ControlCare Panel PC SPC350 Table of Contents

Endress+Hauser 1

Table of Contents

Revision History . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Registered Trademarks . . . . . . . . . . . . . . . . . . . . . . 2

1 Safety . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.1 Designated used . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.2 Installation, commissioning and operation . . . . . . . . 3

1.3 Operational safety . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.4 Declaration of conformity . . . . . . . . . . . . . . . . . . . . 3

1.5 Technical improvement . . . . . . . . . . . . . . . . . . . . . . 3

1.6 Conventions and icons . . . . . . . . . . . . . . . . . . . . . . 4

2 Identification . . . . . . . . . . . . . . . . . . . . 5

2.1 Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.1.1 Visual check . . . . . . . . . . . . . . . . . . . . . . . . 5

2.1.2 Scope of delivery . . . . . . . . . . . . . . . . . . . . . 5

2.1.3 Storage and transport . . . . . . . . . . . . . . . . . . 5

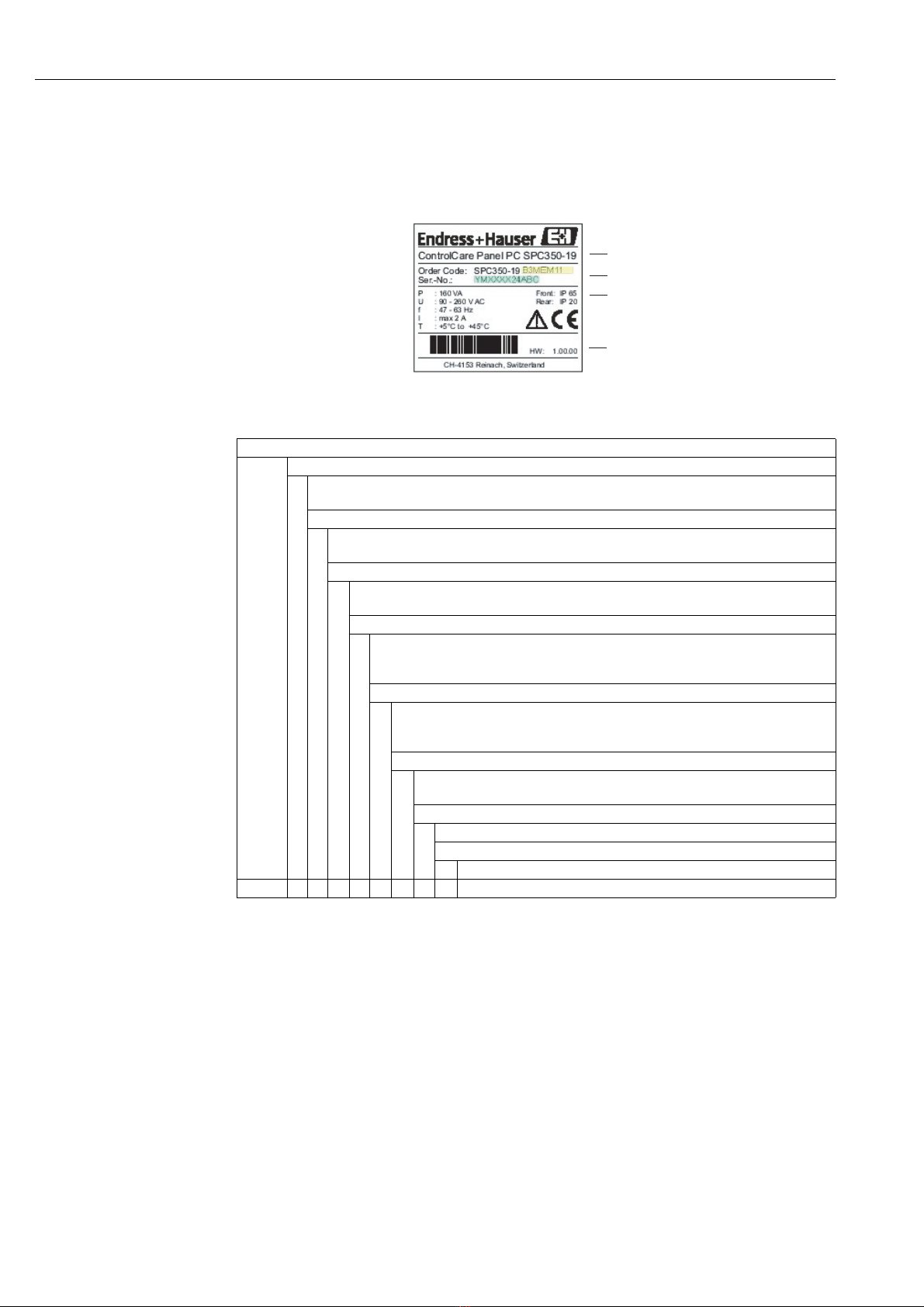

2.2 Device name . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3 Function and System Design . . . . . . . . 7

3.1 Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

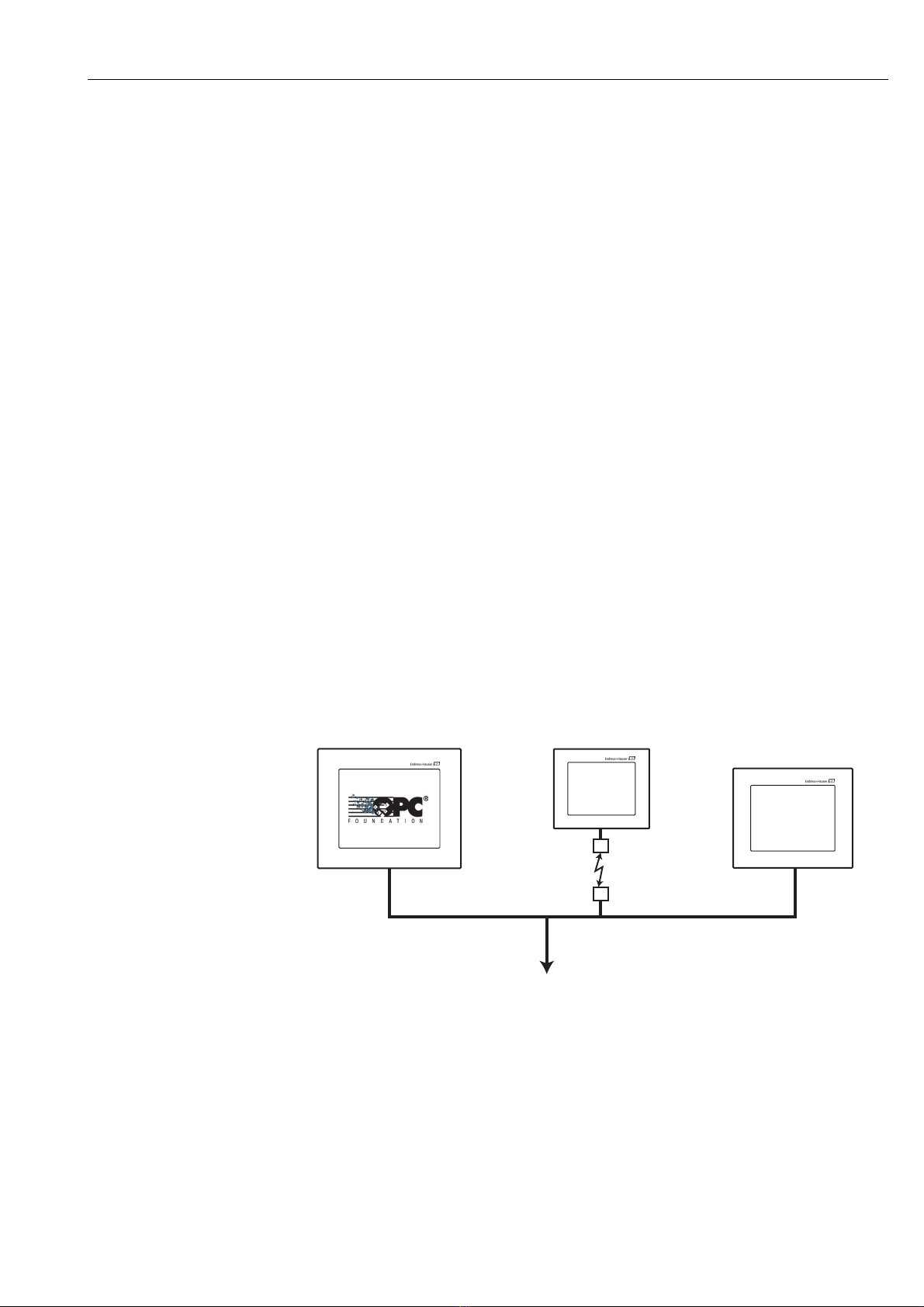

3.2 System design . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

4 Mechanical Installation . . . . . . . . . . . . 8

4.1 Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

4.1.1 Temperature . . . . . . . . . . . . . . . . . . . . . . . . 8

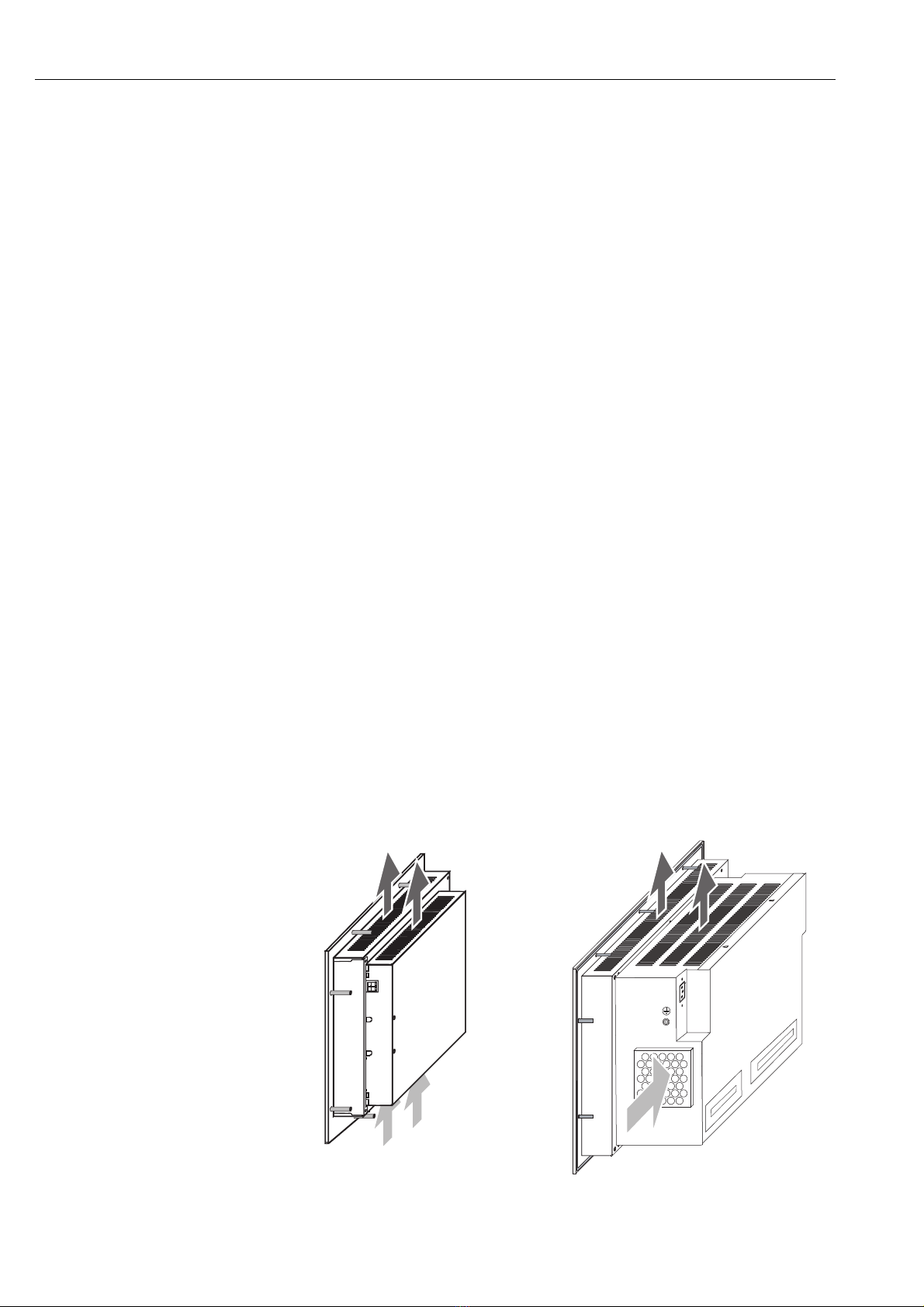

4.1.2 Ventilation . . . . . . . . . . . . . . . . . . . . . . . . . 8

4.2 Installation of the 15" monitor . . . . . . . . . . . . . . . . . 9

4.2.1 Cut-out . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

4.2.2 Fastening and sealing . . . . . . . . . . . . . . . . . . 9

4.3 Installation of the 19" monitor . . . . . . . . . . . . . . . . 10

4.3.1 Cut-out . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

4.3.2 Fastening and sealing . . . . . . . . . . . . . . . . . 10

5 Electrical Installation . . . . . . . . . . . . . 11

5.1 General precautions . . . . . . . . . . . . . . . . . . . . . . . . 11

5.2 Power supply 15" monitor . . . . . . . . . . . . . . . . . . . 12

5.2.1 24 VDC power supply . . . . . . . . . . . . . . . . 12

5.2.2 Plug connector . . . . . . . . . . . . . . . . . . . . . 12

5.3 Power supply 19" monitor . . . . . . . . . . . . . . . . . . . 13

5.3.1 230 VAC plug connector . . . . . . . . . . . . . . 13

5.4 Peripherals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

5.4.1 Access 15" monitor . . . . . . . . . . . . . . . . . . 14

5.4.2 Access 19" monitor . . . . . . . . . . . . . . . . . . 14

5.4.3 Keyboard . . . . . . . . . . . . . . . . . . . . . . . . . . 15

5.4.4 Mouse . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

5.4.5 Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

5.4.6 Monitor . . . . . . . . . . . . . . . . . . . . . . . . . . 15

5.4.7 Ethernet network . . . . . . . . . . . . . . . . . . . 15

5.4.8 Hardware extensions . . . . . . . . . . . . . . . . . 15

5.5 External interfaces . . . . . . . . . . . . . . . . . . . . . . . . . 16

5.5.1 Serial port COM1 [RS-232] . . . . . . . . . . . . 16

5.5.2 Ethernet ports . . . . . . . . . . . . . . . . . . . . . . 16

5.5.3 USB ports . . . . . . . . . . . . . . . . . . . . . . . . . 16

5.5.4 VGA port . . . . . . . . . . . . . . . . . . . . . . . . . . 17

5.5.5 PS/2 mouse port . . . . . . . . . . . . . . . . . . . . 17

5.5.6 PS/2 keyboard port . . . . . . . . . . . . . . . . . . 17

5.5.7 PROFIBUS DP port . . . . . . . . . . . . . . . . . . 18

5.5.8 Parallel LPT1 port . . . . . . . . . . . . . . . . . . . 18

6 Commissioning and Operation . . . . . 19

6.1 Start-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

6.2 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

6.3 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

6.3.1 Display backlights . . . . . . . . . . . . . . . . . . . 19

7 Technical Data . . . . . . . . . . . . . . . . . 20

7.1 Panel PC Specification . . . . . . . . . . . . . . . . . . . . . . 20

7.2 Operating Conditions . . . . . . . . . . . . . . . . . . . . . . . 21

7.3 Mechanical Construction . . . . . . . . . . . . . . . . . . . . 21

7.4 Certificates and Approvals . . . . . . . . . . . . . . . . . . . 21

Index . . . . . . . . . . . . . . . . . . . . . . . . . 24