Enerpac MCS7500 Mobile Calibration System

2

TABLE OF CONTENTS

1.0 INTRODUCTION......................................................................................................................................... 3

1.1 System Overview.................................................................................................................................... 3

1.2 Main Components .................................................................................................................................. 4

1.3 Electrical Connections........................................................................................................................... 5

1.4 CE Declaration of Conformity ............................................................................................................... 6

2.0 SAFETY ..................................................................................................................................................... 7

2.1 Introduction .............................................................................................................................................. 7

2.2 General Safety ........................................................................................................................................ 7

2.3 Mobile Calibration System Safety......................................................................................................... 8

2.4 Use and Care .......................................................................................................................................... 8

2.5 Disconnect Electrical Power ................................................................................................................. 8

3.0 SETUP AND ADJUSTMENTS.................................................................................................................... 9

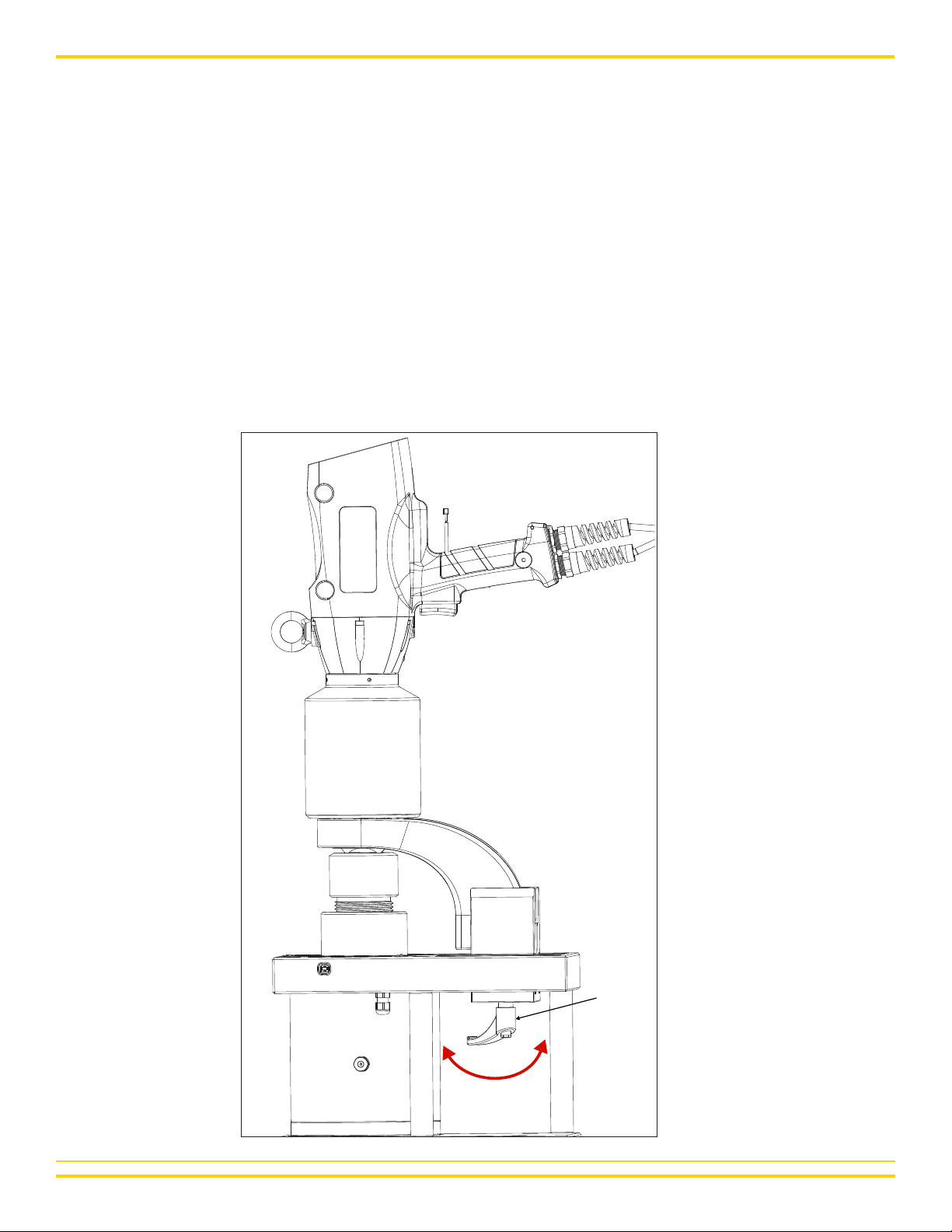

3.1 Mount the Torque Wrench ..................................................................................................................... 9

3.2 Adjust the Run Down Fixture and Reaction Stop.............................................................................. 10

3.3 Torque To Spreadsheet Software (TTS).............................................................................................. 11

4.0 OPERATION.............................................................................................................................................. 12

4.1 Check Torque with Digital Display...................................................................................................... 12

4.2 Using the TTS Software ....................................................................................................................... 13

4.3 Performing a Calibration and Producing a Calibration Certificate for Corded Electronic tools .. 14

4.4 Performing a Calibration and Producing a Calibration Certificate for Pneumatic tools ............... 20

5.0 DIGITAL DISPLAY MODULE.................................................................................................................... 27

5.1 Digital Display Buttons ........................................................................................................................ 27

5.2 Digital Display Window ........................................................................................................................ 27

5.3 Battery Indicator................................................................................................................................... 27

5.4 Mode of Operation ............................................................................................................................... 28

5.5 Engineering Units ................................................................................................................................. 28

5.6 Filter....................................................................................................................................................... 29

6.0 MAINTENANCE........................................................................................................................................ 30

7.0 RECALIBRATION...................................................................................................................................... 31

8.0 TROUBLESHOOTING .............................................................................................................................. 32

8.1 Digital Display....................................................................................................................................... 32

8.2 Joint Run Down .................................................................................................................................... 32

8.3 Repair and (Re)Calibration .................................................................................................................. 32

9.0 TECHNICAL SPECIFICATIONS ............................................................................................................... 33