Table of contents RIA14

2 Endress+Hauser

Table of contents

1 About this document ................ 3

1.1 Symbols .............................. 3

1.2 Documentation ........................ 4

2 Basic safety instructions ............ 5

2.1 Requirements for the personnel ............ 5

2.2 Intended use .......................... 5

2.3 Workplace safety ....................... 5

2.4 Operational safety ...................... 5

2.5 Product safety ......................... 6

2.6 IT security ............................ 6

3 Incoming acceptance and product

identification ....................... 6

3.1 Incoming acceptance .................... 6

3.2 Product identification .................... 7

3.3 Storage and transport ................... 7

3.4 Certificates and approvals ................ 7

4 Mounting .......................... 8

4.1 Mounting requirements .................. 8

4.2 Mounting the measuring device ............ 8

4.3 Post-installation check .................. 10

5 Electrical connection .............. 10

5.1 Connection requirements ................ 10

5.2 Connecting the device .................. 11

5.3 Ensuring the degree of protection .......... 12

5.4 Post-connection check .................. 12

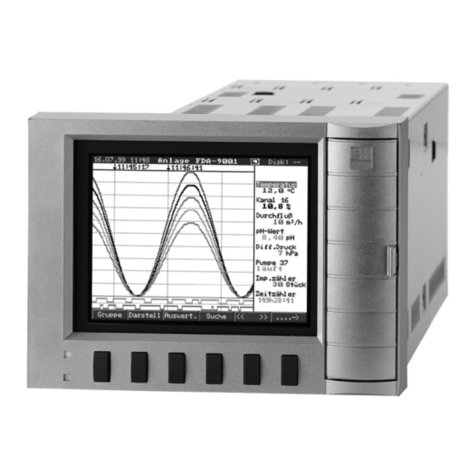

6 Operation options ................. 13

6.1 Overview of operation options ............ 13

6.2 Access to the operating menu via operating

keys ............................... 13

6.3 Structure and function of the operating

menu .............................. 15

6.4 Access to the operating menu via the

operating tool ........................ 16

7 Commissioning .................... 17

7.1 Post-installation check .................. 17

7.2 Switching on the device ................. 18

7.3 Configuring the measuring device .......... 18

8 Diagnosis and troubleshooting ..... 22

8.1 General troubleshooting ................. 22

8.2 Diagnostic list ........................ 22

9 Maintenance ...................... 23

9.1 Cleaning ............................ 23

10 Repair ............................ 23

10.1 General information ................... 23

10.2 Spare parts .......................... 23

10.3 Return .............................. 25

10.4 Disposal ............................ 25

11 Accessories ....................... 25

11.1 Communication-specific accessories ........ 25

12 Technical data .................... 26

12.1 Input ............................... 26

12.2 Output ............................. 26

12.3 Power supply ......................... 27

12.4 Performance characteristics .............. 28

12.5 Mounting ........................... 28

12.6 Environment ......................... 28

12.7 Mechanical construction ................ 29

12.8 Human interface ...................... 30

12.9 Certificates and approvals ............... 32

12.10 Documentation ....................... 32