2

Use of additional P.P.E. safety items such as dust mask,

non-skid safety shoes, hard hat, and hearing protection

(used as appropriate for the conditions) will reduce the

chance of personal injuries. The use of these items may also

be required by local regulations or laws.

• Do not handle pressurized hoses. Escaping oil under

pressure can penetrate the skin. If oil is injected under the

skin, see a doctor immediately.

• Do not pressurize disconnected couplers.

• Use hydraulic cylinders only in a coupled system. It is

acceptable to use a cylinder with a disconnected coupler

only if the load is mechanically supported by the cylinder

lock nut, and all hydraulic pressure is completely relieved.

• When holding loads, be certain that the lock nut is turned

down firmly against the cylinder base so that the load is

mechanically supported. Also be sure that all hydraulic

pressure is completely relieved.

• Do not remove or disable the pump relief valve.

• Do not remove or disable the cylinder relief valve (if equipped).

• The system operating pressure must not exceed the pressure

rating of the lowest rated component in the system.

• Install pressure gauge(s) in the system to monitor operating

pressure. It is your window to see what is happening in the system.

• Never set a relief valve to a higher pressure than the

maximum rated pressure of the pump and cylinder. If ratings

are dierent, relief valve setting should not exceed the

setting of the lowest rated component (pump or cylinder).

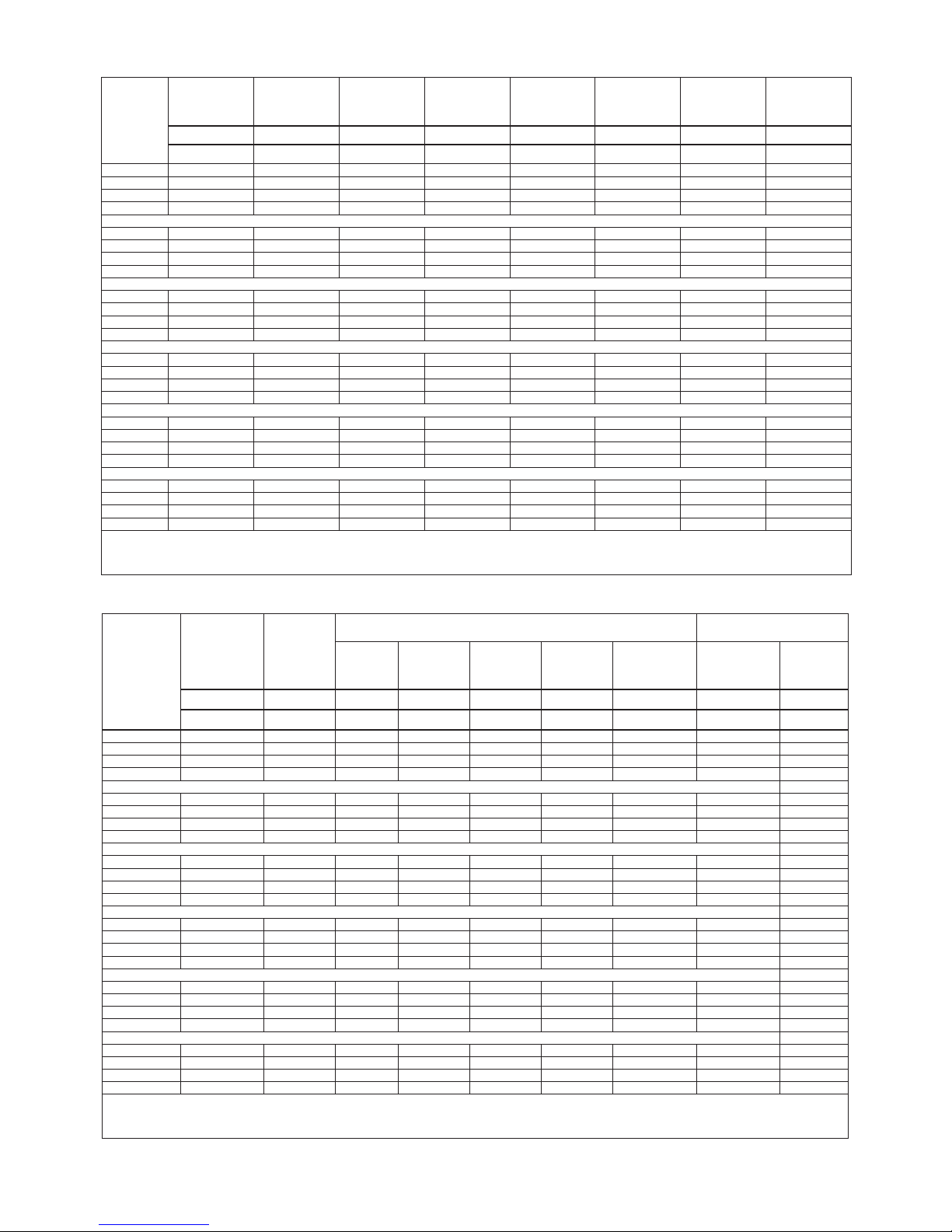

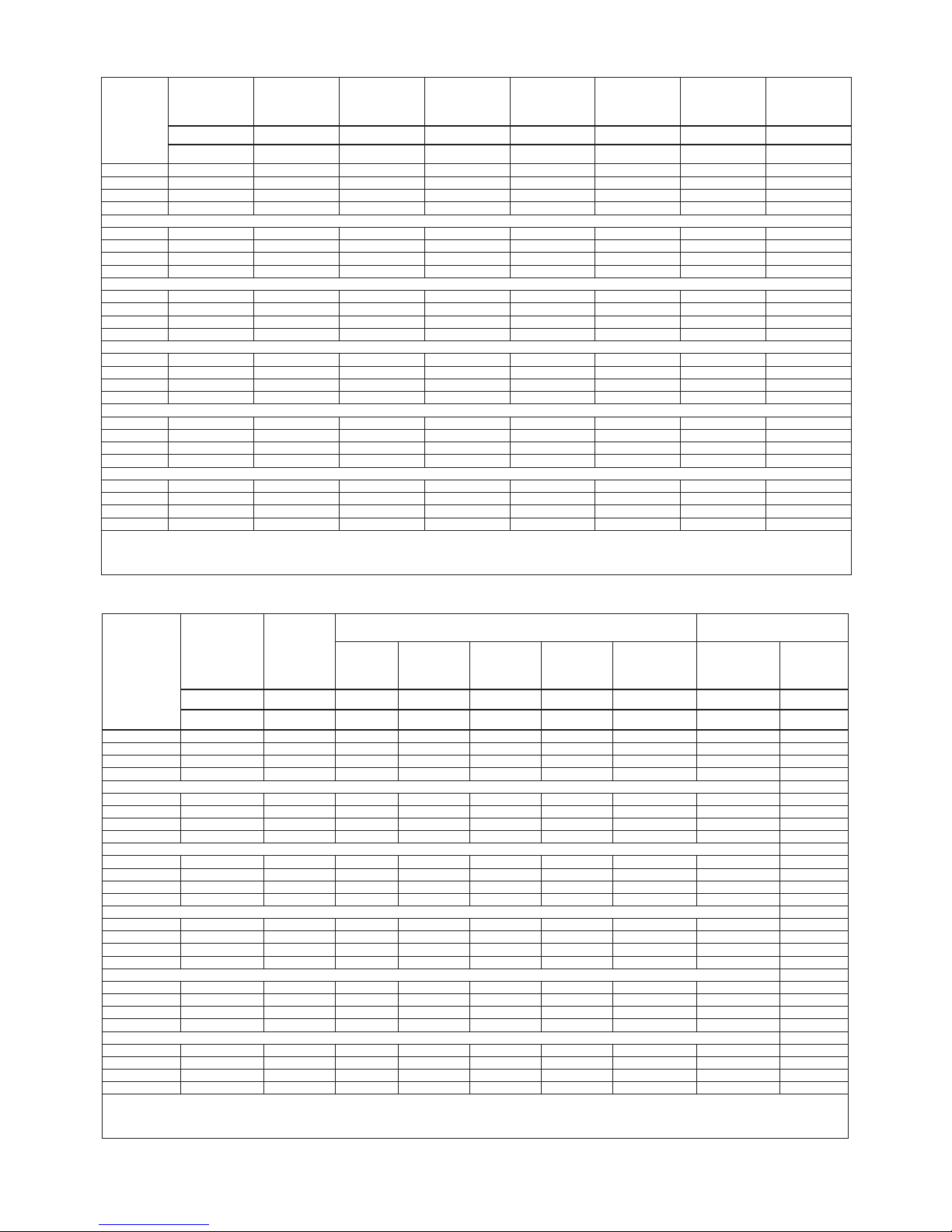

• The HCRL-Series cylinders are designed for a maximum

working pressure of 10150 psi [700 bar]. Do not connect a

pump with a higher pressure rating to these cylinders.

• Do not exceed equipment ratings. Never attempt to lift a

load weighing more than the rated capacity of the cylinder.

Overloading may cause equipment failure and possible

personal injury.

• Be sure setup is stable before lifting load. Cylinders should

be located on a firm and level surface capable of supporting

the full load.

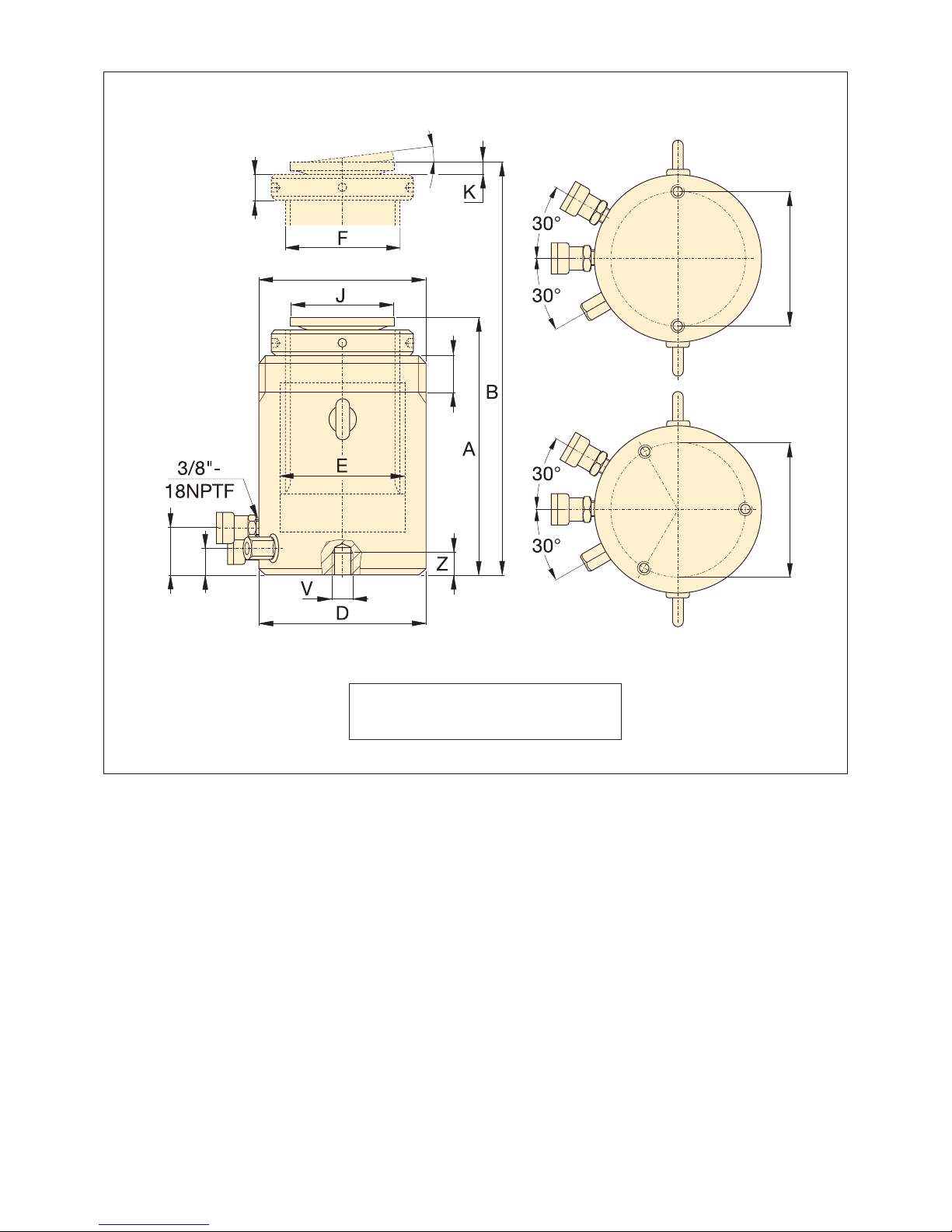

• Where applicable, use a cylinder base plate to provide

added stability. If desired, the cylinder can be bolted to the

base plate, using the bolt holes in the bottom of the cylinder

base.

• Do not weld, drill or otherwise modify a cylinder to attach a

base plate or other support unless approved in writing by

Enerpac Engineering Department. Use only the provided

bolt holes.

• Always perform a visual inspection of the cylinder before

placing it into operation. If any problems are found, do not

use the cylinder. Have the cylinder repaired and tested

before it is returned to service.

• Never use a cylinder that is leaking oil. Do not use a cylinder

that is damaged, altered or in need of repair.

• Always lift the cylinder using a hoist, crane or other suitable

lifting device of sucient rated capacity. Use only the

supplied cylinder lifting eyes to attach the cylinder to the

lifting device. Replace any missing or damaged lifting eyes.

• Allow only trained and experienced personnel to supervise

and perform lifting and lowering procedures.

• Be certain that no persons are working on or near any

cylinders before lifting or lowering of the load begins. Alert all

personnel in advance that lifting or lowering is about to occur.

• Use suitable cribbing of rigid construction to hold loads.

• Never use a hydraulic cylinder as a shim or spacer in any

lifting or pressing application.

• Be certain that the load is centered and covers the entire

plunger saddle surface. Avoid situations where loads are not

directly centered on the plunger saddle. The load may slip or

fall, causing potential danger.

• Lift only dead weight loads. Avoid lifting live weight loads.

• Be especially careful when lifting loads such as partially filled

storage tanks, in which the center of gravity could move or

shift during lifting. Be aware that the distribution of some

loads can change quickly and without warning.

• Do not use the cylinder to lift people. Do not allow people to

be on top of the load during lifting or lowering.

• Keep all personnel clear of the work area while lifting or

lowering is in progress. To avoid personal injury, keep hands

and feet away from cylinder and load during operation.

• Maintain communication with the operator at all times during

lifting or lowering to avoid accidents. Use hand signals, two-

way radios or other appropriate forms of communication (as

required by applicable laws and regulations) if the load is not

visible to the operator.

• Operate pump and valve as required to ensure that the load

is lifted and lowered evenly and at a controlled rate.

• Closely watch the load at all times during lifting and lowering.

Stop lifting or lowering immediately if the load becomes

unstable or appears to be lifting or lowering unevenly.

• Stay clear of loads supported only by hydraulics. As required,

follow the lifted load with cribbing.

• Never allow persons to work under or near the load while the

load is being supported hydraulically. After the load has been

raised or lowered, it always must be blocked mechanically

by the cylinder lock nut or via suitable cribbing.

• Always be certain that hydraulic pressure is fully relieved

and that the load is fully removed from the cylinder(s) before

disconnecting hydraulic hoses, loosening hydraulic fittings,

or performing any cylinder disassembly or repair procedures.

CAUTION

Failure to observe and comply with the following

precautions could result in minor or moderate personal

injury. Property damage could also occur.

• Be careful to avoid damaging hydraulic hoses. Avoid sharp

bends and kinks when routing hydraulic hoses. Do not

exceed the minimum bend radius specified by the hose

manufacturer. Using a bent or kinked hose will cause severe

back-pressure. Sharp bends and kinks will internally damage

the hose, leading to premature hose failure.

• Do not drop heavy objects on hoses. A sharp impact may

cause internal damage to hose wire strands. Applying

pressure to a damaged hose may cause it to rupture.

• Do not lift hydraulic equipment by the hoses or couplers.

Use the cylinder lifting eyes and appropriately rated lifting

equipment.

• Keep hydraulic equipment away from flames and heat.

Excessive heat will soften packings and seals, resulting in

fluid leaks. Heat also weakens hose materials and packings.

• For optimum performance, do not expose hydraulic

equipment to temperatures of 150˚F [65˚C] or higher. Protect

all hydraulic equipment from weld spatter.

• Immediately replace worn or damaged parts with genuine

Enerpac parts. Enerpac parts are designed to fit properly

and to withstand high loads. Non-Enerpac parts may break

or cause the product to malfunction.