Endurance RWP2000-01 User manual

INSTALLATION AND OPERATION

MANUAL

WORMGEARHANDWINCH

TO PREVENT SERIOUS INJURY,

READ AND UNDERSTAND ALL WARNINGS AND INSTRUCTIONS BEFORE USE.

Due to continuing improvements,actual product may differ slightly from the product described herein.

210- 13198 26th Ave, Surrey British Columbia V3S3V7

[email protected] www.shop-endurance-marine.com Toll Free: 1-877-535-0669

Operating Instructions & Parts Manual

Please read and save these instructions. Read carefully before attempting to assemble, install, operate or maintain the product described.

Protect yourself and others by observing all safety information. Failure to comply with instructions could result in personal injury and/or

property damage! Retain instructions for future reference.

Unpacking

RWP2000-01 and RWP2000-02

3/16” 1/4” 5/16"

Winch drum capacity

for steel cable

(ft)

Model

Number Application Capacity

(lbs)

Gear

ratio

Handle

force

(lbs)

Remark Net

Weight

(lbs)

Specifications

Model Model

Cable

Layer

Rated Line Pull

with 1/4" cable with 5/16" cable

RWP2000-01

RWP2000-02

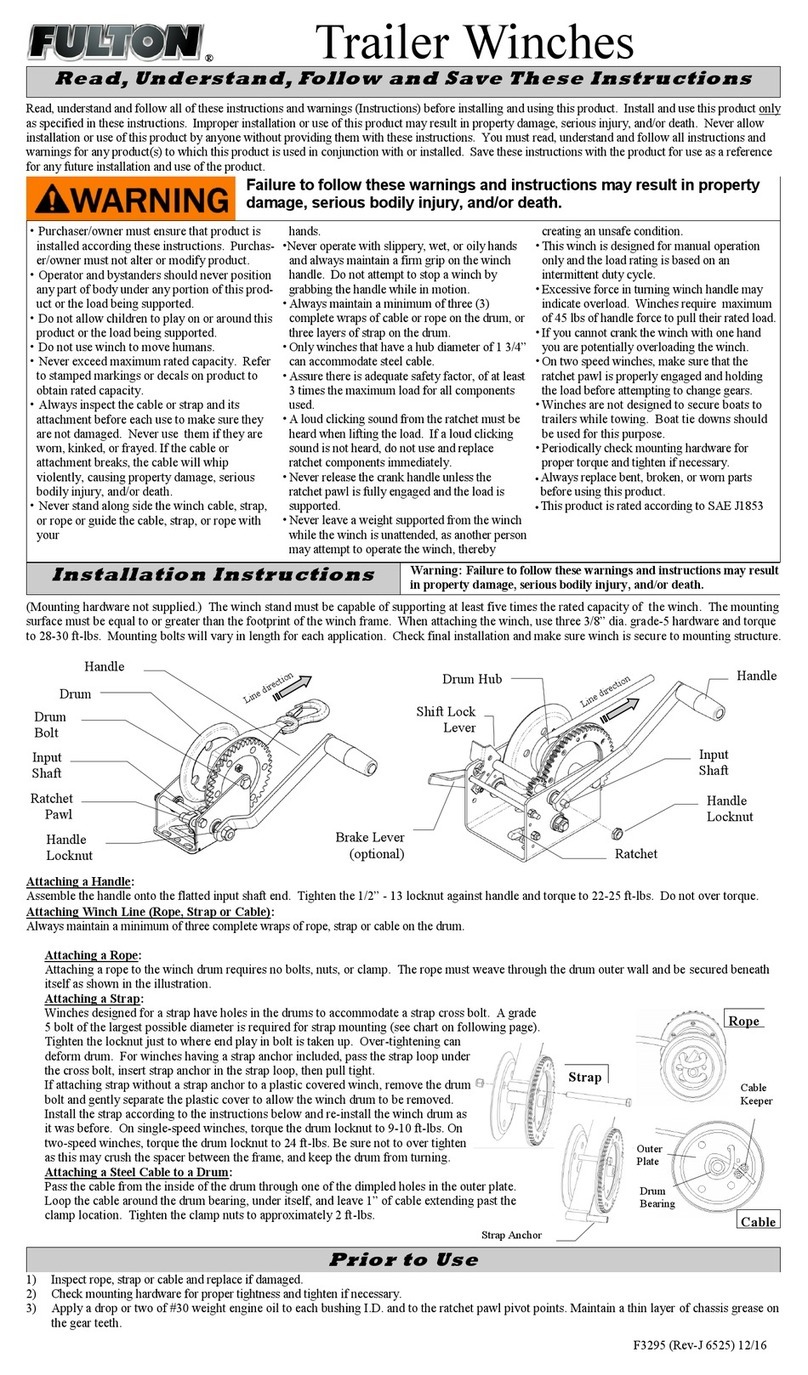

Description

Model RWP2000-02

Description

Model RWP2000-01

Field of application

Worm Gear Winch model RWP2000-02 is

suitable for lifting,raising, and pulling of

various loads without jerking and are mainly

used as a trailer winch.

It is not tested for building hoists.

It is not suitable for continues operation.

It is not approved for stages and studios.

It is not approved for lifting persons.

It is not approved for motor-driven operation.

Field of application

Worm Gear Winch model RWP2000-01 is

suitable for horizontal towing and pulling

only.

It is not permitted for lifting load.

It is not permitted for hoisting load.

It is not permitted for lowering down load.

It is not designed for stage and studio

applications.

It is not designed for personnel mobiling

application.

It is not designed for motor driven operation.

It is not designed for continuous operation.

After unpacking the winch, inspect carefully

for any damage that may have occurred during

transit. Check for loose, missing, or damaged

parts. Shipping damage claims must be filed

with carrier. Winch handle and winch enclosed

should be ready to install.

RWP2000-01

RWP2000-02

pulling

Lifting

2000

2000

≤48.4

≤45

140 ft.

-

77 ft.

77 ft.

52 ft.

52 ft.

manual

auto-brake

RWP2000-01

RWP2000-02 (lbs)

RWP2000-01 RWP2000-02

(lbs)

31

37

1st

Mid

Full

Model

with 3/16" cable

RWP2000-01

RWP2000-02 (lbs)

24:1

32:1

-

-

-

2000

1700

1300

2000

1700

1300

2000

1700

1300

2000

1500

1200

2000

1500

1200

1

2

Safety warning and precaution

1. KEEP WORK AREA CLEAN AND DRY

Cluttered, or wet work areas can cause

injuries.

2. KEEP CHILDREN AWAY FROM

WORK AREA

Do not allow children to handle this

winch.

3. DO NOT USE THIS WINCH IF

UNDER THE INFLUENCE OF

ALCOHOL OR DRUGS

Read warning labels on the winch to

determine if your judgement of

reflexes are impaired while taking

drugs. If there is any doubt, do not

attempt to use this winch.

4. USE EYE AND HAND PROTECTION

Wear safety impact eyeglasses and

heavy duty work gloves when using

this winch.

5. DRESS SAFELY

Do not wear loose clothing or

jewelry, as they can become caught

in moving parts. Wear a protective

hair covering to prevent long hair

from becoming caught in moving

parts. If wearing a long sleeve shirt,

roll sleeves up above elbows.

6. DO NOT OVERREACH

Keep proper footing and balance at

all times to prevent tripping, falling,

back injury, etc.

7. STAY ALERT

Watch what you are doing at all times.

Use common sense. Do not use this

winch when you are tired.

8. CHECK FOR DAMAGED PARTS

Before using this winch, carefully check

that it will operate properly and

perform its intended function. Check

for damaged parts and any other

conditions that may affect the operation

of this winch. Replace or repair damaged

or worn parts immediately.

9. REPLACEMENT PARTS AND

ACCESSORIES

When servicing, use only identical parts.

Only use accessories intended for use

with this winch.

10.MAINTENANCE

For your safety, service and maintenance

should be performed regularly by a

qualified technician.

WARNING:

The warnings, precautions and

instructions discussed in this Manual

cannot cover all possible conditions

and situations that may occur. It must

be understood by the operator that

common sense and caution are factors

which cannot be built into this product,

but must be supplied by the operator.

Special warnings and

precautions

1. CAUTION: Never exceed the

maximum load capacity specified

for each model.

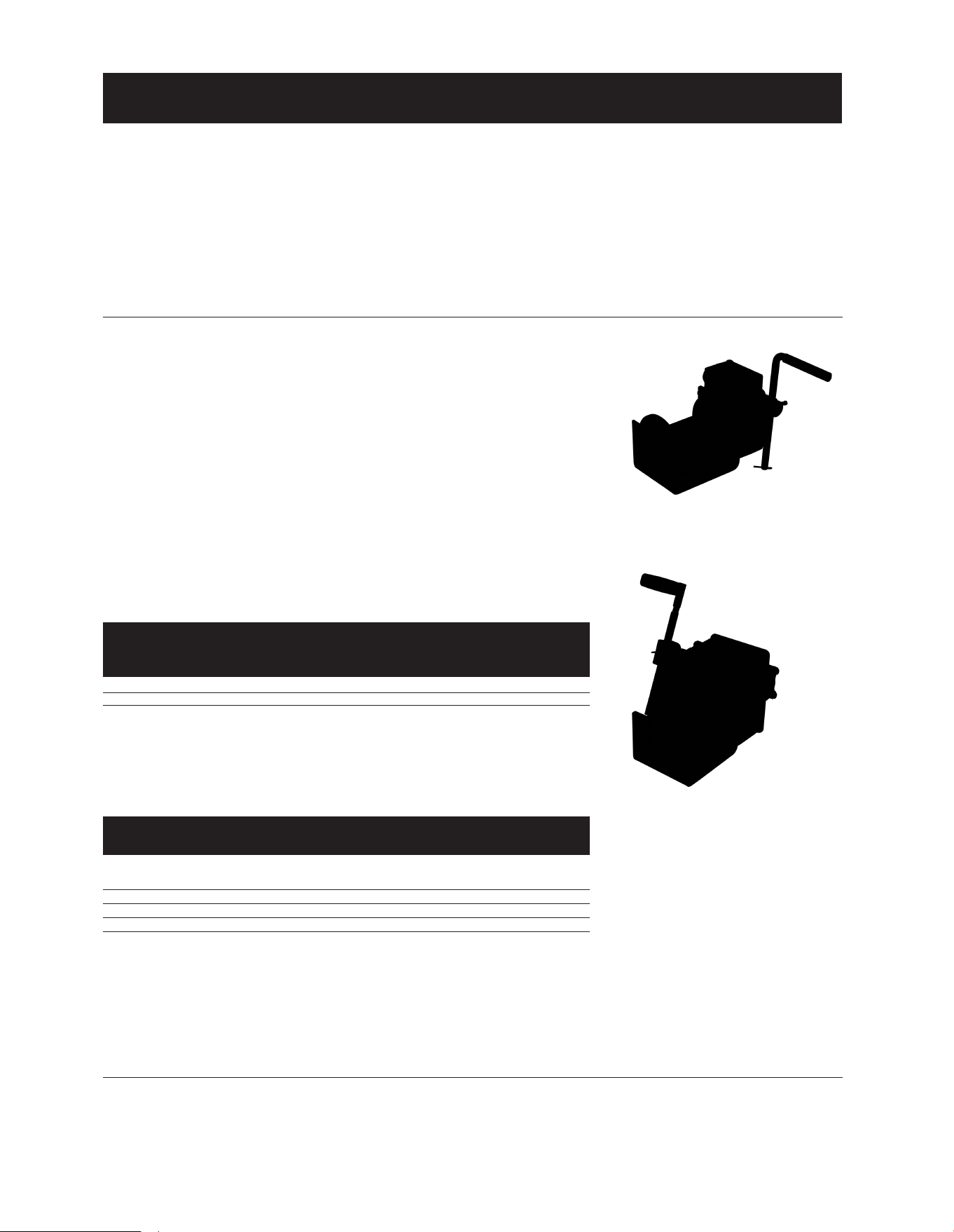

3. AVOID SIDEWAYS CABLE SLIP

The cable under a load should

only be wound on to the drum to

such an extent that a minimum

space of 2 times the cable diameter

remains on the drum flange

(see Figure 1). Winch overloading

and a sideway cable slip will here

be avoided.

2. AUTOMATIC MECHANICAL

BRAKE REQUIREMENT

The minimum tractive force (pulling

load) required for a proper braking

function on the winch is 55 lbs

(25kgs). Without this minimum

load, the braking function will

not take place.

Figure 1

4. ALWAYS LEAVE AT LEAST 5

WRAPS OF THE CABLE ON

THE DRUM

Failure to do so may break cable

connection to drum and may

result in serious accident.

(see Figure 2)

Figure 2

5. DO NOT OIL OR GREASE THE

BRAKE MECHANISM

Oil or grease will make the winch

reduce or lose brake function.

6. ALWAYS USE PROPER

COUPLINGS WHEN CONNECTING

THE WINCH CABLE HOOK TO A

LOAD.

7. MAKE SURE THE WINCH BASE

IS PROPERLY BOLTED TO A

STRUCTURE (OR VEHICLE)THAT

CAN HOLD WINCH AND WINCH

LOAD

Failure to bolt down the winch

properly can result in personal

injury and/or property damage.

8. DO NOT USE ANY ATTACHMENTS

to extend the length of the winch

cable.

9. AFTER MOVING AN OBJECT WITH

THE WINCH, SECURE THE OBJECT.

DO NOT RELY ON THE WINCH TO

HOLD AN OBJECT FOR AN

EXTENDED PERIOD OF TIME.

RWP2000-01 and RWP2000-02

5 wraps

m=freeboard≥2d(mm)

D

d

m

F

W

Model RWP2000-01 and RWP2000-02

10. DO NOT APPLY A LOAD to the winch

when the winch cable is fully extended.

The cable anchor on the winch is not

capable of holding the maximum rated

load capacity.

11. STAND BACK

Stay out of the direct line that the

winch cable slips or breaks, it will

“whip lash” along this line.

winch cable is pulling. In the event the

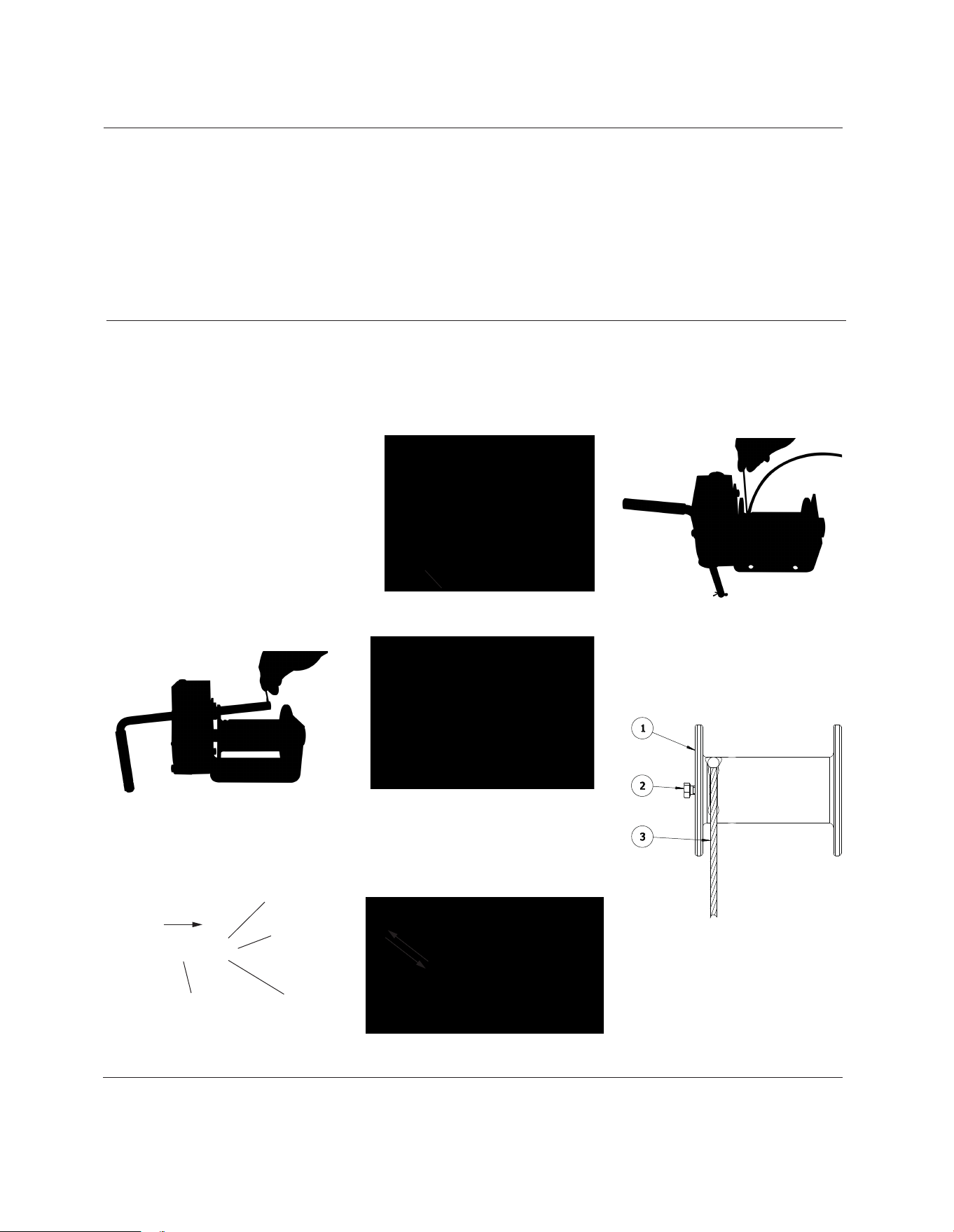

FITTING THE CABLE:

FITTING THE CABLE for RWP2000-01:

Push the steel cable into Drum cable

hole. Let the cable extrude out of the

hole by 15mm (not exceeding drum

circumference). Screw the cable

tightly.(Figure 7)

Assembly

1. Loosen the thumbscrew and slide the

handle toward the Adjustable handle

holder as shown

(see Figure 4)

2. Line up the notch in the handle with the

point of the Hex in the Holder.

3. Slide the handle and Holder install

onto the Hex drive on the brake until

the flat of the handle lines up with the

groove in the Hex drive. (see Figure 5-1,

5-2)

thumbscrew

notchnotch

slide Adjustable

handle holder

Figure 4

Figure 3

Figure 5-1

groove

Figure 5-2

Figure 6

slide handle out to desired length

and tighten thumbscrew

Handle Installing for RWP2000-01

4. Slide the handle outward away from

the Holder to the desired length then

tighten the thumbscrew. (see Figure 6)

Handle Installing for RWP2000-02

1. Insert Handle Assembly into the

handle Socket. Adjust the handle

length to suit the operation.

2. Tighten the set screw to hold it in

place.

3. Insert Cotter Pin into the pin hole

at the end of the handle and bend

it to secure in place.

FITTING THE CABLE for RWP2000-02:

Put the ball-headed steel cable into

Drum cable slot. Let the cable extrude

out of the slot by 20mm (not exceeding

drum circumference).

Screw the cable tightly.(Figure 8 )

Drum

Screw

Steel Cable

Figure 7

Figure 8

handle flat lines up

with groove

3

4

RWP2000-01 and RWP2000-02

WARNING

Fit the winch with the fleet angle

no more than 4°(Figure 10)

Figure 9

cable

cable clamp

Spring latch Hook

Figure 10

Figure 11

The belt breaking strain must be at

least 3 times the pulling capacity

and 7 times the lifting capacity of

the winch.

Grommet

Thimble

FITTING POSITION OR DIRECTION

OF OPERATION

≤4°

Lubricating

Lubricate the bearing regularly

with 2 to 3 drops of SAE 30

non-detergent oil

5

Overall dimension (Inches)

RWP2000-01 8 10 3/8

5 91/2

75/8

21/2

33/43/84 5

Model A B C D E F G

H I J

Model A

RWP2000-02

137/8

71/4

15 91

/8115

/8

5

81/233/43/84

21/25 61/812

B C D E F G

H I J K L M S

Model RWP2000-01 and RWP2000-02

Ø

Ø

Ø

A

B

DE

F

J

G

H

I

C

S

M

L

F

C

B

A

D

E

I

H

J

K

G

Repair Parts List for Manual Winch

Ref. Ref.

No. Description Qty. No. Description Qty.

(*) Not available as a repair part.

Operating Instructions and Parts Manual RWP2000-01 and RWP2000-02

Please provide following information:

-Model number

-Serial number (if any)

-Part description and number as shown in parts list

6

Repair Parts Illustration for RWP2000-01

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

Front Cover

Spring Pin 5x24

Bolt M8x80

Nut M8

Worm

Worm Gear

Copper Disc

Square-head Screw Plug 1/8-27

Spring Pin 6x32

Spring Pin 4x32

Handle Assembly

Socket-handle

Dry Bushing

Square-head Screw Plug 3/8-27

Flat Key A type 8x7x25

Set Screw 1/8-27

Back Cover

1

2

4

4

1

1

2

1

1

1

1

1

2

2

1

3

1

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

Square-head Screw M8x12

Set Screw M8x12

Tapered Cotter 8x60

Drum Assembly

Screw M8x16

Nut M8

Frame

Output Shaft

Cotter Pin 4x25

Label -Model

Label -Handle

Label -Caution

Label -Oil

Label -Warning

Label -Spool

1

1

1

1

1

1

1

1

1

1

1

1

1

3

1

1

1

2

3

4

56789 10

11

12

14

15

16

17 18

19 20 21 22

23 24

25

27

13

26

30

31

31

33

28

32

29

Repair Parts List for Manual Winch

Ref. Ref.

No. Description Qty. No. Description Qty.

Operating Instructions and Parts Manual RWP2000-01 and RWP2000-02

7

Please provide following information:

-Model number

-Serial number (if any)

-Part description and number as shown in parts list

Repair Parts Illustration for RWP2000-02

1

2

3

4

5

6

7

8

9

10

(*) Not available as a repair part.

11

12

13

14

15

16

17

18

19

20

2

2

1

1

1

1

1

1

1

1

Reducer Assembly

Hex Input Assembly

Key

Handle Medallion Assembly

Nut M10

Screw M8x20

Drum Assembly

Tapered Cotter 8x64

Frame

Flange Bearing

1

1

1

1

4

1

1

1

1

1

Square-head Screw M16x40

Nut M16

Label ( warning-do not adjust brake when )

Name Plate

Label ( code number)

Labe ( warning to avoid injury or property damage )

Label ( warning-keep hands away from drum )

Seal Plug R 1/8)

Label ( warning )

Label ( model/capacity)

210- 13198 26th Ave, Surrey British Columbia V3S3V7

[email protected] www.shop-endurance-marine.com Toll Free: 1-877-535-0669

This manual suits for next models

1

Table of contents

Other Endurance Winch manuals

Popular Winch manuals by other brands

Fransgard

Fransgard V6521 manual

HyQuest Solutions

HyQuest Solutions BAROSSA DDT700 user manual

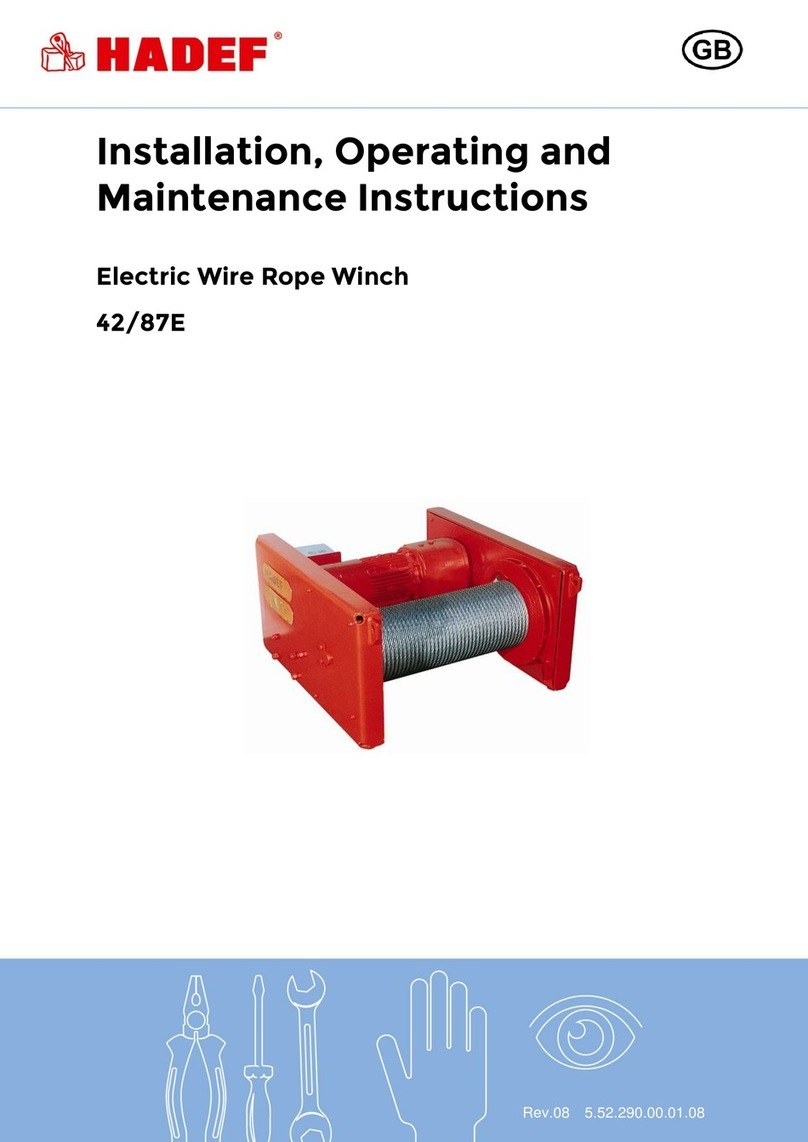

HADEF

HADEF 42/87E Installation, Operating and Maintenance Instruction

POWERWINCH

POWERWINCH 212 owner's manual

HERKULES

HERKULES SHZ 125/250 operating instructions

Haklift

Haklift VAVINTH300EL Original instructions