Contents

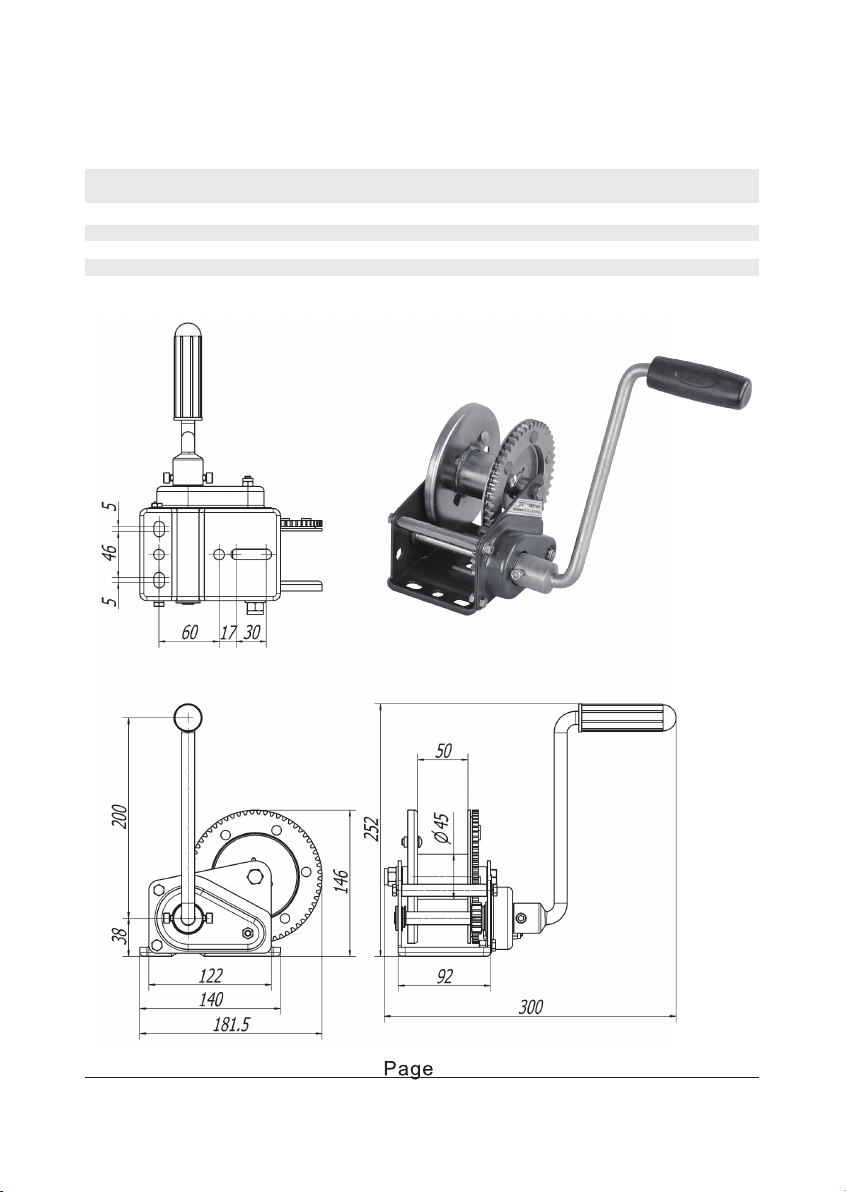

HAND WINCH MODEL ..................................................................................................

(RBW1000/RBW1200/RBW1500) ............................................................................

(RBW2000/RBW2500) ..............................................................................................

(RBW3500) ...............................................................................................................

(RBW1000F/RBW1200F/RBW1500F) ......................................................................

(RBW2000F/RBW2500F) .........................................................................................

(RBW3500F) .............................................................................................................

(RWS2000) ...............................................................................................................

ACCESSORIES FOR HAND WINCH........................................................................

(RWC1200/RSS2000) ...............................................................................................

SAFETY WARNING AND PRECAUTION ..............................................................

SPECIAL WARNINGS AND PRECAUTIONS ......................................................

ASSEMBLY .........................................................................................................................

OPERATION .......................................................................................................................

1

1

2

3

4

5

6

7

8

8

9

11

13

17

FIELD OF APPLICATION

Auto Brake winches are suitable fo r li fti ng , ra i si ng, and p u ll i ng

o f v a ri o u s l o a d s w i th o u t j e r ki n g a n d a re m a i n l y u se d a s a

trai l er w i nch.

It is not tested for building hoists.

It is not suitable for continuous operation.

It is not approved for stages and studios.

It is not approved for lifting persons.

It is not approved for motor-driven operation.