatstone bridge.

INITIAL CHECKOUT

Upon receipt, the accelerometer should be checked to ensure that it was not damaged in transit. A

simple resistance test is a quick way of verifying that all legs in the Wheatstone bridge sensing

element are intact.

Resistance Test – Open the accelerometer container and unwind a few inches of cable.

Measure the input resistance (red to black) and output resistance (green to white while

shorting red and black) with an ohmmeter and a pair of clips leads. The measured resistance

should be within the specified tolerance as listed on the product specification data sheet.

Typical specification for Model 727 input/output resistance is 650Ω ±

300Ω

If any of the above resistance measurements are not within the noted specification there may be a

problem with the accelerometer and the factory should be consulted for further troubleshooting.

MOUNTING SURFACE PREPARATION AND INSTALLATION

Special care should be taken to provide a smooth, clean mounting surface to ensure maximum

transmissibility of the shock input. Any small particles or debris trapped between the mounting

surface and the accelerometer will degrade the transmission of the high- frequency components of

the shock input. An uneven mounting surface could also preload the accelerometer and cause

IM727 Rev A, Page 4 of 9

®

unwanted static strain, resulting in possible zero shift during a shock measurement. The surface on

which the accelerometer is mounted should have a surface roughness of 32 micro inches rms or

better and a surface flatness tolerance of 0.0003”.

For use up to 60oC: Aremco CrystalbondTM 509 is recommended, following this mounting procedure:

o Apply a moderate amount of CrystalbondTM 509 on the bottom of the Model 727 accelerometer

o Use a toothpick and spread the wax to form a thin, uniform layer covering area of contact, and

immediately position accelerometer on mating surface

o Press down and hold accelerometer firmly in place for 30 seconds while the wax sets. Allow wax

to set for at least 1 minute for maximum strength.

Cyanoacrylate (super glue) is not recommended as a temporary adhesive unless an appropriate solvent

(such as acetone) is used to weaken the glue joint before attempting to remove the accelerometer. The

solvent should be swabbed around the base of the accelerometer; under no circumstances should the

accelerometer be soaked or immersed in any liquid. Similarly, if wax is used as a temporary adhesive,

always remove the unit using the appropriate amount of heat. Trying to remove the accelerometer by

shearing or twisting will excite the resonance and could cause permanent damage to the accelerometer.

Mounting to low strength material (such as aluminum) is not recommended. Additionally, adhesive

must always be used between the transducer and any low-strength mounting surface.

CABLE HANDLING

The 727 series of drop-test accelerometers are supplied with integral cables, which are terminated

in pigtails. The user can select an appropriate end-connector.

There are two important considerations regarding the integral cable when installing the

accelerometer. First, since the cable will be exposed to the same high level shocks as the

accelerometer, care needs to be taken to prevent damage to the cable. Relative motion between the

cable and the accelerometer can cause cable failure and/or a significantly shortened life. Second, the

signal voltage on the leads of the cable will be at a very low level and any excessive movement of

the cable could cause noise on the signal lines. Because of the above factors, it is important that the

following cable recommendations be observed.

If possible, the mounting preparation should allow for the cable to be routed perpendicular to the

primary shock direction to reduce the amount of tensile stress on the cable. To strain relieve the

cable close to the accelerometer, form a small bend (~¼” radius) in the cable within two inches of

the case and then tack the cable to the mounting surface with tape. Next, completely secure the cable

between the accelerometer case and the tape to the mounting surface by encapsulating with a

silicone RTV. A recommended silicone RTV is Loctite® item number 37463, an air curing RTV

which will be tack-free in 15-20 minutes, test-ready in roughly an hour and fully cured in 24 hours

(assuming 70ºF and 50% relative humidity). In routing the remaining portion of the cable to the

signal conditioner, it is important that there be sufficient slack in the cable, i.e. the cable should not

be pulled tight between the test specimen and the signal conditioner.

IM727 Rev A, Page 5 of 9

®

ELECTRICAL CONSIDERATIONS

1. Excitation Voltage – The drop-test accelerometers are calibrated using an excitation voltage of

10.000±0.005 Vdc, unless otherwise specified at the time of order (the maximum excitation

voltage without damage is 12 Vdc). If a voltage other than the voltage used at the time of

calibration is applied to the unit, the ZMO and sensitivity will differ from the specified value on

the Calibration Certificate, thus excitation voltages other than 10 Vdc should be specified at the

time of order. The accelerometer requires a clean, well-regulated, constant voltage power supply.

Endevco offers a wide range of signal conditioners that ensure optimal performance from

Endevco® piezoresistive accelerometers, including the 126, 136 and 4430A. Contact Applications

Engineering to discuss your specific signal conditioning needs.

2. Power and Signal Leads – The cable leads are assigned as follows:

The cable shield is not connected to the accelerometer case. It is recommended that the shield be

connected to the power supply ground.

3. Cable Length Considerations – The 727 accelerometers are calibrated with 120 inches of cable,

unless otherwise specified at the time of order. When using cables longer than 10 – 20 feet , three

effects must be taken into account:

a. Input Voltage Attenuation: Resistance in the excitation voltage wires may reduce the

voltage to the sensor, resulting in a loss of sensitivity. The reduced sensitivity can be

calculated as follows:

!

EOL = loaded output sensitivity

Eo = sensitivity into an infinite load (from Cal. Cert.)

RO = output bridge resistance (from Cal. Cert.), includes cable

RL = load resistance

IM727 Rev A, Page 6 of 9

®

If cable lengths longer than 20 feet are required then it is recommended to use a

signal conditioner with an excitation sense (remote sense) feature. In brief, to use

excitation sense a secondary cable (longer) is spliced to the existing accelerometer

cable (shorter). The extension cable has two extra wires; one wire is connected to the

accelerometer’s positive input lead and the other to the accelerometer’s negative input

lead. The two extra wires are used to measure the actual voltage at the accelerometer

and adjust the supplied excitation voltage accordingly until the target value is

achieved. The effect of the voltage drop due to the series resistance in the wires is

eliminated by measuring the voltage using a high input impedance voltmeter.

b. Signal Attenuation: Similar to the input voltage attenuation discussion, the resistance

in the output leads will also cause attenuation of the output signal. The reduced

sensitivity is calculated as follows:

EO = sensitivity into an infinite load (from Cal. Cert.)

EOL = loaded output sensitivity

RO = output bridge resistance (from Cal. Cert.), including

cable.

RL = load resistance

RCO = resistance of the spliced output wire

c. Cable Capacitance: Long cable leads act as an RC filter, which can cause significant

attenuation of high frequencies. A rough calculation for the cut-off frequency of such

a filter is as follows:

fc = cut-off frequency, in Hertz (-3 dB)

R = output resistance, in Ohm

C = cable capacitance, in Farad

In general, the above effects are insignificant when cable length is 20 feet (6 meters) or less. The

effects discussed in sections (a) and (b) above are typically accounted for in any factory

calibration, so they must only be considered when longer extension cables are installed by the

customer. Contact Applications Engineering for more information, if required.

IM727 Rev A, Page 7 of 9

®

OPERATING PRECAUTIONS

While these drop-test accelerometers can be extremely rugged, they can also be extremely fragile

under very specific operating conditions, namely under resonance excitation. Due to the extremely

high levels of shock encountered and the potential for resonance excitation, the user should read

this section carefully before operating.

RESONANT FREQUENCY EXCITATION

The 727 series utilizes an undamped sensing element which means its resonant frequency is excited

more easily as compared to a damped device. Additionally, the 727 series does not incorporate any

mechanical overtravel stops, which means the displacement of the proof mass is not restricted. Since

the amplification factor for an undamped accelerometer can be up to 100, if there is sufficiently high

frequency content in the shock event, the excessive amplitude of the seismic mass can be well over

the overrange capability and cause permanent damage to the accelerometer.

Another thing to note is that each seismic element used on the 727 series includes two masses, each

with its own resonant frequency. If both resonant frequencies are excited, a beat frequency may

appear in your data that will be at a frequency equivalent to the difference between the two resonant

frequencies. Although the beat frequency will be apparent in the time history it will not translate to

the Fourier transform. Although resonance excitation cannot always be avoided, it possible for the

user to take measures to reduce the amount of high-frequency energy the accelerometer will be

subjected to.

BANDWIDTH AND AMPLITUDE LINEARITY

Because the 727 series is undamped and does not use mechanical over travel stops, accurate

measurements are permitted over a wide frequency and amplitude range. Undamped accelerometer

data are typically considered accurate (±5%) to one-fifth of the resonant frequency and, because

there are no overtravel stops to limit the displacement of the proof mass, reasonable amplitude

linearity can be observed well beyond the rated full-scale range.

DATA ACQUISITION AND ANTI-ALIASING PRECAUTIONS

With any shock testing it is always best practice to use recording equipment with enough bandwidth

to resolve the highest frequency component present, which is usually the resonant frequency of the

accelerometer. Even with the excitation of resonance, if linear filtering is used and the amplitude

during resonance does not cause saturation to the signal conditioning (or go beyond the linear range

of the damped accelerometer), the high amplitudes experienced during resonance will not degrade

the accuracy of the actual shock data recorded at lower frequencies.

The user should also be aware of aliasing and its effect on the data. A simple, and by no means

complete, explanation of aliasing is as follows. Aliasing occurs during digitization when you have

energy in the analog time history at a frequency higher than one-half of the sampling rate (the

IM727 Rev A, Page 8 of 9

®

Nyquist frequency). Once digitized, the aliased frequencies will fold back over the Nyquist

frequency into the frequency range of interest resulting in errors in the data. To prevent aliasing, the

sampling rate should be at least two times (and preferably ten times) the highest frequency present.

The highest frequency present in almost all situations will be the resonant frequency of the high

shock accelerometer. Better yet, an analog anti-aliasing filter should be placed before

digitization with a cutoff frequency of at least one-half (and preferably one-tenth) the sampling

rate. The anti-aliasing filter safeguards against any unpredictable out-of-band energy and is the

most reliable approach to acquiring good quality, non-aliased data.

See Endevco Technical Paper TP284 for further information on high-frequency, high-level testing

and calibration.

REMOVAL OF THE ACCELEROMETER

To remove the 727 accelerometer from your application, please use the supplied removal tool,

Endevco® part number 42894. The tool should be placed over the accelerometer with the cable

positioned away from the tool to shear the accelerometer off the surface of your application by

gently wriggling the tool in clockwise and counterclockwise directions.

CLEANING

If desired, dirty accelerometers may be wiped clean using a damp cloth and a solvent such as

acetone. Do not soak or immerse the unit in any solvent or water. Do not use any sharp tool such

as a screwdriver to remove dirt or contaminants. Any temporary adhesives, such as wax or

cyanoacrylate, used to mount the accelerometer, should be cleaned with an appropriate solvent (such

as acetone).

RECALIBRATION

As with any measuring device, optimum accuracy is maintained by periodic recalibration.

Sensitivity and ZMO calibration should be performed at 6 to 12 month intervals depending on usage.

Ordinarily, recalibration need only be performed at 12 month intervals if it is known that the

accelerometer has not been used beyond its rated specifications. If the unit is used under severe

environments, it may be desirable to use shorter calibration intervals. When testing at high levels

(levels exceeding the accelerometer’s full-scale range) it is recommended that calibration be

performed every six months or after each high-amplitude test.

The general health of the accelerometer can be assessed by measuring the ZMO and comparing the

value to the most recent calibration certificate. The ZMO can be checked by applying a well-

regulated excitation voltage (10 Vdc in most cases, unless otherwise specified at time of order) to

the red-black leads and reading out the differential voltage between the green-white leads. Changes

in ZMO of up to ±20mV with time and usage are not uncommon and are not necessarily a sign of a

damaged accelerometer. Changes of greater than ±20mV may indicate damage to the sensor and the

IM727 Rev A, Page 9 of 9

®

accuracy of subsequent measurements is in question. If possible, an accelerometer that has

experienced a large ZMO shift should be replaced or returned for recalibration. Any ZMO reading

approaching one-half of the excitation voltage up to the excitation voltage is a sure sign of

accelerometer failure. The simple resistance check described in the “Initial Checkout” section above

can also be used to evaluate accelerometer health.

After performing the above tests, if you are still uncertain about the health of your accelerometer

please contact Applications Engineering. An Application Engineer will be able to discuss the health

of your accelerometer in more detail and suggest if it is healthy, needs recalibration or needs

replacement. Endevco maintains an accelerometer recalibration service with NIST traceability in the

United States. Endevco European Regional offices maintain accelerometer recalibration services

with traceability to applicable national standards.

QUESTIONS

If you have any questions regarding the use of these accelerometers (or any other Endevco®

product) please contact Endevco’s Application Engineering at +1 (866) ENDEVCO [+1 (866) 363-

3826] in North America, or your local sales representative.

Table of contents

Popular Control Unit manuals by other brands

Graff

Graff AMETIS G-1025 installation instructions

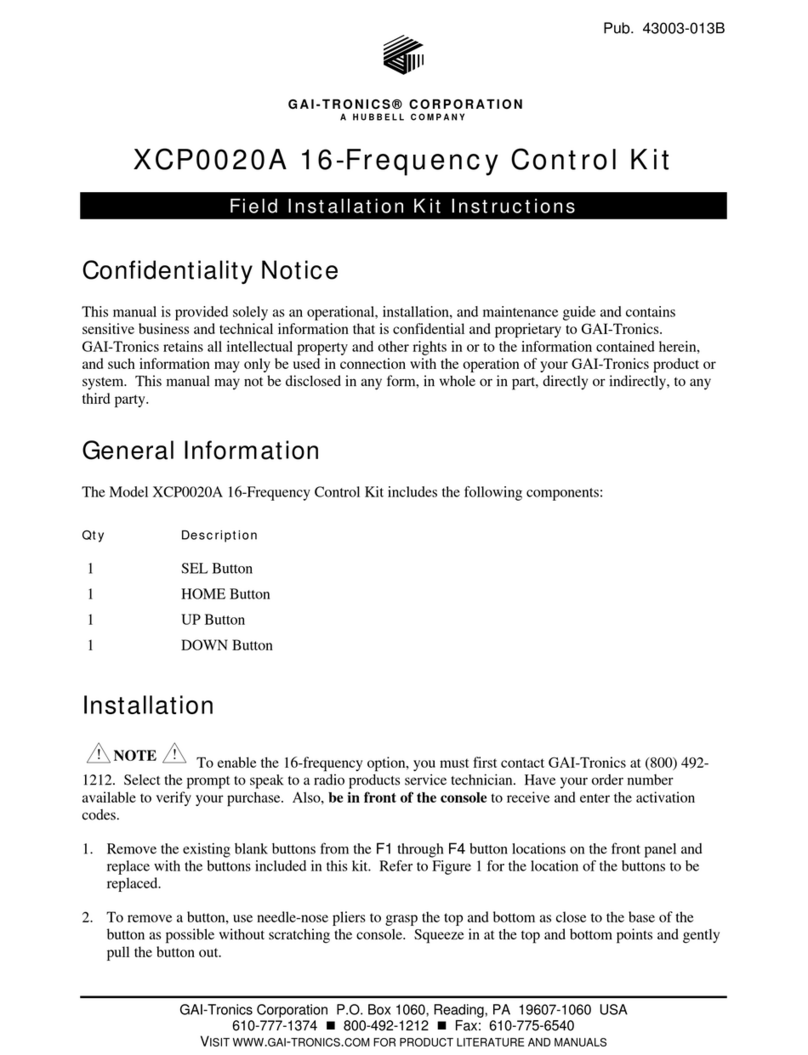

Hubbell

Hubbell GAI-TRONICS XCP0020A instructions

Pentair

Pentair Fleck 5800 XTR Installer manual

Leadshine Technology Co.

Leadshine Technology Co. EM870S user manual

Sartorius

Sartorius YSB01CI-X Series installation instructions

Bitzer

Bitzer CM-RC-01 reference guide

ADC

ADC HiGain H2TU-C-319 List 4E Quick installation

Rockwell Automation

Rockwell Automation Allen-Bradley FactoryTalk Historian ME installation instructions

Emerson

Emerson Tartarini PRX Series manual

4D systems

4D systems gen4-uLCD-50 D quick start guide

Wistron NeWeb

Wistron NeWeb XRAV-1 user manual

LOVATO ELECTRIC

LOVATO ELECTRIC VLB X L Series installation manual