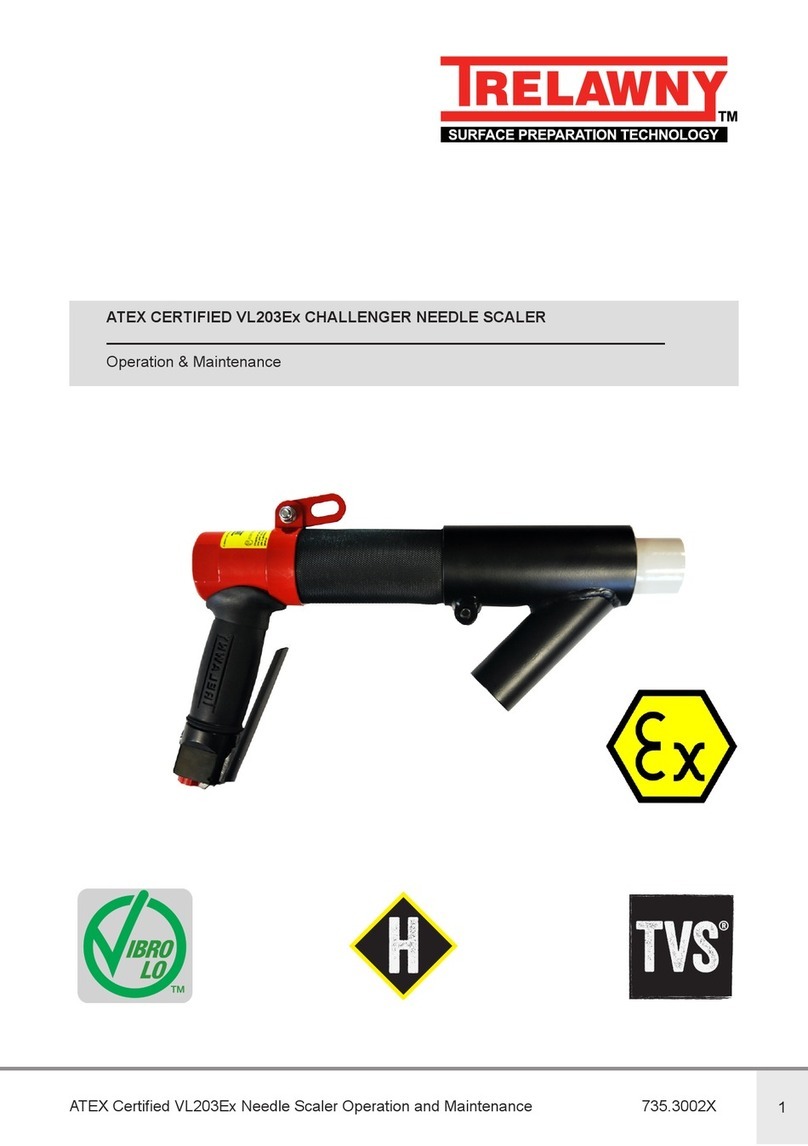

Trelawny Trident Neptune User manual

Trident Neptune

Operation and Maintenance Manual

www.trelawnyspt.co.uk

OPERATION

Foreword

Thank you for your purchase of the

TRELAWNY TRIDENT NEPTUNE DE-

SCALING MACHINE.

This manual contains the necessary

maintenance information for you to

ensure proper operation and care for this

machine.

See also the manual that is supplied

by the motor manufacturer.

It is essential for you to read through

these manuals thoroughly.

In the unlikely event that you experience

problems with your Trident Neptune

please do not hesitate to contact your

local Trelawny dealer or agent.

We always welcome feedback and

comments from our valued customers.

General Information

Before operating, performing

maintenance or repairing the Trident

Neptune this manual must be read and

understood by the operator, if in any

doubt, ask your supervisor before using

this equipment.

Local safety regulations must be

followed at all times.

Failure to follow these instructions could

result in damage to the machine and/or

personal injury.

Trelawny SPT Limited disclaims all

responsibility for damage to persons or

objects arising as a consequence of

incorrect handling of the machine, failure

to inspect the machine for damage or

other faults that may influence the

operation prior to starting work, or failure

to follow the safety regulations listed or

applicable to the job site.

This machine is primarily designed for

the removal of heavy rust or paint from

steel surfaces. Typically used on ships

decks and superstructures.

It can be used both indoors and out.

This machine must not be used in a

fixture.

The electric motor used has dual 50 or

60 hertz compatibility, no modification is

required, it can be converted easily for

use on a 110v or 220v electricity supply.

See motor plate for further information.

Risk of Hand-arm

Vibration injury

These tools may cause Hand-arm

Vibration Syndrome injury if their use is

not adequately managed.

We advise you to carry out a risk

assessment and to implement measures

such as; limiting exposure time [i.e.

actual trigger time, not total time at

work], job rotation, ensuring the tools are

used correctly, ensuring the tools are

maintained according to our

recommendations, and ensuring that the

operators wear personal protective

equipment [PPE] particularly gloves and

clothing to keep them warm and dry.

Employers should consider setting up a

programme of health surveillance to

establish a benchmark for each operator

and to detect early symptoms of vibration

injury.

We are not aware of any PPE that

provides protection against vibration

injury by attenuating vibration emissions.

See ‘Specifications’ section for

vibration emission data.

Further advice is available from our

Technical Department.

We strongly advise you to visit the U/K

Health & Safety Executive website http://

www.hse.gov.uk/vibration.

This site provides excellent advice and

information on HAV and currently,

includes a Hand-arm Vibration Exposure

Calculator that is easy to use to work out

the daily vibration exposure for each of

your operators.

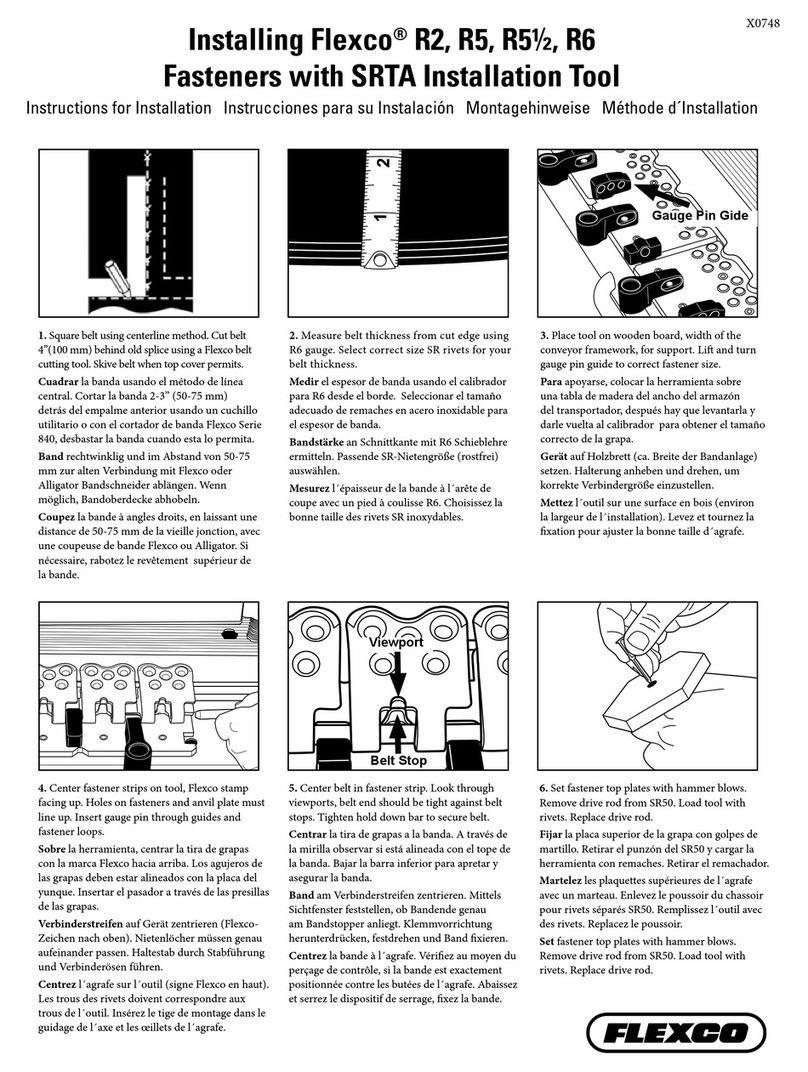

Cutter Types &

Applications

Cutter Wheels

These the most aggressive, they are

designed for the rapid removal of very

heavy rust and scale and are also

suitable for the rapid removal of two part

epoxy paint coatings.

Chipping Leaves

These are fitted as standard, they are

designed for the rapid removal of very

heavy rust and scale, they are less

aggressive than cutter wheels, and

should provide a surface finish suitable

for coating with most modern paint

systems.

Wire Brush

These are the least aggressive of all,

and are generally used for the removal of

light rust and paint, or for final finishing to

provide a surface suitable for painting.

There are various types available, see

parts list for further information.

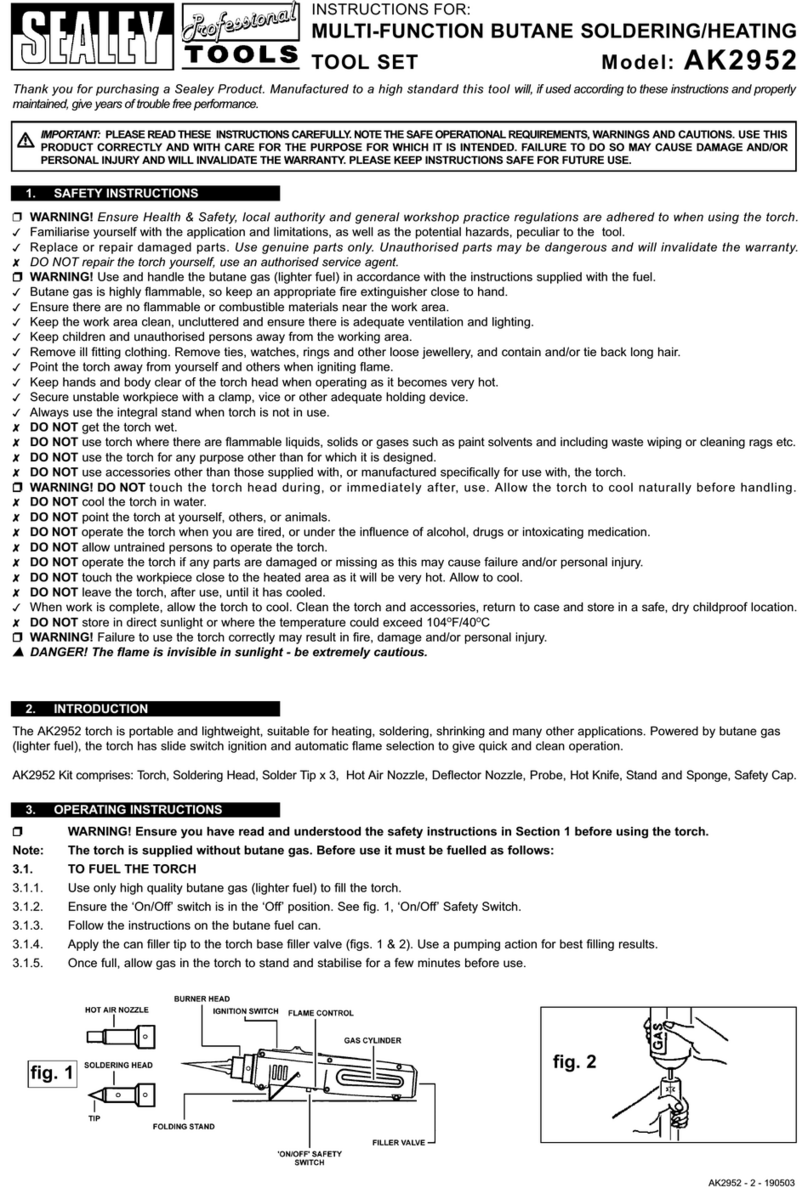

Safety

FACE MASK,

EAR DEFENDERS,

SHATTERPROOF GLASSES,

GLOVES, HELMET,

WEAR SAFETY BOOTS, and any other

personal protective equipment required

for the working conditions.

Avoid loose clothing; this may become

trapped in moving parts and cause

serious injury.

ENSURE THAT THE WORK PLACE IS

WELL VENTILATED.

Avoid operating engine-powered

generators or air compressors used to

power the Trident Neptune in an

enclosed area, since engine exhaust

gases are extremely poisonous.

Ensure that all electrical cables and

connections are in good condition and

that a good earth connection is

established.

Do not use the machine if any electrical

insulation appears to be damaged.

The tool guard is supplied to protect the

operator from flying particles.

Always ensure that it is fitted.

Do not modify the Trident Neptune De-

Scaler in any way.

Do not apply excessive pressure – let

the Scaler do the work .

The electric motor is rated as splash

proof, ensure that the electrics are not

exposed to excessive moisture.

IMPORTANT

Thermal protection:

If the motor overheats the thermal

protector will open the motor circuit,

stopping rotation of the tool.

If this has occurred it is imperative that

the motors power switch is switched

to off, wait until the motor has cooled

sufficiently.

After the motor has cooled, the thermal

protector will reset automatically.

Retry again after 15mins.

If it trips out again investigate the cause

before continuing.

(It maybe caused by a bearing failing or

incorrect grease used in the flexible

shaft, to much force being used etc.)

DO NOT

OPERATE ELECTRIC

VERSIONS IN WET

CONDITIONS.

Before Use

Fit a suitable electric plug for outdoor

use to the cable.

Colour code as follows: -

Blue neutral

Brown live

Green earth

Important: Please ensure the motor is

set to the correct voltage (110v or 120v)

If there is a need to change the setting of

the voltage, remove back plate and

cover from the rear of the motor and re-

connect the leads as illustrated: -

OPERATION

220v Motors

Take particular care when using 220v

machines, ensure that the electrical

supply is earthed and that breakers and

fuses are correct for the loading.

The 220v motor requires the minimum of

a 13amp, 220v power supply. Always

use the shortest possible length of

extension cable. It is recommended that

a residual current device (RCD) or (RCB)

tripping at 30mA is fitted in the supply.

Air Models;

The correct air pressure for this

machine is to 6.2bar (90psi). Do not let

the operating pressure fall below 5.5bar

(80p.s.i.) or rise above 6.9bar (100 psi)

absolute maximum.

Ensure that no moisture (condensation)

is present in the air hose.

Check the security of all hoses clamps

and fittings.

Check that there is sufficient air tool oil in

the inline lubricator’s reservoir.

The air motor requires a minimum of

70cfm of free air delivered (not

displaced, as given by some compressor

manufactures).

Assembly of Flexible Drive

Align D’ shaped connector on the flexible

drive with that on the motor unit and

push home. Secure the flexible drive

with the brass locking collar, tighten by

hand.

Select the appropriate scaling head for

the application and screw into the flexible

drive, initially by hand and then fasten

securely using the supplied 24mm

spanners. Fit the hand guard onto the

end of the dumbbell handle and secure

with the two nuts & bolts and finally

tighten using the two supplied spanners.

Starting

Electric Powered Machines

Inspect the supply cable:

Check that no damage has been caused

to the outer casing and that there are no

exposed or loose wires.

Obtain the assistance of a qualified

electrician if a fault is found.

Do not use the machine until all faults

have been rectified.

Check that the cable is not running

across sharp or jagged edges and that it

is not in contact with any liquid.

Air Powered Machines

Check the security of all hoses clamps

and fittings, and that the supplied air

pressure is correct at 6.2bar (90psi).

Check that there is sufficient air tool oil in

the lubricator’s reservoir.

To Start;

Holding the dumbbell handle securely

and away from your body and clothing,

turn the electric toggle switch or air tap

to ‘on’.

For Low Voltage 110v Setup:

Disconnect the wire labelled “2” from the

terminal numbered (4) and connect it to

terminal numbered (L2).

Disconnect the wire labelled “J” from

terminal numbered (3) and connect it to

terminal numbered (4).

For High Voltage 220v Setup:

Disconnect the wire labelled “J” from

terminal numbered (4) and connect it to

terminal numbered (3).

Disconnect the wire labelled “2” from the

terminal numbered (L2) and connect it to

terminal numbered (4).

110v Motor

The motor requires the minimum of a

16amp, 110v power supply.

Always use the shortest possible length

of extension cable. To avoid voltage drop

the cable must be a minimum core wire

size of 2.5mm2 cross-section.

Maximum length of cable is 30 meters.

Use a centre tap transformer with a

continuous rated output of at least 1.5va.

In practice this means that a 3.0kva

transformer will be required. Be aware

that manufacturers have different

methods of rating their equipment. All

transformers and extension cables

should be fitted with 16amp plugs and

sockets. The 240v supply to the 110v

transformers ideally should be rated to at

least 13amp if supply problems are to be

avoided.

Servicing

Always disconnect power supply from

the tool before performing any servicing

work.

Lubrication

Unscrew cap (2) to expose front ball race

(3) using special tool provided. Please

note this is fitted with a left-hand thread.

Apply a liberal amount of grease to the

front bearing.

Unscrew Dumbbell body (5) from

hexagonal nut (10) (left-hand thread) and

draw apart. Inner coupling is now

exposed and may be unscrewed from

spindle (1) (right-hand thread).

The flexible inner shaft (16) may now be

withdrawn from motor end of the rubber

casing. Apply liberal amount of grease to

the rear bearing and inner shaft.

NOTE: It is recommended to use one of

the following lubricants, or an equivalent.

BP ENERGREASE LC

CASTROL LMX

ESSO BEACON EP2

RAMONOL WHITE GREASE

Cleaning

If the operation of the Trident Neptune

Scaler becomes sluggish or if the electric

motor thermal overload protection

continually has to reset, it is

recommended that the tool be lubricated

as indicated in the previous paragraph.

Dismantling

Changing Scaling Head.

Using spanners provided unlock the

existing head from the dumbbell handle

spindle (1) and unscrew until free. Fit the

alternative scaling head or wire brush to

the spindle and fasten until hand tight.

Hand Guard Removal

Unlock and remove both sets of nuts,

bolts and washers (7). Withdraw the

clamp (8) from the dumbbell handle (5)

and remove the hand guard (9).

Removing Brush Arbor from Wire

Brush

Secure the centre bolt head (29) in vice

and remove the hexagonal nut (19) and

washer (20). Withdraw the wire brush

(30) and the bottom washer (20).

Removing Chipping Leaves

Secure centre bolt head (27) in vice and

remove hexagonal nut (19) and washer

20). Remove side plate (28) withdraw the

washers (22) and chipping leaves (23)

and check for any sign of wear on the

leaf pins (24).

Remove the other side plate (28) from

the centre bolt and check both side

plates for signs of wear.

MAINTENANCE

Removing Cutter Wheels

Secure bolt head (18) in vice and

remove hexagonal nut, (19) washer, (20)

and side plate (21). Withdraw cutter

wheels (25) and check for signs of wear

on cutter wheel pins (26). Remove

bottom side plate from centre bolt and

check both side plates for signs of wear.

Removing Dumbbell Handle

Secure dumbbell handle (5) in a soft

jawed vice and unscrew front cap (2)

with the special tool provided (left-hand

thread). Unscrew the dumbbell body (5)

from the threaded hexagonal adaptor

(10) (left-hand thread) and draw apart.

Ball Race Removal

Unscrew front cap (2) with special tool

provided (left-hand thread) to expose

front ball race (3). Unscrew dumbbell

body (5) (left-hand thread) from large

threaded hexagonal adaptor (10) (left

hand thread) and draw apart.

The Inner shaft with its spanner flats are

now exposed and can be unscrewed

from spindle (1) (right-hand thread).

Remove the spindle from the dumbbell

housing. Both ball races (3) and (4) are

now exposed and can be removed.

Removing Inner Shaft from Outer

Casing

Disconnect Inner shaft (16) from motor

unit (14/15). Remove dumbbell handle

and hand guard as previously instructed.

The inner shaft (16) can now be

withdrawn from the motor end of outer

drive casing.

Removing Nose Piece

Remove flexible drive from motor unit as

previously instructed. Remove dome

headed screws (12) from the motor

casing and withdraw nose piece (13).

Assembly

Ensure all parts are clean. If the Scaler is

being fully serviced, replace all ball

races.

Fitting the Nose Piece

Align the holes in the nose piece (13)

with those on the motor unit (14/15). Fit

and fasten the three dome head screws

(12).

Inner Shaft/Outer Casing Assembly

Insert Inner (16) into the motor end of

rubber casing after ensuring that the ball

race (11) has been packed with grease.

The inner shaft needs to be pre-

tensioned.

Screw the threaded dumbbell spindle

screw onto the inner shaft and pull the

end out of the outer shaft until the

spanner flats on the inner shaft are

visible.

Insert the supplied spanner into the flats

and tighten the spindle onto the inner

shaft.

Fitting of Dumbbell Handle

Fit both ball race bearings into the

corresponding bores of the dumbbell

handle. Ensure that the ball races are

fitted correctly and have been packed

with the recommended grease.

Fit the dumbbell handle onto the large

threaded hexagonal adaptor (10) on the

outer drive casing (6) and secure (left-

hand thread).

Fit locking cap (2) to front of dumbbell

handle ensuring that the recessed holes

are on the exposed side to enable

locking with special tool provided.

Assembly of Scaling Heads

Wire Brush

Secure centre bolt (29) head in vice

vertically and fit washer, (20) wire brush

(30) and top washer (20).

Screw hexagonal nut (19) down by hand

before fastening securely with the

spanners provided.

Fit a pin into the side plate and place a

chipping leaf, (23) and washer (22)

alternate with chipping leaf and washer

for the length of the pin.

The 3 pins must be equally spaced about

the 6 holes. Align top plate (28) holes

with 3 exposed pins (24).

Fit washer (20) and hexagon nut (19) to

centre bolt thread.

Screw nut down by hand before

fastening securely with the spanners

provided.

Fitting Assembled Scaling Head to

Dumbbell Handle

All scaling heads are fitted to the

dumbbell handle by screwing the centre

bolt (18), (27) or (29) into the dumbbell

handle spindle, (1) and fastening

securely using the spanners provided.

Fitting of Hand Guard

Place rubber guard (9) onto front of

dumbbell handle (5), align holes with

metal clamp (8) and fasten securely with

bolts, nuts and washers (7).

Machine Storage

Short period storage: up to 3months.

Clean the outside of the machine and

inspect the cutters and pins for wear,

replace any worn parts as required.

Liberally spray the cutterhead assembly

with a rust preventative solution which is

also safe to use on the rubber

components, if accidentally applied.

See also motor manufactures operation

and maintenance instruction book.

Cover the machine to protect it.

Store the machine in a dry place.

Be sure to check the security of all

fastenings after any lay up period.

Long period storage: over 3months

Clean the outside of the machine and

strip down the flexible shaft and

dumbbell handle, grease all bearings

and the flexible inner shaft. Inspect the

cutters and pins for wear, replace any

worn parts as required.

Liberally spray the cutterhead assembly

with a rust preventative solution which is

also safe to use on the rubber

components, if accidentally applied.

See also motor manufactures operation

and maintenance instruction book.

Cover the machine to protect it. Store the

machine in a dry place.

Be sure to check the security of all

fastenings after any lay up period.

Cutter Head Types

Chipping Leaves

Wire Brush

Cutter Wheels

Cutter Wheels

Secure centre bolt (18) head in vice

vertically and fit bottom side plate (21).

Insert the cutter wheels (25) with pins

(26) into holes in the plate.

Align top plate (21) holes with the six

exposed pins. Fit washer (20) and

hexagonal nut (19) to centre bolt thread.

Screw nut down by hand before

fastening securely with the spanners

provided.

Chipping Leaves

Secure centre bolt (27) head in vice

vertically and fit one of the side plates

(28).

It is important that the chipping leaves

are orientated in the correct manner so

that the tip of the leaf is first to contact

the surface.

See exploded diagram for clarification.

MAINTENANCE

MAINTENANCE

Item Part Number Description Item Part Number Description

1340.542 Dumbbell Handle Spindle 23b 340.348 Thin Chipping Leaf (not shown)

2340.536 Front Cap 24 340.553/12 Leaf Pin for Scaling Head (Pack of 12)

3340.251 Ball Race (Large) 24a 340.546 Leaf Pin for Single Leaf Scaling Head x 6

4340.252 Ball Race (Small) 24b 340.556 Leaf Pin for Light Duty Scaling Head x 6

5340.541 Dumbbell Body

5a 340.540 Dumbbell Handle Assembly 25 340.332 Cutter Wheel x 6

6340.290 Outer Drive Casing Assembly 26 340.583/12 Cutter Wheel Pin (Pack of 12)

6a 340.285 Flexible Drive Assembly 27 340.552 Centre Bolt for Chipping Leaves

7Nut / Bolt & Washer Set (Part of item 9) 27a 340.545 Centre Bolt for Single Leaf Cutting Head

8Hand guard Clamp (Part of item 9) 28 340.551/2 Side Plate for all Chipping Leaves (Pack of 2)

9340.633 Hand guard Assembly 29 340.558 Centre Bolt for 6” Power Brush

10 Threaded Hexagon Adapter (Part of item 6) 29a 340.559 Centre Bolt for 6” Twisted Knot Brush

11 340.252 Ball Race 29b 340.557 Centre Bolt for Crimped Wire Cup Brush

12 340.TN/11 Domed Screw x 3

13 340.664A Threaded Nose Piece 30 340.160 6” Crimped Wire Power Brush

14 340.TN/110 Electric Motor (inc Skid) 30a 340.166 Crimped Wire Cup Brush

15 340.490 Air Motor (inc base) 30b 340.167 Twisted Knot Cup Brush

16 340.288 Inner Shaft 30c 340.548 Thin Leaf Scaling Head

18 340.581/A Centre bolt kit - 6 Cutter Scaling Head (inc nut). 30d 340.550 Heavy Duty Scaling Head

19 340.160A Hexagon Nut 30e 340.581 6 x Cutter Scaling Head

20 340.584 Washer 30f 340.163 6” Twisted Knot Power Brush

21 340.575/2 Side Plate for 6 Cutter Scaling Head (Pack of 2)

22 340.584/50 Washer for Leaf Scaling Head (Pack of 50) Not Shown in Exploded View

23 340.347/24 Chipping Leaf (Pack of 24) 340.755 Spanner Pack

340.TN/12 Baldor Motor On/Off Switch

PARTS LIST

(k) ** Equals the factor of uncertainty, which allows for variations in measurement and production. Vibration Data figures

are tri-axial, which gives the total vibration emission. Because of various factors, the range of vibration emission during

intended use can vary.

The vibration is dependent on the task, the operators grip, and feed force employed etc.

NOTE: The above vibration levels were obtained from tri-axial measurements to comply with the requirements of “The

Control of Vibration at Work Regulations 2005*” and the revisions to the (8662) now EN ISO 28927-3:2012 and EN ISO

20643:2005 series of standards. These values are at least 1.4 times larger than the values obtained from single axis

measurements.

*Based on European Union Council Directive 2002/44/EC (Physical Agents (Vibration) Directive)

This tool has been designed and produced in accordance with the following directives:

2006/42/EC Machinery Directive

2006/95/EC Low Voltage Directive

If your company has any problem with our products or would like to discuss the possibility of an improvement being made

to them, then please do not hesitate to contact us. Your comments are both important and appreciated.

All rights reserved. Any unauthorised use or copying of the contents or part thereof is prohibited.

This applies to trademarks, model denominations, part numbers and drawings.

Use only genuine Trelawny spares.

The use of non-Trelawny spare parts invalidates the warranty.

Flexible Shaft Length (approximately) 2.7 metres 9ft

Flexible Inner Shaft Diameter 16mm 5/8”

Total Weight Approximately 34 kg 75 lbs

Life expectancy of the cutterheads 50 hrs 50 hrs

Cutting Width Chipping Leaves - 30mm Cutter Wheels - 17mm

Electric Motor 110v / 220v 50 / 60Hz

Amperage 110v = 11.4amp / 115v = 9.8amp 220v = 5.7amp / 230v = 4.9amp

Power 0.75hp

Revolutions per minute 2850rpm at 50Hz / 3450rpm at 60Hz

Time to stop rotation 9 sec

Air Motor - (Air inlet J-Mac Claw Coupling) 6.2bar (90psi) - 32.1 lps (68cfm) 1.1kw (1.5hp )

Revolutions per minute 3000rpm

Noise (process noise not inc) (LwA SWL) 73.1dB (A)

Vibration at Dumbbell Handle (Leaf Cutters) 8.7m/s2 (AEQ) (k = -0% +40% **)

(Cutter Wheels) 5.4m/s2 (AEQ) (k = -0% +40% **)

(Wire Brush) 10.1m/s2 (AEQ) (k = -0% +40% **)

TECHNICAL SPECIFICATIONS

NOTES

Trelawny SPT Ltd

13 Highdown Road, Sydenham Industrial Estate, Leamington Spa,

Warwickshire, CV31 1XT, United Kingdom

Telephone: +44 (0)1926 883781 - Fax: +44 (0)1926 450352

Email: sales@trelawny.co.uk

© TSPT UK 2009 Part No: 735.TN01 issue 21.11.16 www.trelawnyspt.co.uk

Other manuals for Trident Neptune

1

Table of contents

Other Trelawny Tools manuals

Trelawny

Trelawny VL203Ex Troubleshooting guide

Trelawny

Trelawny Vibro Lo Troubleshooting guide

Trelawny

Trelawny VL223EX Series User manual

Trelawny

Trelawny SF3EX User manual

Trelawny

Trelawny Single Scaler Standard Duty User manual

Trelawny

Trelawny SF11EX User manual

Trelawny

Trelawny VLSF1EX User manual

Trelawny

Trelawny LPS55 User manual