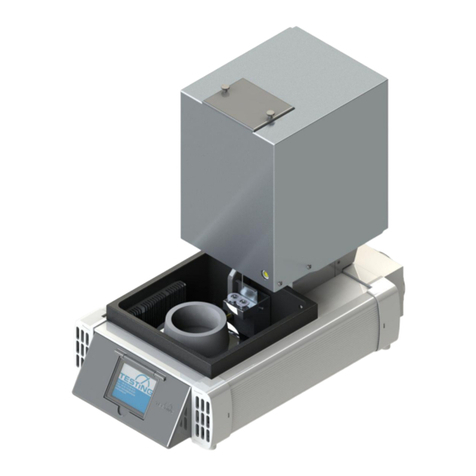

Neomeris Testomat 2000 Technical specifications

1

Testomat 2000®

Testomat ECO®

Maintenance Instructions

Contents

2

Contents

Contents...............................................................................................2

Important safety information .............................................................3

Qualification of the staff ........................................................................3

Warning notices in these instructions ...................................................3

Further documents................................................................................4

General instructions...........................................................................4

Testomat2000®in steam boiler plants with BOB operation: ................5

Prior to carrying out maintenance work ................................................6

Permissible tools...................................................................................6

Carrying out maintenance..................................................................7

Cleaning the measuring chamber and the sight-glass windows...........7

Cleaning the receiver optics..................................................................7

Cleaning the filter housing ....................................................................8

Cleaning the housing ............................................................................8

Removing and installing the measuring chamber holder......................9

Re-adjusting the measuring chamber holder (Overflow detection) .....9

Replacing the EPROM (software update)...........................................10

Opening the factory programming ......................................................10

Installing the interface cards SK910, UK910, RS910 (only Testomat

2000®) .................................................................................................11

Position and function of the fuses.......................................................12

Repairing or replacing the dosing pump.............................................14

Checking dosing .................................................................................15

Special function “Adjust mode”......................................................15

Testing of the overflow detection........................................................16

Checking the automatic adjustment....................................................16

Water consumption ..........................................................................17

Indicator consumption .....................................................................17

Indicator TH2025, TH2100, TH2250...................................................18

Indicator TH2005 ................................................................................18

Manual measured value check........................................................19

Troubleshooting................................................................................20

Error message MST analysis..............................................................20

Switching on the real-time clock (only Testomat2000®).....................22

Low water level ...................................................................................22

Error message FST optics (Testomat 2000®).....................................23

Error message MST turbid..................................................................23

Error message Ff outlet to drain .........................................................23

Error due to defective hardware .........................................................23

Readjusting the current interface........................................................24

Spare parts lists ..................................................................................25

Component positions.......................................................................26

Check List Testomat 2000®................................................................29

Product overview Testomat 2000®-Instruments ............................32

Important safety information

3

Important safety information

Please read the operating instructions and maintenance instruc-

tions carefully and completely prior to carrying out maintenance

work at Testomat instruments.

Observe the warning notices in these maintenance instructions

and the operating instructions of the respective instrument.

Always adhere to hazard warnings and safety tips when using

reagents, chemicals and cleaning agents. Please adhere to the re-

spective safety data sheet! Download the safety data sheets for

the supplied reagents at http://www.heyl.de.

Qualification of the staff

Maintenance work requires fundamental electrical and process engi-

neering knowledge as well as knowledge of the respective technical

terms. Assembly and commissioning should therefore only be carried

out by a specialist or by an authorised individual supervised by a

specialist.

A specialist is someone who due to his/her technical training, know-

how and experience as well as knowledge of relevant regulations can

assess assigned tasks, recognise potential hazards and ensure ap-

propriate safety measures. A specialist should always adhere to the

relevant technical regulations.

Warning notices in these instructions

The warning notices in these instructions warn the user about poten-

tial dangers to individuals and property resulting from incorrect han-

dling of the instrument. The warning notices are structured as follows:

Description of the type or source of danger

Description of the consequences resulting from non-observance

Preventive measures. Always adhere to these preventive

measures.

“DANGER” indicates an immediate hazardous situation which, if not

avoided, will result in death or serious injury.

“WARNING” indicates a potentially hazardous situation which, if not

avoided, could result in death or serious injury.

“CAUTION” indicates a potentially hazardous situation which, if not

avoided, could result in minor or moderate injuries or property dam-

age.

“NOTE” indicates important information. If this information is not ob-

served, it may result in an undesirable result or state.

DANGER

!

WARNING

!

CAUTION

!

SIGNAL WORD!

NOTE

General instructions

4

Further documents

Testomat instruments are plant components. Therefore, always ob-

serve the documentation of the plant manufacturer.

General instructions

Regular maintenance is necessary to ensure trouble-free operation of

the Testomat instrument. Regular visual inspections also increase

operational reliability. Also refer to the notes in the operating instruc-

tions!

Fix errors by yourself.

Experience has shown that many errors that occur in day-to-day op-

erations you can fix by yourself.

This ensures that the instrument is soon working again. In this

maintenance manual you will find possible causes of malfunctions

and helpful hints for their elimination.

Overview of maintenance work to be executed

The maintenance intervals may vary depending on the water and

pipeline quality.

Maintenance work

Quarterly

Semi-

annually

Triquarterly

Annually

Biennially

/ Trienni-

ally

Page

Cleaning sight-glass

windows

X

X

X

X

7

Measuring chamber

Cleaning / Measuring

chamber holder

X

X

X

X

7

Cleaning the receiver

optics

X

X

7

Cleaning the control-

ler/filter housing

X

X

8

Cleaning the waste

water line

X

X

X

X

Checking

the dosing pump

incl. suction and

pressure hoses

X

X

Electrical and hy-

draulic connections

X

X

Renewing the sealing

kit (40124) and

sight-glass windows

X

Recommendation:

Allow the manufac-

turer to overhaul the

dosing pump

X

NOTE

General instructions

5

Clean the measuring chamber at regular intervals (approx. every 6

months) and, if possible, replace the two seals of the measuring

chamber holder and the sight-glass windows.

If the water has high iron content, cleaning might be necessary

more often.

Only use a dry, lint-free cloth for cleaning.

To carry out maintenance work after the error message “Mf. soil-

ing” or “Ff. optics”, always confirm the error message.

Only Testomat 2000®: If maintenance is carried out after an in-

strument maintenance message (maintenance interval), mainte-

nance must be confirmed. (In SERVICE I menu)

Wait at least 5 seconds before switching the instrument on and

then off again at the main switch.

The repair of a defective instrument –irrespective of the warranty

period - is only possible after the instrument has been dismantled

and returned to us with a description of the error. Furthermore,

please inform us of the indicator type being used and the meas-

ured medium. Before you return the instrument for repair work, re-

move the bottle and ensure that the measuring chamber has been

flushed out and is empty. Prior to dismantling, always write down a

description of the error (failure effect). For Testomat 2000®and

Testomat ECO®please download the respective checklist from our

website www.heyl.de.

Do not carry out any actions at the instrument which are not de-

scribed in these instructions; failure to adhere to the instructions

will negatively affect the warranty claims that you make thereafter.

Testomat2000®in

steam boiler plants

with BOB operation:

In accordance with the pro-

visions of TRD 604, Sheet 1

(new WÜ 100), Testomat

2000®must be regularly

maintained and, if neces-

sary, inspected. Mainte-

nance must be carried out

every six months by the

plant operator or an author-

ised service and mainte-

nance provider. Please con-

tact us if you require a regu-

lar maintenance service. We

will then provide you with an

offer.

Download of check list

General instructions

6

Prior to carrying out maintenance work

Carry out a visual inspection of the instrument:

Are the instrument doors closed properly?

Is the instrument heavily soiled?

Is there air inside the dosing hoses?

Are the hose connections of the dosing pump free of leaks?

Has the use-by date of the indicator expired?

Always make sure that the sight-glass windows are clean before in-

serting a new indicator bottle.

Cleaning agents

Never use organic solvents to clean the measuring chamber or

other plastic parts!

Use an acidic cleaning agent for cleaning.

Please observe the safety regulations when handling cleaning

agents!

Permissible tools

Always use suitable tools for the described tasks. Refer to the table

below for an overview of suitable tools, which can be purchased as

tool kit T2000 (Art. no. 40138).

Content of the tool kit T2000 (Art. no. 40138)

Size

Application

Art. no.

Adjustment pin

2 mm

Alignment of the overflow sensor

measuring chamber holder (only re-

quired up to device number 22899)

30990

Torx, TX 20x100

Measuring chamber, snap-on installa-

tion

30991

Torx, TX 10x80

Measuring chamber holder

30992

Torx, TX 8x60

Display circuit board, measuring cham-

ber holder

30993

CAUTION

!

Carrying out maintenance

7

Carrying out maintenance

Cleaning the measuring chamber and the sight-

glass windows

Proceed as follows:

Switch off the instrument or press the "STANDBY" key. If required,

remove any water from the measuring chamber:

Close the manually-operated valve of the supply line to Testomat

2000®.

Unhook the toggle type fastener , tilt the measuring chamber

upwards and remove it.

Release both sight-glass window holders , remove and clean the

sight-glass windows.

Use alcohol to clean off the film on the sight-glass windows. If the

instrument has been used with hard water for a longer period of

time (measuring range exceeded!), a hard-to-remove film may

have formed on the sight-glass windows. In this case, clean the

sight-glass windows as described below for cleaning the measur-

ing chamber.

The measuring chamber can be cleaned with a cleaning agent

suitable for decalcification and rust removal. Flush the measuring

chamber thoroughly after cleaning.

After cleaning, re-insert the sight-glass windows and secure them

using the sight-glass window holders b. (Do not forget the flat

seals, making sure they are fitted correctly in the groove).

Re-insert the measuring chamber and use the toggle type fastener

to secure it.

Cleaning the receiver optics

If you detect that the lenses of the receiver optics (left-hand side of

the measuring chamber holder) are soiled, please clean them using a

dry, lint-free cloth.

Carrying out maintenance

8

Cleaning the filter housing

Close the manually-operated valve of the supply line to Testomat

2000®.

Depressurise the lines of Testomat 2000®via the function:

Switch off the instrument and loosen the hose connections at the

filter housing.

Unscrew the inlet connection using an open ended spanner (size

22).

Remove the seal, spring and filter and clean them.

Remove the retaining pin and extract the flow controller, subse-

quently remove the flow controller valve body.

Clean the filter housing with water or alcohol; then reassemble the

unit.

If required, replace the seals.

Insert the filter strainer with the cone facing downwards!

Re-attach the hose connections at the filter housing.

After assembly

After assembly, make sure the connections are leak-free.

Leaking water at sealed points can damage unit components.

How to check the unit for leaks:

Switch the instrument to "STANDBY" .

Manually fill the measuring chamber:

Manually dose the indicator ("Manual" key).

Check the connections and seals for leaks.

Drain the measuring chamber.

Cleaning the housing

The surface of the instrument housing is untreated. Therefore, avoid

any soiling caused by indicators, oil or grease. However, if the hous-

ing becomes soiled, please clean the surface with alcohol (never use

other solvents).

Inlet

connector

Regulator/filter

CAUTION

!

Carrying out maintenance

9

Removing and installing the measuring chamber

holder

(Required tool: Torx 10x80)

Please stop the water supply to the instrument and drain the

measuring chamber.

Switch off the instrument.

Unhook the toggle type fastener, tilt the measuring chamber up-

wards and remove it.

Remove the stirring bar.

Loosen the pressure hose (1).

Loosen the four fastening screws of the measuring chamber holder

(2).

Loosen the valve block (3) from the measuring chamber holder

(two fastening screws).

Disconnect the plug from the flexible cable connection (4) on the

base circuit board by pressing together and raising the two lateral

levers. Unplug the flexible cable.

Remove the measuring chamber holder from the front. To achieve

this, remove the drain pipe (5) from the hose connection of the

measuring chamber holder (see fig. push locking ring upwards).

Install the new measuring chamber holder in reverse order.

Ensure that the plug is locked into position after inserting the flexi-

ble cable connection.

Re-adjusting the measuring chamber holder

(Overflow detection)

(Required tool: Adjustment pin 2 mm, Art. no. 30990)

Testomat2000®/ ECO instruments have been factory set. Therefore,

instrument adjustment during start-up is not required.

All instruments from instrument number 222.899 and higher are

equipped with a self-adjusting electronic circuit.

Adjustments are no longer required and no longer possible!

If the re-adjustment of instruments with a serial number below

222.899 is required after replacing the measuring chamber holder

(error message "low water level" in spite of noticeable filling process),

carry out the re-adjustment as follows:

Switch off the instrument, press and hold the "DOWN" key and

switch on the instrument again (Call the special function “Adjust

mode”).

Push locking

ring upwards

NOTE

Carrying out maintenance

10

Use a suitable adjustment pin to turn the potentiometer on the

base of the measuring chamber holder A(hole in the base) clock-

wise until the "Analysis" LED (overflow detection) illuminates.

Subsequently turn the potentiometer anti-clockwise by an approx.

1/8 turn.

Check correct functioning of the overflow detection circuit via the

key = input valve: The "Analysis" LED must illuminate while

water is overflowing. Press key again for quitting. The LED

must extinguish once the overflow has finished.

Back to normal operation: Press the “LEFT” and “DOWN” keys

simultaneously.

Checking water recognition

Use the key to check the water recognition function for in-

struments equipped with a self-adjusting electronic circuit.

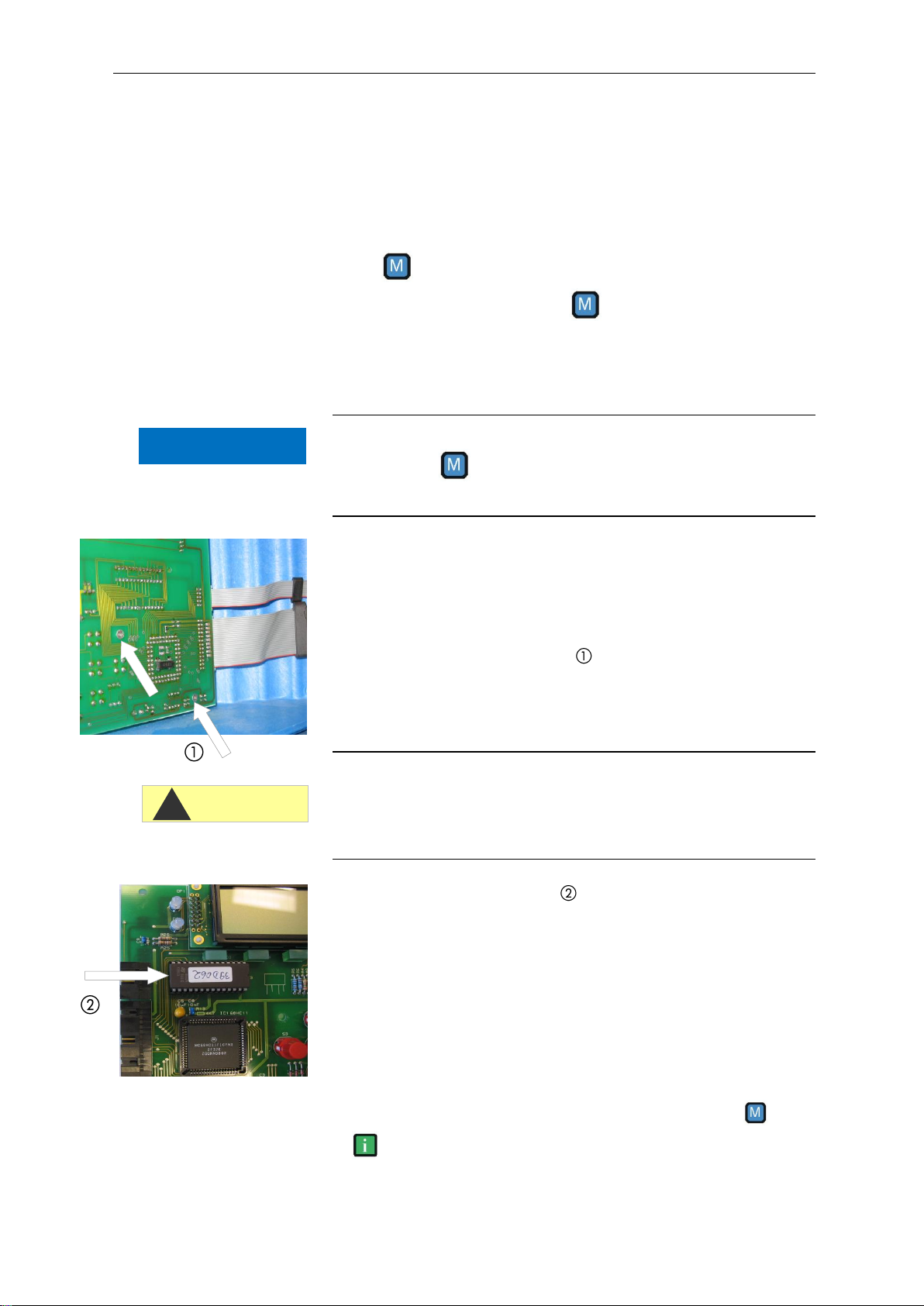

Replacing the EPROM (software update)

(Required tool: Torx 8x60)

Switch off the instrument.

Loosen the six fastening screws of the display circuit board

Avoid static charges during installation/de-installation and ob-

serve the direction of installation!

Non-adherence can result in damage to or destruction of the elec-

tronic components on the circuit board or of the EPROM.

Carefully remove the EPROM from the socket (please make a

note of the direction of the marking).

Insert the new EPROM.

Fasten the display circuit board.

Switch on the instrument.

Opening the factory programming

After replacing the EPROM, carry out basic programming.

Switch on the instrument by simultaneously pressing the and

keys. Your programmed settings are lost and the factory set-

tings are reset (also see the operating instructions!).

CAUTION

!

NOTE

Carrying out maintenance

11

Installing the interface cards SK910, UK910,

RS910 (only Testomat 2000®)

Switch off the instrument:

Open the upper housing cover:

Insert the plug-in circuit board into the left-hand slot with the com-

ponent side on the left (contact no.1 is at the top).

Switch on Testomat 2000®.

Under menu item

select either or for

the cards SK910/UK910.

Select for the interface card RS910.

Voltage interface UK 910 Interface RS910 (RS232)

Avoid static charges during installation!

Non-adherence can result in damage to or destruction of electronic

components on the circuit board.

Interface SK910

CAUTION

!

Carrying out maintenance

12

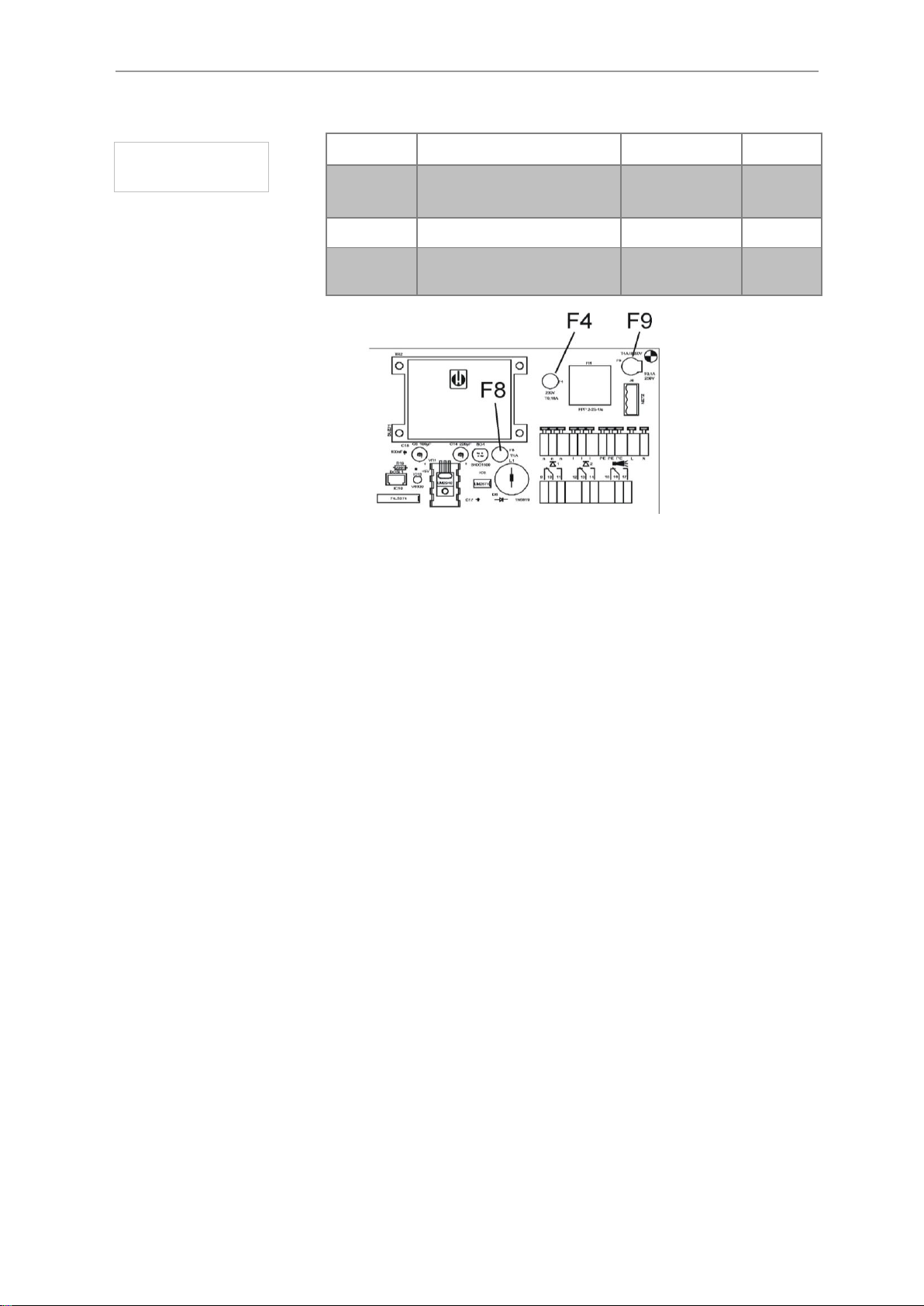

Position and function of the fuses

Description

Error during failure

Rate

Art. No.

F1

Instrument not functioning

T0,2A (115V)

31594

F2

Instrument not functioning

T0,1A (230V

T1A (24V)

31595

31592

F4

"Ff. 24V failure" dosing

pump not functioning

T0,16A (230V)

T0,315A(115V)

31622

31585

F5

Display failure

T0,315A

31585

F6

"Low water level", alarm

relay active

T0,315A

31585

F7

Power output not function-

ing

T0,08A

31596

F8

"Ff. 24V failure" dosing

pump not functioning

T1A

31592

F9

Instrument not functioning

GS-M 5x20V

4A

31582

F8 F1 F2 F4 F9

F7 F5 F6

Fuses

Testomat 2000®

Carrying out maintenance

13

Description

Error during failure

Rate

Art. No.

F4

Instrument not functioning

T0,16A (230V)

T0,315A(115V)

31622

31585

F8

Instrument not functioning

T1A

31592

F9

Instrument not functioning

GS-M 5x20V

4A

31582

In case of overload or short circuiting at the relay outputs, fuse F9 is

triggered (if the power for the external consumers is supplied from

terminals "l" of "n").

Fuses

Testomat ECO®

Carrying out maintenance

14

Repairing or replacing the dosing pump

Maintenance rate

The dosing pump DOSIClip®is a high-precision piston dosing pump,

which makes up to 400 000 pump strokes per year depending on the

settings (a measurement all 10 minutes x 4 pump strokes every day).

To ensure proper operation for many years, we recommend sending

in the pump for servicing every 2-3 years.

Calibration on-site not possible!

We would like to point out that a repair of the dosing pump should be

performed only marginally, because calibration of the dosing pump

on-site is not possible.

We recommend exchanging a defective pump and sending it in for

servicing to the factory.

A pump which does not function properly results in incorrectly meas-

ured values (e.g. error message "Mf. Analysis"). If you have problems

with the dosing pump, we recommend replacing it.

Proceed as follows to replace it:

1. Switch off the instrument.

2. Loosen the five cables of the terminal connections using a

suitable screwdriver.

3. Loosen the hose connections at the indicator bottle and at

the measuring chamber holder.

4. Collect the indicator in a container!

5. Use a screwdriver to push the lock of the pump housing

downwards and remove the housing from the top

6. At first, place the replacement pump on top of the DIN rail

and push the housing downwards until the lock engages

7. Reconnect the cables (observe the colour sequence!)

8. Reconnect the hose connections (note the suction and pres-

sure side!)

CAUTION

!

NOTE

Special function “Adjust mode”

15

Checking dosing

When measuring the hardness, it is checked whether the yellow val-

ue is at least 50 below the limit value after each (except the first)

dosing stroke. Each stroke usually results in the value being reduced

by 80 to 100 digits.

Manually activate the dosing pump once.

In “Adjust mode”, display the yellow value under “G:####”.

It is essential that the stirrer is switched on during the checking pro-

cedure.

Checks can only be carried out with indicator type TH!

Special function “Adjust mode”

The adjust mode is used for adjusting the overflow detection and

testing the optical amplification setting.

The amplification setting is carried out in the normal measuring mode

of the instrument, i.e. manual adjustment is not required. The test

described below is only used for checking and error detection.

Call of adjust mode

Press and hold the "DOWN" (1) key and switch on the instrument.

Back to measuring mode

Press the "DOWN" (1) and "LEFT" (9) keys simultaneously.

NOTE

NOTE

Special function “Adjust mode”

16

Testing of the overflow detection

Press the “M” (3) key to open the input valve IN.

Only Testomat2000®:the “IN” LED (6) illuminates.

The “ANALYSIS” (7) LED must illuminate when the water flows

through the overflow borehole of the measuring chamber (If this is

not the case, adjust the overflow detection as described above).

Press the “i” (4) key to open the output valve OUT.

Only Testomat2000®:the “OUT” LED (8) illuminates.

Checking the automatic adjustment

Prior to adjustment, fill the measuring chamber with water until

overflow occurs.

Switch to “Adjust mode” (see “Calling adjust mode”).

Press the “ENTER” (2) key to switch on the transmit diodes and

the stirring mechanism.

Press the "UP" (5) key to start automatic adjustment.

Press the “Manual” button on the dosing pump.

Read the values for yellow (Y:) and red (R:). Both values have to

be 900 +/- 20.

If these values are not achieved, it may be due to the following rea-

sons:

The water is turbid.

Air bubbles in the water.

The measuring chamber is not filled correctly.

The sight-glass windows are soiled or cracked.

The receiver optics (lenses) is soiled.

The plug connector of the flexible cable is not locked (loose con-

tact).

The measuring chamber holder is leaky, entered water has de-

stroyed the electronics on the circuit board.

Electronic component on the plug-in circuit board T2000-SE (Art.

no. 40091) is defective.

Water consumption

17

Water consumption

Water consumption of the instruments is composed of the analysis-

relevant volume (18.1 ml per analysis), of the measuring water ad-

justment (150 –200 ml per analysis), the water consumption for the

internal flushing time 0.5 l (500 ml /minute). and the water consump-

tion for flushing after analysis (approx. 50 ml).

Flushing is carried out by simultaneously opening the inlet and

outlet valve.

The values for measuring water adjustment and internal flush-

ing are variable and depend on the input water pressure.

Water consumption for internal flushing with a programmed flush-

ing time of 10 seconds is 83 ml. Shorter or longer flushing times in-

fluence the required volume of water in a linear fashion.

Default setting:

Measuring water inlet pressure 2 bar = approx. 200 ml measuring

water adjustment + 18.1 ml analysis volume = 218.1 ml / per analysis

Example: 10 sec. internal flushing time + analysis = total waste water

quantity / per analysis

83 ml + 218.1 ml = 301.1 ml / per analysis

For connections longer than 3 m and with an internal hose diameter

of 6 mm a minimum internal flushing time of 10 seconds is required

to ensure that a valid sample is taken from the sampling line.

Indicator consumption

Testomat functions via automatic titration. During the analysis pro-

cess, the indicator is titrated drop-by-drop into the measuring cham-

ber by the dosing pump until the colour changes. Please note that the

applied indicators each provide a specific resolution.

The greater the hardness of the water being analysed, the higher

the indicator consumption!

Moreover, indicator consumption is influenced by the frequency of

analysis.

Example: Three strokes are dosed into the measuring chamber by

the dosing pump at a hardness of 0.1 °dH. In this case, a 500 ml

bottle of indicator is sufficient for 16 667 strokes. In other words, 5

555 analyses are possible. If an analysis is carried out every 30

minutes, for instance, the indicator bottle will last for approx. 2 777

hours. Resulting in an annual consumption of 3.15 bottles. Please

remember that this calculation is an approximate value for indicator

type TH 2005.

NOTE

Indicator consumption

18

Indicator TH2025, TH2100, TH2250

Number of analysis and range with 500 ml

Range in hours

Water hardness (°dH)

Num. of

Analysis

Interval (as a result of idle time and flush times/AUX) minutes

TH2025

TH2100

TH2250

0

2

5

10

30

60

90

200

0,25

1,0

2,5

8333

278

556

972

1667

4444

8611

12778

28056

0,50

2,0

5,0

5556

185

370

648

1111

2963

5741

8519

18704

1,00

4,0

10,0

3333

111

222

389

667

1778

3444

5111

11222

1,50

6,0

15,0

2381

79

159

278

476

1270

2460

3651

8016

2,00

8,0

20,0

1852

62

123

216

370

988

1914

2840

6235

2,50

10,0

25,0

1515

51

101

177

303

808

1566

2323

5101

Annual requirement indicator 500 ml (365d x 24h) 8760 hours/year

Water hardness (°dH)

Num. of

Analysis

Interval (as a result of idle time and flush times/AUX) minutes

TH2025

TH2100

TH2250

0

2

5

10

30

60

90

200

0,25

1,0

2,5

8333

32

16

9

5

2

1,0

0,7

0,3

0,50

2,0

5,0

5556

47

24

14

8

3

1,5

1,0

0,5

1,00

4,0

10,0

3333

79

39

23

13

5

2,5

1,7

0,8

1,50

6,0

15,0

2381

110

55

32

18

7

3,6

2,4

1,1

2,00

8,0

20,0

1852

142

71

41

24

9

4,6

3,1

1,4

2,50

10,0

25,0

1515

173

87

50

29

11

5,6

3,8

1,7

Indicator TH2005

Number of analysis and range with 500 ml

Range in hours

Water hard-

ness (°dH)

Num. of

Analysis

Interval (as a result of idle time and flush times/AUX) minutes

0

2

5

10

30

60

90

200

0,05

8333

278

556

972

1667

4444

8611

12778

28056

0,10

4167

139

278

486

833

2222

4306

6389

14028

0,20

2381

79

159

278

476

1270

2460

3651

8016

0,30

1667

56

111

194

333

889

1722

2556

5611

0,40

1282

43

85

150

256

684

1325

1966

4316

0,50

1111

37

74

130

222

593

1148

1704

3741

Annual requirement indicator 500 ml (365d x 24h) 8760 hours/year

Water hard-

ness (°dH)

Num. of

Analysis

Interval (as a result of idle time and flush times/AUX) minutes

0

2

5

10

30

60

90

200

0,05

8333

32

16

9

5

2

1,0

0,7

0,3

0,10

4167

63

32

18

11

4

2,0

1,4

0,6

0,20

2381

110

55

32

18

7

3,6

2,4

1,1

0,30

1667

158

79

45

26

10

5,1

3,4

1,6

0,40

1282

205

102

59

34

13

6,6

4,5

2,0

0,50

1111

237

118

68

39

15

7,6

5,1

2,3

(All information without guarantee)

Manual measured value check

19

Manual measured value check

The measured value check of the Testomat instruments is usually

carried out during a laboratory analysis of the measuring water. In

special cases, this check can also be carried out via direct input of a

standard solution, created especially for this task, into the measuring

chamber.

Creating a standard solution

The standard solution must be created on-site for rapid application.

For example, take a 1000 ppm solution and dilute it until you

achieve the desired value in the upper third of the measuring

range.

Manual supply of the standard solution

Please stop the water supply to the instrument.

Please remove the right-hand plug from the measuring chamber.

The measuring chamber is manually filled with the standard solu-

tion via this borehole after starting the measurement. Common la-

boratory spray bottles can be used for this task.

To start the check, activate the measurement via the key.

Testomat 2000® starts with an analysis cycle. If you have pro-

grammed a flushing time, do not fill the measuring chamber until

the output valve has closed (“OUT” LED extinguishes).

Fill the measuring chamber with the standard solution until it over-

flows. The input valve closes (“IN” LED extinguishes). This solution

is then drained (flushing the measuring chamber).

Once the output valve has closed ("OUT” LED extinguishes), refill

the measuring chamber with the standard solution until it over-

flows. The filling level falls to the intended sample volume.

The measured value is displayed once the analysis has finished.

Valve

block

NOTE

Troubleshooting

20

Troubleshooting

Error message MST analysis

A measuring fault analysis occurs when the water in the measuring

chamber is too “light” after the second dosing.

Check the following points if MST analysis is displayed:

1. The indicator’s expiry date has been exceeded.

Remedy:

There is insufficient dye in the indicator. Use a new indicator.

When using an indicator that is not from Gebr. Heyl, replace it with

the one recommended by us.

2. The stirring bar in the measuring chamber holder fails to

rotate, resulting in an insufficiently mixed indicator.

Remedy:

The stirring bar is stuck due to soiling in the stirring area of the

measuring chamber holder. Clean the measuring chamber.

The measuring chamber holder is leaky, entered water has de-

stroyed the electronics on the circuit board. Change the measuring

chamber holder.

The plug connector of the flexible cable is not locked (loose con-

tact). Insert the plug properly into the socket.

The magnet in the stirring bar is too weak. Change the stirring bar.

If necessary, insert a stirring bar.

Check the plug contact of the flexible printed circuit board. If nec-

essary, replace the measuring chamber holder.

3. The pump doses insufficient indicator.

Remedy:

Check the dosing pump (see “Checking the dosing pump”). Contact

your customer service representative or if necessary, replace the dos-

ing pump.

Check pump dosing (see “Checking dosing”). Contact your custom-

er servicerepresentative or if necessary, replace the dosing pump.

4. Air is trapped in the indicator hose.

Remedy:

Bleed the dosing hoses by pressing the “Manual” button on the

dosing pump several times.

Make sure that all the indicator hoses are fitted correctly. If not, air

may enter the hoses!

If the error re-occurs, replace the bottle insert for a screw cap with

a suction tube (art. no.: 40135).

Make sure that the suction and pressure hose set is not kinked or

trapped. If necessary, replace the hoses. Complete suction hose

(art. no. 40011), complete pressure hose (art. no. 40016).

This manual suits for next models

1

Table of contents

Other Neomeris Test Equipment manuals