ENERCON Ejector User manual

JECTOR

CONTAINER EJECT SYSTEM

ML0068-001-02

OWNERS REFERENCE MANUAL

Enercon Industries Corp.

W140 N9572 Fountain Blvd.

P.O. Box (53052-0773)

Menomonee Falls, WI 53051

Phone: (262) 255-6070

Fax: (262) 255-7784

E-mail: info@enerconind.com

Web Site: www.enerconind.com

01/07/2003

EJECT SYSTEM

TABLE OF CONTENTS

SECTION 1 – INTRODUCTION...................................................................................................................................1

SAFETIES AND WARNINGS.......................................................................................................................1

GENERAL....................................................................................................................................................2

EJECT SYSTEM FEATURES.......................................................................................................................2

EJECT SYSTEM SPECIFICATIONS............................................................................................................2

SECTION 2- INSTALLATION.......................................................................................................................................3

UNPACKAGING AND INSPECTION............................................................................................................3

EJECT SYSTEM CONTROL BOX................................................................................................................3

COMPRESSED AIR.....................................................................................................................................3

EJECT SIGNAL............................................................................................................................................3

INPUT POWER.................................................................................................................................3

EJECT SYSTEM INSTALLATIONWITH FOIL LINER DETECTOR (Figure 1)...............................................4

EJECT SYSTEM INTALLATION WITH CAP INSPECTION SYSTEM (Figure 2)............................................4

SECTION 3 – PRINCIPLES OF OPERATION............................................................................................................5

METHOD OF OPERATION..........................................................................................................................5

SECTION 4 – EJECT SYSTEM MAINTENANCE..............................................................................................................6

CLEANING...................................................................................................................................................6

ADJUSTING.................................................................................................................................................6

SECTION 5 – TROUBLESHOOTING..........................................................................................................................7

SECTION 6 – PARTS LIST ..........................................................................................................................................8

GENERAL....................................................................................................................................................8

DESCRIPTION.............................................................................................................................................8

HOW TO USE THIS PARTS LIST ................................................................................................................8

HOW TO ORDER PARTS............................................................................................................................8

EJECTOR PARTS BREAKDOWN (Figure 3)................................................................................................9

SECTION 7– MISCELLANEOUS...............................................................................................................................10

EJECT SYSTEM PRODUCTION SETUP ...................................................................................................10

NOTES.......................................................................................................................................................11

ML0068-001-02 Container Eject System ENERCON INDUSTRIES

1

SECTION 1 – INTRODUCTION

WARNING

Please read carefully before installing or servicing.

HIGH VOLTAGE is present within the control box enclosure. Install according to local electrical codes to

insure personnel safety. When SERVICING, technician must insure that external electrical power is

disconnected and locked out before making contact with the equipment.

As with any piece of ELECTRICAL equipment, one should become familiar with the manual and all

associated drawings furnished before applying power. Proper connections and operation are required for safe

use. FOLLOW INSTRUCTIONS for safety of personnel when operating or maintaining this equipment.

SAFETY AND WARNING

Before you install this Eject System, you should

take the time to carefully read all the instructions

contained in this manual.

Before installing, wiring, starting, operating or

making any adjustments, identify the components

of the Eject System, using this manual as a guide.

The operator should use common sense and good

working practices while operating and maintaining

this unit. Check the safety devices following the

procedures contained in this manual.

Qualified personnel, adequately equipped with

proper tools should do maintenance. Follow the

maintenance schedules as outlined in the manual

to insure problem free operation after start-up.

Safety instructions in this manual are bold-faced for

emphasis. The signal words WARNING and

CAUTION are used to indicate hazard seriousness

levels as follows:

*** CAUTION ***

Caution is used to indicate the presence of a

hazard, which will or can cause minor

personal injury or property damage if the

caution is ignored.

*** WARNING ***

Warning is used to indicate the presence of a

hazard which can cause severe personal

injury, death, or substantial property

damage, if the warning is ignored.

ML0068-001-02 Container Eject System ENERCON INDUSTRIES

2

GENERAL

The Enercon Eject System was designed to provide

the packaging industry with a simple system to

eject bad containers off a conveyer. The eject

system can be used with any “bad container”

detectors, such as; missing foil detectors, high cap

detectors and missing cap detectors to name a few.

The system accepts a contact closure from the

desired “bad container” detector which starts a

delay timer. Once timed out, the eject timer is

activated, causing the plunger to eject the container

off the conveyor.

EJECT SYSTEM FEATURES

a. Delay timer

Used to set the time from when the bad

container is detected to when the container

reaches the eject zone.

b. Eject time

Used to set the time for how long the eject

plunger is activated.

c. Cylinder speed adjust

Used to set the extension and retraction

speed of the plunger .

d. Air pressure regulator and gauge

Used to set the force of the plunger.

EJECT SYSTEM SPECIFICATIONS

Electrical

a. A power cord is supplied for customer

connection to a local power source. The

power required is either 120VAC or 240VAC ±

10%, 50/60 Hz, 1ph, 2A. Check rating plate of

eject system for correct voltage.

b. A 12ft. two conductor cable is also supplied

for the external signal input.

Air requirements

a. Filtered air is required at 70-90 PSI.

*** WARNING ***

BE SURE ALL POWER IS DISCONNECTED AND

LOCKED OUT FROM UNIT BEFORE PERFORMING

ANY PREVENTATIVE MAINTENANCE PROCEDURES.

ML0068-001-02 Container Eject System ENERCON INDUSTRIES

3

SECTION 2- INSTALLATION

UNPACKAGING AND INSPECTION

Carefully open all shipping containers and remove

the contents. Each item should be thoroughly

inspected for damage.

NOTE: Be extra careful if using a sharp instrument

when removing the protective wrapping from the

equipment. File a claim with the freight carrier for

any damage incurred. Enercon Industries should

also be contacted as soon as possible to expedite

the shipment of replacements parts.

CONTACT:

IMPORTANT:

If concealed loss or damage is discovered after

delivery, notify your carrier at once and request an

inspection. This is absolutely necessary for the

carrier to consider your claim. If damage is

detected, be sure to note it on freight bill before

signing it to acknowledge receipt. The carrier agent

should make an inspection and issue a loss or

damage report. If you give the carrier a clear

receipt for goods that have been damaged or lost in

transit, you do so at your own risk and expense.

EJECT SYSTEM CONTROL BOX

The eject system control box should be mounted

near the bad container detection system that is

being used. If the eject system is being used with

an Enercon supplied Foil Liner Detector it should

be mounted “downstream” of the detector (See

Figure 1). If the eject system is being used with an

Enercon supplied Cap Inspection System it should

be mounted between the high cap sensor and the

power supply (See Figure 2). The eject system

must be mounted no further than 9.99 seconds

“down stream” due to the maximum range of the

delay timer. To calculate the maximum distance the

ejector can be mounted from the bad container

detector simply multiply the conveyer speed in

feet/second times 9.99 seconds. The ejector should

then be mounted somewhere within this window.

The ejector can then be mounted on the side of the

conveyor using the angle brackets and hardware

supplied.

COMPRESSED AIR

Once the eject system control box has been

installed, filtered compressed air (70-90 PSI) will

need to be supplied to the control box (see the

installation diagram for the location). For ease of

installation, a one – touch fitting for 3/8 outside

diameter plastic tubing is supplied.

EJECT SIGNAL

The eject control box requires a normally open

contact signal that momentarily closes from the bad

container detector for activation. A 12ft two-

conductor cable for this signal is supplied. If you

have purchased this for an Enercon cap sealer this

cord will have a plug on the end which is to be

connected to the back of the power supply.

INPUT POWER

A power cord is supplied with the eject system and

can be plugged into a standard 120V receptacle to

power the system. (240V power is optional.

Observe the rating plate for the correct voltage)

Enercon Customer Service Department

Phone Number: (262) 255-6070

Fax Number: (262) 255-2462

E-Mail Address: info@enerconind.com

Website: www.enerconind.com

24hr Customer Service is available.

ML0068-001-02 Container Eject System ENERCON INDUSTRIES

4

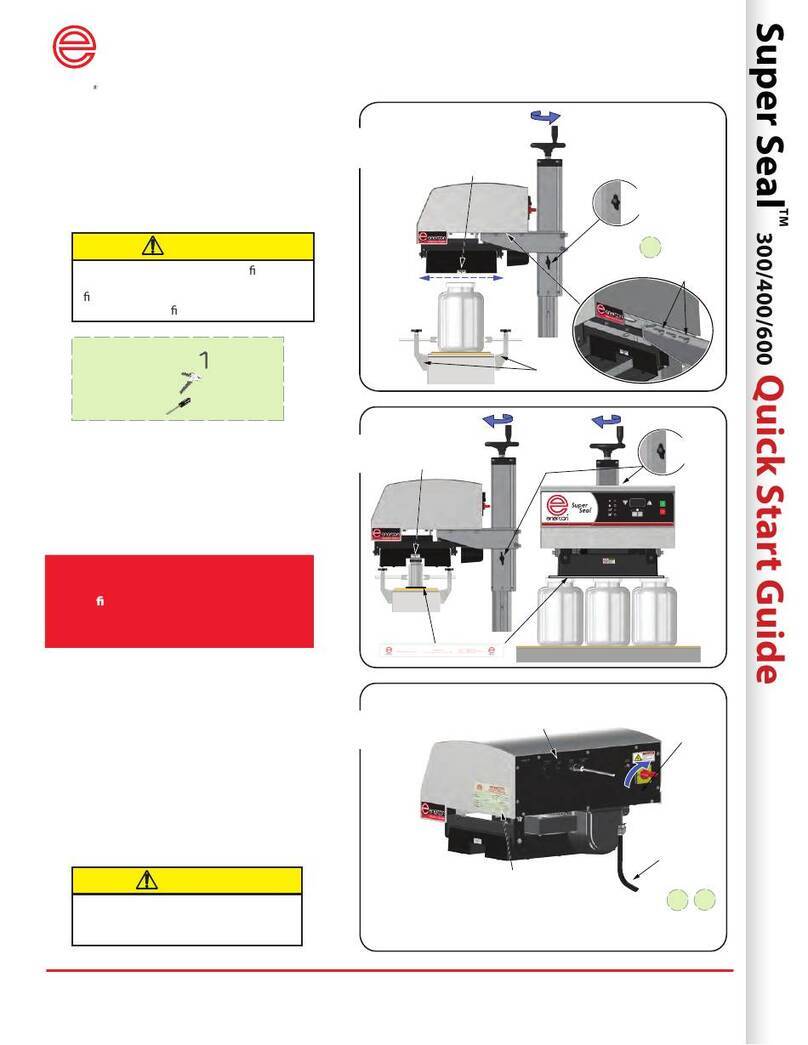

EJECT SYSTEM INSTALLATION WITH FOIL LINER DETECTOR

Figure 1

EJECT SYSTEM INTALLATION WITH CAP INSPECTION SYSTEM

Figure 2

ML0068-001-02 Container Eject System ENERCON INDUSTRIES

5

SECTION 3 – PRINCIPLES OF OPERATION

METHOD OF OPERATION

Once the eject system has been installed, adjust

the air pressure regulator to 70 PSI. Apply power to

the eject system by using the power on switch on

the right side of the box to turn the unit on. (Insure

the timer displays energize with power applied.)

The system is now ready for testing and calibrating.

The eject system is designed to use an external

eject signal from a bad container detector. Upon

receiving an eject signal, the delay timer is

activated. As the bad container approaches the

eject box, the delay timer will time out. Once timed

out the plunger will be activated for a set time and

consequently push the container off the conveyor.

If the plunger activates prior to the container

reaching the plunger increase the delay time by

using the up arrow and repeat the test. Continue

this process until the plunger makes contact with

the center of the container as it passes in front of

the plunger.

If the plunger activates after the container reaches

the plunger decrease the delay time by using the

down arrow and repeat the test. Continue this

process until the plunger makes contact with the

center of the container as it passes in front of the

plunger.

The amount of time the plunger is in the extended

position is also adjustable and can be increased or

decreased by using the up/down arrows. (It is

recommended to adjust this time to approximately

0.08 seconds as a starting point when setting up

the system) This timer should not be operated with

a timer setting longer then the delay timer setting

To ensure the proper ejection on the container you

may need to adjust the speed of the cylinder

plunger by adjusting the speed control valves

located on the front of the eject box.

NOTE: The ejector was designed with a built in

cache of 29 containers, which means a total of 29

bad containers can occur between when a bad

container is sensed and when the first bad

container is ejected. This should be more than

adequate for the spacing between the detection

device and the eject system. (If more than 29

containers are detected before the first bottle is

ejected the timing function of the ejector will be out

of synchronization.)

ML0068-001-02 Container Eject System ENERCON INDUSTRIES

6

SECTION 4 – EJECT SYSTEM MAINTENANCE

Due to the nature of this system the amount of maintenance required will be minimal. The main priority for

maintenance will be keeping the unit and air supply clean and properly adjusted.

CLEANING

As long as clean air is supplied to the ejector

minimal cleaning is required for proper operation.

ADJUSTING

If the line speed or product type does not change

there should be no reason to make any

adjustments to the system, however you may want

to periodically check the mounting hardware, if this

loosens the timing of the system may be thrown off.

NOTE: For each new product that is run you may

have to adjust the eject delay, eject time and

plunger speed to ensure proper ejects.

ML0068-001-02 Container Eject System ENERCON INDUSTRIES

7

SECTION 5 – TROUBLESHOOTING

SYMPTON

CHECK

No power to the control box.

(Seven segment LED’s do not light)

1. Check the input power

2. Is the power switch on at the power entry

module

3. Check the fuse inside the power entry module

4. Remove power and open the box and ensure

the ribbon cable is properly connected between

the display board and the ejector control board

5. Contact Enercon service department for

assistance

Eject plunger does not function

1. Check the eject signal

2. Check for proper inlet air pressure

3. Remove power and open the box and inspect

the hose connections, looking for an open hose

or a kink in a hose.

4. Check solenoid wiring

5. Possible bad solenoid

6. Contact Enercon service department for

assistance

Ejector timing seems to change

1. Are the containers sliding on the conveyor?

2. Is the conveyor speed changing?

3. Check the “bad container” detector for proper

adjustment.

Delay time or eject time are not

adjustable

1. Remove input power and open the box and

ensure the ribbon cable is properly connected

between the display board and the eject control

board

2. Bad display board

3. Bad eject control board

4. Contact Enercon service department for

assistance

*** WARNING ***

BE SURE ALL POWER IS DISCONNECTED

AND LOCKED OUT FROM UNIT BEFORE

PERFORMING CHECK.

ML0068-001-02 Container Eject System ENERCON INDUSTRIES

8

SECTION 6 – PARTS LIST

GENERAL

This manual, which contains an illustrated parts

breakdown, has been prepared as an aid in

identifying and ordering parts in the ejector. All of

the parts listed in the parts breakdown are

manufactured with the same precision as the

original equipment.

DESCRIPTION

The illustrated parts breakdown illustrates the

various assemblies, sub-assemblies and detailed

parts that make up the ejector. The following

illustration shows each part clearly and in its correct

location relative to the other parts in the illustration.

The description and quantity required per station is

listed in numerical order on the following pages.

HOW TO USE THIS PARTS LIST

1. Turn to the Parts Section to locate the desired

illustrations.

2. Locate the part on the illustration by visual

identification and the Index Number.

3. Find the Index Number on the tabulated page,

along with the description.

HOW TO ORDER PARTS

In order that all avoidable errors are eliminated

when ordering parts, please specify the following:

1. The Model Number of the unit as shown on the

Ejector Rating Plate.

2. The Serial Number of the unit as shown on the

Ejector Rating Plate.

3. The Form Number of this manual located on

cover.

4. The Part Number, description and quantity

needed exactly as listed on parts breakdown

drawings.

To order, contact:

Enercon Customer Service Department

Phone Number: (262) 255-6070

Fax Number: (262) 255-2462

E-Mail Address: info@enerconind.com

Website: www.enerconind.com

24hr Customer Service is available.

ML0068-001-02 Container Eject System ENERCON INDUSTRIES

9

EJECTOR PARTS BREAKDOWN

INDEX NO. PART NO. DESCRIPTION QTY.

1 PN0093 Pressure Gauge, Panel Mount 1

2 PN0092 Regulator, Panel Mount 1

3 PN0091 Flow Control, Panel Mount 2

4 HW0101 Bumper 1

5 CN0059 Power Entry Module 1

6 LM4439-01 Eject Display Board 1

7A LM4440-01 Eject Control Board (120 VAC) 1

7B LM4440-02 Eject Control Board (240 VAC) 1

8 PN0090 Body Ported Valve, Dual Solenoid 1

9 PN0094 Air Cylinder 1

10 CA1085 20 Pin Ribbon Cable 1

Figure 3

ML0068-001-02 Container Eject System ENERCON INDUSTRIES

10

SECTION 7 – MISCELLANEOUS

EJECT SYSTEM PRODUCTION SET-UP

Product

Delay

Time Eject

Time Plunger

Speed Air

Pressure Line

Speed High Cap

Ejects (Y/N)

Missing Foil

Ejects (Y/N)

ML0068-001-02 Container Eject System ENERCON INDUSTRIES

11

NOTES

________________________________________________________________________________

________________________________________________________________________________

________________________________________________________________________________

________________________________________________________________________________

________________________________________________________________________________

________________________________________________________________________________

________________________________________________________________________________

________________________________________________________________________________

________________________________________________________________________________

________________________________________________________________________________

________________________________________________________________________________

________________________________________________________________________________

________________________________________________________________________________

________________________________________________________________________________

________________________________________________________________________________

________________________________________________________________________________

________________________________________________________________________________

________________________________________________________________________________

________________________________________________________________________________

________________________________________________________________________________

________________________________________________________________________________

________________________________________________________________________________

________________________________________________________________________________

________________________________________________________________________________

________________________________________________________________________________

________________________________________________________________________________

________________________________________________________________________________

________________________________________________________________________________

________________________________________________________________________________

________________________________________________________________________________

________________________________________________________________________________

________________________________________________________________________________

________________________________________________________________________________

________________________________________________________________________________

________________________________________________________________________________

________________________________________________________________________________

________________________________________________________________________________

________________________________________________________________________________

________________________________________________________________________________

________________________________________________________________________________

________________________________________________________________________________

________________________________________________________________________________

________________________________________________________________________________

________________________________________________________________________________

________________________________________________________________________________

________________________________________________________________________________

Table of contents

Other ENERCON Industrial Equipment manuals