Liquiline CM442/CM444/CM448 Table of contents

Endress+Hauser 3

Table of contents

1 About this document .............................................................. 4

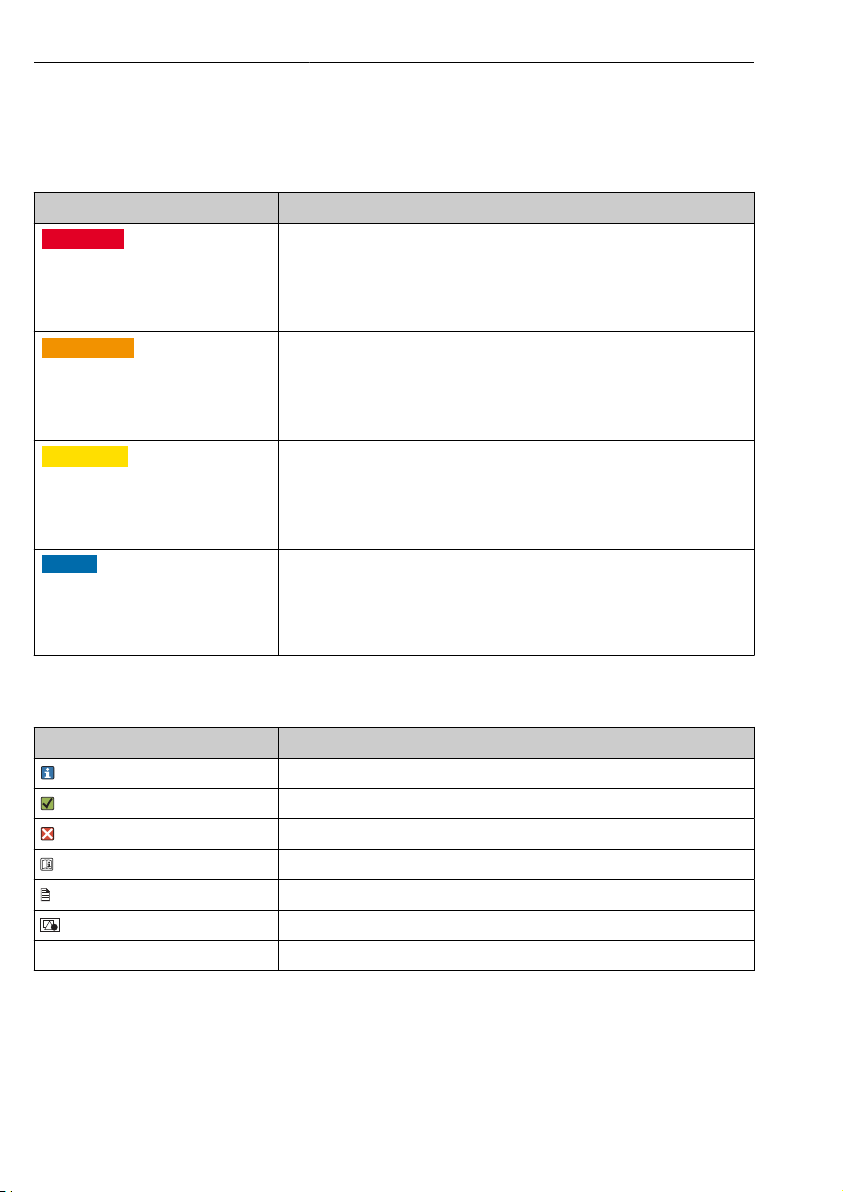

1.1 Warnings ............................................................................ 4

1.2 Symbols ............................................................................. 4

1.3 Symbols on the device ................................................................... 5

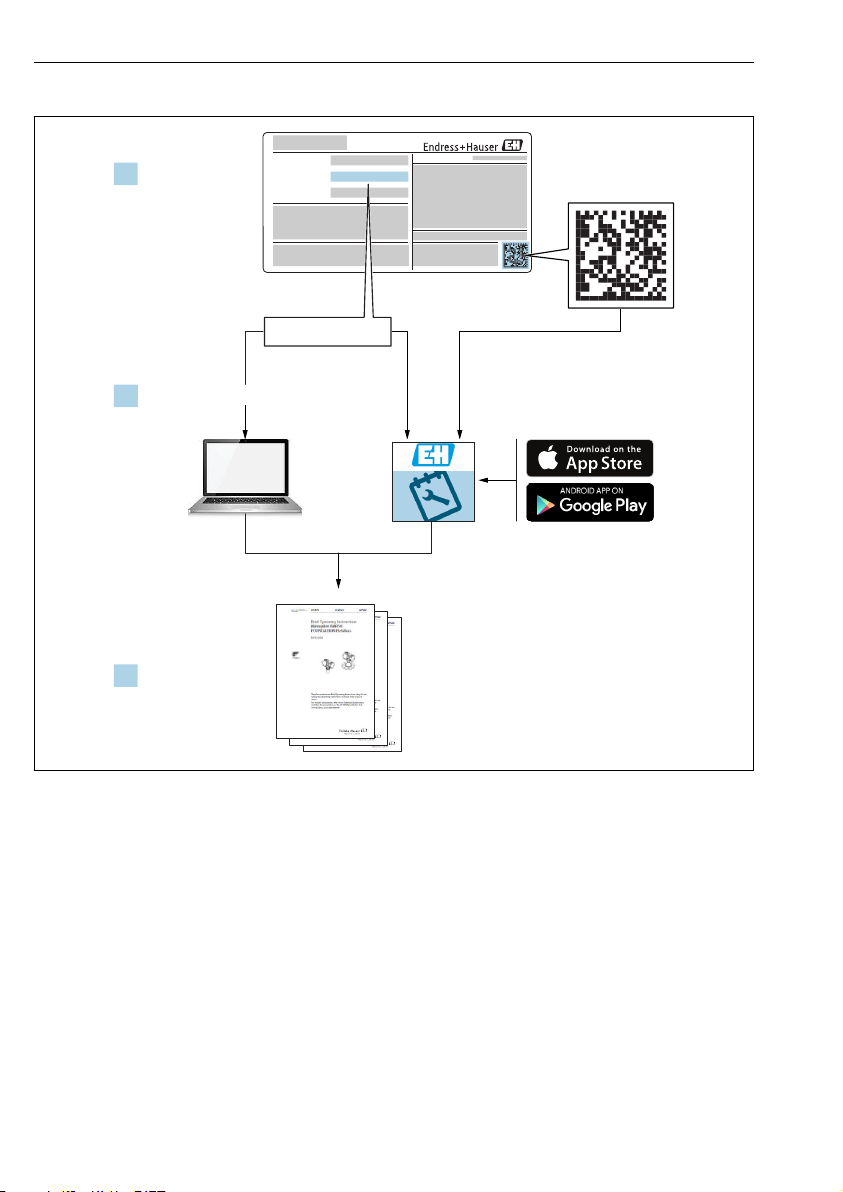

1.4 Documentation ........................................................................ 5

2 Basic safety instructions .......................................................... 6

2.1 Requirements for personnel .............................................................. 6

2.2 Designated use ........................................................................ 6

2.3 Workplace safety ...................................................................... 7

2.4 Operational safety ......................................................................7

2.5 Product safety ......................................................................... 7

3 Incoming acceptance and product identification ................................... 9

3.1 Incoming acceptance .................................................................... 9

3.2 Product identification ................................................................... 9

3.3 Scope of delivery ...................................................................... 10

4 Installation ...................................................................... 11

4.1 Mounting conditions ................................................................... 11

4.2 Mounting the measuring device ...........................................................12

4.3 Post-installation check ................................................................. 15

5 Electrical connection ............................................................ 16

5.1 Connecting the measuring device ......................................................... 16

5.2 Connecting the sensors ................................................................. 23

5.3 Connecting additional inputs, outputs or relays ............................................... 27

5.4 Connecting PROFIBUS or Modbus 485 ...................................................... 30

5.5 Hardware settings ..................................................................... 34

5.6 Ensuring the degree of protection ......................................................... 35

5.7 Post-connection check ..................................................................36

6 Operation options ............................................................... 37

6.1 Overview ........................................................................... 37

6.2 Access to the operating menu via the local display ............................................. 38

7 Commissioning .................................................................. 39

7.1 Function check ....................................................................... 39

7.2 Switching on ......................................................................... 39

7.3 Basic setup .......................................................................... 40